Li3PS4 solid electrolyte, solid mixed electrolyte, all-solid-state lithium-sulfur battery and production method thereof

A solid-state electrolyte, lithium-sulfur battery technology, applied in non-aqueous electrolyte batteries, solid electrolytes, lithium batteries, etc., to achieve the effects of improved performance, simple process, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

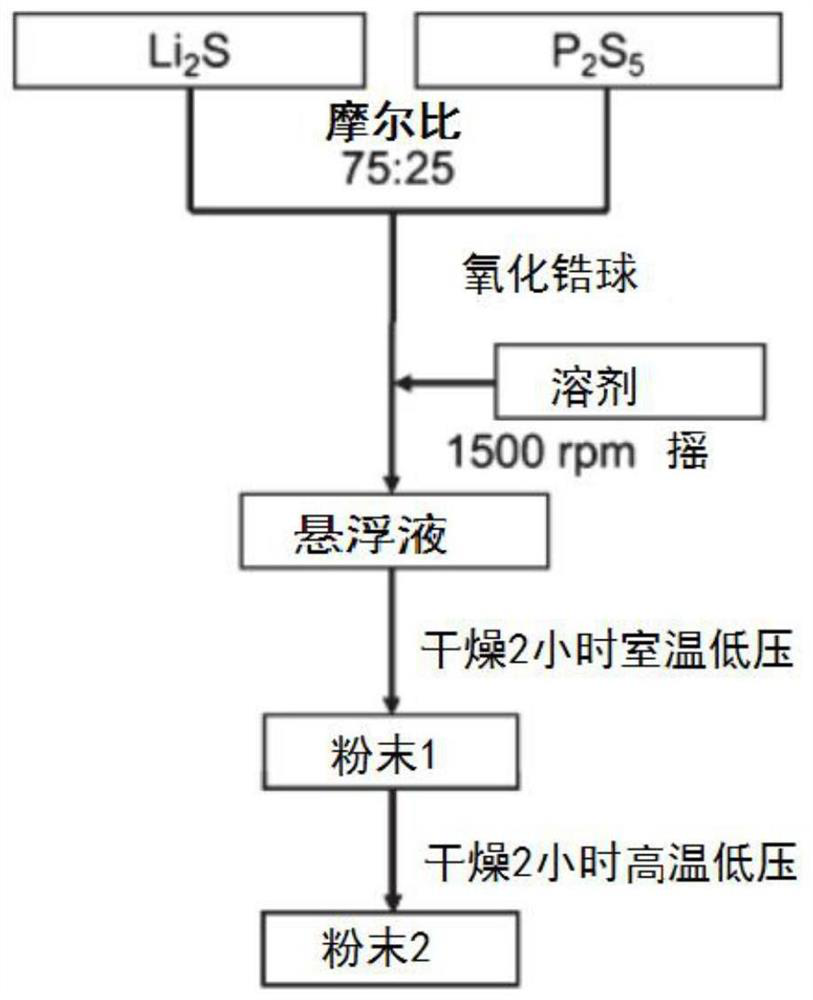

[0055] Embodiment 1 (preparation of Li with DMC as organic solvent 3 P.S. 4 (lithium thiophosphate)):

[0056] Will Li 2 S (0.3827 g), P 2 S 5 (0.6170 g; Li 2 S:P 2 S 5 Molar ratio=3:1), 4 mm zirconia balls (30 g) and DMC (20 ml) were mixed in a 45 mL polypropylene centrifuge tube; shaken at a speed of 1500 rpm for 24 h in a dry Ar atmosphere, the amplitude was about Then, the test tube was sealed and centrifuged at 10,000rpm for 5 minutes, decanted; the solid phase was evacuated at room temperature, and then evacuated at 190°C for 2h at low pressure using a rotary vacuum pump to obtain a white powder product .

