Preparation method of intermediate for improving efficacy of lipid-lowering traditional Chinese medicine composition containing panax notoginseng

A composition and technology of notoginseng, applied in the field of production and processing of Chinese patent medicines, can solve problems such as quality control problems, low product quality standards and production control levels, and mixing uniformity of intermediate drug powders and extract concentrates, so as to prevent drug loss, beneficial to production quality control, and the effect of improving batch-to-batch uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

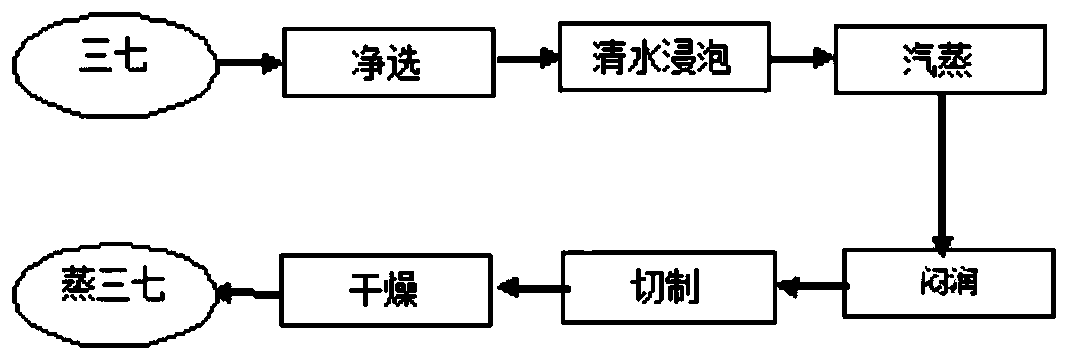

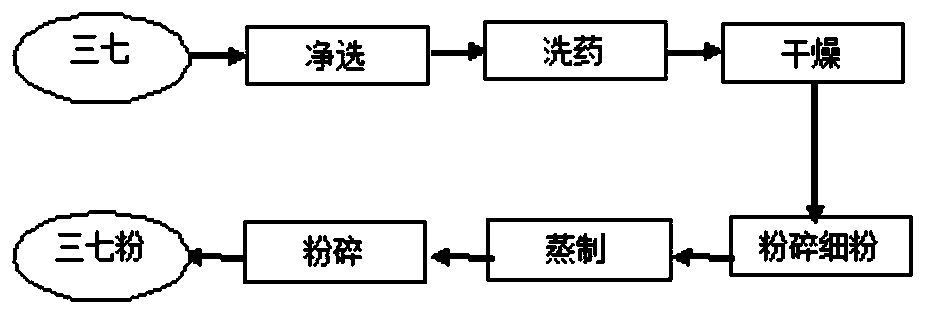

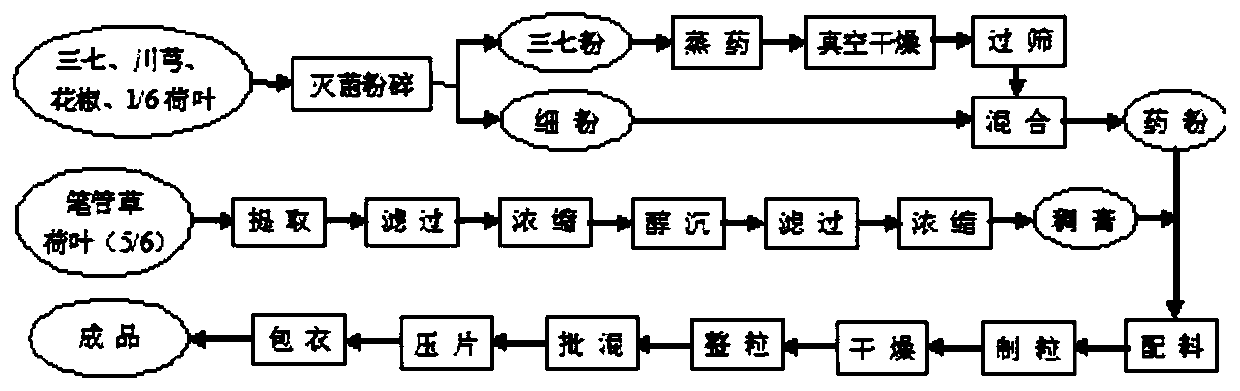

[0112] The invention provides an intermediate preparation method for improving the efficacy of a lipid-lowering traditional Chinese medicine composition containing Panax notoginseng. Improve the level of the element, and prevent the loss of the drug in the production process to change the formula ratio; optimize the mixing process of the intermediate powder, that is, the steamed powder of notoginseng and the prefabricated fine powder of Chuanxiong, Zanthoxylum bungeanum, and lotus leaf are mixed for the second time and then pulverized to improve the mixing uniformity of the powder. It is conducive to production quality control and improvement of standards; and secondary crushing can also increase the cell wall breaking effect of Rhizoma Chuanxiong and Zanthoxylum bungeanum, so that Rhizoma Chuanxiong and Zanthoxylum bungeanum can release more volatile matter, which is beneficial to absorption; Batch-to-batch uniformity and drug efficacy of lipid-lowering traditional Chinese med...

Embodiment 1

[0132] Embodiment 1: 500,000 pieces / batch feeding, and production verification.

[0133] (1) Take 320 kg of pen tube grass, 25.5 kg of Chuanxiong, 129 kg of lotus leaves, 21 kg of Panax notoginseng, and 6.3 kg of Zanthoxylum bungeanum, remove mildew, moths, counterfeit products, impurities and non-medicinal parts, pen tube grass, lotus leaves, Panax notoginseng is cleaned, drenched, cut into sections, lotus leaves shredded, notoginseng broken, and dried to obtain net materials of pen tube grass 312.5kg, Chuanxiong 25kg, lotus leaf 125kg, Sanqi 20.8kg, Zanthoxylum bungeanum 6.25kg, spare.

[0134] (2) Take 25kg of dried and clean Ligusticum chuanxiong, 20.8kg of Panax notoginseng, 6.25kg of Zanthoxylum bungeanum, and 20.8kg of lotus leaves, respectively crush them with a linkage crushing unit, pass through a No. 6 sieve, and fine powder 65-70kg for later use;

[0135] (3) Put the fine powder of notoginseng into 20 stainless steel trays and flatten it, flatten it with a stainle...

Embodiment 2

[0140] Embodiment 2: Feed 500,000 pieces / batch, and carry out production verification.

[0141](1) Take 320 kg of pen tube grass, 25.5 kg of Chuanxiong, 129 kg of lotus leaves, 21 kg of Panax notoginseng, and 6.3 kg of Zanthoxylum bungeanum, remove mildew, moths, counterfeit products, impurities and non-medicinal parts, pen tube grass, lotus leaves, Panax notoginseng is cleaned, drenched, cut into sections, lotus leaves shredded, notoginseng broken, and dried to obtain net materials of pen tube grass 312.5kg, Chuanxiong 25kg, lotus leaf 125kg, Sanqi 20.8kg, Zanthoxylum bungeanum 6.25kg, spare.

[0142] (2) Take 25kg of dried and clean Ligusticum chuanxiong, 20.8kg of Panax notoginseng, 6.25kg of Zanthoxylum bungeanum, and 20.8kg of lotus leaf, respectively pulverize with a linkage crushing unit, pass through a No. 6 sieve, and fine powder 60-65kg for later use;

[0143] (3) Put the Panax notoginseng fine powder into 20 stainless steel trays and spread it flat, flatten it with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com