A preparation method of low-temperature fast-curing resistance flame-retardant structural adhesive

A fast-curing, structural adhesive technology, applied in the direction of adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve the problems of lack of flame retardancy, long curing time, high curing temperature, etc., to meet the requirements of various processes Good adhesion, good bonding strength, and fast curing at low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

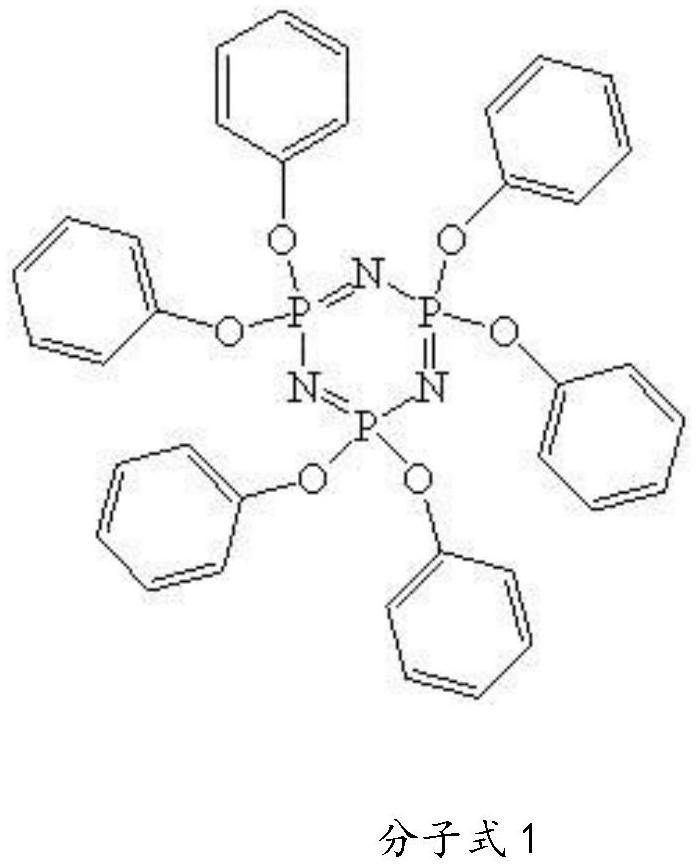

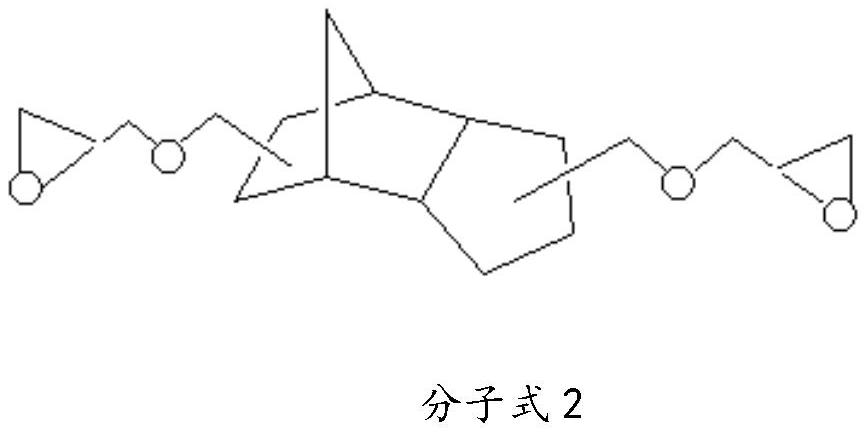

[0032] a. According to the mass parts: Add epoxy resin EXA-830CRP 300g to the reactor, heated to 60 ° C, set the rotational speed 10 rpm, start stirring; the stirring conditions were added to the hexaglexyl ring triosphaconitrile HPCTP 690G parts , Heated to 120 ° C, the rotational speed 40 rpm was set under vacuum conditions, stirred for 1 hour; adding isophorone diamine IPDA 10g, continued for 3 hours in a nitrogen protection environment, resulting from self-synthetic flame retardant epoxy resin gel;

