Patents

Literature

34results about How to "Improving Impedance Performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

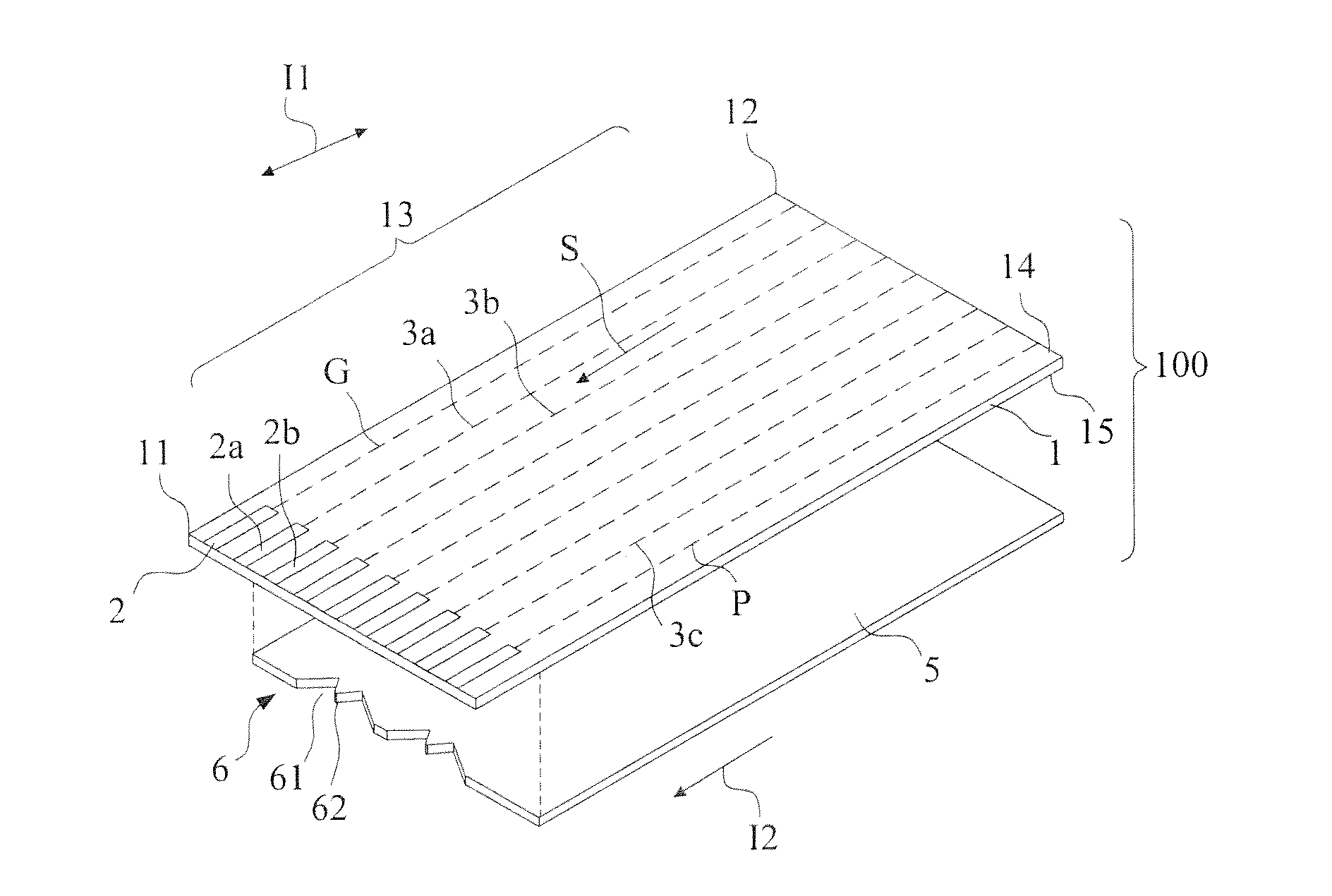

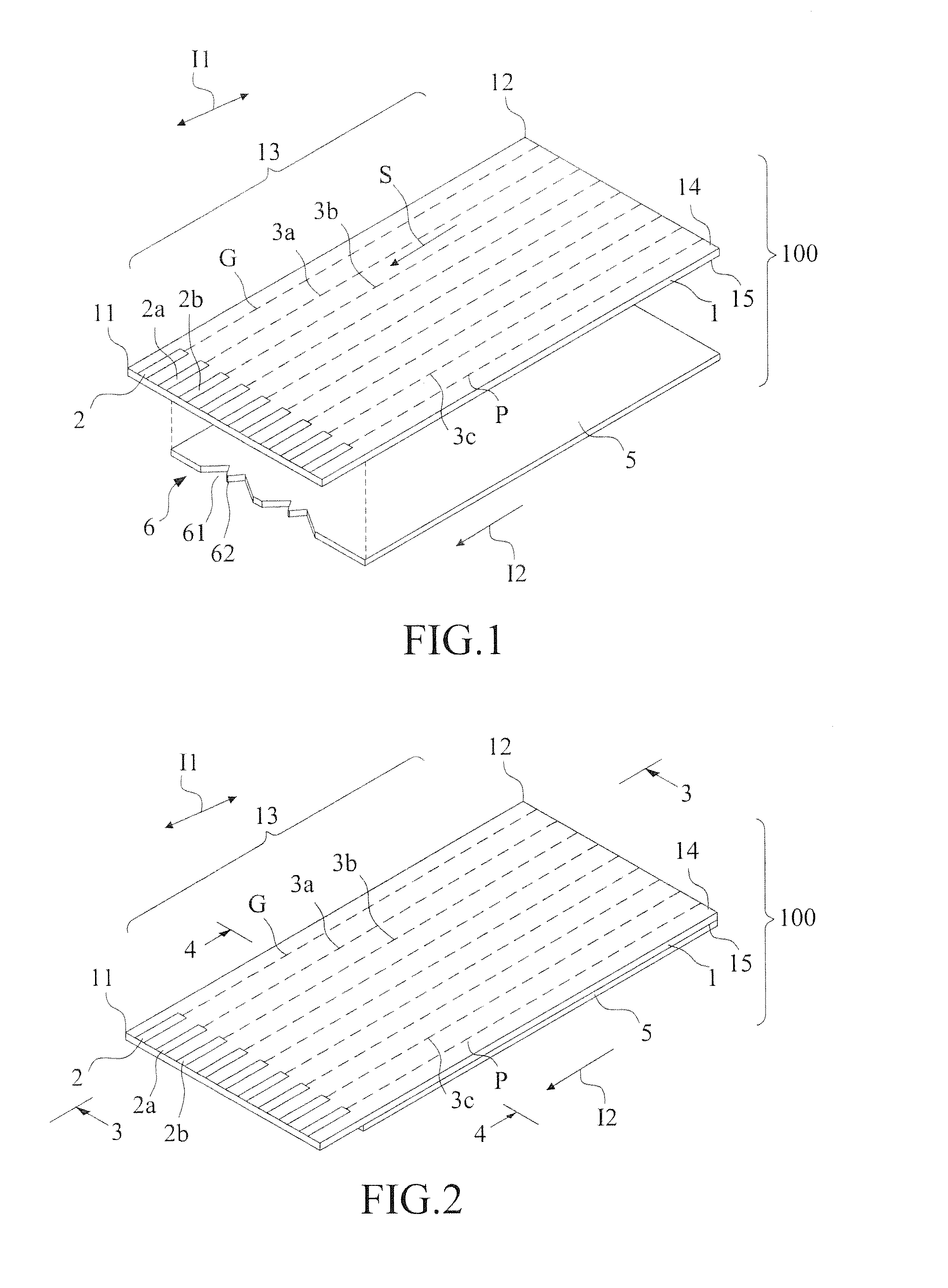

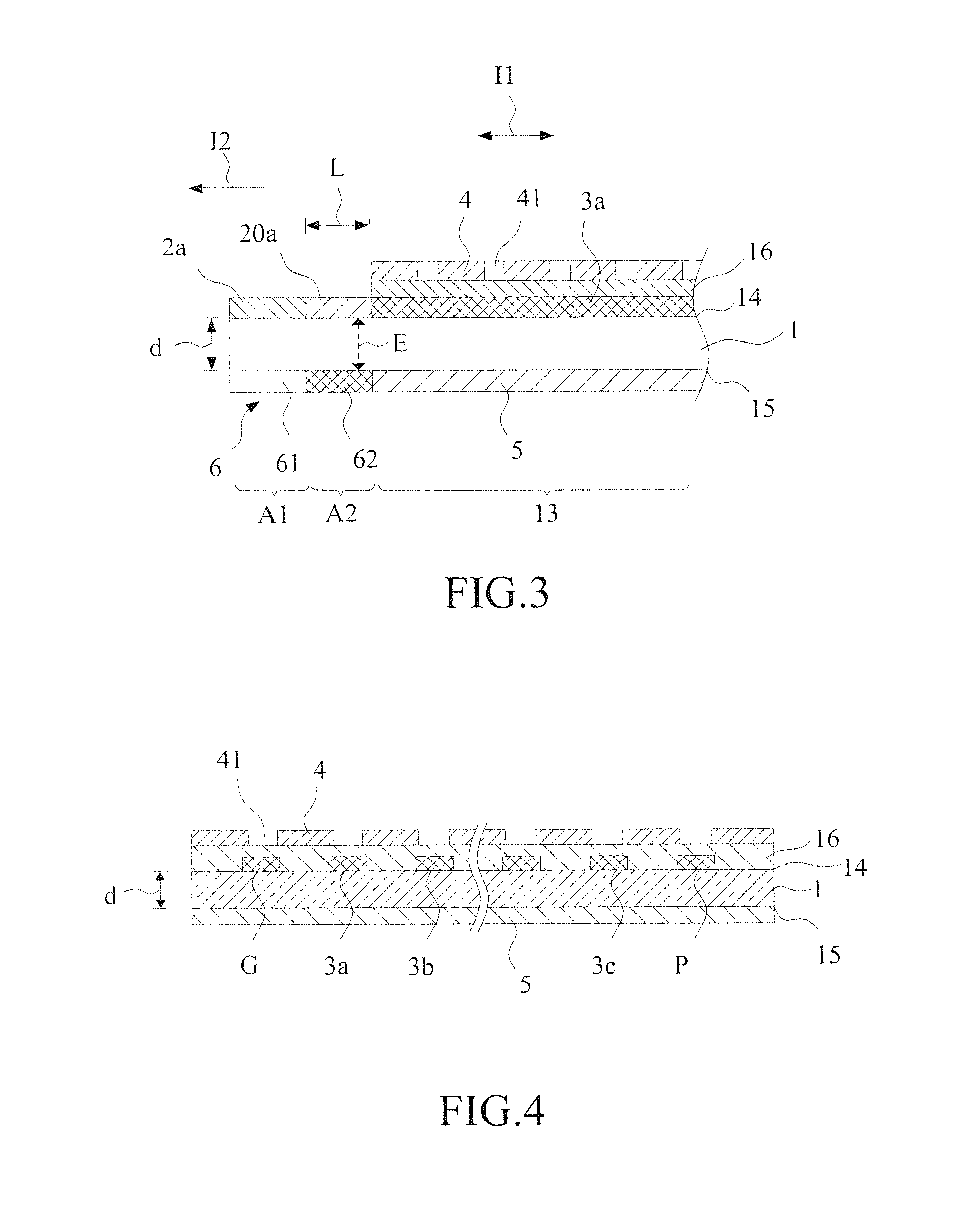

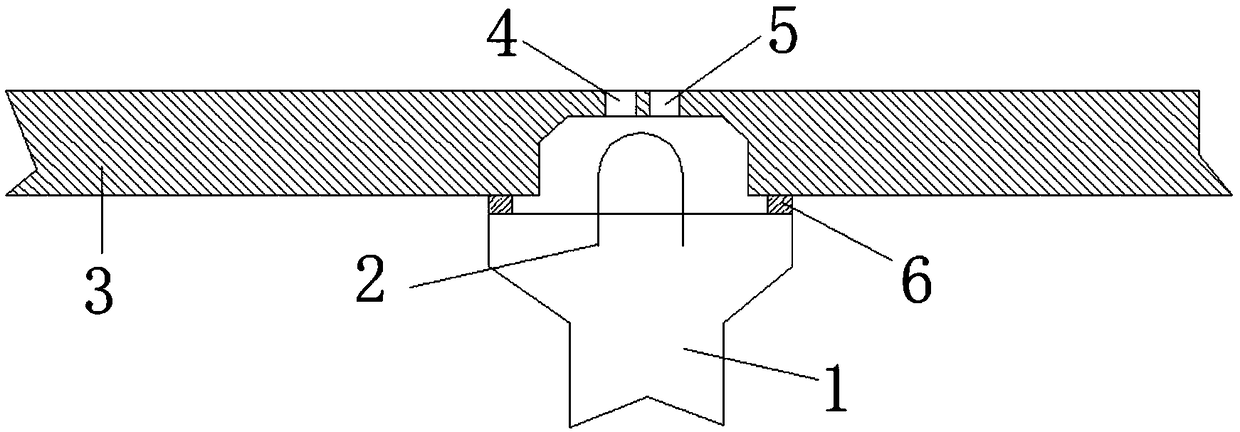

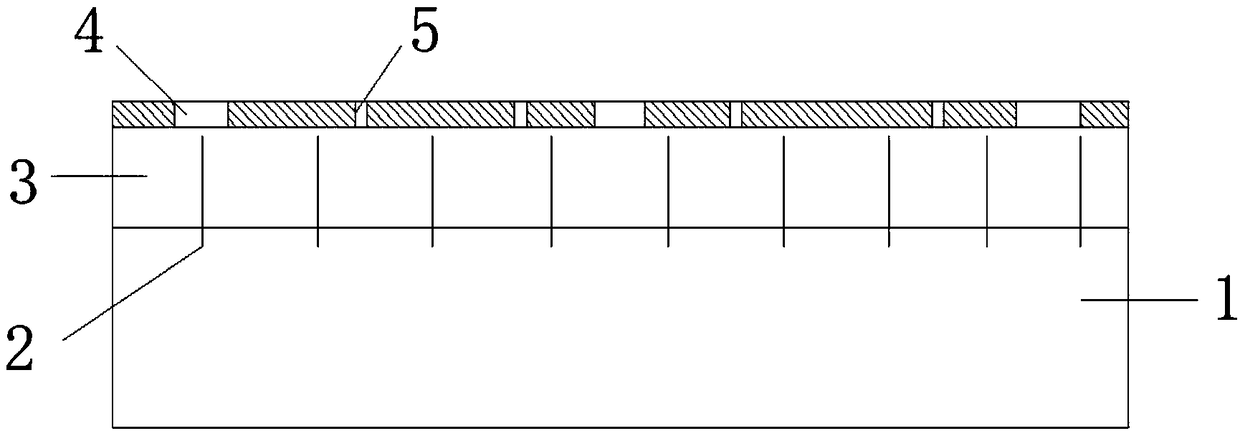

Attenuation reduction grounding pattern structure for connection pads of flexible circuit board

ActiveUS20140318833A1Reduce reflection lossEnsure qualityHigh frequency circuit adaptationsPrinted circuit aspectsUltrasound attenuationFlexible circuits

An attenuation reduction grounding pattern structure for connection pads of a flexible circuit board includes a plurality of high frequency connection pads formed on a component surface of a substrate and a plurality of differential mode signal lines arranged on the substrate and connected to the high frequency connection pads. The substrate has a grounding surface forming a grounding layer. The grounding layer includes an attenuation reduction grounding pattern structure formed at a location corresponding to the transition zone and including a hollowed area and a protruded portion. The protruded portion extends a predetermined length in a direction from the grounding layer toward the high frequency connection pads and along the adjacent high frequency connection pads to reach the transition zone. The protruded portion and the high frequency connection pads form a polarization-direction-varying electric field in the transition zone.

Owner:ADVANCED FLEXIBLE CIRCUITS

Impregnated-type non-woven fabric and manufacturing method thereof

ActiveCN102912651AImprove dust filtering effectIncrease concentrationTextiles and paperPolyesterPolymer science

The present invention relates the field of non-wovens, and discloses an impregnated-type non-woven and a manufacturing method thereof. A first fiber comprises a low melting point fiber and a polyester fiber; and a second fiber comprises a low melting point fiber, a viscose staple fiber and the polyester fiber. The raw materials of the first fiber are as follows: the low-melting fiber accounts for 5% to 20% by mass of the total mass of the first fiber, and the polyester fiber accounts for 80%-95% by mass of the total mass of the first fiber. The raw materials of the second fiber are as follows: the low melting point fiber accounts for 5% to 20% by mass of the total mass of the second fiber, the polyester fiber accounts for 80% to 95% by mass of the total mass the second fiber, and the viscose staple fiber accounts for 5% to 15% by mass of the total mass of the second fiber. The concentration percentage by mass of polyacrylate is divided into two types, 10% and 25%. According to the invention, the impregnated-type non-woven are manufactured by performing the process of first tiling, punching through up and down, hot baking, hot ironing, adding the polyacrylate, drying, and hot ironing to the fibers for the first time. The impregnated-type non-woven has the characteristics of good adsorptivity, high filterability, and a large dust-holding capacity.

Owner:DONGGUAN RETOP FILTER MATERIAL

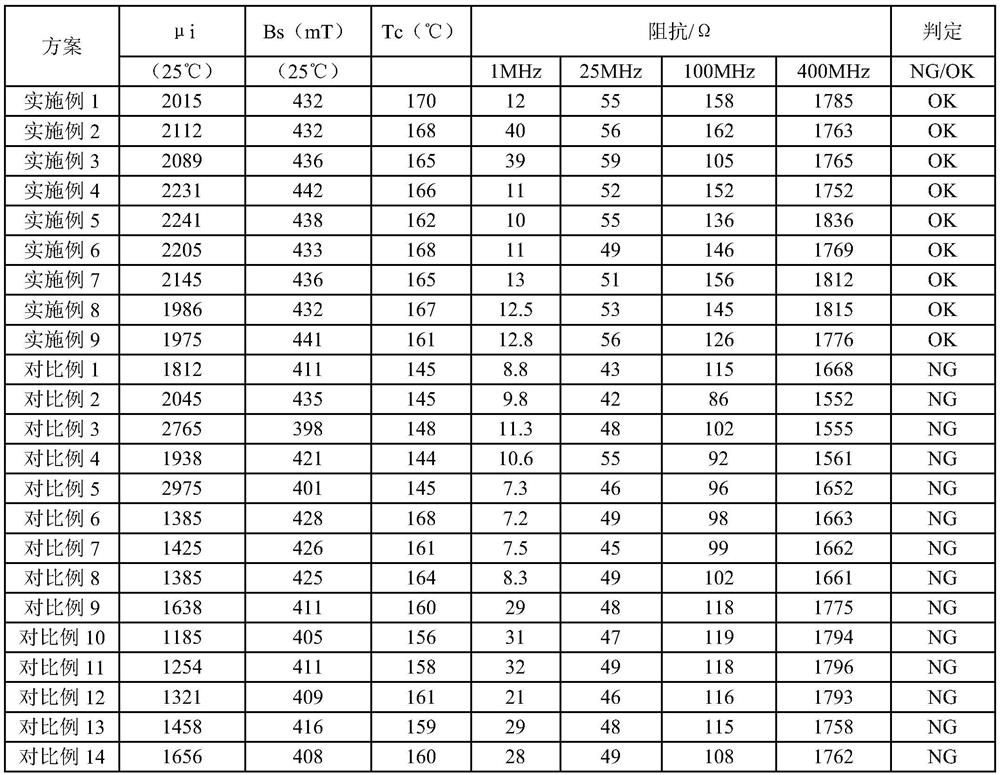

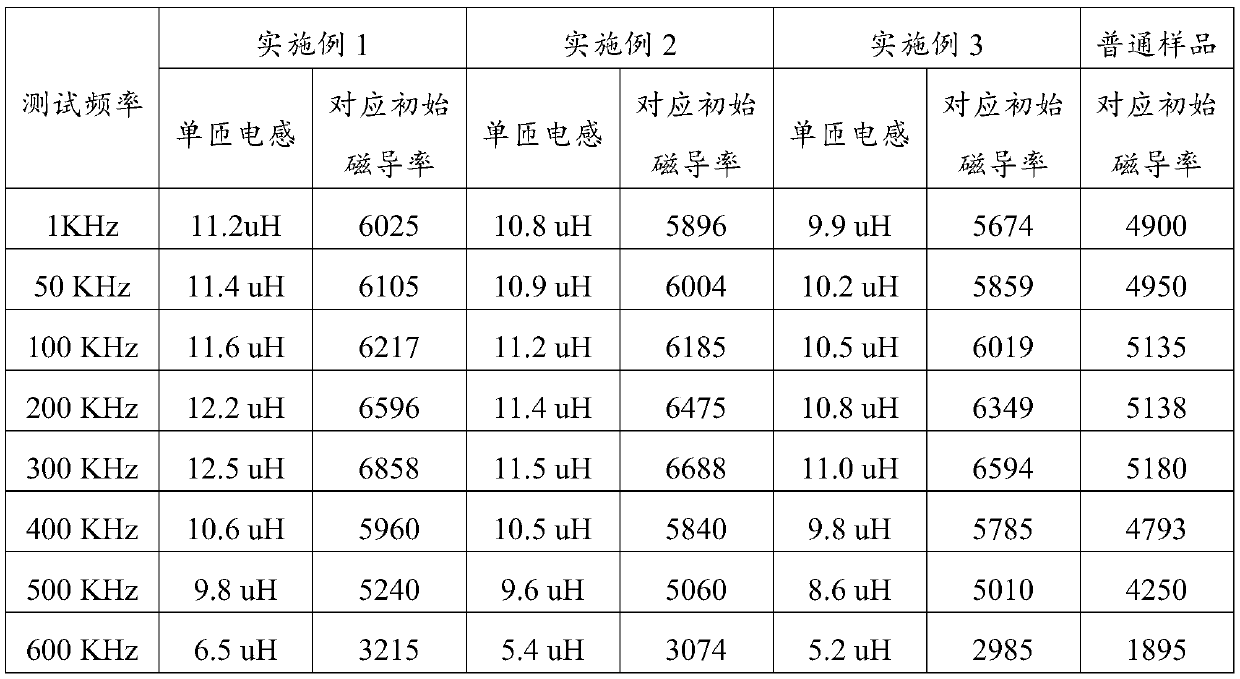

High-frequency high-impedance iron-poor manganese-zinc ferrite and preparation method thereof

