Multi-cell material complex loading system

A technology for complex loading and cellular materials, applied in the direction of analyzing materials, using stable tension/pressure testing material strength, force/torque/work measuring instruments, etc., can solve the problems of poor adhesion, unfavorable research verification, and impact testing and other problems, to achieve the effect of simple and effective installation, high collection accuracy and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further illustrate the technical means and effects adopted by the present invention to achieve the predetermined purpose of the invention, the following in conjunction with the accompanying drawings and preferred embodiments, the specific embodiments, structures, features and effects of the application according to the present invention are described in detail as follows .

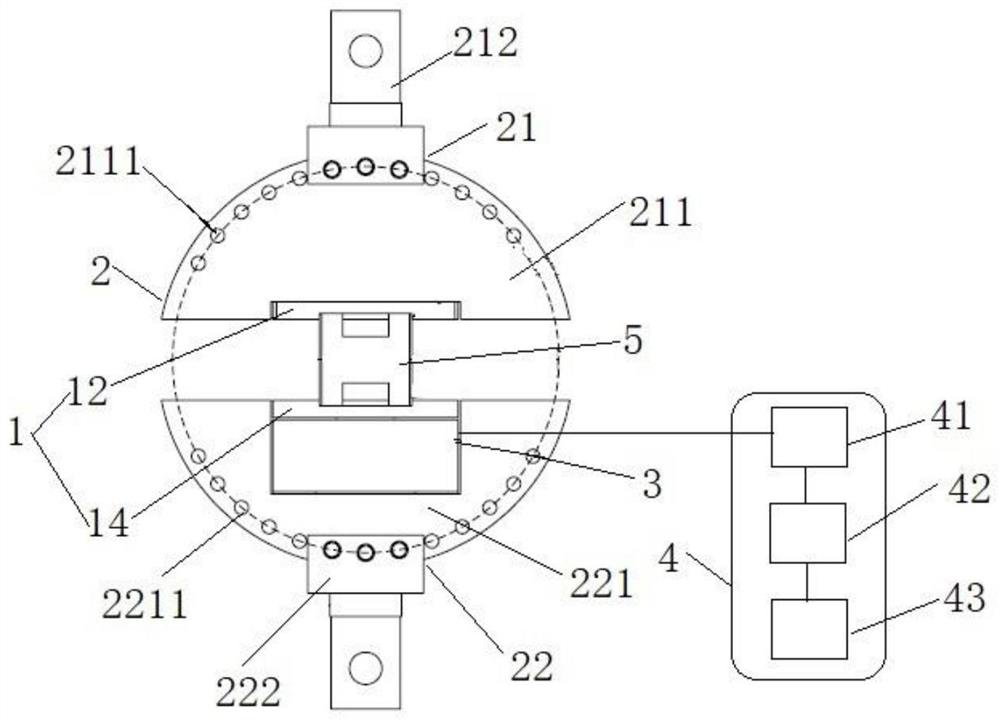

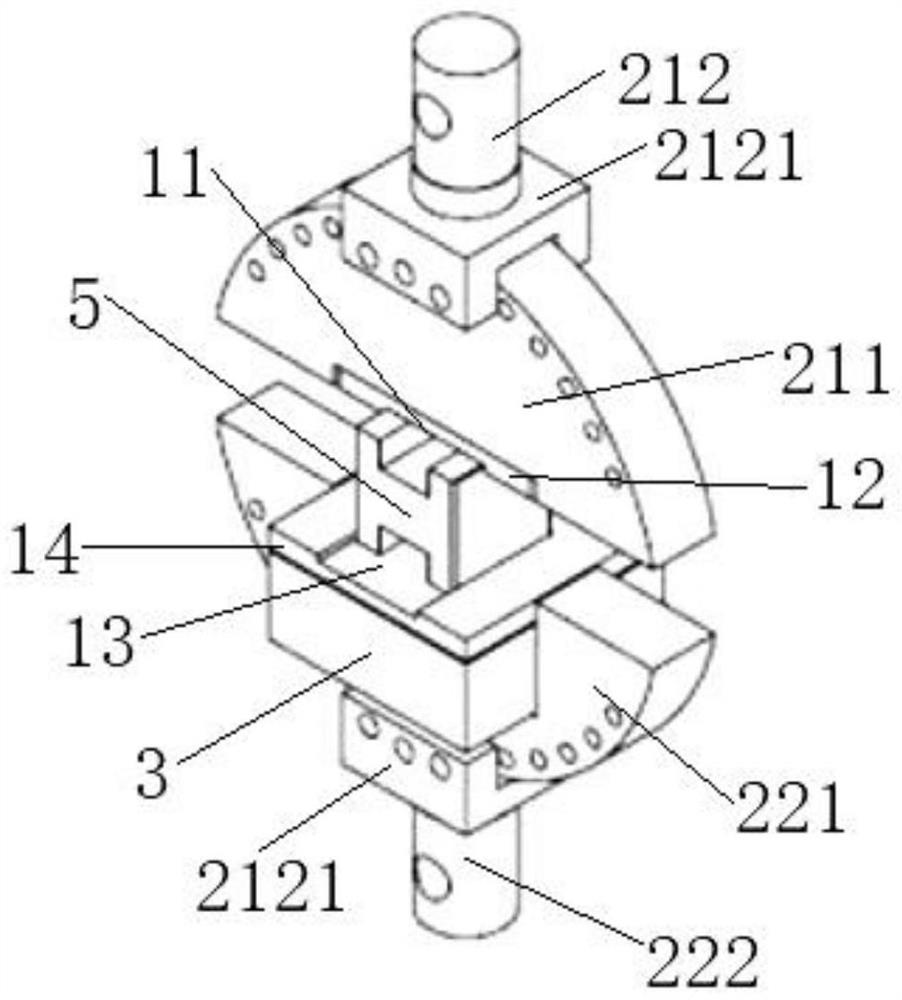

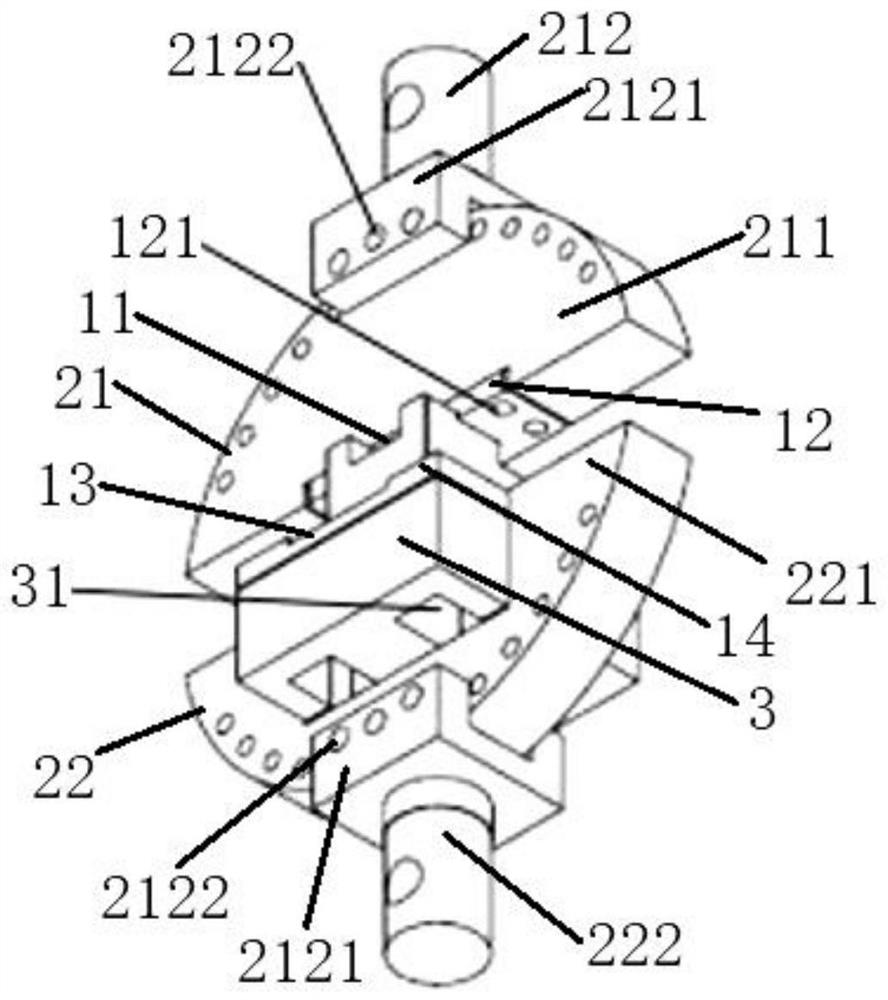

[0031] like figure 1 As shown, an embodiment of the present invention proposes a complex loading system for multicellular materials, which includes: a plurality of specimen clamping devices 1 , a loading condition angle adjustment device 2 , a stress monitoring device 3 and a data acquisition and analysis device 4 .

[0032] like Figure 1 to Figure 4As shown, the specimen clamping device 1 is provided with a rectangular space structure for installing and fixing the specimen 5 and matching the structural size of the specimen 5. Each of the specimen clamping devices 1 has a rectangular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com