Cabling filling material injection device and injection method

A filling material, injection device technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of twist shape, triangle shape or square shape, uneven cable surface, uneven cable surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

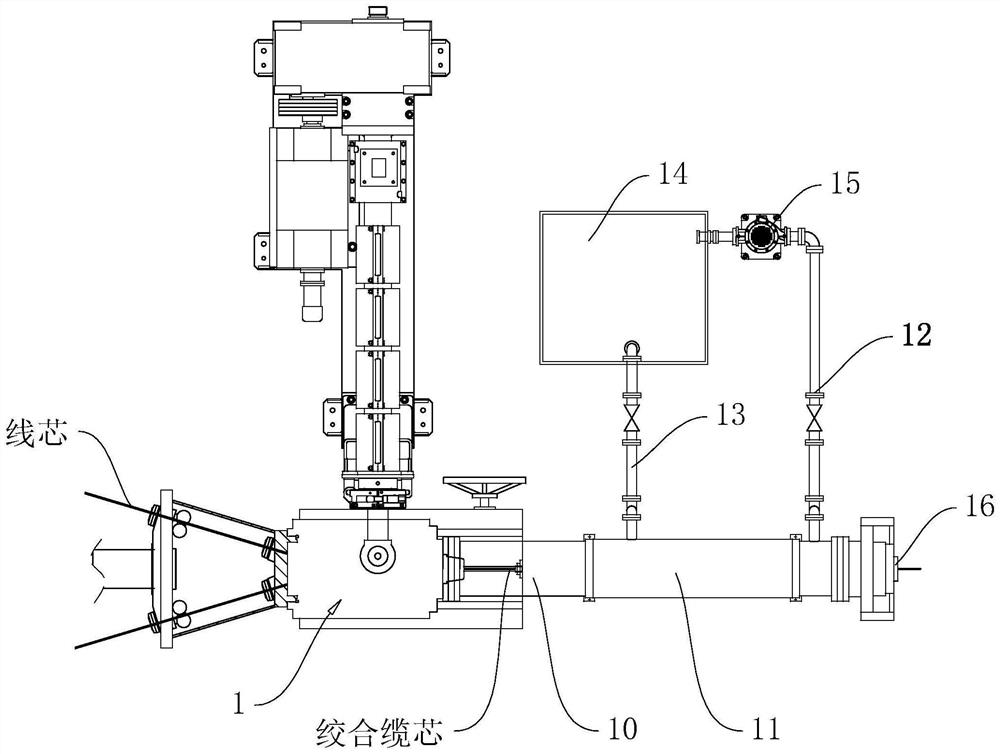

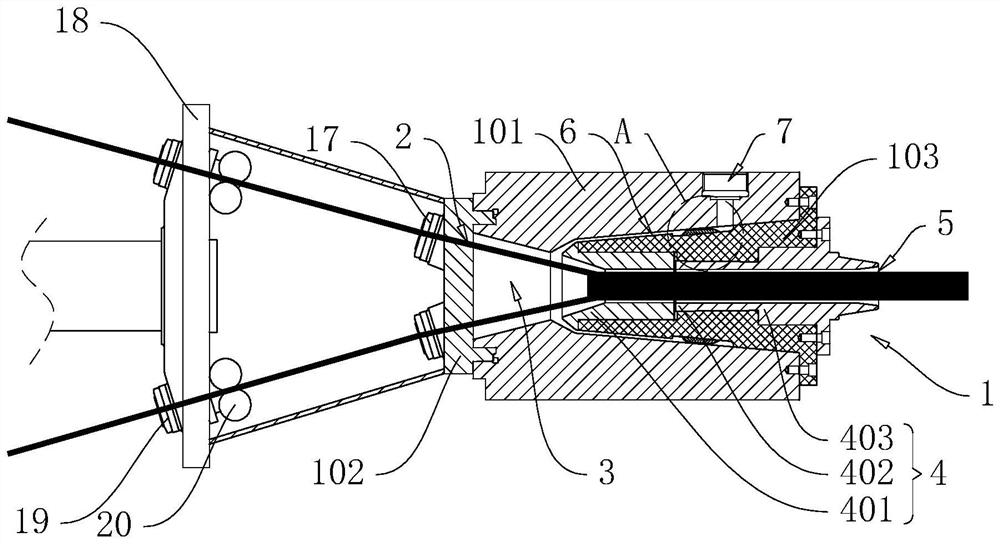

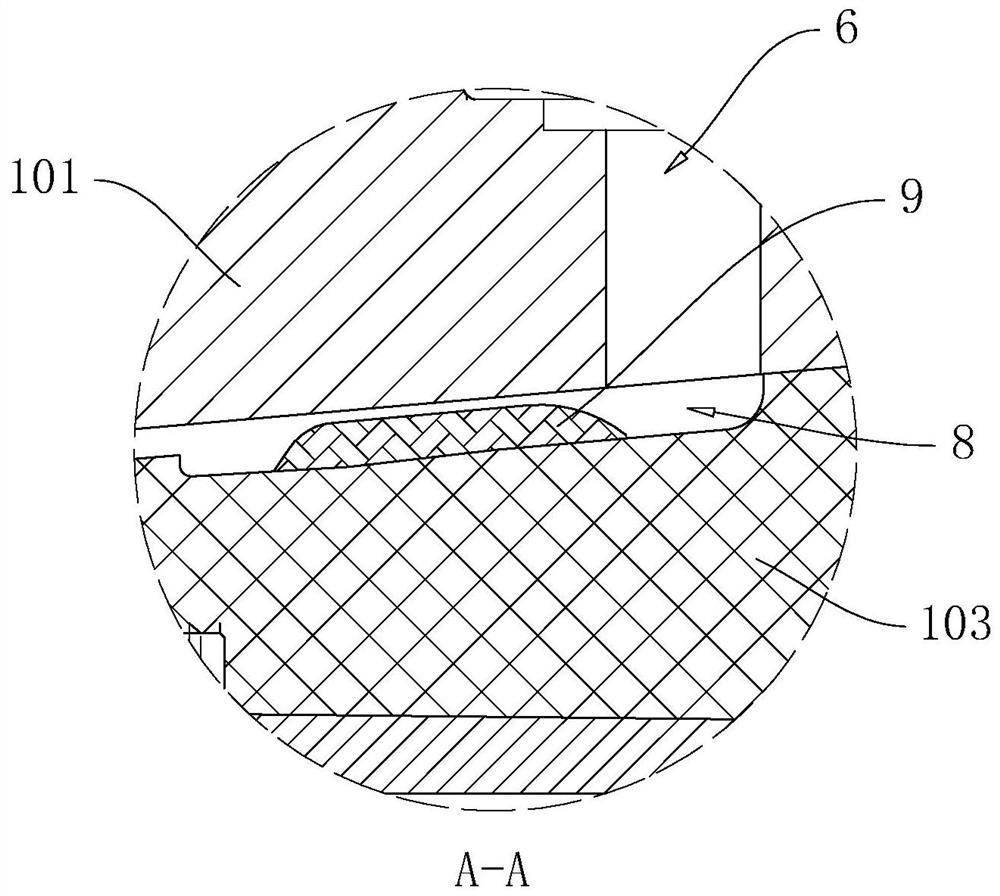

[0042] Attached to the following Figure 1-3 This application will be described in further detail.

[0043] The embodiment of the present application discloses a method for injecting a cable cabling filling material, which includes the following steps:

[0044] S1: The two wire cores are transported through the traction box, and the foam material is evenly spread on the surfaces of the two wire cores during the transportation process;

[0045] S2: the wire core is coated with foam material through a container filled with foam material, and twisted by a winch in the container;

[0046]S3: pass the stranded cable core formed after each wire core is twisted through the mold, and carry out filling, sizing and shaping treatment;

[0047] S4: hold the pressure of the shaped stranded cable core, and cool and form through the circulating cooling water system;

[0048] S5: After the cooled and formed stranded cable core is wrapped through the wrapping head, the process flow is compl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com