The invention relates to the technical field of soft magnetic ferrites. The high-frequency high-impedance iron-poor manganese-zinc ferrite comprises main components and additives, the main componentscomprise the following raw materials in percentage by mole: 47.8%-49.8% of Fe2O3, 31%-36% of MnO, 15%-18.5% of ZnO and 0.7%-2% of Co2O3, the additives comprise 10 to 100 ppm of SiO2, 200 to 1000 ppm of CaCO3, 100 to 300 ppm of Bi2O3, 100 to 300 ppm of ZrO2 and 100 to 600 ppm of TiO2. According to the invention, the Co2O3 is added into the main components, the ratio of the main components is reasonably adjusted, and meanwhile, the additives are added for modification, so that the prepared iron-poor manganese-zinc ferrite also has high magnetic conductivity, high saturation flux density and highimpedance at high frequency.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

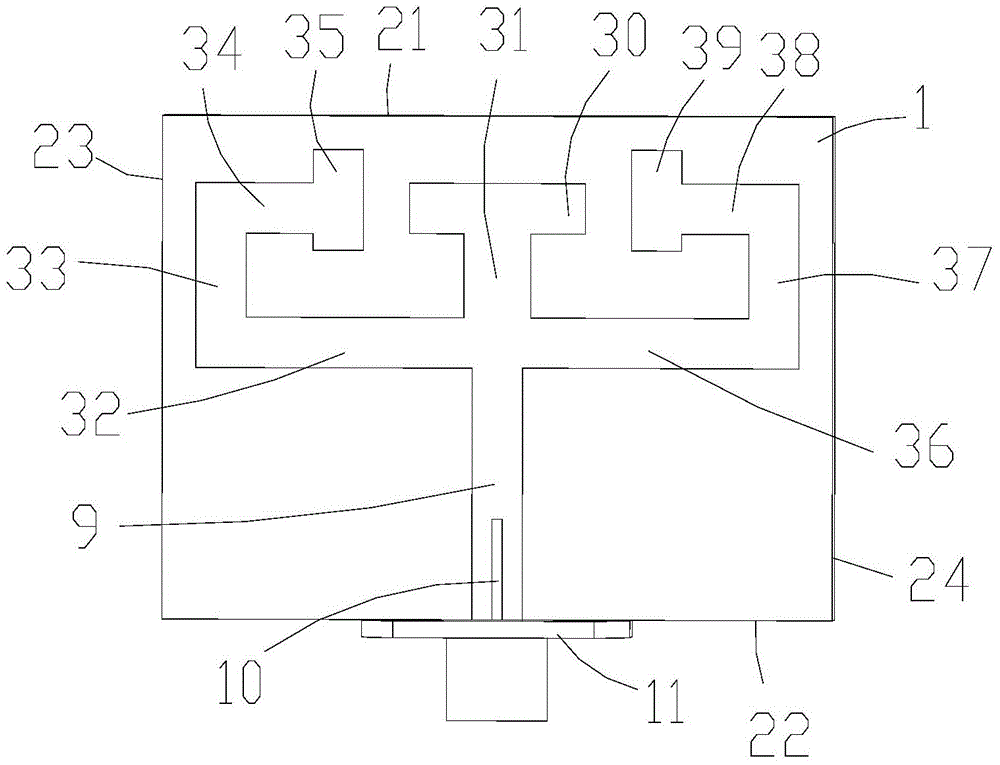

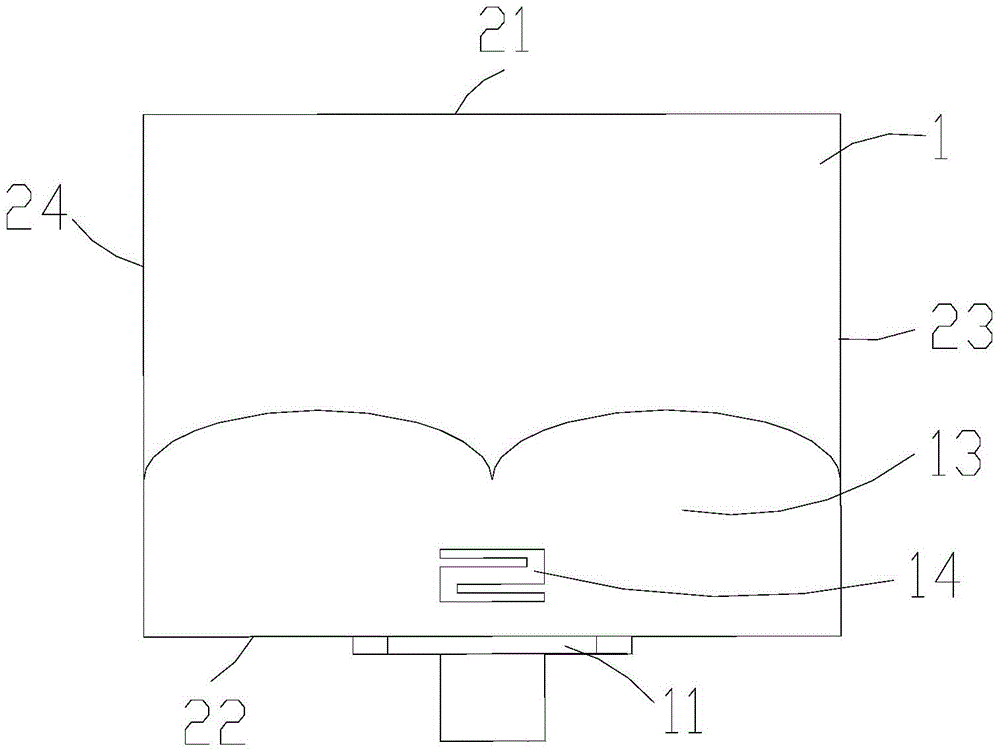

Minimized monopole antenna

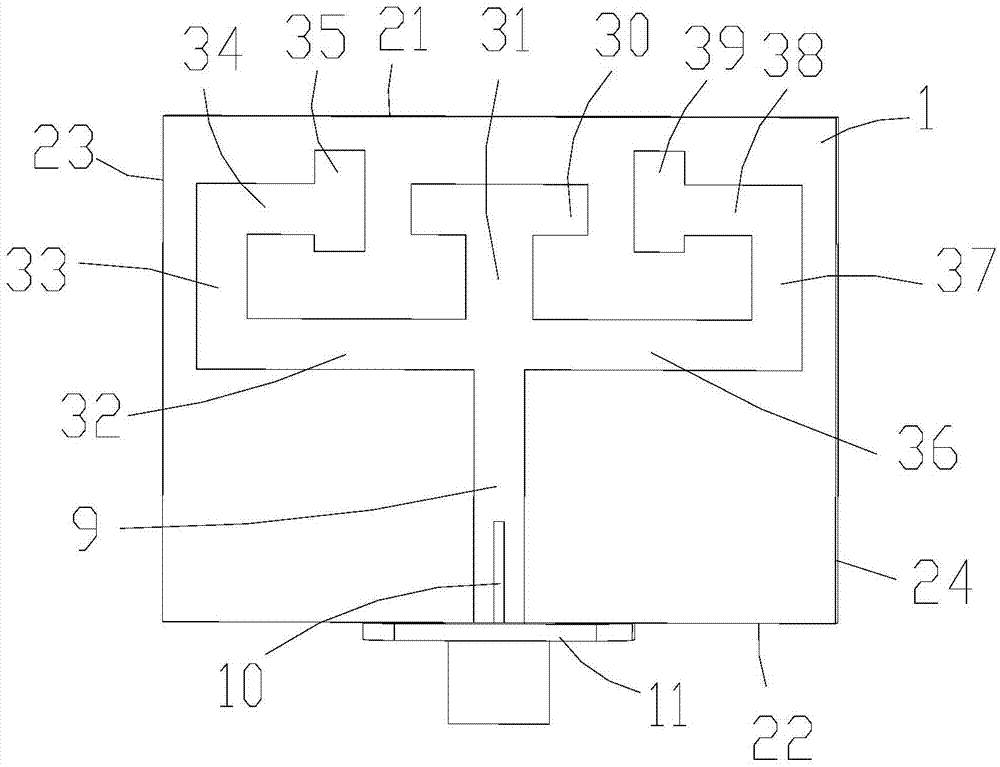

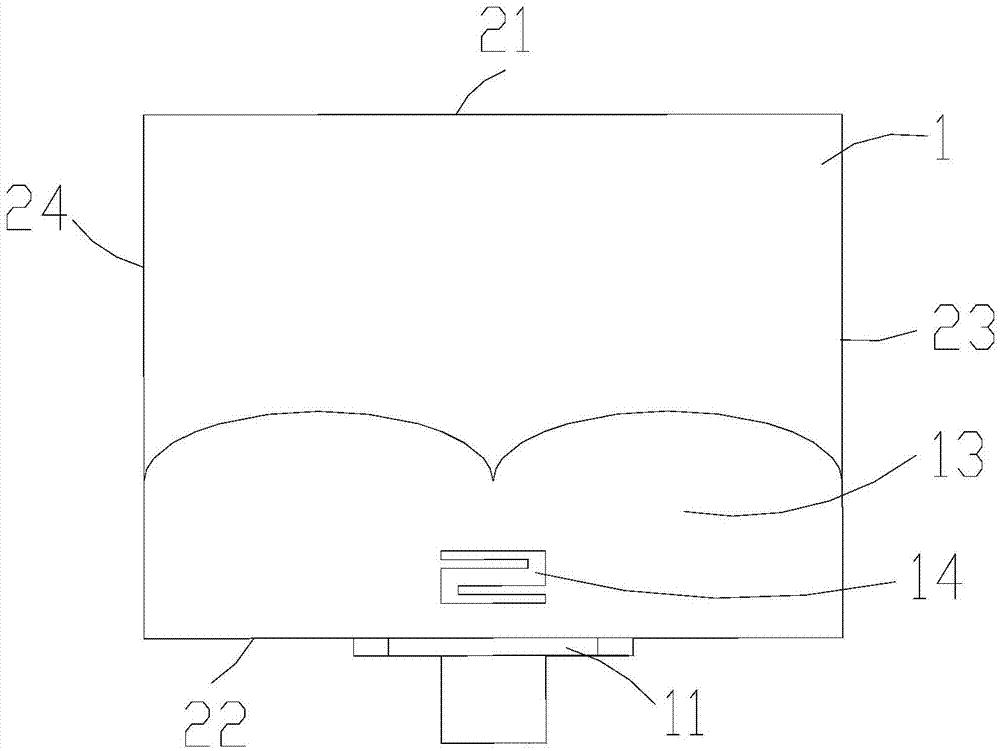

ActiveCN103887603AReduce volumeCompact structureRadiating elements structural formsAntenna earthingsDielectric substrateOptoelectronics

The invention discloses a minimized monopole antenna which is characterized by comprising a dielectric substrate, a radiator, a grounding board and a feeder, wherein the dielectric substrate is rectangular and is provided with a front side and a back side which are opposite to each other, the radiator is printed on the front side, the dielectric substrate is provided with a top edge, a bottom edge, a left edge and a right edge, the radiator is composed of a first radiation part, a second radiation part, a third radiation part, a fourth radiation part, a fifth radiation part, a sixth radiation part, a seventh radiation part, an eighth radiation part, a ninth radiation part and a tenth radiation part, and all the radiation parts are rectangular. The minimized monopole antenna is compact in structure, small in size and capable of meeting performance requirements. Three electric signal paths in different lengths are formed by the radiator, the operation bandwidth can be effectively expanded, and therefore the minimized monopole antenna can be applied to various communication occasions. Furthermore, the wavy edges and hollowed-out structure of the grounding board enable a good impedance function to be realized.

Owner:广东智视数字技术有限公司

Modified black pigment liquid used for black matrix and preparation method thereof

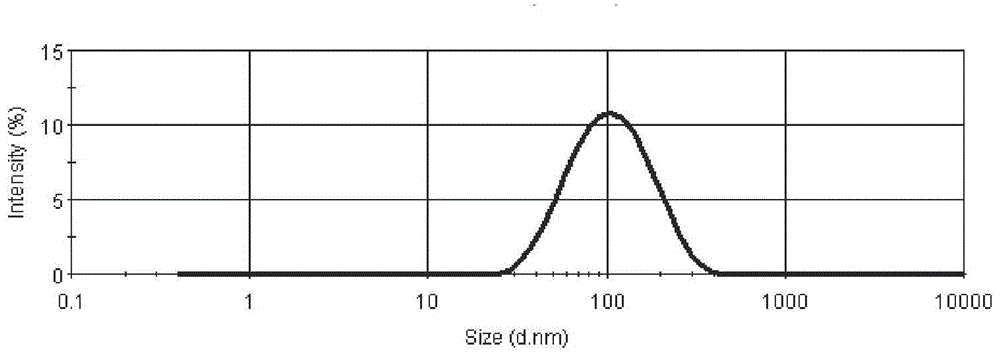

ActiveCN104830160AImprove shadingImprove thermal stabilityPigment pastesHigh resistanceThermal stability

The invention discloses a modified black pigment liquid used for black matrix, and a preparation method thereof. According to the preparation method, poly dopamine nano particles are added into a black pigment liquid, wherein weight amount of the poly dopamine nano particles accounts for 1 to 4% of that of the black pigment liquid. The preparation method comprises modification of the black pigment liquid, wherein the poly dopamine nano particles are added into the black pigment liquid, and the modified black pigment liquid is obtained via 1 to 3h of stirring. The obtained modified black pigment liquid and black matrix prepared from the modified black pigment liquid possess excellent light shading capacity, extremely high thermal stability, and high resistance value.

Owner:BEIJING SINEVA TECH

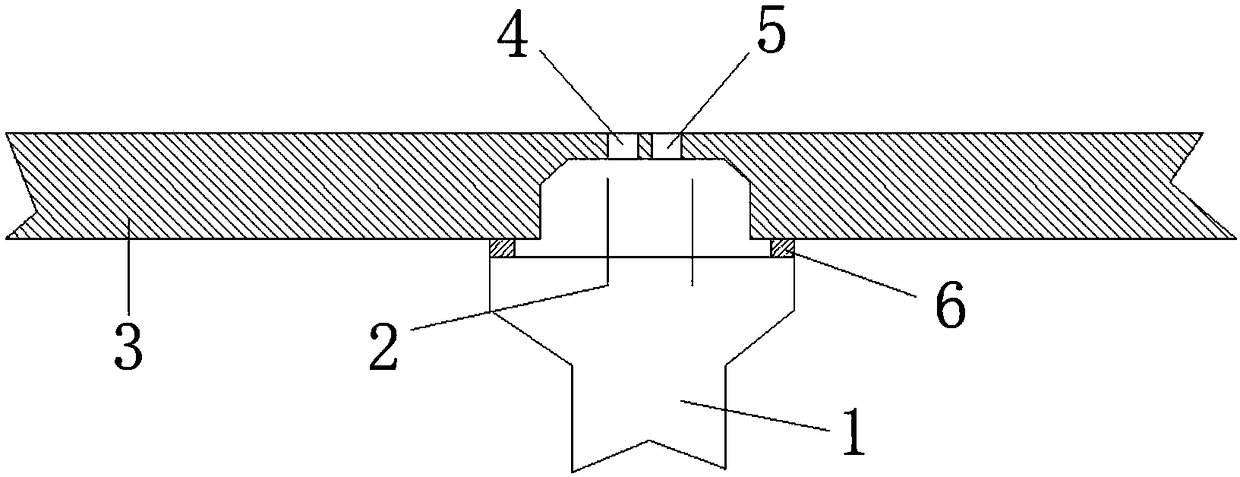

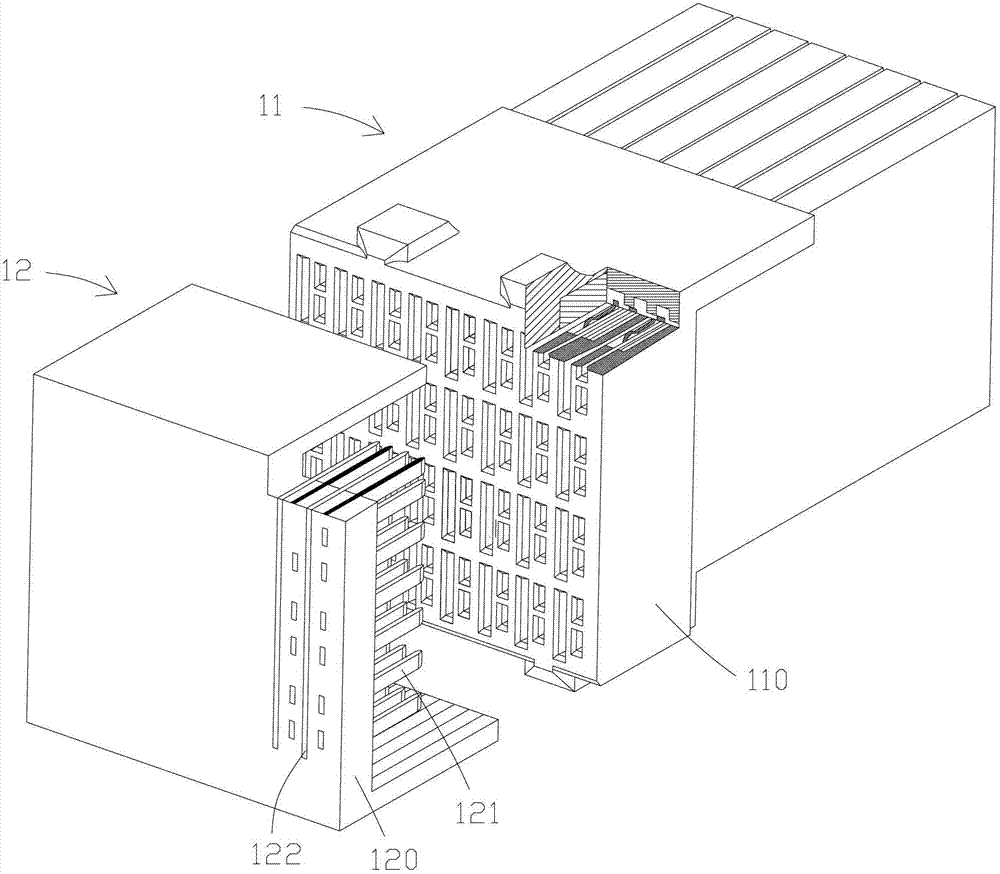

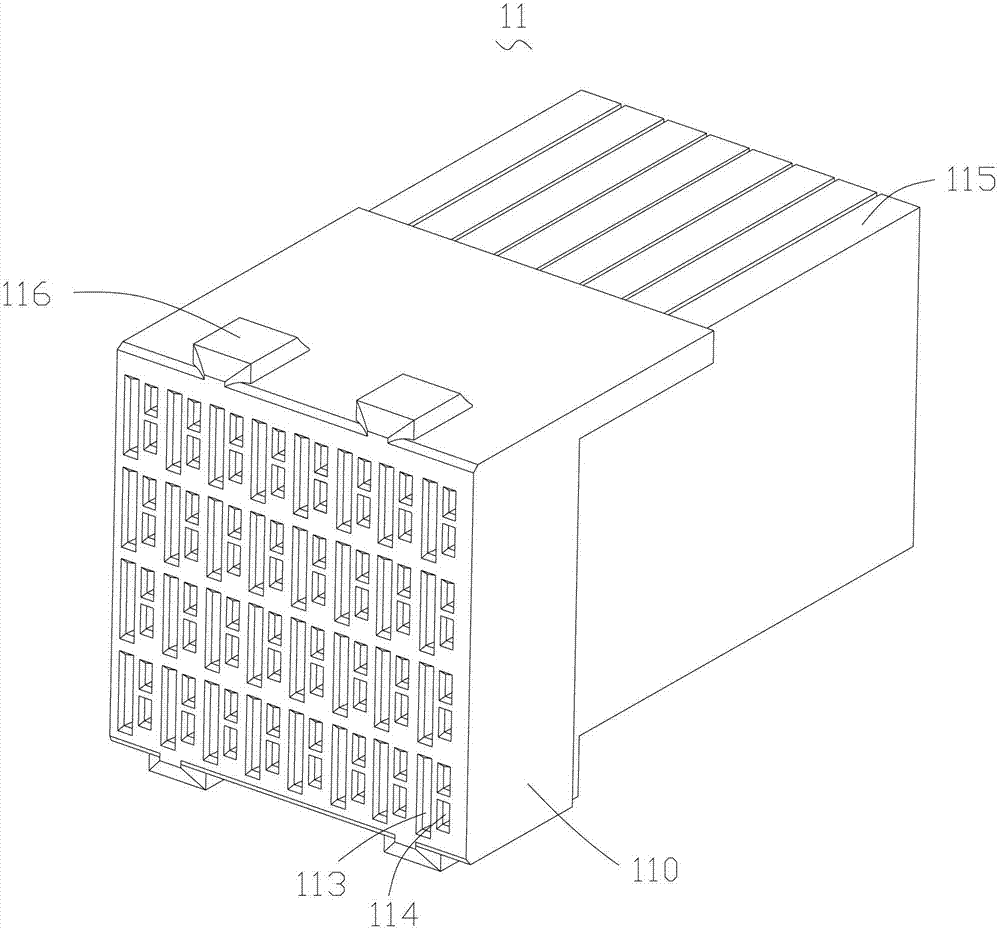

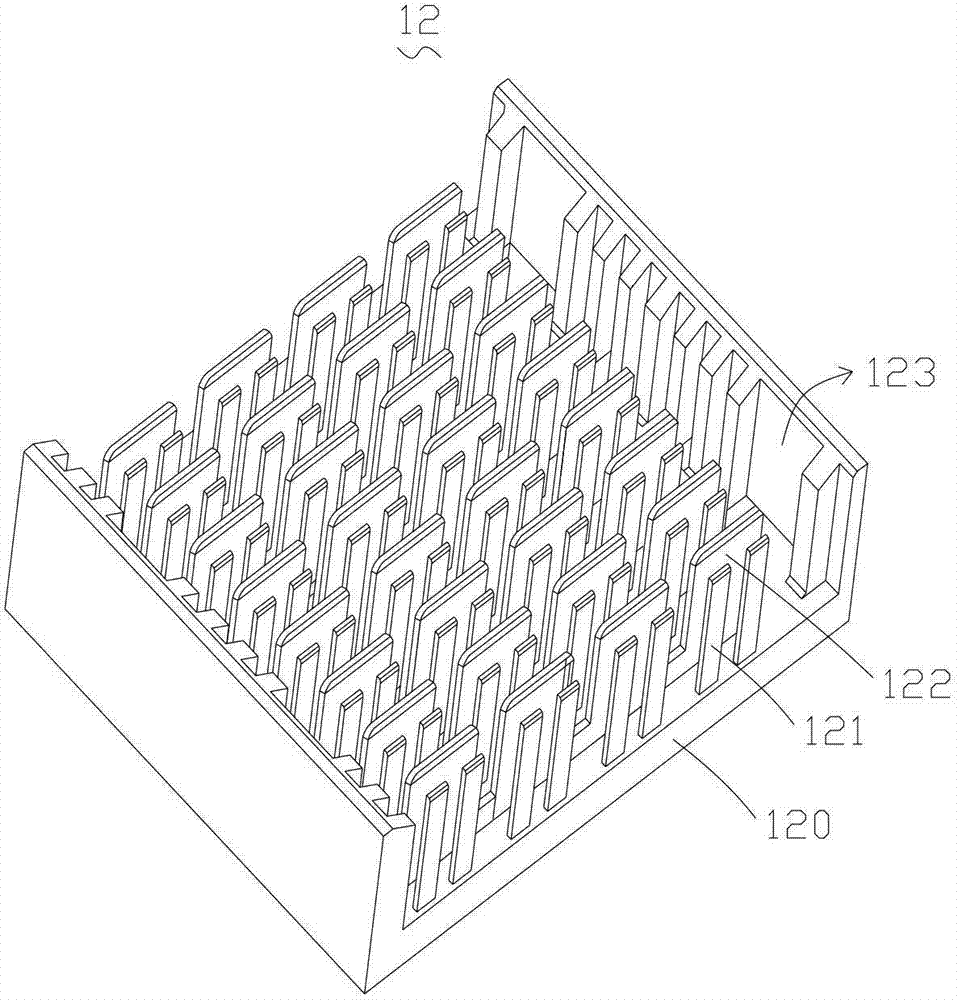

Communication equipment, electric connector assembly and electric connector

ActiveCN103219619AImproving Impedance PerformanceReduce manufacturing costCoupling device detailsTwo-part coupling devicesElectricityEngineering

