High-temperature coating material for forming weldable metal circuit, and preparation method thereof

A technology for welding metal and wires, which is applied in the direction of fireproof coatings, epoxy resin coatings, coatings, etc., can solve the problems that antennas are incompetent, unsatisfactory, and limit applications, so as to improve heat resistance and weather resistance, and improve overall performance , the effect of strong weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

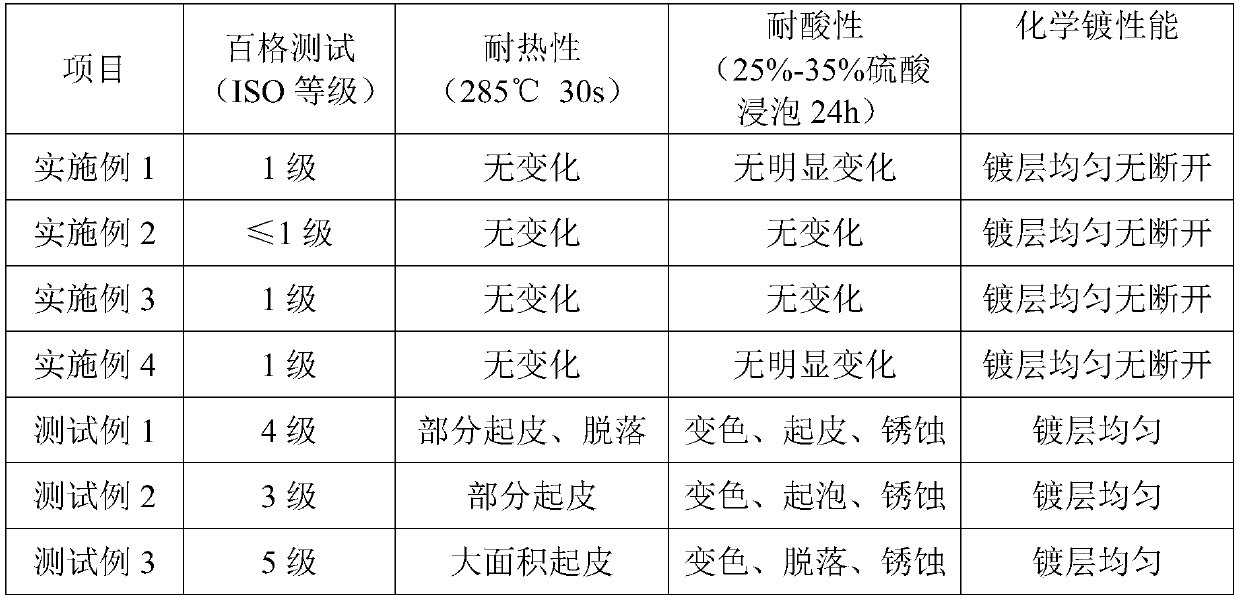

Examples

Embodiment 1

[0038] A high-temperature coating for forming weldable metal circuits, comprising the following components by mass percentage: 50% of high-temperature resistant resin, 15% of radium engraving powder, 2% of leveling agent, 2% of active diluent, and 31% of curing agent.

[0039]Wherein, in the high temperature resistant resin, the weight ratio of epoxy resin, silicone resin and polyphenylene sulfide is 3:3:1.

[0040] The high-temperature coating in this example is prepared by the following method: first mix the epoxy resin, the silicone resin and the active diluent in the formulated amount at high speed, dry and pulverize, and then add the remaining components, according to the routine in the field Methods Mixing, crushing, that is.

[0041] The application process of the high-temperature coating in this embodiment on the conductive circuit is as follows:

[0042] The above-mentioned high-temperature coating is sprayed on the substrate by thermal spraying method, and the spray...

Embodiment 2

[0045] A high-temperature coating for forming weldable metal circuits, comprising the following components by mass percentage: 60% high-temperature-resistant resin, 20% laser engraving powder, 0.8% leveling agent, 1% active diluent, and 18.2% curing agent.

[0046] Among them, in the high temperature resistant resin, the weight ratio of epoxy resin, silicone resin and polyphenylene sulfide is 2:3:1.5.

[0047] The high-temperature coating in this example is prepared by the following method: first mix the epoxy resin, silicone resin and 2 / 3 of the reactive diluent in the formula amount at high speed, dry and pulverize, then add the remaining components, according to It is obtained by mixing and pulverizing by conventional methods in the art.

Embodiment 3

[0049] A high-temperature coating for forming weldable metal circuits, comprising the following components by mass percentage: 70% of high-temperature resistant resin, 18% of radium engraving powder, 0.5% of leveling agent, 0.5% of active diluent, and 11% of curing agent.

[0050] Wherein, in the high temperature resistant resin, the weight ratio of epoxy resin, silicone resin and polyphenylene sulfide is 2:2:2.

[0051] The preparation method of the high-temperature coating in this example is the same as that in Example 1, and will not be described in detail here.

[0052] The high-temperature coating in this example is prepared by the following method: first mix the epoxy resin, silicone resin and 1 / 3 of the reactive diluent in the formula at high speed, dry and pulverize, then add the remaining components, according to It is obtained by mixing and pulverizing by conventional methods in the art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com