Videoscope

An endoscope and video technology, applied in the field of video endoscope, can solve the problems of horizontal and vertical instability, can no longer be used or controlled, lateral dislocation, etc., to achieve the effect of being beneficial to production quality control and reducing the number of rejections

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

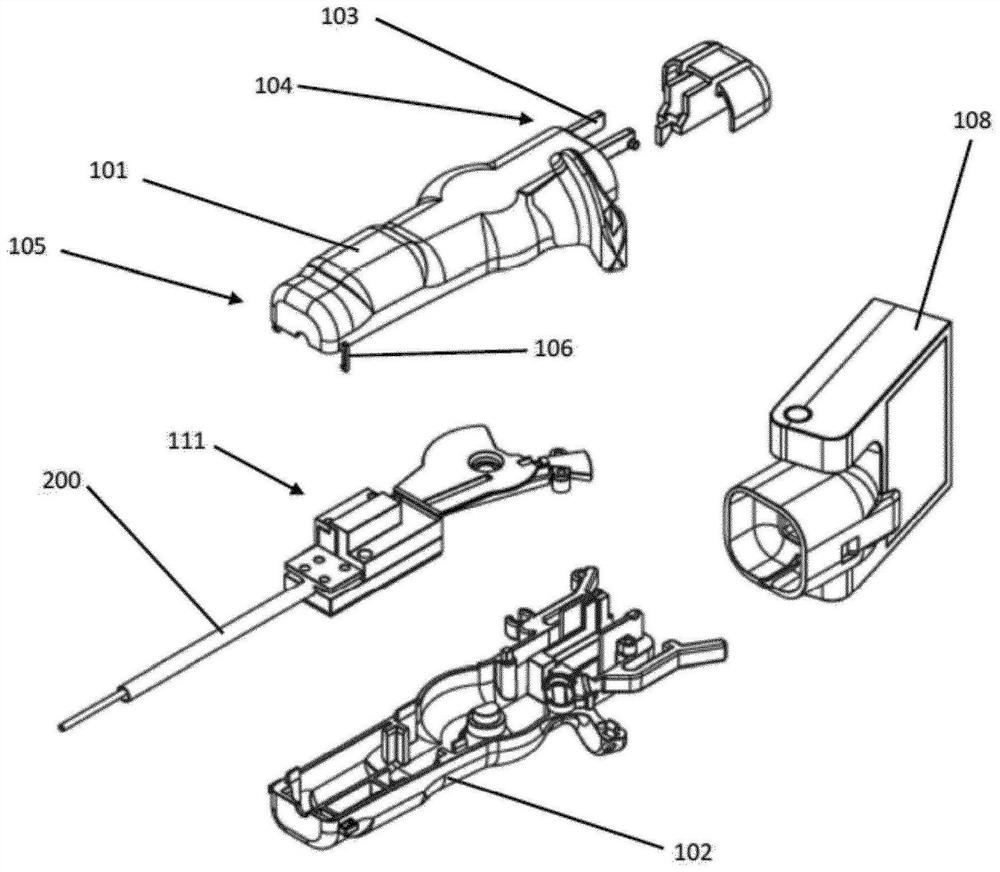

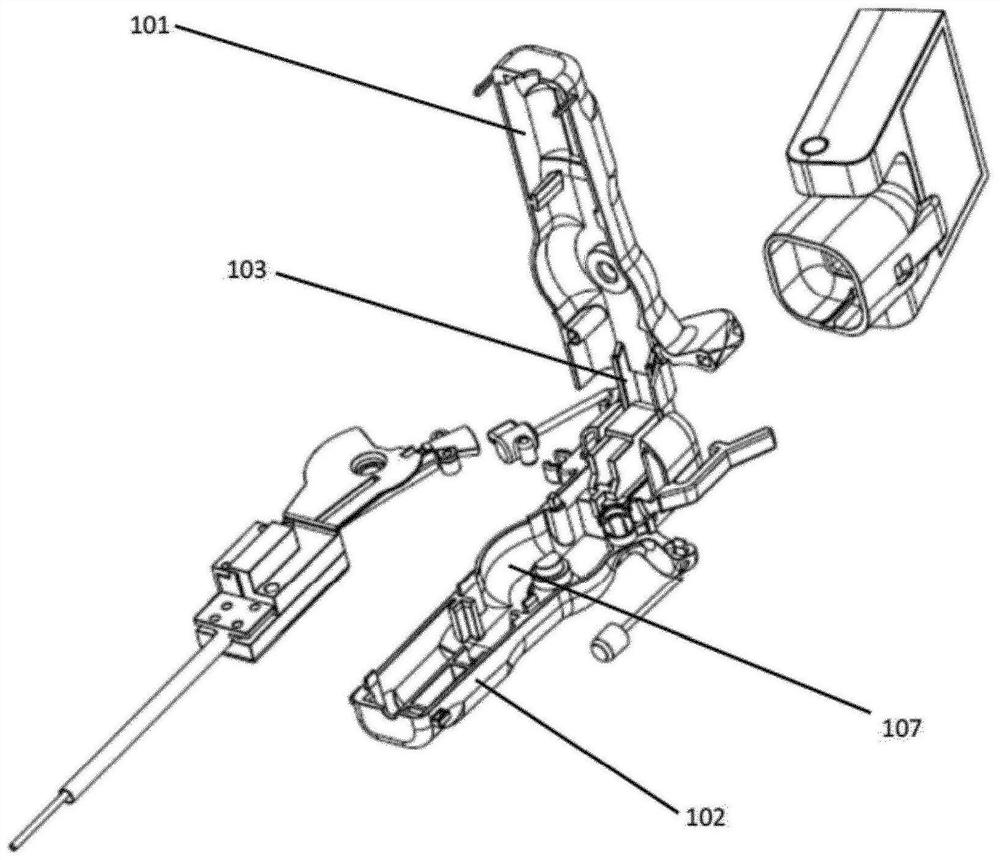

[0081] As mentioned above, the present invention relates to video endoscopes or fiberscopes.

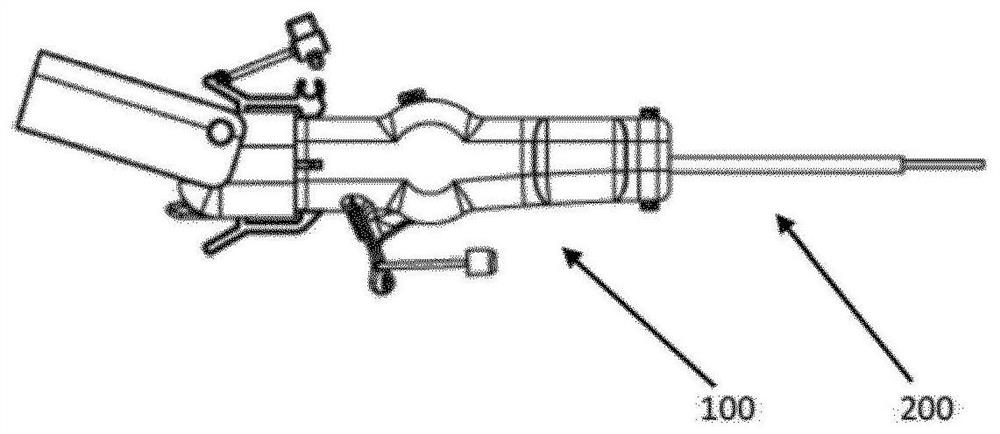

[0082] One of the main features of the videoscope / fiberscope object of the invention is its modular nature, which allows making the grip (100) or body of the videoscope independent of the tube with the miniature camera ( 200).

[0083] Therefore, video borescopes include (see Figures 1 to 3 ) a grip (100) formed of two parts (a first part (101) and a second part (102)) through a hinge present at a first end (104) of the grip (100) ( 103) and hinged or clipped to the second end (105) of the grip (100) with a closure (106).

[0084] This accesses the internal cavity (107) of the grip when said grip (100) is opened by relative rotation of the two parts (101, 102) around the hinge (103) in an articulated fashion.

[0085] Inside said cavity (107) there are mechanical, electrical and electronic connections for connecting the tube (200) and the miniature camera to said grip (100). The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com