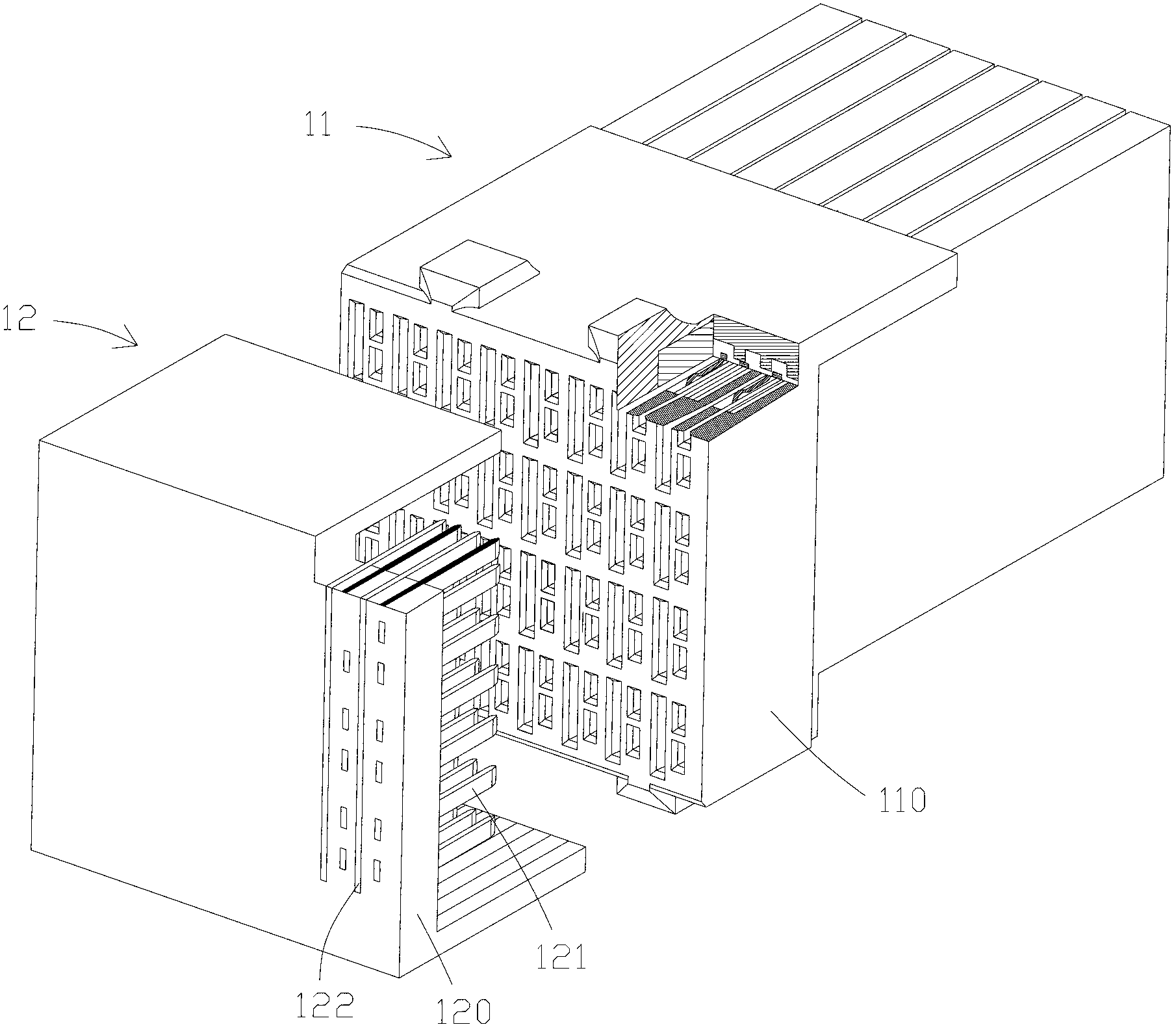

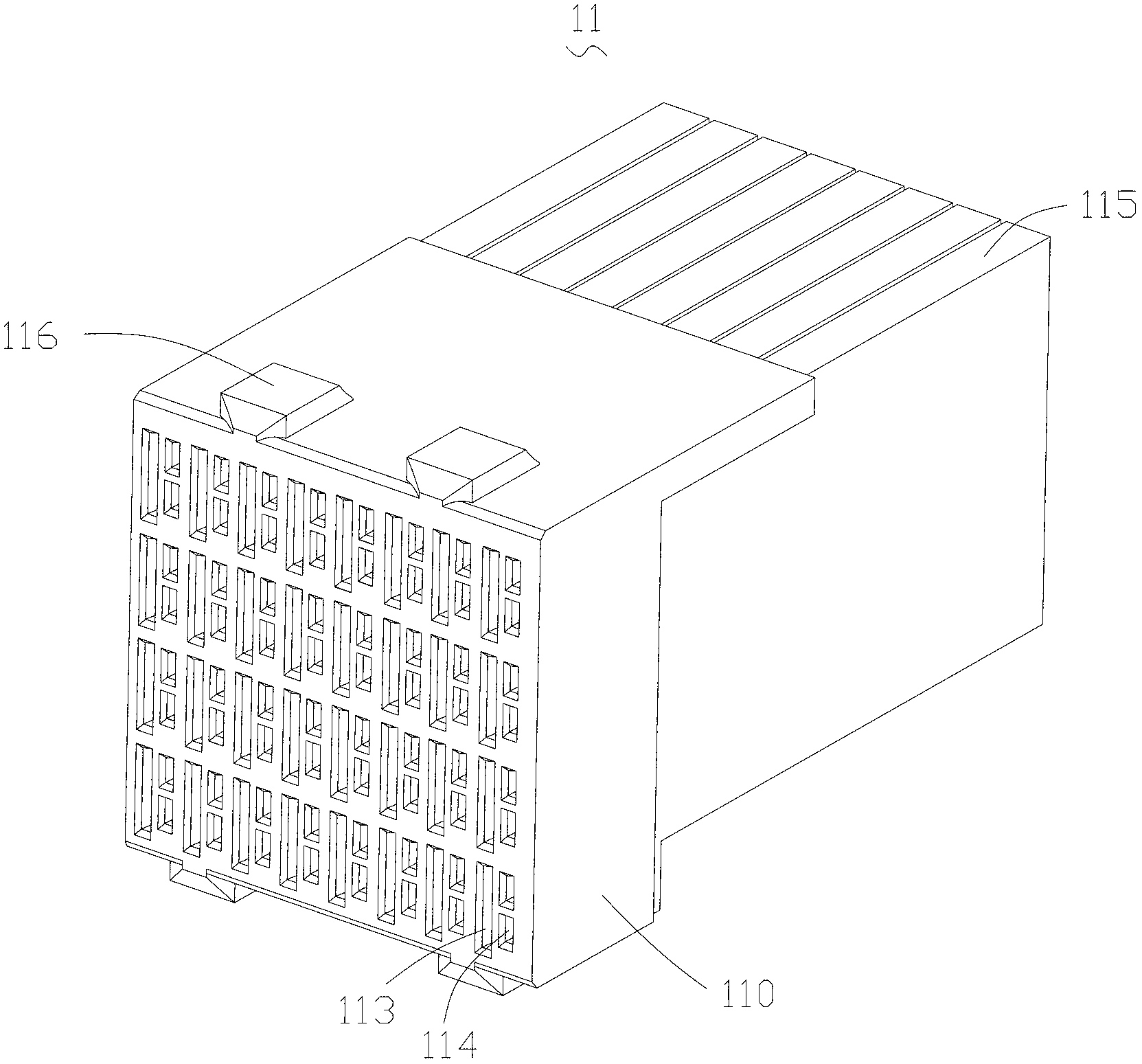

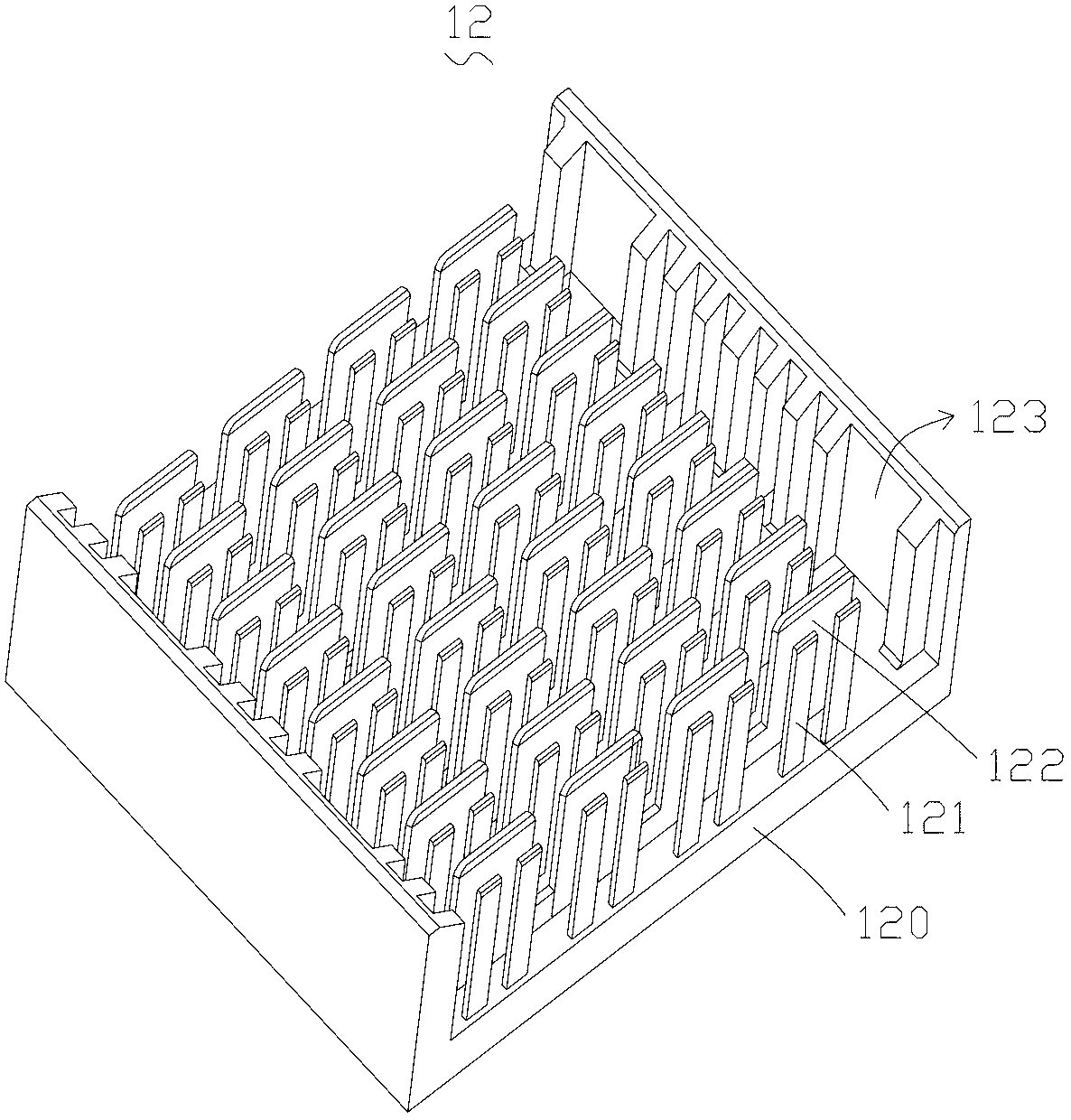

The invention provides communication equipment, an electric connector assembly and an electric connector. The electric connector assembly comprises a first electric connector, a second electric connector and a dielectric layer, wherein the first electric connector assembly comprises a first insulating main body and a first conductive terminal arranged in the first insulating main body; the second electric connector comprises a second insulating main body and a second conductive terminal arranged on the second insulating main body; the dielectric layer comprises a capacitive dielectric layer or inductive dielectric layer; and the dielectric layer is positioned between the first conductive terminal and the second conductive terminal when the first electric connector is connected with the second electric connector, so that the first conductive terminal is capacitively connected with the second conductive terminal by the capacitive dielectric layer or is inductively connected with the second conductive terminal by the inductive dielectric layer. According to the communication equipment, the electric connector assembly and the electric connector disclosed by the invention, the technical problems of high production cost and poor effect caused by optimization impedance in the prior art are effectively solved, the production cost is reduced and better impedance performances are obtained.

Owner:HUAWEI TECH CO LTD

Water-based polyurethane emulsion with high water resistance and ethanol resistance and preparation method thereof

ActiveCN109721707AImprove water resistanceImprove ethanol resistancePolyurea/polyurethane coatingsWater basedEmulsion

The invention belongs to the technical field of fine chemical engineering, and particularly relates to a water-based polyurethane emulsion with high water resistance and ethanol resistance and a preparation method thereof. The invention provides the preparation method of the water-based polyurethane emulsion with high water resistance and ethanol resistance. The preparation method comprises the following steps: a) carrying out a first reaction on poly(propylene carbonate) polyol, diisocyanate, castor oil and a hydrophilic chain extender under the action of a catalyst to obtain a first product;b) adding a silane coupling agent into the first product to carry out a second reaction to obtain a second product; and c) adding a neutralizer into the second product to carry out a neutralization reaction, then adding deionized water for emulsifying, and then adding a non-hydrophilic chain extender to carry out a third reaction to obtain the water-based polyurethane emulsion. Experimental results show that a coating film formed by the water-based polyurethane emulsion disclosed by the invention has excellent boiling water resistance and ethanol resistance.

Owner:GUANGDONG UNIV OF TECH

Corrosion etching method of ultra-small quartz wafer

InactiveCN111058095AReduce edge effectsImproving Impedance PerformancePolycrystalline material growthAfter-treatment detailsEtchingWafering

The invention provides a corrosion etching method for an ultra-small quartz wafer. The corrosion etching method comprises the following steps: 1) processing a large quartz wafer; 2) coating a Mesa region with a film; (3) etching the Mesa region; 4) carrying out size coating; 5) carrying out size corrosion etching; and 6) removing gold from the ultra-small quartz wafer. According to the invention,processing is carried out on a large quartz wafer to indirectly obtain a single quartz wafer; the marginal effect of the low and medium frequency quartz wafer is reduced by using a precision processing technology of Mesa coating and Mesa corrosion etching; the shape processing of an ultra-small-size quartz plate is indirectly completed through size coating and size corrosion etching, so that the problem of huge investment caused by introduction of a photoetching technology is avoided, a subsequent crystal processing coating material can be selected, and the cost pressure is reduced.

Owner:NANJING CHINA ELECTRONICS PANDA CRYSTAL TECH CORP

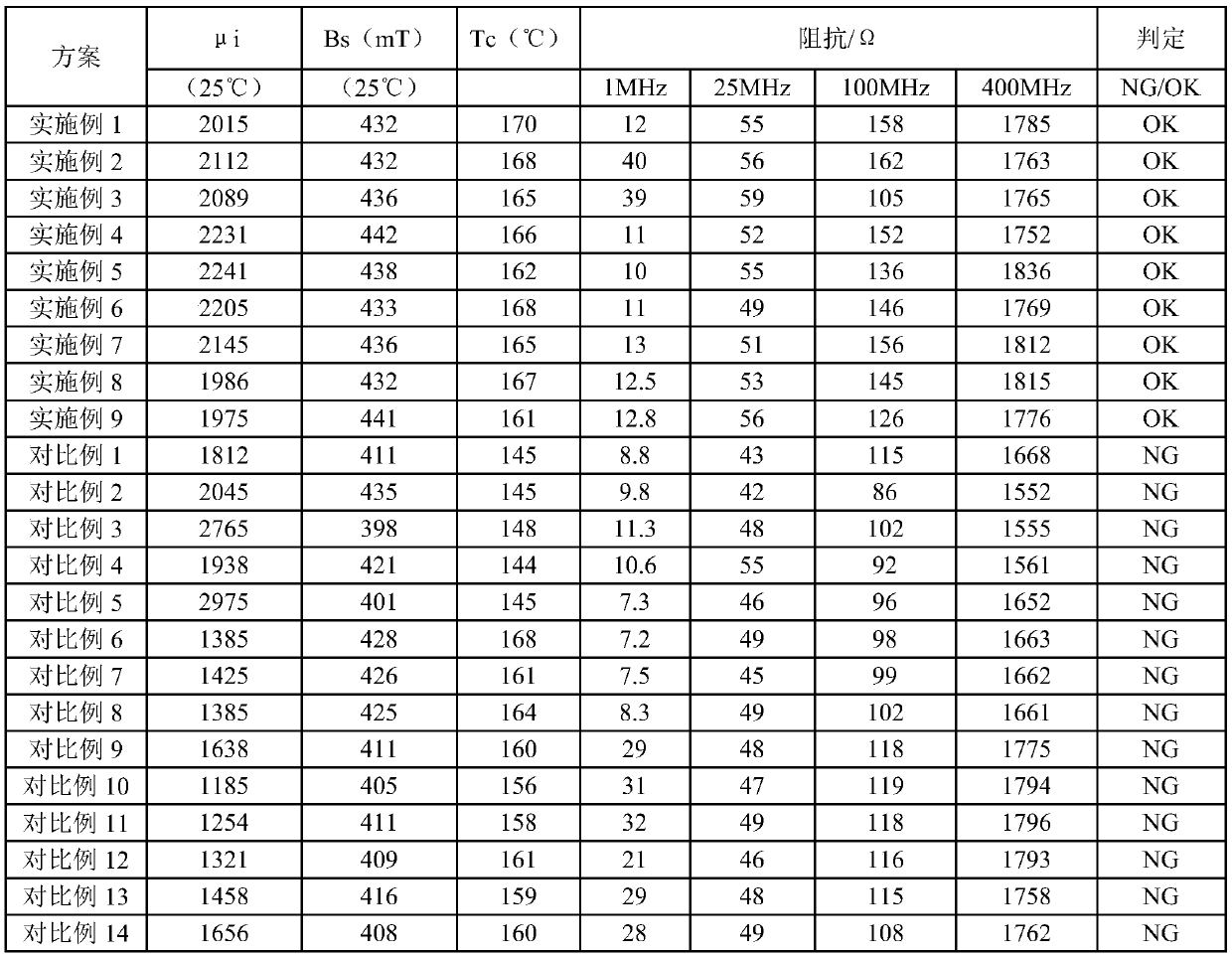

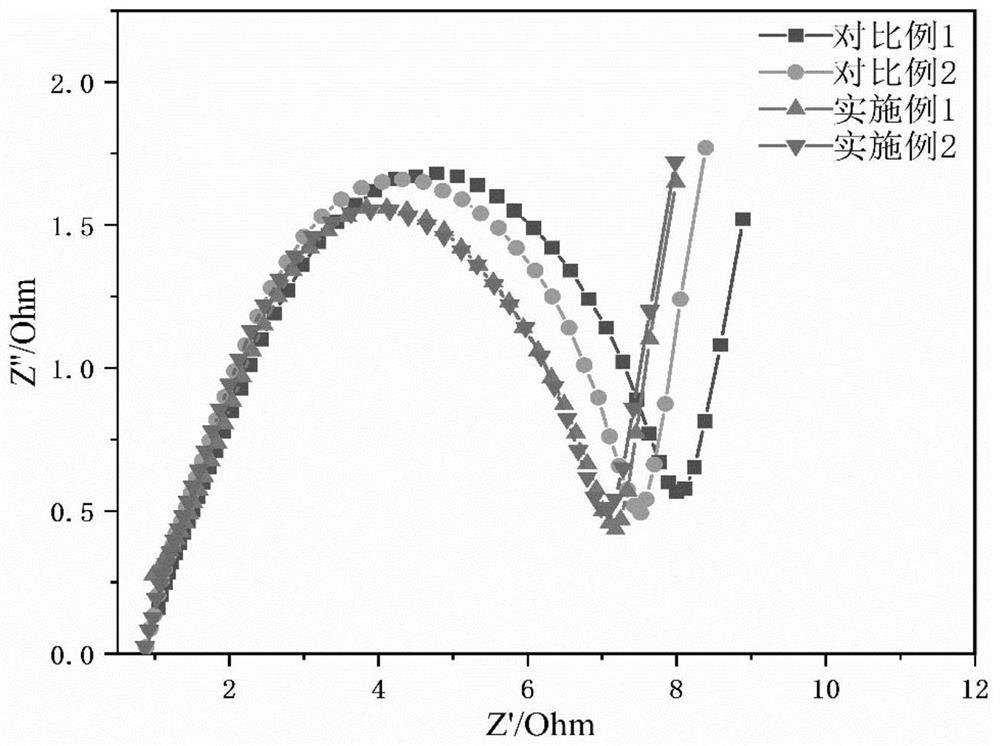

A high-frequency high-impedance iron-poor manganese-zinc ferrite and its preparation method