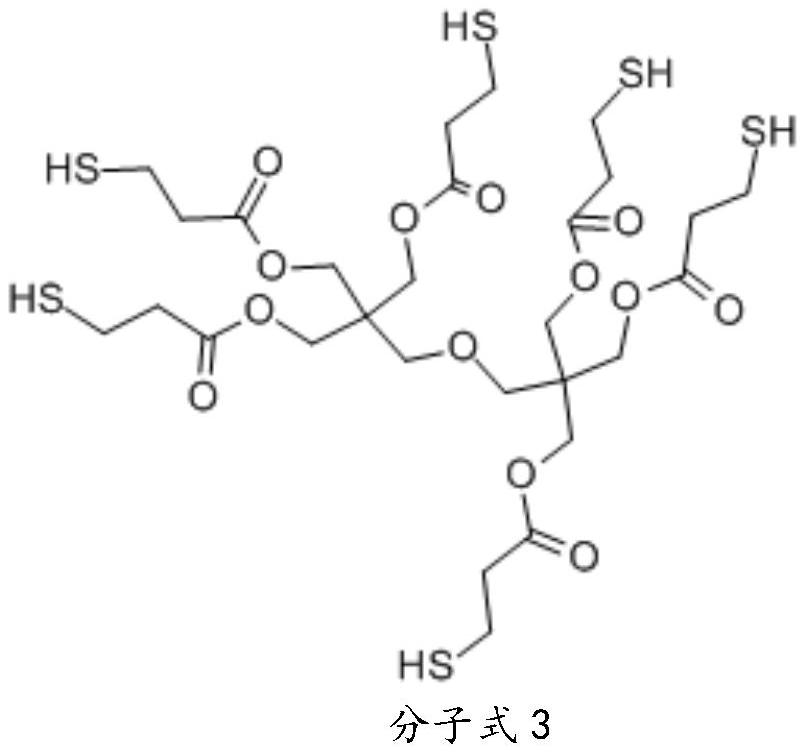

[0033] b. According to the number of mass parts: self-synthetic flame retardant epoxy resin gel 100g, tricyclic pentyl dimethoxy epoxy resin EP-4088S 250G, new low viscosity toughening agent LME11335 80g, intanin 6 ( Mercapto propionate) thiocure 360200 g, imidazole fed PN-23J 40g, ultrafine hydroxide 104 330 g. In sequential input, a rotational speed of 30 rpm was set under vacuum conditions, stirred for 4 hours, and the structural adhesive of the present invention was produced. ...

Embodiment 2

[0035] a. Press the mass part: Add epoxy resin EXA-830CrP 330g to the reactor, heated to 55 ° C, set the rotational speed 10 rpm, start stirring; the stirring conditions were added to the hexaglexyl cyclic triosphaconitrile HPCTP 660G parts , Heated to 115 ° C, set the rotational speed of 40 rpm under vacuum conditions, stirred for 0.5 hours; adding isophorone diamine IPDA 9G, continued to stir in nitrogen protection for 2 hours, resulting from synthetic flame retardant epoxy resin gel;

[0036] b. According to the number of mass parts: self-synthetic flame retardant epoxy resin gel 150g, tricyclic pentyl dimethoxy epoxy resin EP-4088L 300g, new low viscosity toughen lipong LME11335 60G, intanin 6 ( Mercapropathyl ester) thiocure 360250 g, imidazole fed PN-H 50g, ultrafine hydroxide 104 190 g. In sequential input, a rotational speed of 30 rpm was set under vacuum conditions, stirred for 4 hours, and the structural adhesive of the present invention was produced.

Embodiment 3

[0038] a. According to the mass parts: Add epoxy resin EXA-830CRP 320g to the reactor, heated to 55 ° C, set the rotational speed 10 rpm, start stirring; the stirring conditions are added to the hexagle-cyclo-trikanoonitrile HPCTP 680G parts Heating to 115 ° C, set the rotational speed 40 rpm under vacuum conditions, stirred for 1 hour; adding isophorone diamine IPDA 10g, continued to stir for 3 hours in a nitrogen protection environment, resulting from self-synthetic flame retardant epoxy resin gel;

[0039] b. According to the number of mass parts: self-synthetic flame retardant epoxy resin gel 200g, tricyclic pentyl dimethoxy epoxy resin EP-4088S 350g, new low viscosity toughening agent LME11335 30g, intraminolysis Mercapropathyl ester) Thiocure 360300 g, imidazole fed PN-40J 60g, ultrafine hydroxide 104 60g. In sequentially put the stirred tank, the rotational speed of 30 rpm was set under vacuum conditions, stirred for 3 hours to prepare the structural glue of the present inv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com