Continuous casting slab width on-line accurate measurement method

A technology of precise measurement and width measurement, applied in the field of iron and steel metallurgy continuous casting, can solve the problem of no slab treatment, and achieve the effect of reducing the number of rejections, considerable economic benefits, and increasing the hot rolling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

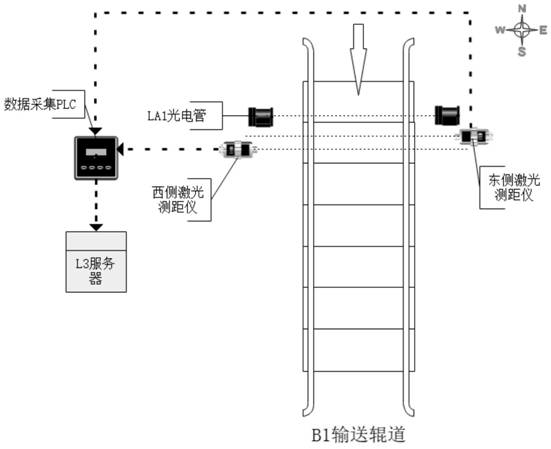

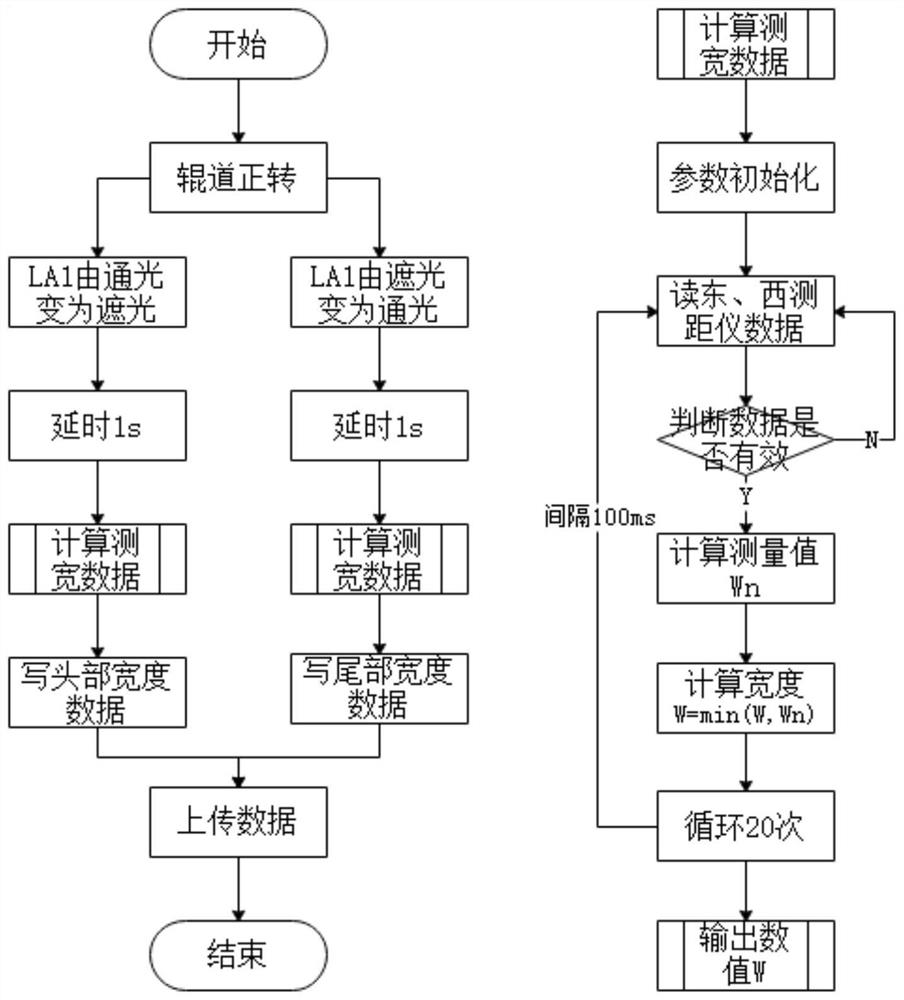

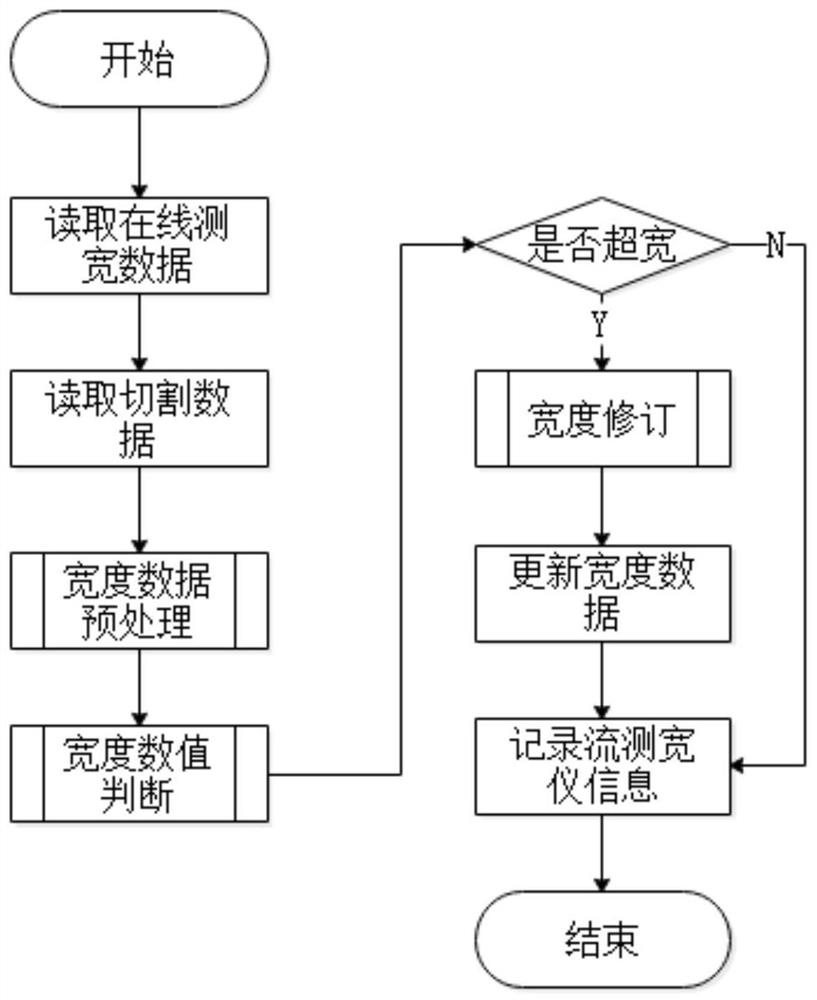

[0072] Example 1: see figure 1 , an on-line accurate measurement method for continuous casting slab width, the method comprises the following steps:

[0073] Step 1: Installation of the slab width information collection device;

[0074] 1.1 Install a laser range finder and a set of photocells for detecting the position information of the slab on both sides of the slab delivery conveyor (see the layout method). figure 1 ).

[0075] 1.1.1 Two laser rangefinders are arranged on the east and west sides of the roller table respectively, and are arranged horizontally (perpendicular to the center line of the billet roller table, equidistant) in the opposite way;

[0076] 1.1.2 In order to realize the automatic calibration of the equipment, the two rangefinders are misaligned by 40mm-60mm in the north-south direction.

[0077] 1.1.3 In order to prevent the high temperature radiation of the slab from interfering with the measurement accuracy, two rangefinders are set up to measure t...

specific Embodiment

[0129] Specific embodiment: refer to figure 1 — Image 6 , Slab continuous casting in a steel plant, the minimum width of the slab is 880mm, the maximum width is 1700mm, and the thickness of the slab is 230mm. In order to realize the accurate measurement of the slab width online and provide accurate information for the subsequent rolling, the technology provided by the method of the present invention is used. Process, its specific implementation is as follows:

[0130] An online accurate measurement system for continuous casting slab width

[0131] Step 1. Installation of slab width information collection device;

[0132] 1.1 Install a laser range finder and a set of photocells for detecting the position information of the slab on both sides of the slab delivery conveyor (see the layout method). figure 1 ).

[0133] 1.1.1 Two laser rangefinders are arranged on the east and west sides of the roller table respectively, and are arranged horizontally (perpendicular to the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com