ActiveCN111233452BImprove permeabilityHigh saturation magnetic inductionInorganic material magnetismSoft magnetManganese

The invention relates to the technical field of soft ferrite, and discloses a high-frequency and high-impedance poor iron-manganese-zinc ferrite and a preparation method thereof. 2 O 3 , 31~36%MnO, 15~18.5%ZnO and 0.7~2%Co 2 O 3 ; Additives include 10~100ppm SiO 2 , 200~1000ppm CaCO 3 , 100~300ppm Bi 2 O 3 , 100~300ppm ZrO 2 and 100~600ppm TiO 2 . In the present invention, Co is added to the main component 2 O 3 , and reasonably adjust the proportion of each main component, and add additives for modification at the same time, the prepared iron-manganese-zinc ferrite has high magnetic permeability, high saturation magnetic induction intensity and high impedance at high frequency.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

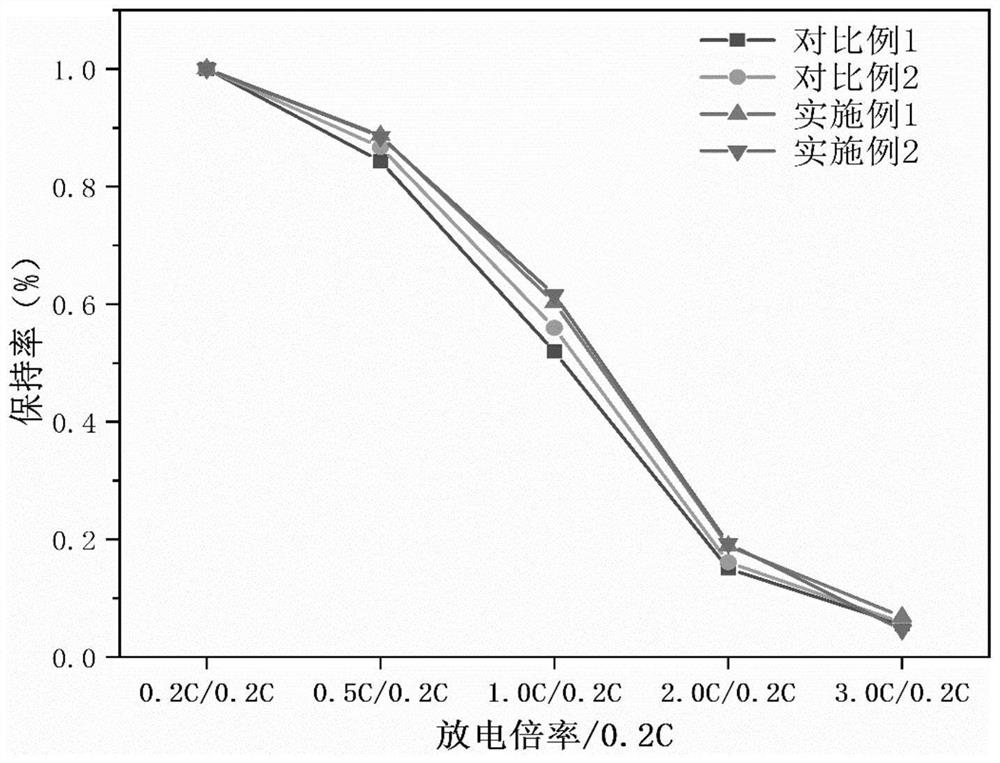

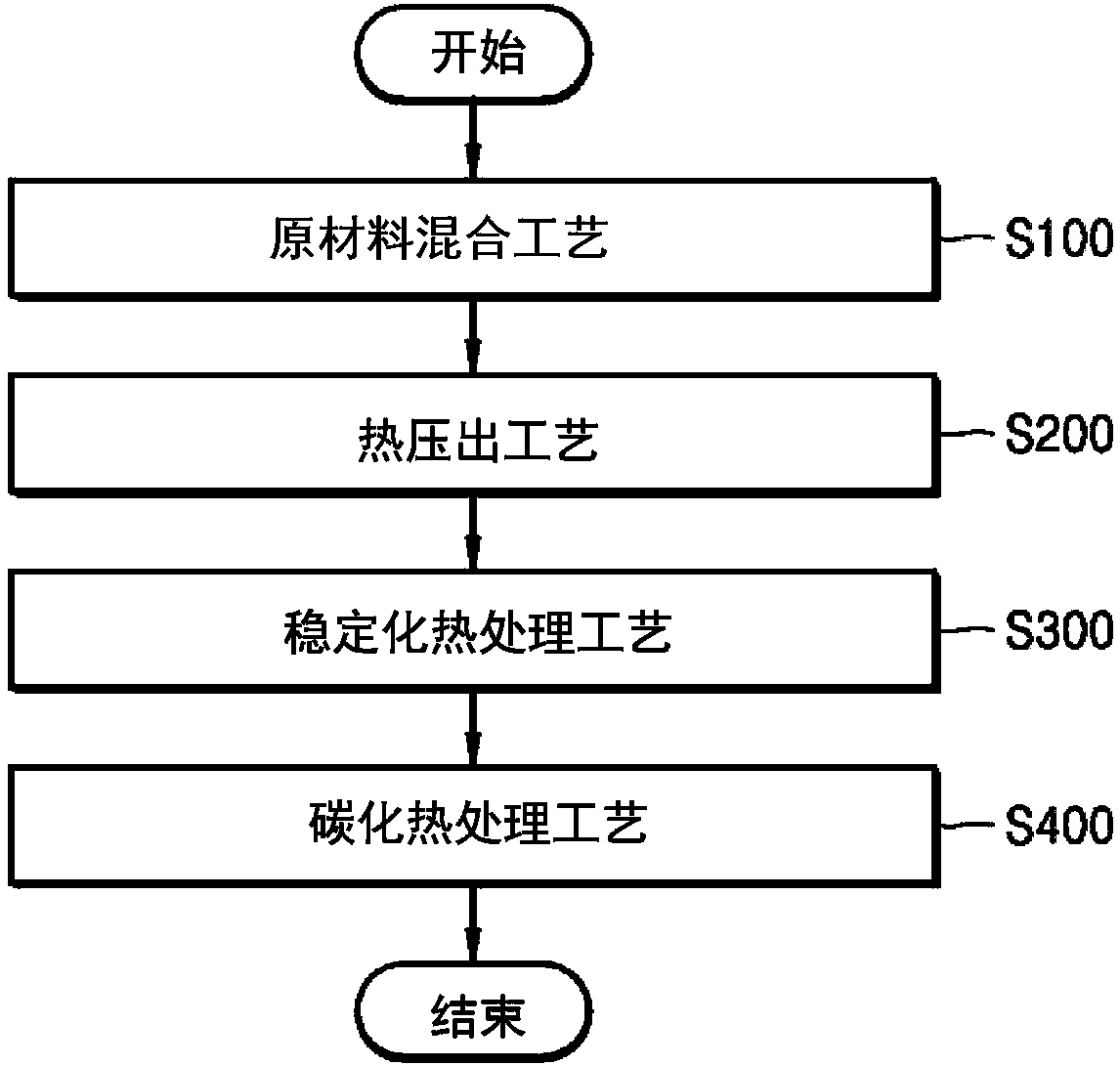

Modified graphite material, preparation method and application thereof and lithium ion battery

PendingCN112694086AIncrease capacityImproved magnification performanceGraphiteCell electrodesElectrical batteryGraphene

The invention discloses a modified graphite material, a preparation method and application thereof and a lithium ion battery. The preparation method of the modified graphite material comprises the steps of S1, preparing graphite particles, specifically, sequentially carrying out heat treatment and graphitization on a graphite raw material to obtain the graphite particles; S2, carrying out primary coating, specifically, fusing the graphite particles and the oily graphene slurry, and carrying out first carbonization to obtain primarily coated graphite particles; and S3, carrying out secondary coating, specifically, fusing the primarily coated graphite particles and a polyvinylpyrrolidone aqueous solution, and carrying out secondary carbonization to obtain the modified graphite material. The lithium ion battery prepared from the modified graphite material is high in discharge capacity and excellent in rate capability and impedance performance.

Owner:NINGBO SHANSHAN NEW MATERIAL TECH

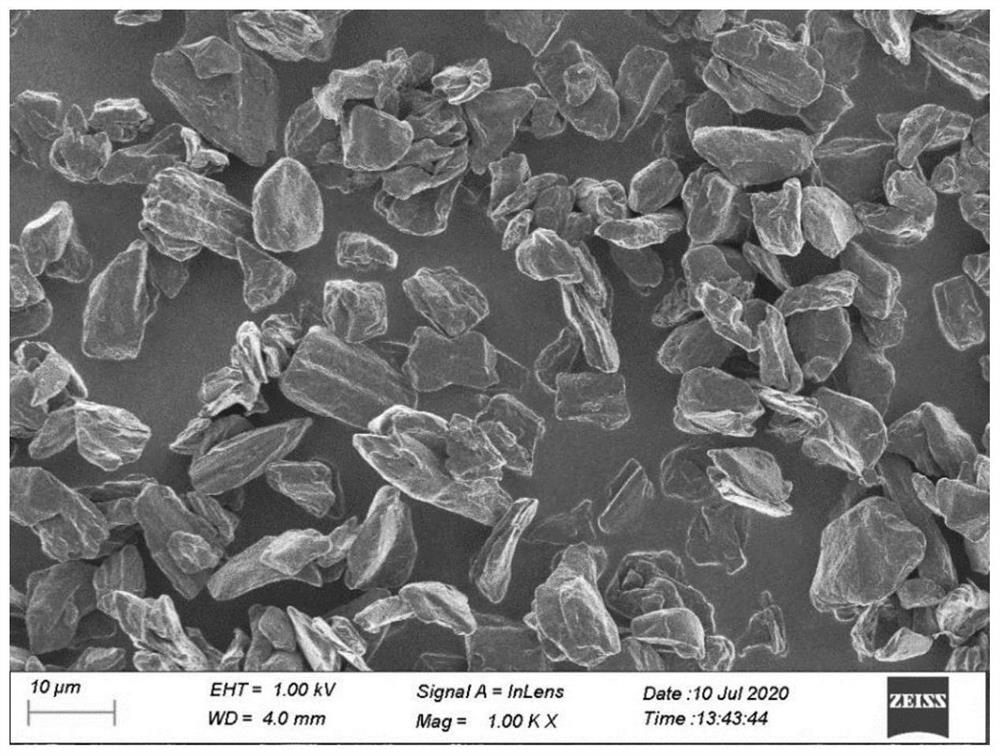

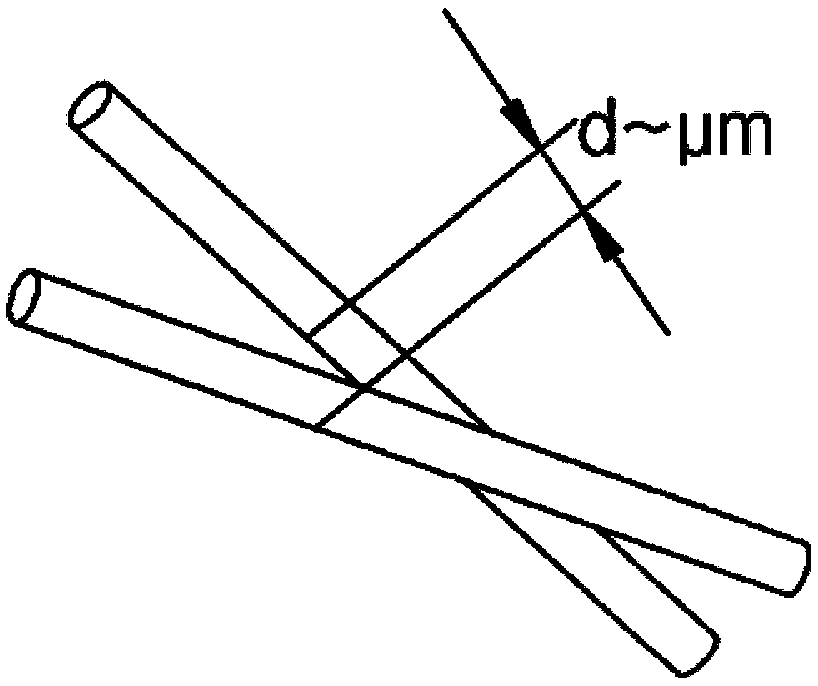

Preparation method of high-frequency high-impedance manganese zinc ferrite

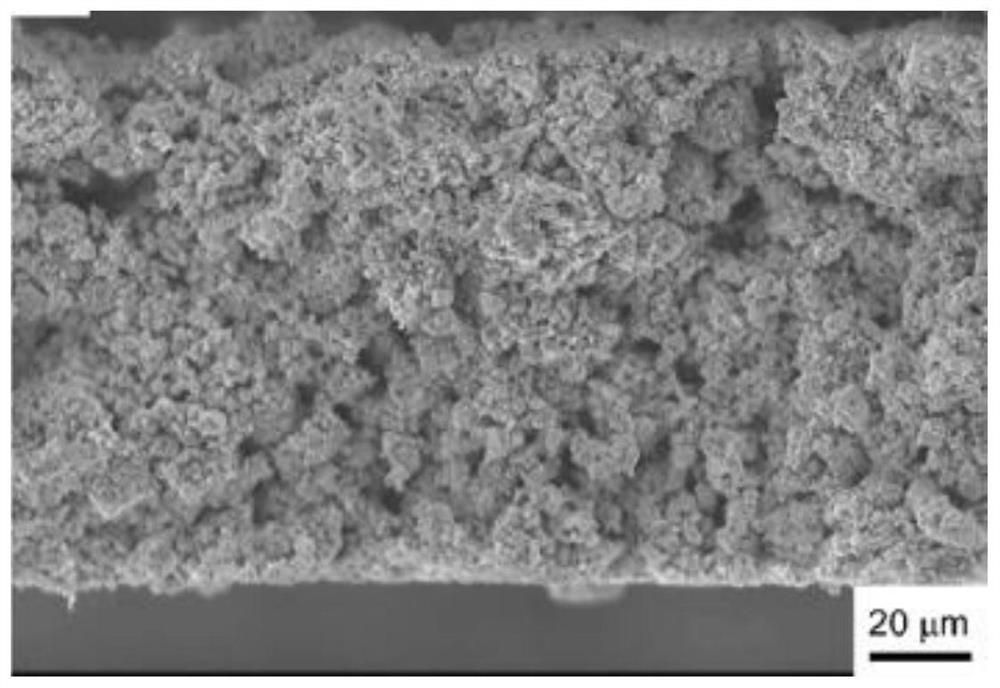

InactiveCN109896850AReduce lossImprove Q value and resistivityInorganic material magnetismInductances/transformers/magnets manufactureSolventMicrometer

The invention discloses a preparation method of a high-frequency high-impedance manganese zinc ferrite. The preparation method sequentially includes the steps: S1 distribution; S2 dispersion; S3 sanding, to be specific, sanding obtained slurry with pure water serving as a solvent; S4 filter pressing, to be specific, performing filter pressing and dewatering on the sanded slurry; S5 extruding granulation, to be specific, granulating filter pressed powder by a double-screw extruder; S6 drying, to be specific, drying extruded particle raw materials; S7 presintering by a rotary kiln at the presintering temperature of 800-1000 DEG C for 30-60 minutes; S8 crushing and sanding, to be specific, crushing particles into 1-2 micrometers, adding auxiliary materials and additives, and sanding the materials into the particle size of 0.7-1.5 micrometers; S9 spray granulation and blank preparation, to be specific, performing spray granulation on the crushed and sanded slurry in the step S8 to obtain granules, and pressing the granules into a blank by a die; S10 sintering at the sintering temperature of 1000-1100 DEG C to obtain a finished product. The prepared manganese zinc ferrite is good in impedance performance and high in cut-off frequency, and the sintering temperature is greatly reduced.

Owner:NANTONG GUANYOUDA MAGNET

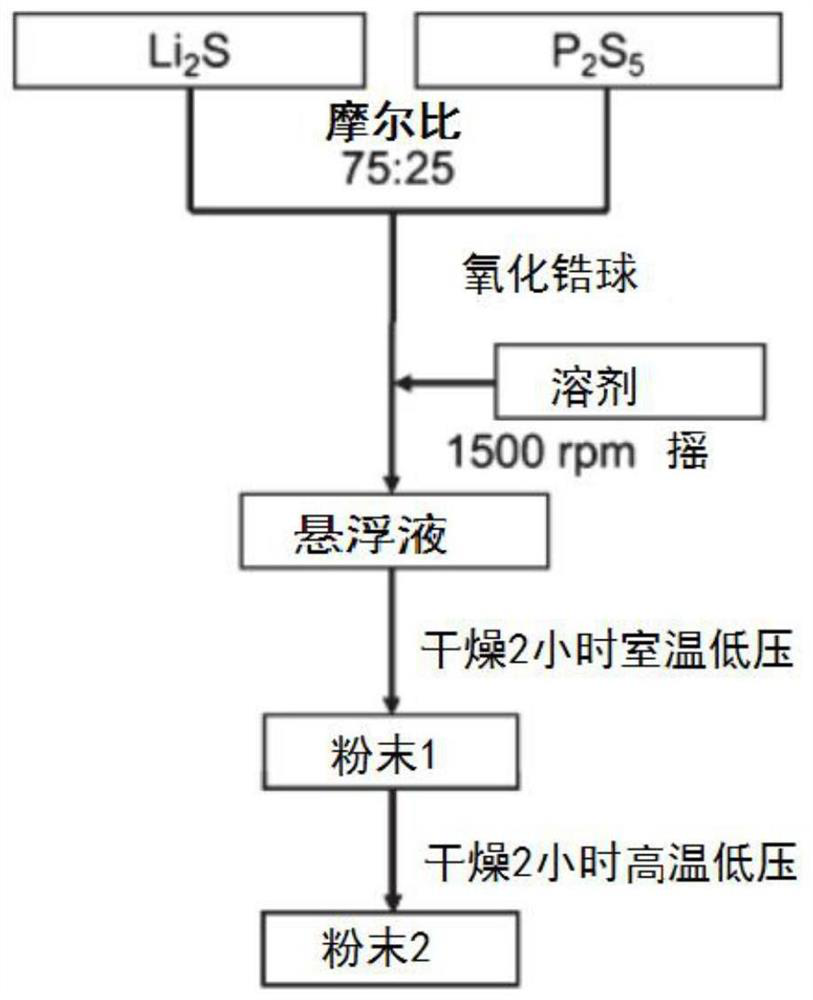

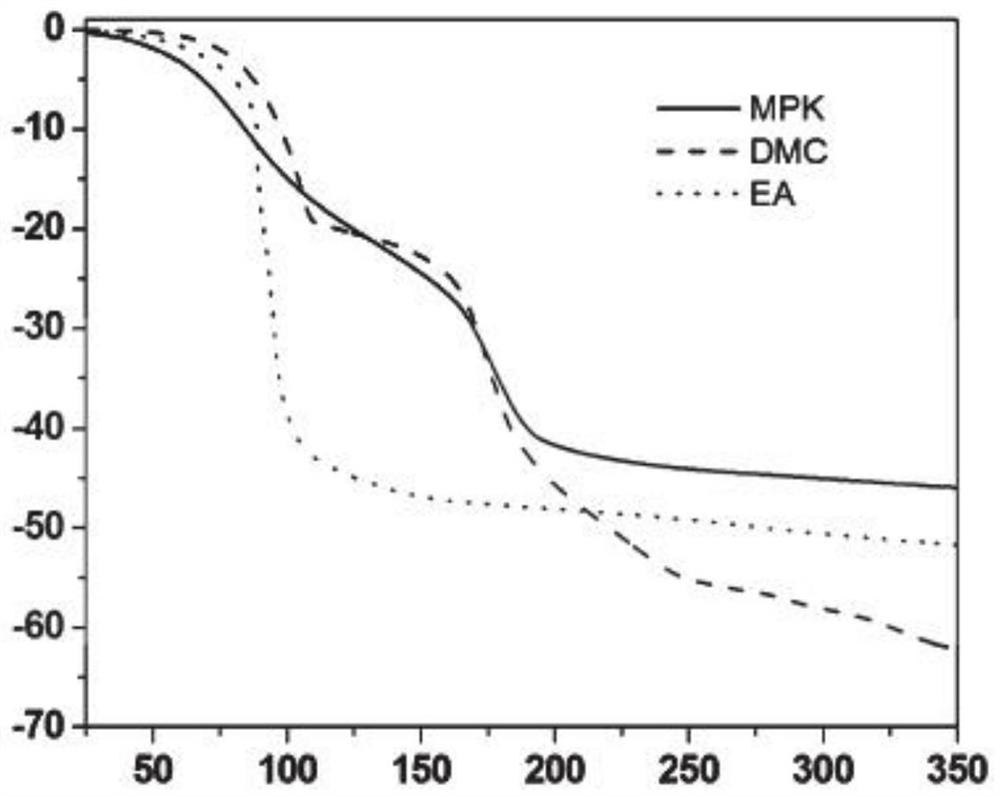

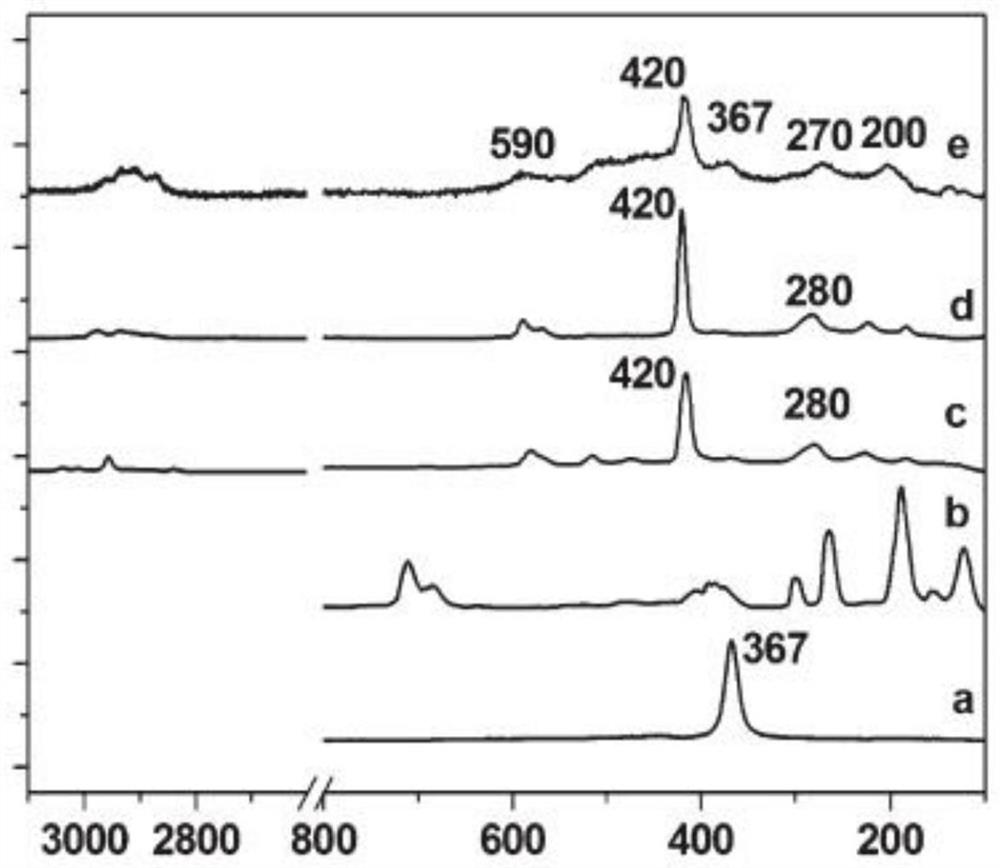

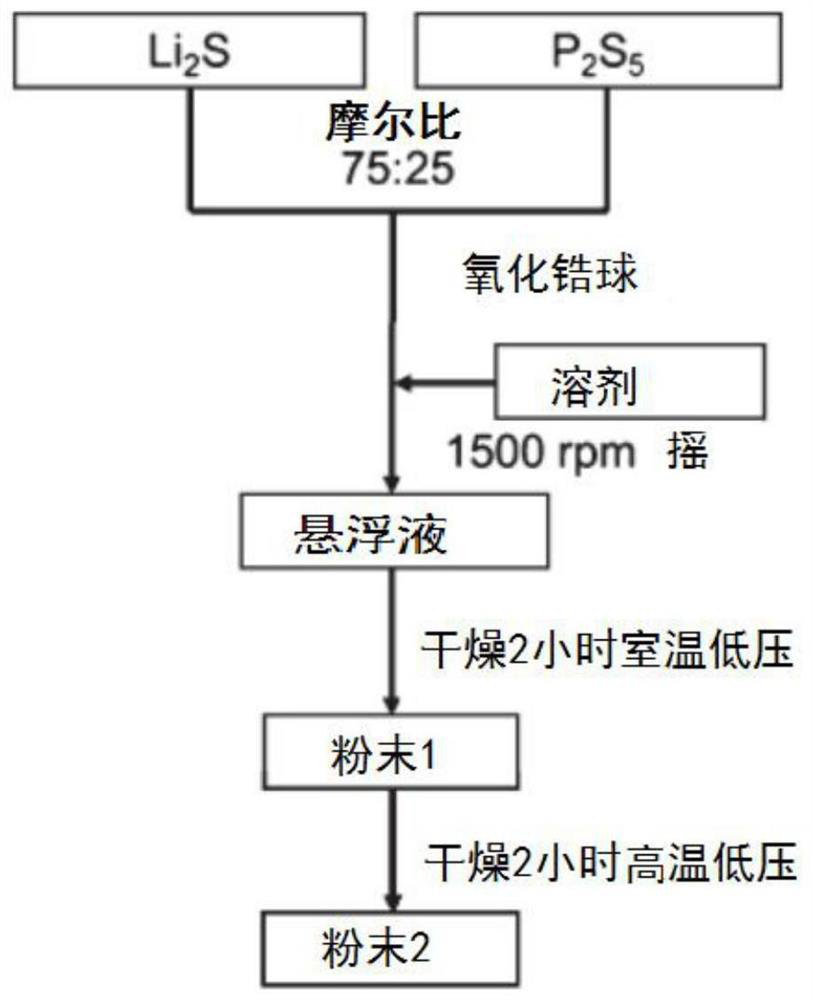

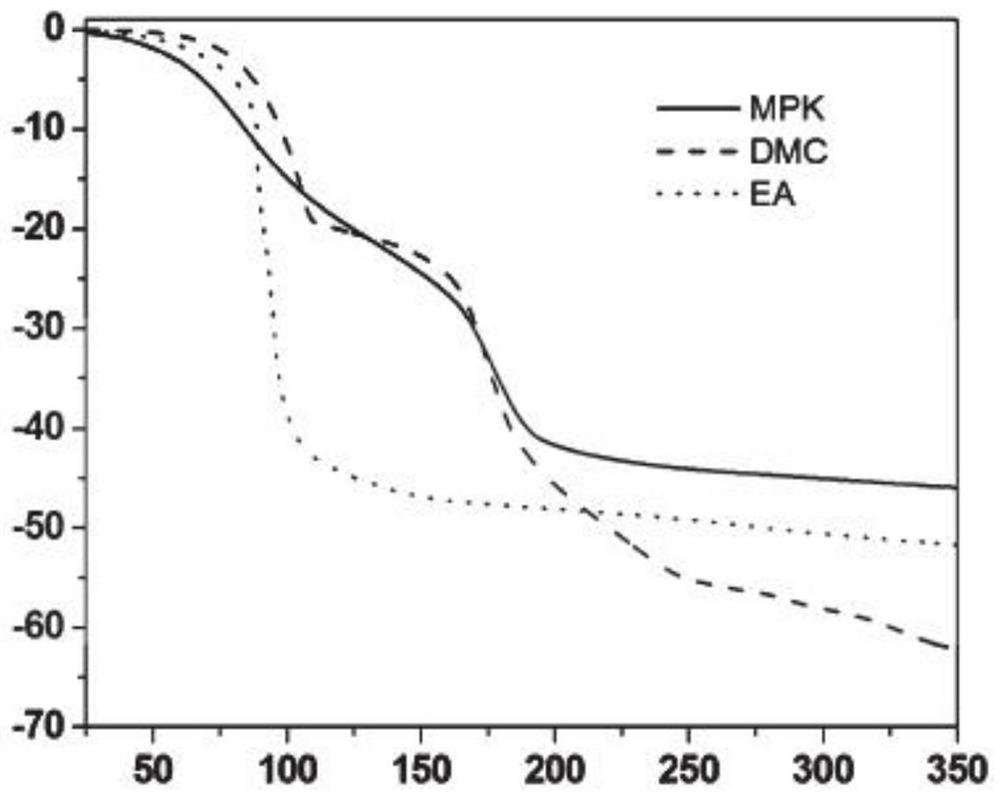

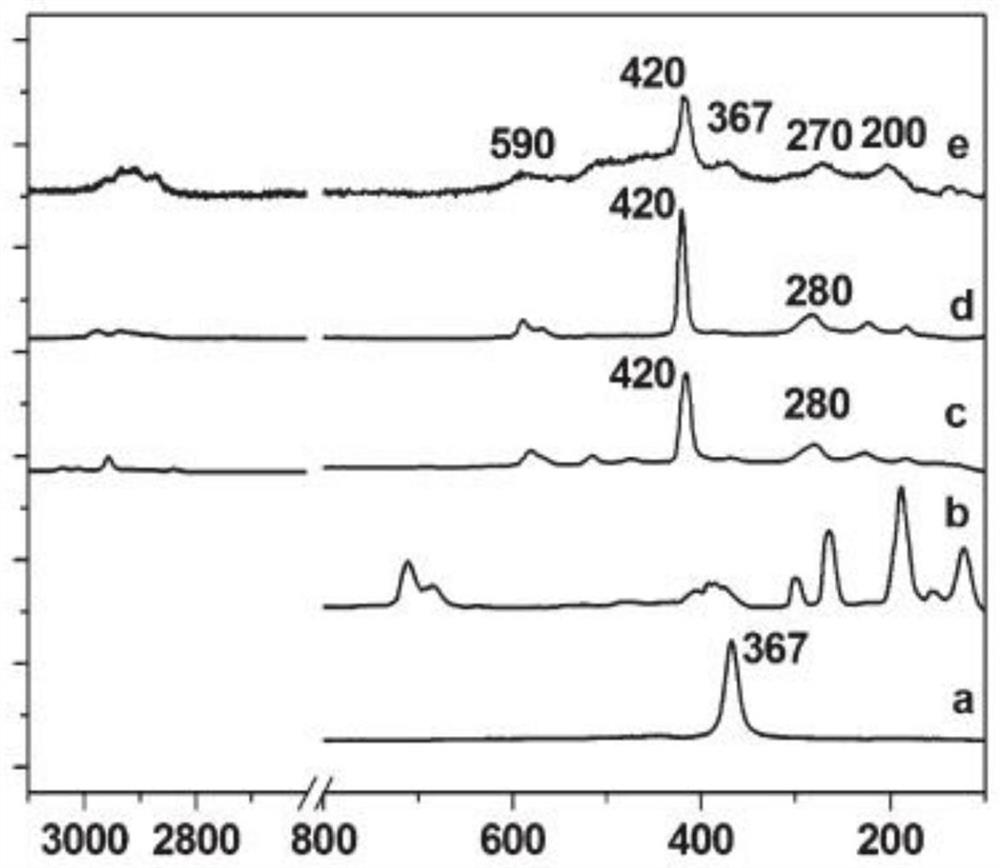

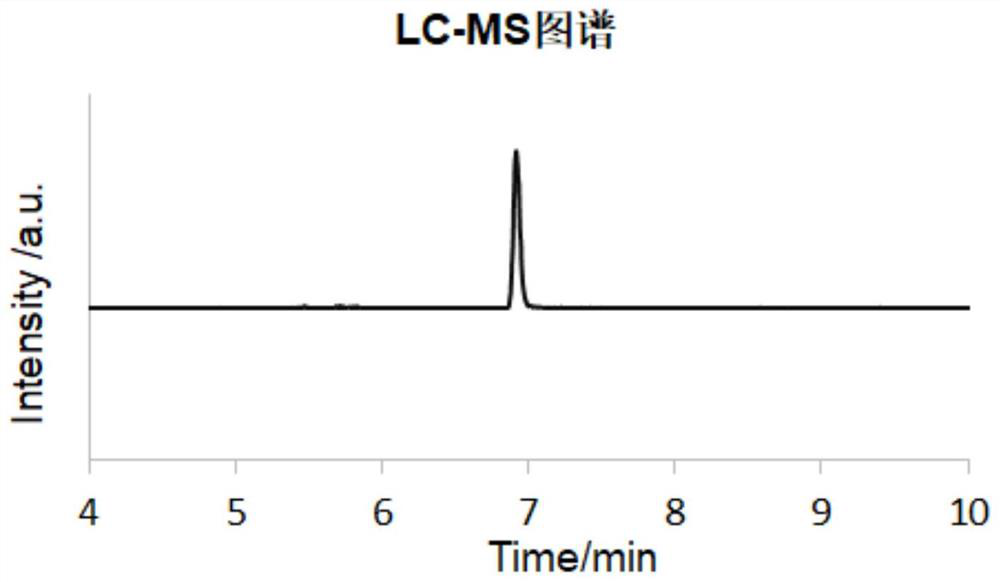

Li3PS4 solid electrolyte, solid mixed electrolyte, all-solid-state lithium-sulfur battery and production method thereof

ActiveCN112397775ASimple processLow costSolid electrolytesLi-accumulatorsSolid state electrolyteHigh energy

The invention discloses a Li3PS4 (lithium thiophosphate) solid electrolyte, a solid mixed electrolyte, an all-solid-state lithium-sulfur battery and a production method thereof. The Li3PS4 (lithium thiophosphate) is prepared by reacting Li2S (lithium sulfide) and P2S5 (phosphorus pentasulfide) in several organic solvents which are used as complex forming media containing carbonyl functional groupsthrough a liquid-phase oscillation method. According to the invention, core problems of lithium dendritic crystal growth, a low coulomb effect and an interface side reaction faced by the mass production of the three solid-state batteries are effectively solved, and the obtained all-solid-state lithium-sulfur battery based on the Li3PS4 (lithium thiophosphate) solid electrolyte has excellent performance; and high energy density of 900 Wh / L, 1000 times or more of charge-discharge cycles and 95% or more of coulombic efficiency can be achieved, and the safety performance is good. A traditional lithium ion battery can be replaced, and the battery is particularly suitable for electric transport vehicles, electric power storage and the like, and has a wide application prospect.

Owner:GUANG DONG DONGBOND TECH CO LTD

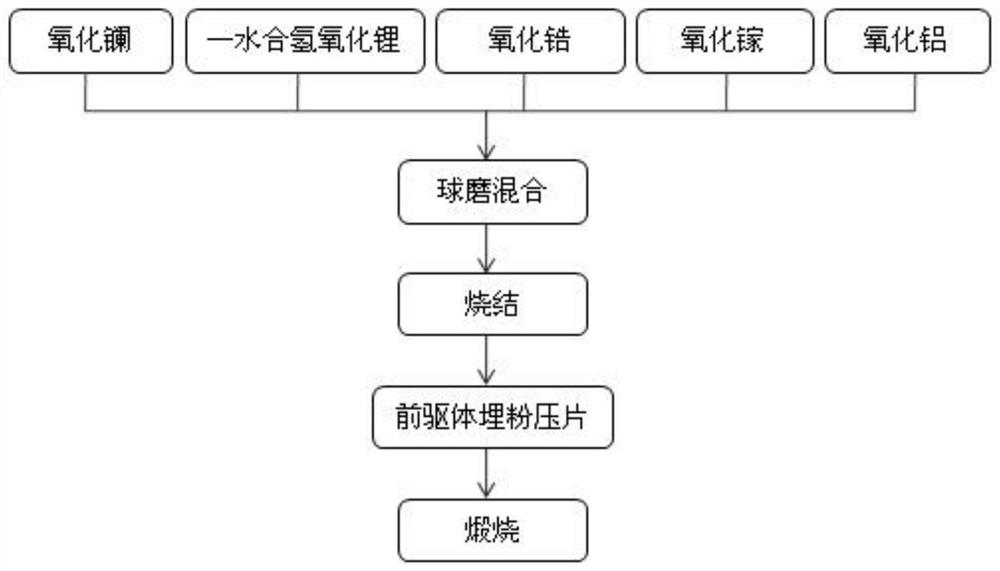

A kind of Ga, Al co-doped llzo solid electrolyte, multi-element solid battery and preparation method thereof

ActiveCN112397776BConducive to promoting industrializationImprove sintered densitySecondary cellsElectrolytesSolid state electrolyteSolid-state battery

The invention belongs to the technical field of all-solid-state batteries, and in particular relates to a Ga, Al co-doped LLZO solid electrolyte, a multi-component solid-state battery and a preparation method thereof. The Ga, Al co-doped LLZO inorganic oxide solid electrolyte prepared by the invention has ion conductivity High efficiency, good stability and other excellent performance. The invention introduces Ga, Al co-doped LLZO inorganic oxide solid electrolyte and quantum carbon-based film / metal composite interface layer to prepare multi-component solid-state battery, which effectively solves the three major problems of lithium dendrite growth, low Coulomb effect and interface side reaction. The core problem faced by the mass production of solid-state batteries.

Owner:GUANG DONG DONGBOND TECH CO LTD

Broadband miniaturized base station antenna and communication equipment

PendingCN113270722AImproving Impedance MatchingAchieve Impedance MatchingSimultaneous aerial operationsRadiating elements structural formsMiniaturizationBroadbanding

The invention discloses a broadband miniaturized base station antenna and communication equipment, the broadband miniaturized base station antenna comprises a reflecting plate, an antenna radiation unit and a plurality of door-shaped branches, the antenna radiation unit is arranged above the reflecting plate, and the plurality of door-shaped branches are uniformly arranged on the reflecting plate and located around the antenna radiation unit. The broadband miniaturized base station antenna has the characteristics of novel structure, planar structure, simplicity in manufacturing, large bandwidth, low profile and the like.

Owner:SOUTH CHINA UNIV OF TECH +1

Impregnated-type non-woven fabric and manufacturing method thereof

ActiveCN102912651BImprove dust filtering effectIncrease concentrationTextiles and paperPolyesterPolymer science

The invention relates to the field of non-woven fabrics, and discloses an impregnated non-woven fabric and a manufacturing method thereof, wherein the first fibers include low-melting-point fibers and polyester fibers, and the second fibers include low-melting-point fibers, viscose staple fibers and Polyester fiber, the raw material mass percentage of the first fiber is: low melting point fiber accounts for 5% ~ 20% of the first fiber total amount, polyester fiber accounts for 80% ~ 95% of the first fiber total amount; the second fiber The mass percentage of raw materials is: low melting point fiber accounts for 5%~20% of the total amount of the second fiber, polyester fiber accounts for 80%~95% of the total amount of the second fiber, viscose staple fiber accounts for 5% of the total amount of the second fiber ~15%, the concentration percentage of the polyacrylate is divided into two types: 10% and 25%. In the present invention, the processes of fiber laying, puncturing up and down, heat drying, hot blanching, addition of polyacrylate, drying, and hot blanching are completed. The characteristics of large quantity.

Owner:DONGGUAN RETOP FILTER MATERIAL

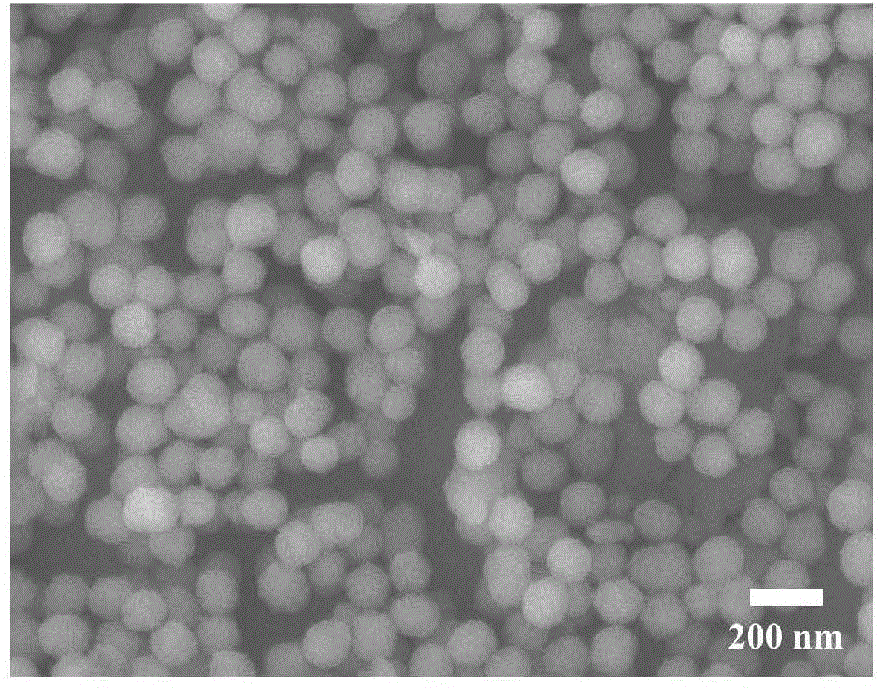

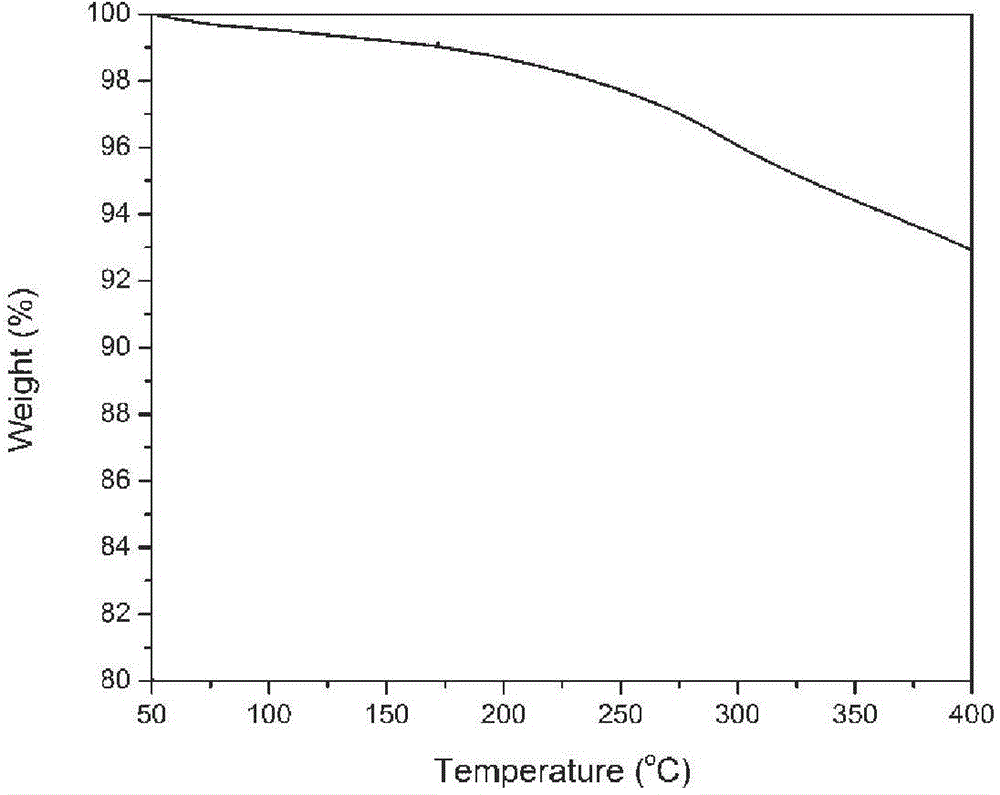

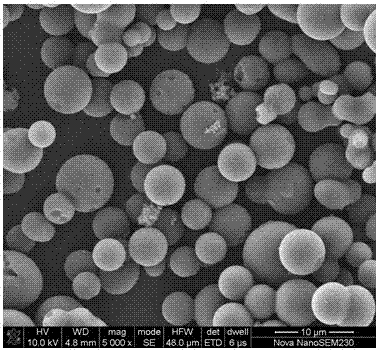

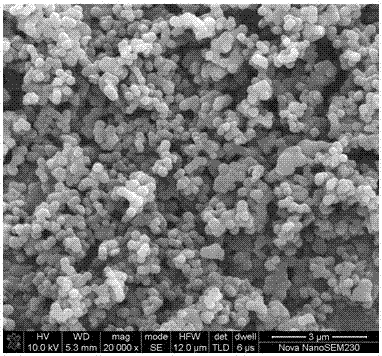

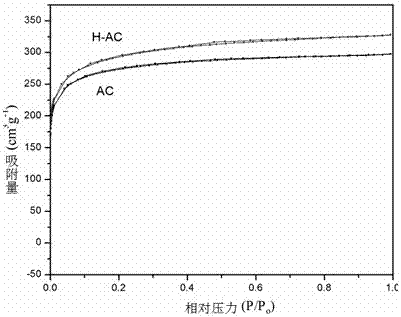

A kind of activated carbon microsphere and preparation method thereof

ActiveCN105948038BSimple processLow costCarbon compoundsHybrid capacitor electrodesActivated carbonMicrosphere

An activated carbon microsphere and a preparation method thereof. The activated carbon microsphere of the present invention has a diameter of 3-10 microns, a specific surface area of 803-1109 m2 g-1, pores mainly micropores, and a nitrogen doping amount of 2.0-6.6%. The present invention also includes the preparation method of the activated carbon microspheres. The invention has simple process and low cost, and the used template and nitrogen-doped reagent are g-C3N4 quantum dots, which can be easily removed by high temperature. The obtained activated carbon has high yield, high specific surface area, good impedance performance of the supercapacitor, high degree of graphitization, and good specific capacitance performance of the supercapacitor.

Owner:NAT UNIV OF DEFENSE TECH

A miniaturized monopole antenna

ActiveCN103887603BReduce volumeCompact structureRadiating elements structural formsAntenna earthingsDielectric substrateOptoelectronics

The invention discloses a minimized monopole antenna which is characterized by comprising a dielectric substrate, a radiator, a grounding board and a feeder, wherein the dielectric substrate is rectangular and is provided with a front side and a back side which are opposite to each other, the radiator is printed on the front side, the dielectric substrate is provided with a top edge, a bottom edge, a left edge and a right edge, the radiator is composed of a first radiation part, a second radiation part, a third radiation part, a fourth radiation part, a fifth radiation part, a sixth radiation part, a seventh radiation part, an eighth radiation part, a ninth radiation part and a tenth radiation part, and all the radiation parts are rectangular. The minimized monopole antenna is compact in structure, small in size and capable of meeting performance requirements. Three electric signal paths in different lengths are formed by the radiator, the operation bandwidth can be effectively expanded, and therefore the minimized monopole antenna can be applied to various communication occasions. Furthermore, the wavy edges and hollowed-out structure of the grounding board enable a good impedance function to be realized.

Owner:广东智视数字技术有限公司

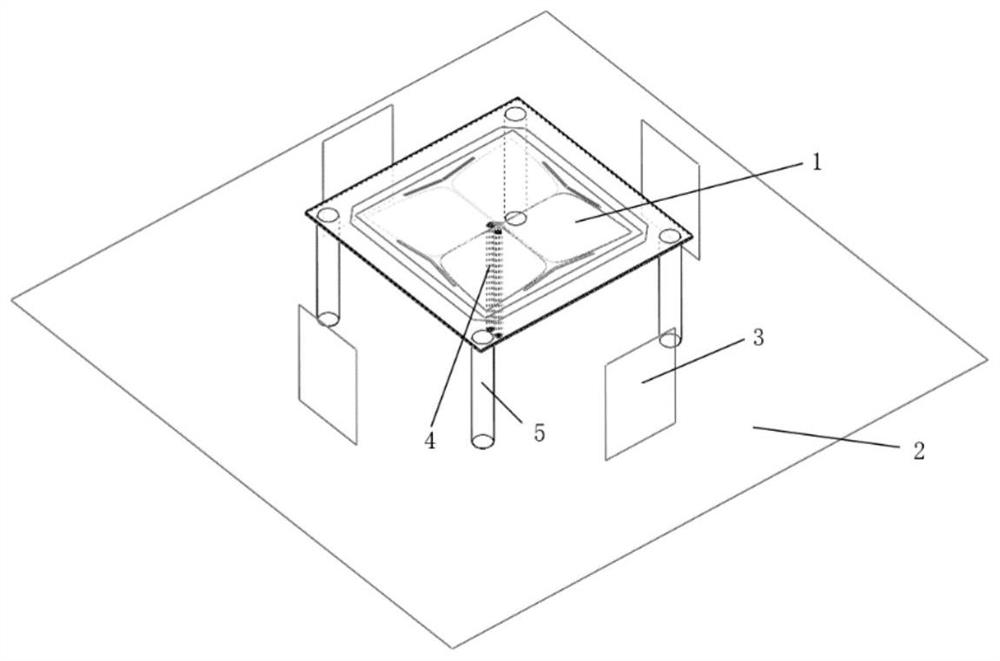

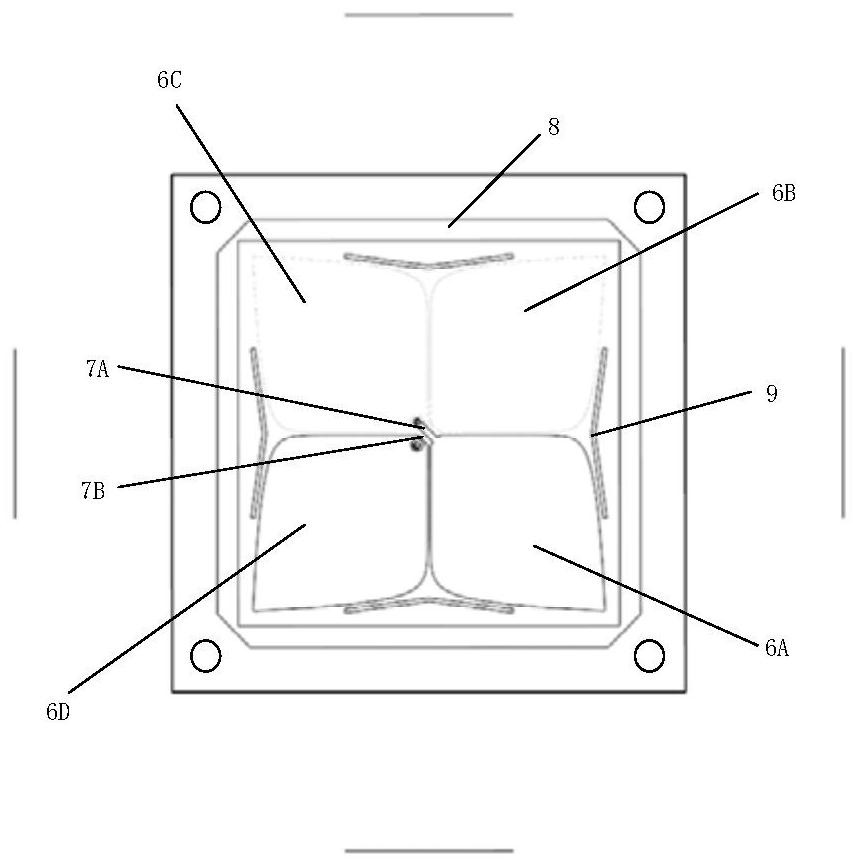

Prefabricated assembled UHPC composite beam and rapid construction method

ActiveCN108385522AHigh strengthImprove toughnessBridge erection/assemblyBridge engineeringEconomic benefits

The invention discloses a prefabricated assembled UHPC composite beam and a rapid construction method. The prefabricated assembled UHPC composite beam comprises a UHPC main beam, a bridge floor plateand a grouting material; the UHPC main beam is a main beam prefabricated by UHPC, and the upper surface of the UHPC main beam is provided with a plurality of U-shaped rebars; grooves are formed in theconnecting positions of the lower surface of the bridge floor plate and the UHPC main beam, and the U-shaped rebars are accommodated in the grooves; and the upper surface of the bridge floor plate isprovided with grouting holes and exhaust holes, wherein the grouting holes and the exhaust holes communicate with the grooves; the grooves are filled with the grouting material; and connection of theUHPC main beam and the bridge floor plate is achieved through the grouting materials. The prefabricated assembled UHPC composite beam has the advantages that on-site pouring is reduced, the strengthis high, the durability is high, and economic benefits are good, and can be widely used in the technical field of bridge engineering.

Owner:CCCC SECOND HARBOR ENG +1

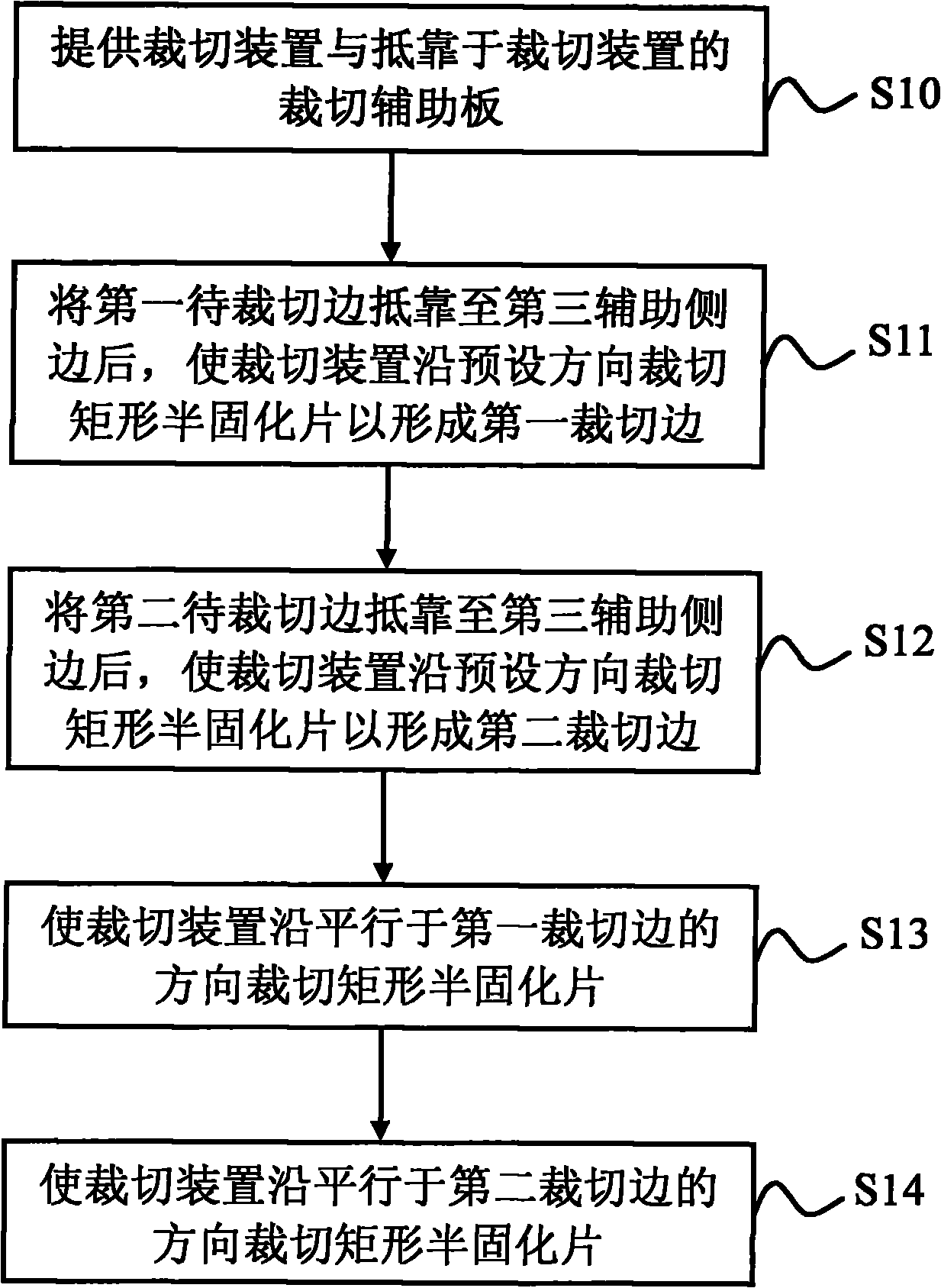

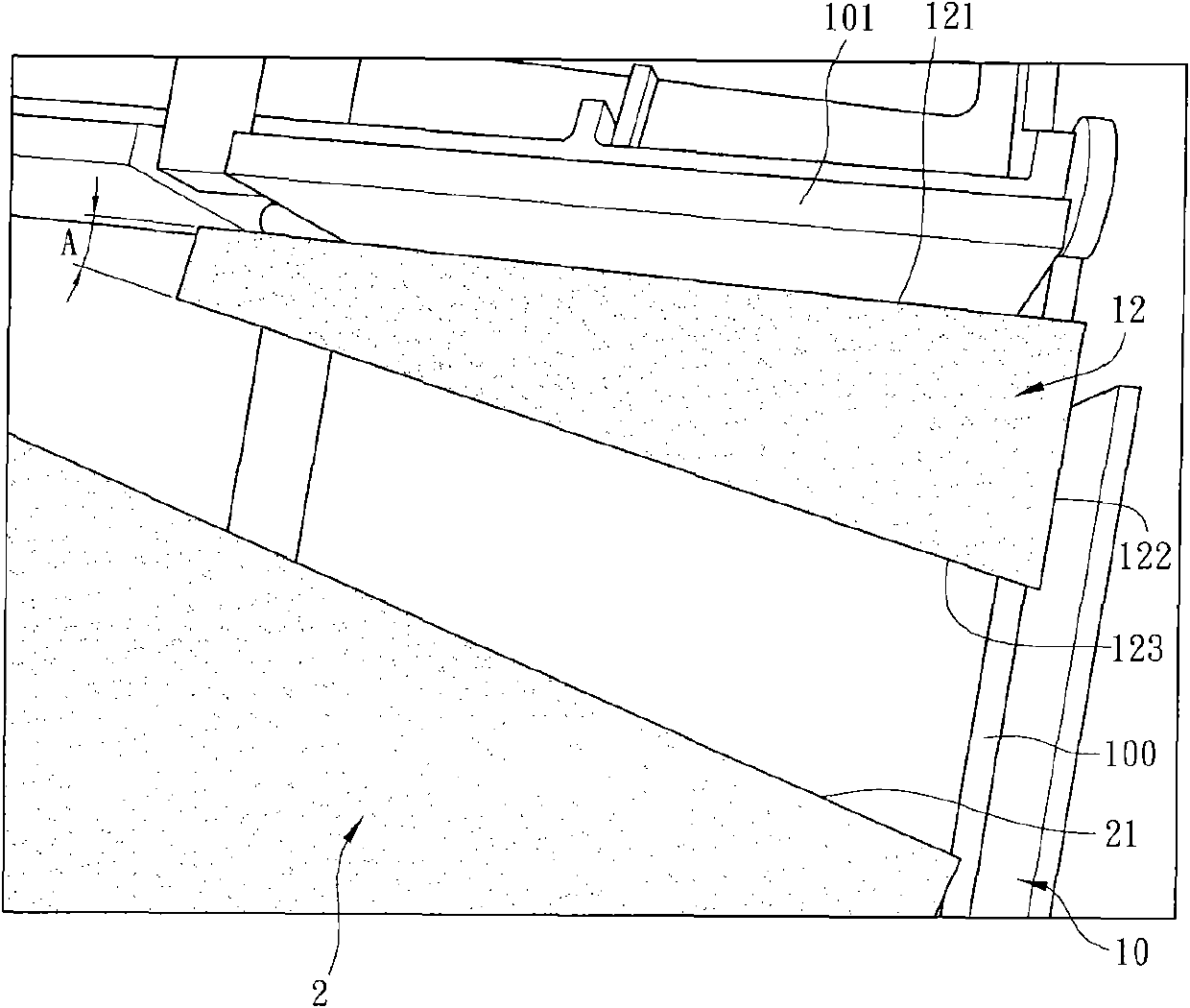

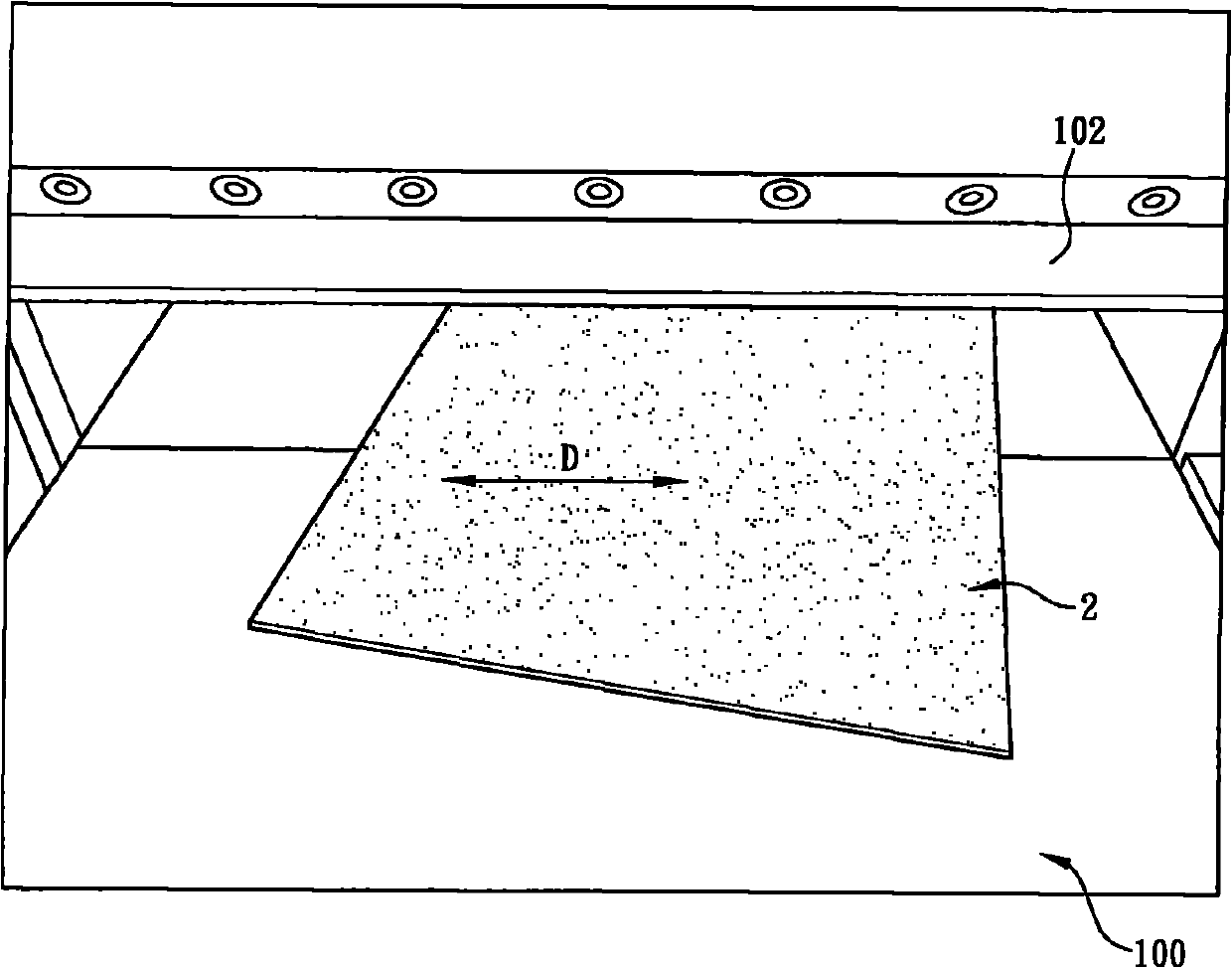

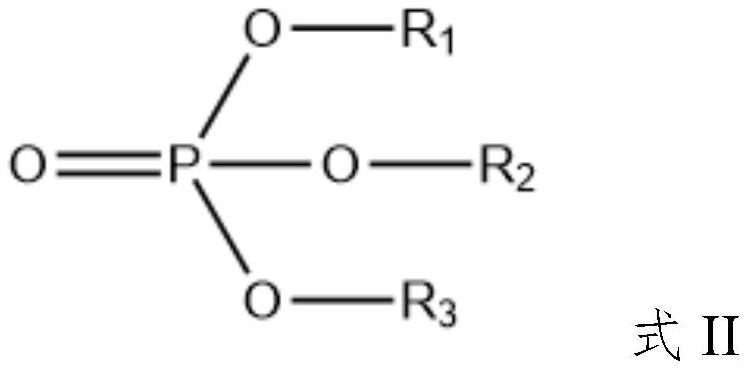

Semi-solidified sheet cutting method

InactiveCN102528840BAchieving a diagonal cutImproving Impedance PerformanceMetal working apparatusImpedance propertiesEngineering

The invention discloses a semi-solidified sheet cutting method which comprises the following steps that: a cutting device and a cutting auxiliary plate which is propped against the cutting device are provided; a second auxiliary side of the cutting auxiliary plate is connected with a first auxiliary side and a third auxiliary side and is vertical to the first auxiliary side; and an included angle between the first and the third auxiliary sides is 10 degrees. After a first side to be cut is propped against the third auxiliary side, the cutting device cuts a rectangular semi-solidified sheet along a direction which is in parallel with a preset direction of the first auxiliary side to form a first cut side. After a second side to be cut is propped against the third auxiliary side, the cutting device cuts the rectangular semi-solidified sheet along the preset direction to form a second cut side. The cutting device cuts the rectangular semi-solidified sheet along the direction which is in parallel with the direction of the first cut side. The cutting device cuts the rectangular semi-solidified sheet along the direction which is in parallel with the direction of the second cut side. Consequently, the impedance property of a circuit board which is manufactured from the semi-solidified sheet can be improved and the signal interference can be reduced.

Owner:BOARDTEK COMP SUZHOU +2

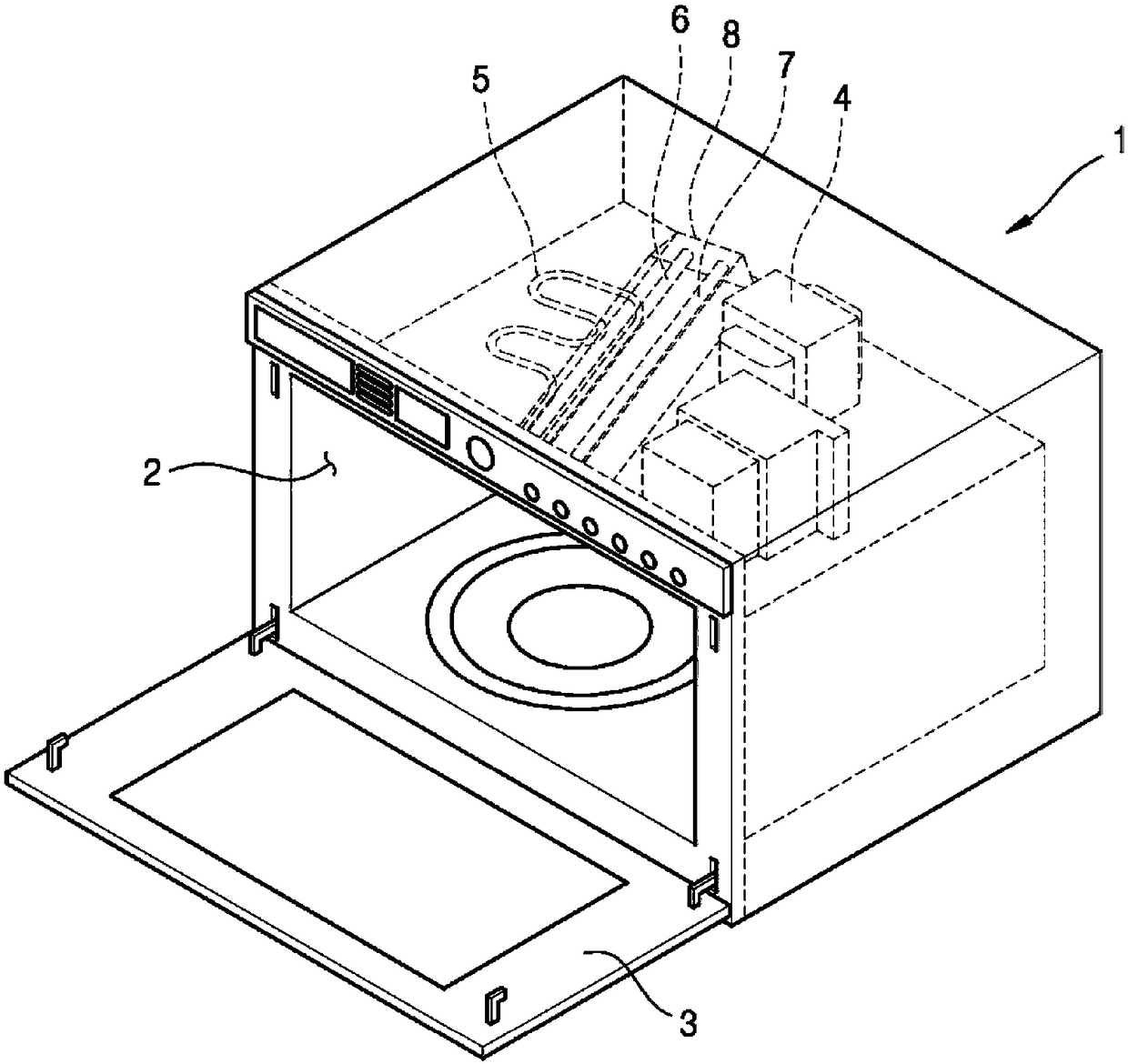

Carbon composite composition and carbon heater manufactured using the same

ActiveCN108863390AAvoid insulation breakdownAvoid sparkingFurnace heating elementsHeating element materialsElectrical resistance and conductanceCarbon composites

The invention provides a carbon composite composition and a carbon heater manufactured using the same. More concretely, the invention relates to the carbon composite composition used in the field of heating devices for electric ovens and the carbon heater manufactured using the same. The carbon composite composition may include a phenolic resin as a binder, a lubricant, and base material that determines a specific resistance of a resistance heating element at a high temperature. The carbon composite composition may prevent a dielectric breakdown, a spark and plasma from occurring in a carbon heater, and may improve radiation efficiency of the carbon heater.

Owner:LG ELECTRONICS INC +1

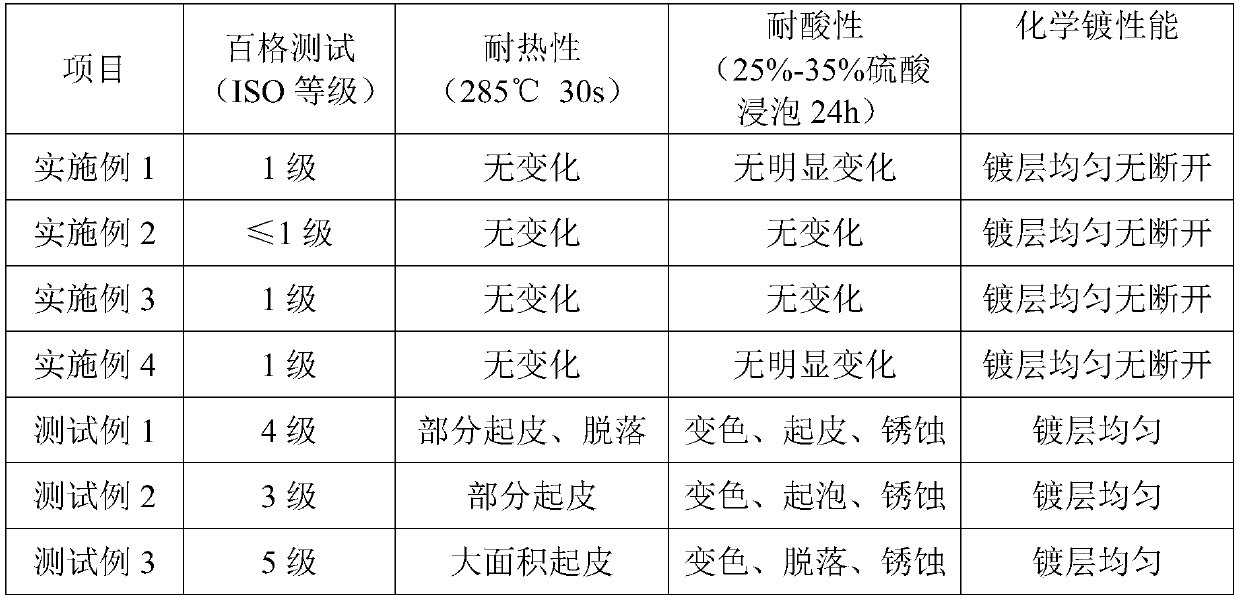

High-temperature coating material for forming weldable metal circuit, and preparation method thereof

InactiveCN110982374AGood high temperature resistanceStrong adhesionFireproof paintsEpoxy resin coatingsSilicone resinChemical plating

The invention discloses a high-temperature coating material for forming a weldable metal circuit. The high-temperature coating material comprises the following components in percentage by mass: 50-70%of a high-temperature-resistant resin, 15-20% of laser engraving powder, 0.5-2% of a leveling agent, 0.5-2% of an active diluent and 10-35% of a curing agent. According to the invention, the high-temperature-resistant resin formed by combining an epoxy resin, an organic silicon resin and polyphenylene sulfide has high adhesion to PPS, LCP materials, glass, ceramics, metals and other base materials; the laser engraving powder is added according to a specific ratio, and laser engraving and chemical plating are carried out after different base materials are sprayed and cured to form a conductivemetal circuit, so that the formed circuit can be subjected to high-temperature tin soldering and has outstanding high-temperature resistance; and the prepared antenna is strong in signal receiving capability, and the impedance performance of the conductive circuit is good. The invention further discloses a preparation method of the high-temperature coating material for forming the weldable metalcircuit, wherein the high-temperature-resistant resin components are good in compatibility, the coating material components are uniformly dispersed, and the operation is simple.

Owner:深圳市玖远科技有限公司

Communication equipment, electrical connector assembly and electrical connector

ActiveCN103219619BAchieve electrical connectionImproving Impedance PerformanceCoupling device detailsTwo-part coupling devicesElectrical connectorDielectric layer

The invention provides communication equipment, an electric connector assembly and an electric connector. The electric connector assembly comprises a first electric connector, a second electric connector and a dielectric layer, wherein the first electric connector assembly comprises a first insulating main body and a first conductive terminal arranged in the first insulating main body; the second electric connector comprises a second insulating main body and a second conductive terminal arranged on the second insulating main body; the dielectric layer comprises a capacitive dielectric layer or inductive dielectric layer; and the dielectric layer is positioned between the first conductive terminal and the second conductive terminal when the first electric connector is connected with the second electric connector, so that the first conductive terminal is capacitively connected with the second conductive terminal by the capacitive dielectric layer or is inductively connected with the second conductive terminal by the inductive dielectric layer. According to the communication equipment, the electric connector assembly and the electric connector disclosed by the invention, the technical problems of high production cost and poor effect caused by optimization impedance in the prior art are effectively solved, the production cost is reduced and better impedance performances are obtained.

Owner:HUAWEI TECH CO LTD

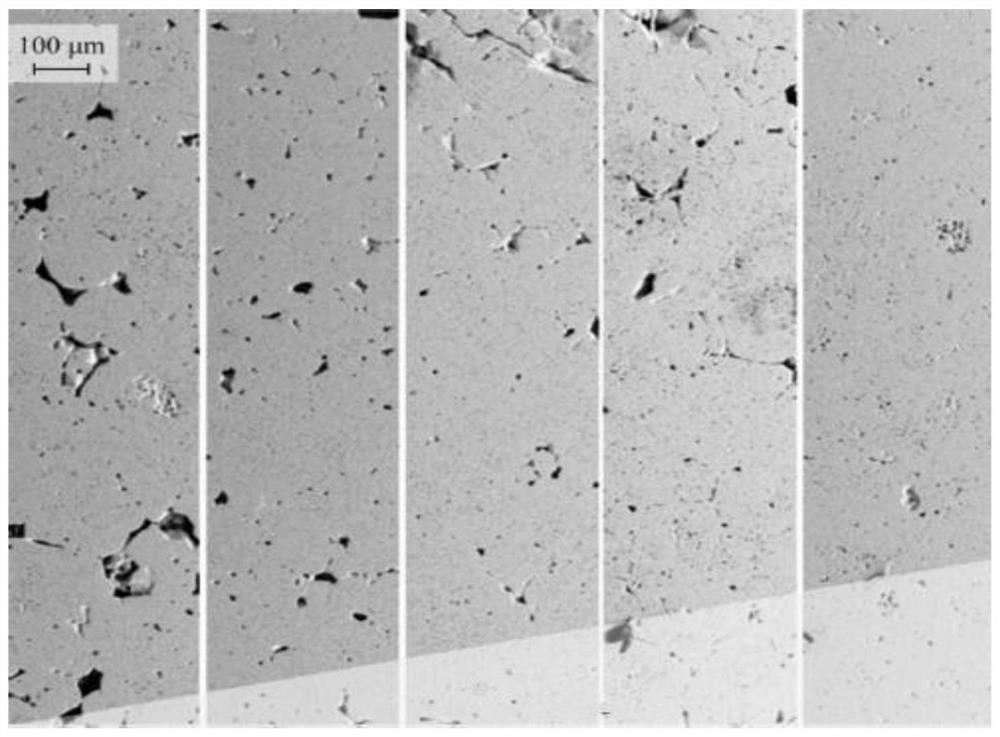

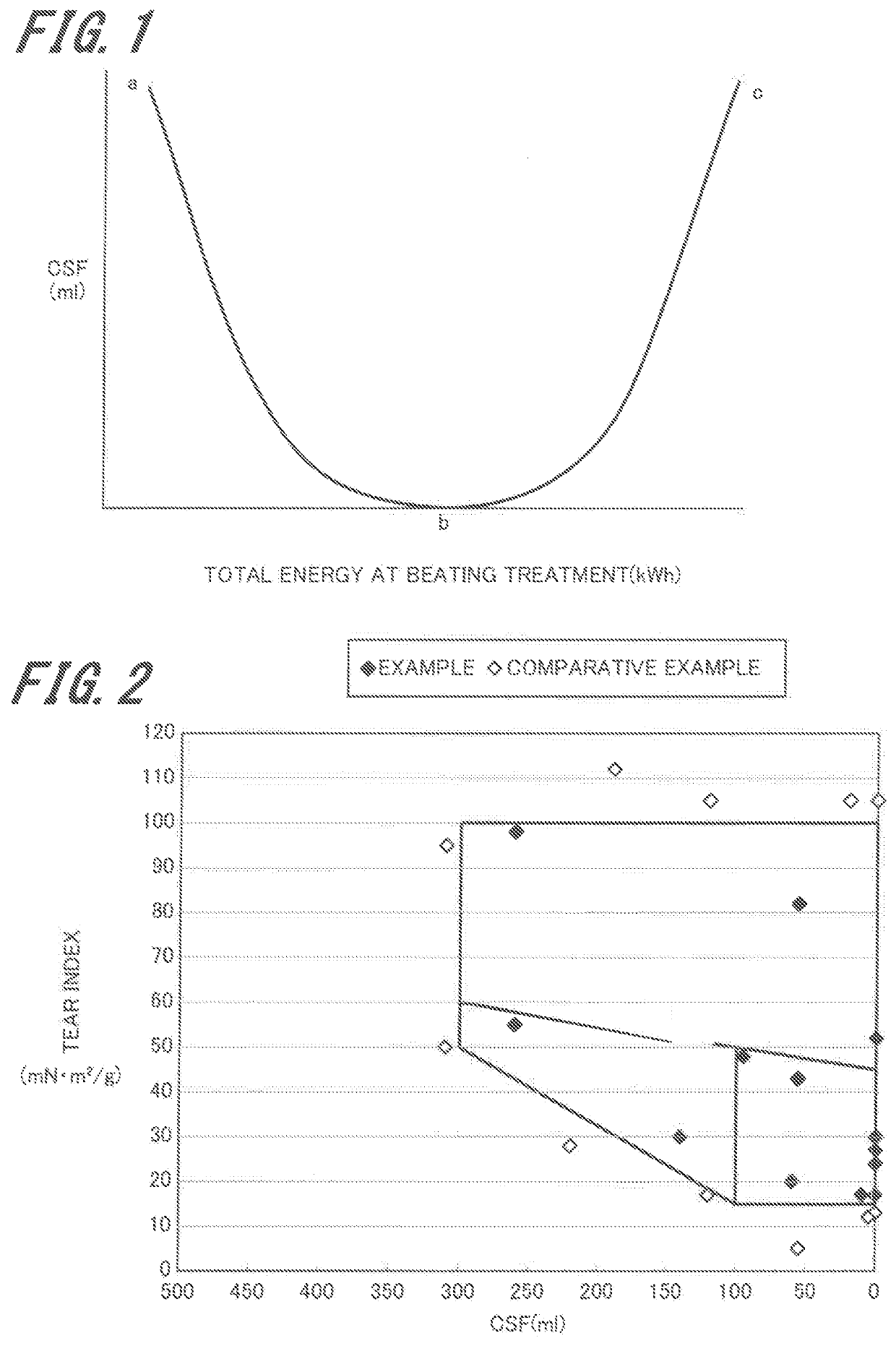

Separator and aluminum electrolytic capacitor

ActiveUS10566141B2Excellent in tearing strength and denseness and impedance performanceImproving Impedance PerformanceHybrid capacitor separatorsElectrolytic capacitorsAluminum electrolytic capacitorAluminum electrolysis

Provided is a separator having excellent tearing strength, denseness, and impedance performance, and an aluminum electrolytic capacitor provided with the separator. The present invention constitutes a separator including beatable regenerated cellulose fibers, the separator having a CSF value X[ml] and tear index Y[mN·m2 / g] within the ranges satisfying the following formulae. The present invention also constitutes an aluminum electrolytic capacitor in which at least one of the separators is used, the capacitor feeing formed by interposing the separator between an anode and a cathode.0≤X≤300 Formula 1 15≤Y≤100 Formula 2 Y≥0.175X−2.5 Formula 3

Owner:NIPPON KODOSHI

Li3ps4 solid electrolyte, solid mixed electrolyte, all-solid lithium-sulfur battery and preparation method thereof

ActiveCN112397775BSimple processLow costSolid electrolytesLi-accumulatorsSolid state electrolyteLithium sulfur

The invention discloses a Li3PS4 (lithium thiophosphate) solid electrolyte, a solid mixed electrolyte, an all-solid lithium-sulfur battery and a preparation method thereof. Li3PS4 (lithium thiophosphate) is prepared by reacting Li2S (lithium sulfide) and P2S5 (phosphorus pentasulfide) in several organic solvents containing carbonyl functional groups as the complex formation medium by liquid phase oscillation method. The invention effectively solves the core problems faced by the mass production of the three major solid-state batteries, lithium dendrite growth, low Coulomb effect and interface side reactions, and the obtained all-solid-state lithium-sulfur battery based on Li3PS4 (lithium thiophosphate) solid electrolyte has excellent Excellent performance, can achieve high energy density of 900Wh / L, more than 1000 charge and discharge cycles, and Coulombic efficiency of more than 95%, and good safety performance. It can replace traditional lithium-ion batteries, and is especially suitable for electric transportation vehicles, power storage, etc., and has broad application prospects.

Owner:GUANG DONG DONGBOND TECH CO LTD

Novel anti-radiation optical glass and preparation method thereof

PendingCN114163141AImproving Impedance PerformanceMaintain high transparency and anti-ultraviolet radiation performanceGlass furnace apparatusCoatingsTransmittanceLanthanum

The invention relates to the technical field of optical glass materials, in particular to novel anti-radiation optical glass and a preparation method thereof.The preparation method comprises the following steps that raw materials including boric acid, lanthanum oxide, zirconium oxide, quartz sand, niobium oxide, zinc oxide and titanium oxide are mixed and then sequentially subjected to melting, clarification, homogenization and forming treatment, an optical glass substrate is prepared, and the optical glass substrate is obtained; and then performing magnetron sputtering on the surface of the substrate, controlling the rotation of the substrate in the sputtering process, and then performing coating treatment on the optical glass substrate through a coating machine to obtain the novel anti-radiation optical glass. The compact protective layer is formed on the surface of the substrate through magnetron sputtering, metal ions and the like in the optical glass substrate are prevented from migrating to the surface functional layer, the metal ions are prevented from affecting the light transmission of the surface functional layer, the impedance performance of the optical glass substrate to ultraviolet rays and near-infrared light is improved through the coating layer on the surface layer of the substrate, and the service life of the optical glass substrate is prolonged. And the finished glass substrate can stably maintain high-transmittance and anti-ultraviolet radiation performance for a long time.

Owner:成都赛林斯科技实业有限公司

Positive plate and lithium ion battery

PendingCN114883519AImprove structural stabilityImprove oxidation resistanceSecondary cellsNon-aqueous electrolyte accumulator electrodesPhysical chemistryPositive current

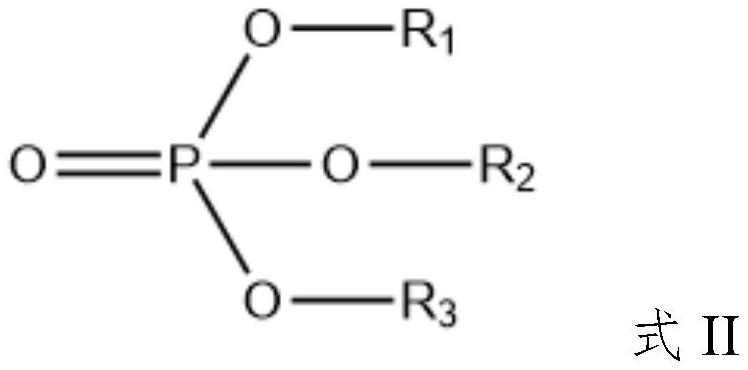

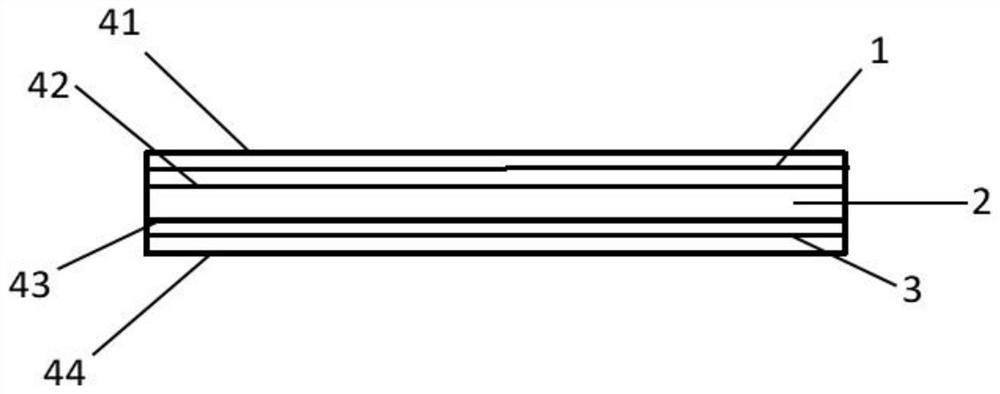

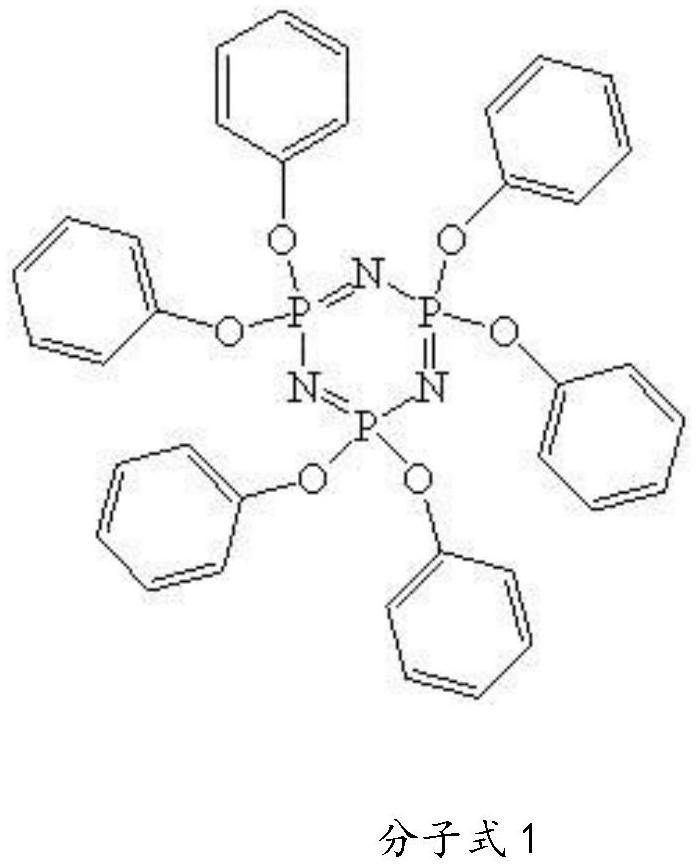

In order to solve the problems of high impedance and short high-temperature cycle life of the existing high-nickel lithium ion battery, the invention provides a positive plate, which comprises a positive current collector and a positive material layer formed on the positive current collector, and is characterized in that the positive material layer comprises a high-nickel positive material as shown in a formula I and a compound as shown in a formula II: LiaNiqCoyMzO2, wherein a is greater than or equal to 0.9 and less than or equal to 1.2, q is greater than or equal to 0.7 and less than or equal to 1, y is greater than or equal to 0, z is greater than or equal to 0, q + y + z = 1, and M is selected from one or two of Mn and Al; the positive plate meets the following conditions: 0.05 < = (b / 10) * (h / x) < = 15; 0.005 < = b < = 1, 0.7 < = x < = 1, and 80 < = h < = 140. Meanwhile, the invention also discloses a lithium ion battery comprising the positive plate. The positive plate provided by the invention can give full play to the synergistic effect between the compound as shown in the formula II and the high-nickel positive electrode material and the thickness of the positive electrode material layer, so that the high-nickel positive electrode material has relatively high structural stability and oxidation resistance, and the cycle and impedance performance of the battery is improved.

Owner:SHENZHEN CAPCHEM TECH

All-solid-state battery and preparation method thereof

ActiveCN112290024AGuarantee normal performanceGuaranteed recyclabilityMaterial nanotechnologyFinal product manufactureSolid state electrolyteDoped graphene

The invention discloses an all-solid-state battery and a preparation method thereof. The all-solid-state battery comprises a positive pole piece, a solid electrolyte layer and a negative pole piece. The positive pole piece comprises a positive pole material layer and a quantum carbon-based film / metal composite interface layer, an active material of the positive pole material layer is a silver-doped graphene material, the solid electrolyte layer comprises a solid electrolyte, and the solid electrolyte is a perovskite type (ABO3) oxide solid electrolyte. The negative pole piece comprises a negative pole material layer and a quantum carbon-based film / metal composite interface layer, and an active material of the negative pole material layer is a lithium manganate material. By introducing thequantum carbon-based film / metal composite interface layer, the core problems of lithium dendritic crystal growth, low coulombic effect and interface side reaction in mass production of the three solid-state batteries are effectively solved.

Owner:GUANG DONG DONGBOND TECH CO LTD

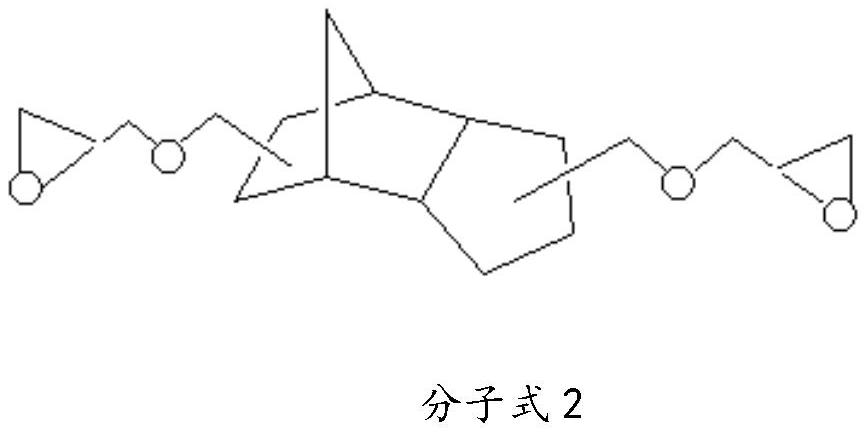

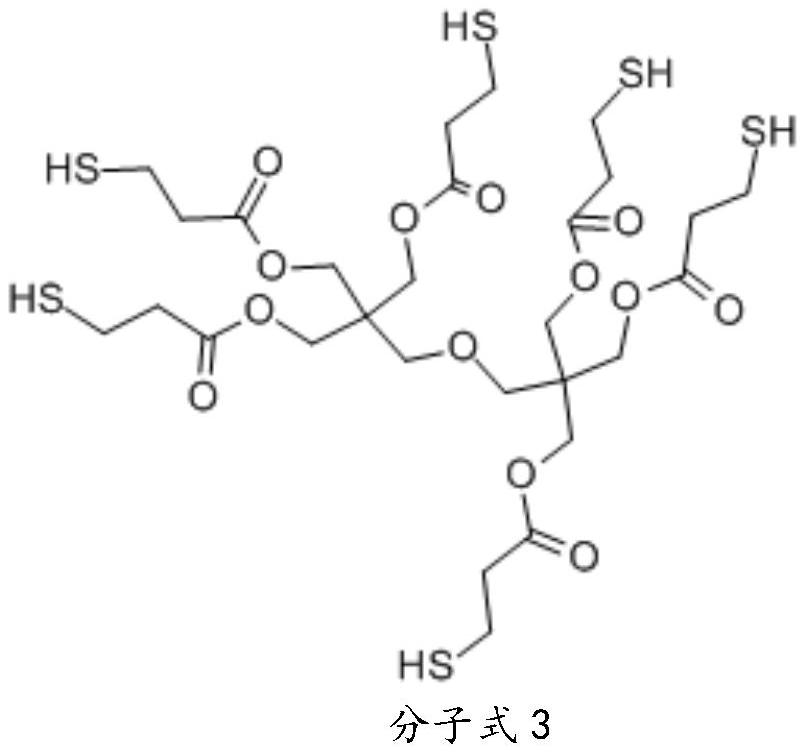

A preparation method of low-temperature fast-curing resistance flame-retardant structural adhesive

ActiveCN112521892BFast curing at low temperatureLower resistanceNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxyPolymer science

The invention relates to a low-temperature fast-curing resistance flame-retardant structural adhesive, which is composed of the following raw materials: 10-20 parts of self-synthesized flame-retardant epoxy resin gel, 25-25 parts of tricyclopentyl dimethoxy epoxy resin 35 parts, 3-8 parts of new low-viscosity toughening agent, 20-30 parts of inositol hexa(mercaptopropionate), 4-6 parts of imidazole adduct, 6-33 parts of superfine aluminum hydroxide. The structural adhesive prepared by the invention has the advantages of fast curing speed at low temperature, easy operation of one component, good impedance performance, good flame retardancy, low shrinkage, good bonding strength, etc., and is suitable for various micro-motor inductance coils and related difficult Structural bonding of sticky materials.

Owner:YANTAI DARBOND TECH

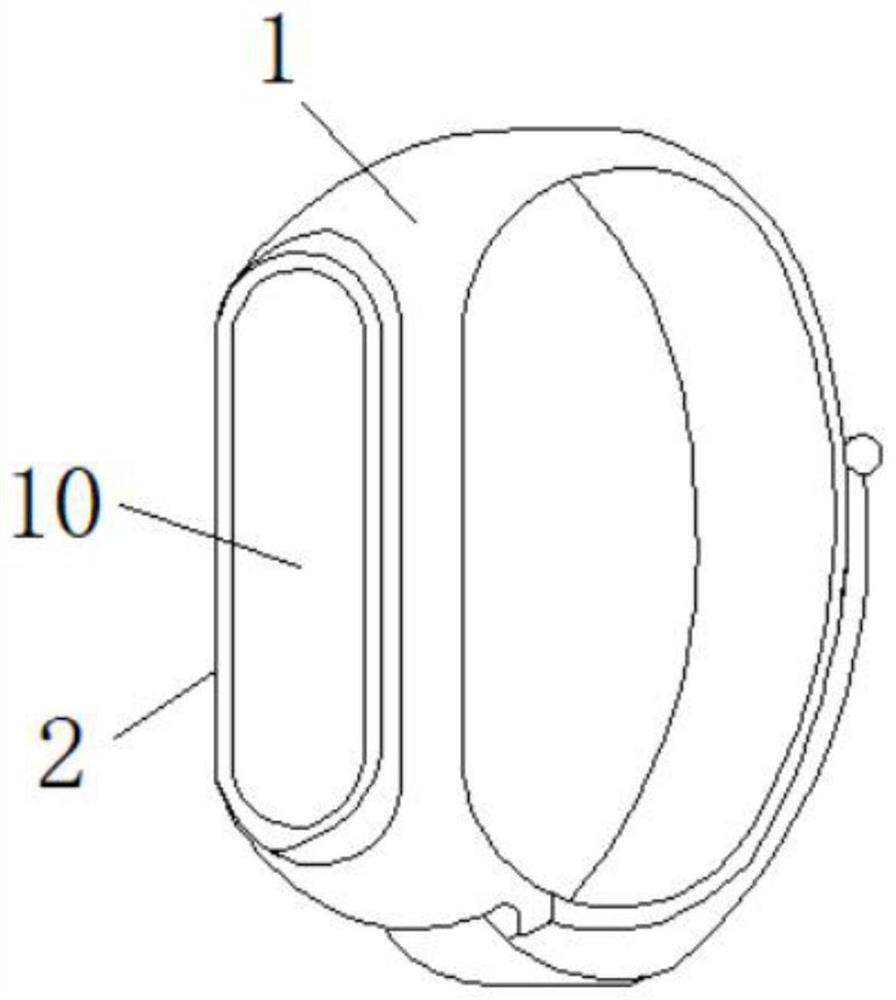

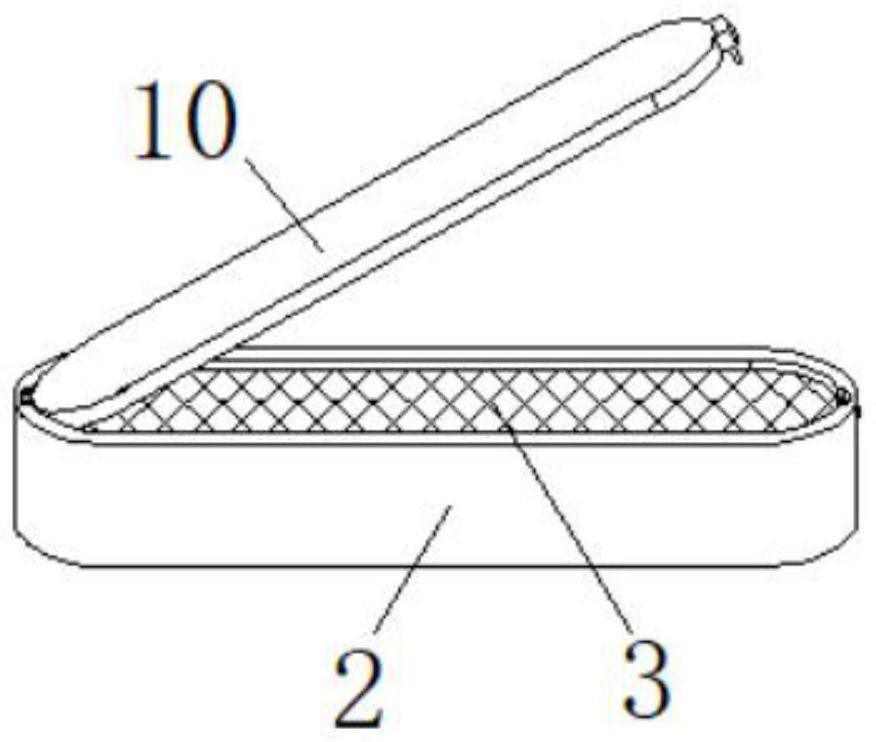

Multifunctional silica gel bracelet convenient to use

InactiveCN113068908AEffective protectionAvoid scratchesBraceletsWrist-watch strapsDisplay deviceStructural engineering

The invention discloses a multifunctional silica gel bracelet convenient to use. The multifunctional silica gel bracelet structurally comprises an integrated silica gel bracelet belt, wherein a protective shell is wrapped in the integrated silica gel bracelet belt; a display, a first groove, a second groove and a through hole are mounted on the protective shell; the display is fixedly mounted in the protective shell; the first groove is located in the left side of the protective shell; the second groove is located in the right side of the protective shell; the through hole is located in the outer right end of the protective shell; and a fixing shaft is fixedly installed in the first groove and connected with the connecting plate through a first reset spring. According to the invention, the glass of the display can be effectively protected, the phenomenon that the glass of the display is scratched or bumped and damaged by a user without attention is avoided, the probability of damage of the bracelet in the use process is reduced, the protection effect of the bracelet in the use process is improved, and the service life of the bracelet in the use process is prolonged.

Owner:深圳市广裕丰橡胶制品有限公司

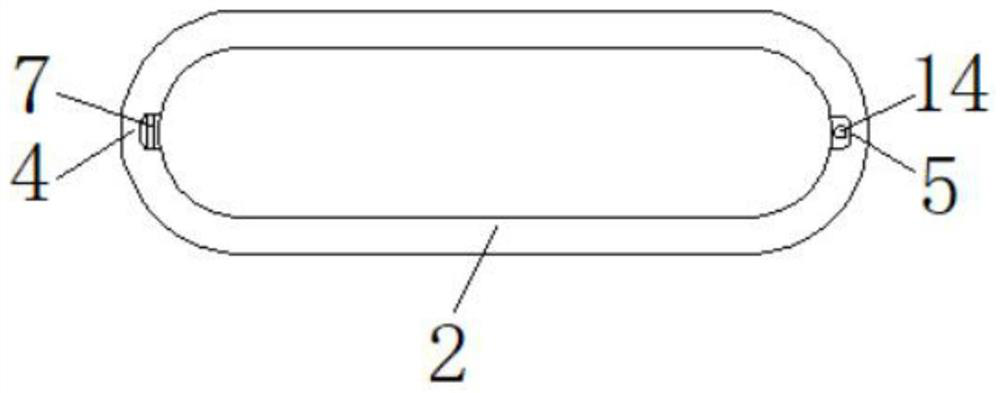

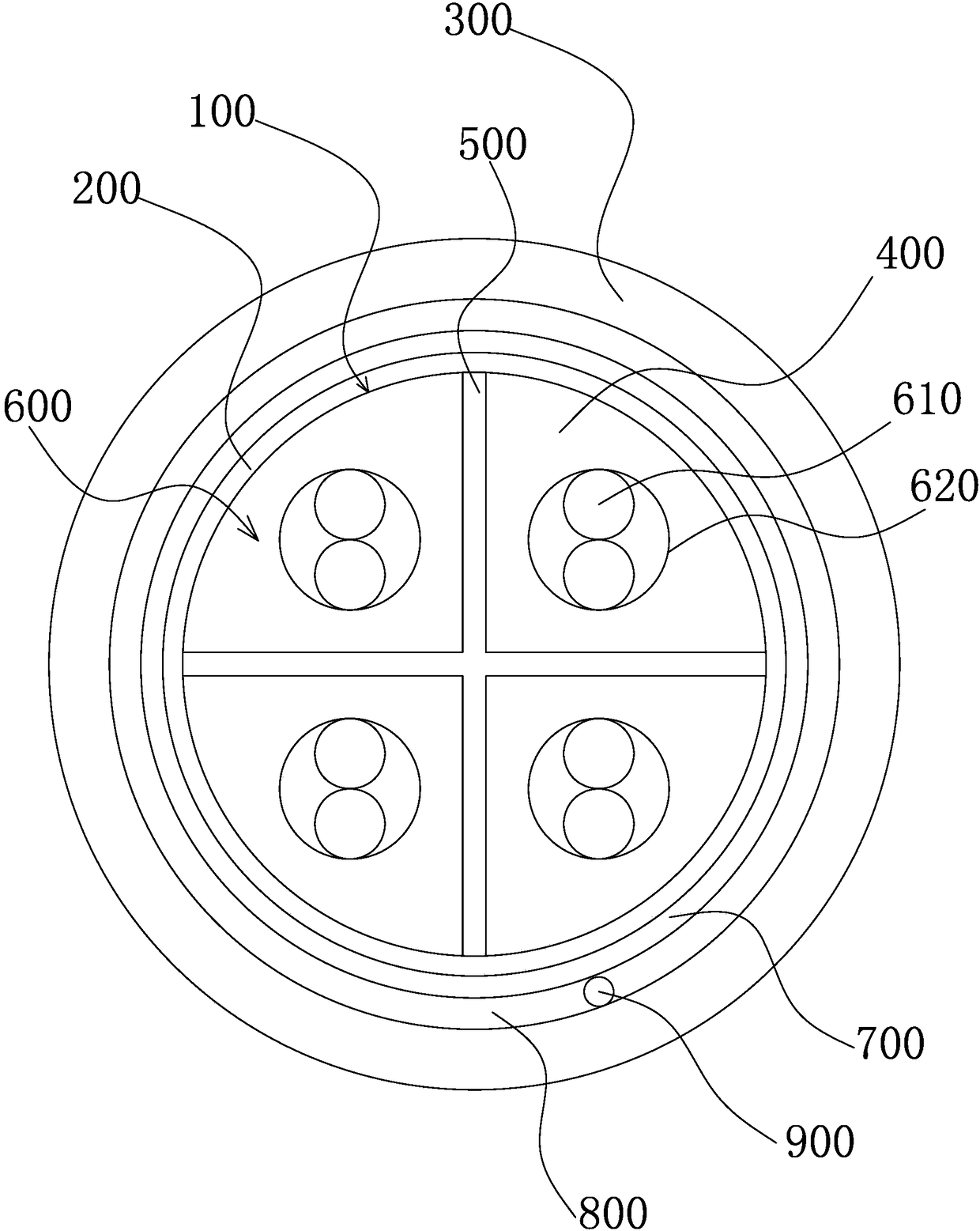

A shielded Cat6e cable with water-blocking and tensile-resistant functions

ActiveCN106981331BImprove waterproof performanceLow densityClimate change adaptationInsulated cablesAntioxidantMicrosphere

Owner:ZHEJIANG SHIP ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com