Embodiment 2

[0057] Embodiment 2 (preparation of Li with EA as organic solvent 3 P.S. 4 (lithium thiophosphate)):

[0058] Will Li 2 S (0.3827 g), P 2 S 5 (0.6170 g; Li 2 S:P 2 S 5 molar ratio=3:1), 4mm zirconia balls (30g) and EA (20ml) were mixed in a 45mL polypropylene centrifuge tube; shaken at a speed of 1500rpm in a dry Ar atmosphere for 24h, the amplitude was about Then, the test tube was sealed and centrifuged at 10,000rpm for 5 minutes, decanted; the solid phase was evacuated at room temperature, and then evacuated at 160°C for 2h at low pressure using a rotary vacuum pump to obtain a white powder product .

Embodiment 3

[0059] Embodiment 3 (preparation of Li with MPK as organic solvent 3 P.S. 4 (lithium thiophosphate)):

[0060] Will Li 2 S (0.3827 g), P 2 S 5 (0.6170 g; Li 2 S:P 2 S 5 Molar ratio=3:1), 4 mm zirconia balls (30 g) and MPK (20 ml) were mixed in a 45 mL polypropylene centrifuge tube; shaken at a speed of 1500 rpm for 24 h in a dry Ar atmosphere, with an amplitude of approx. Then, the test tube was sealed and centrifuged at 10,000rpm for 5 minutes, decanted; the solid phase was evacuated at room temperature, and then evacuated at 160°C for 2h at low pressure using a rotary vacuum pump to obtain a white powder product .

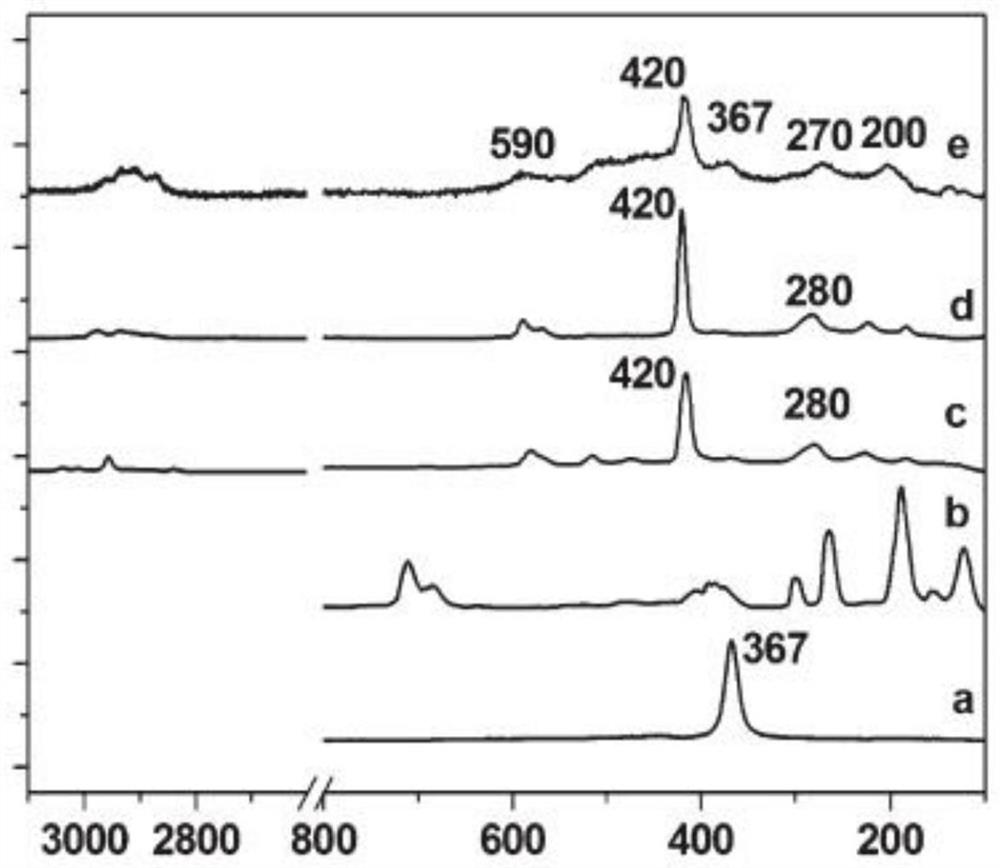

[0061] The following is the test characterization part:

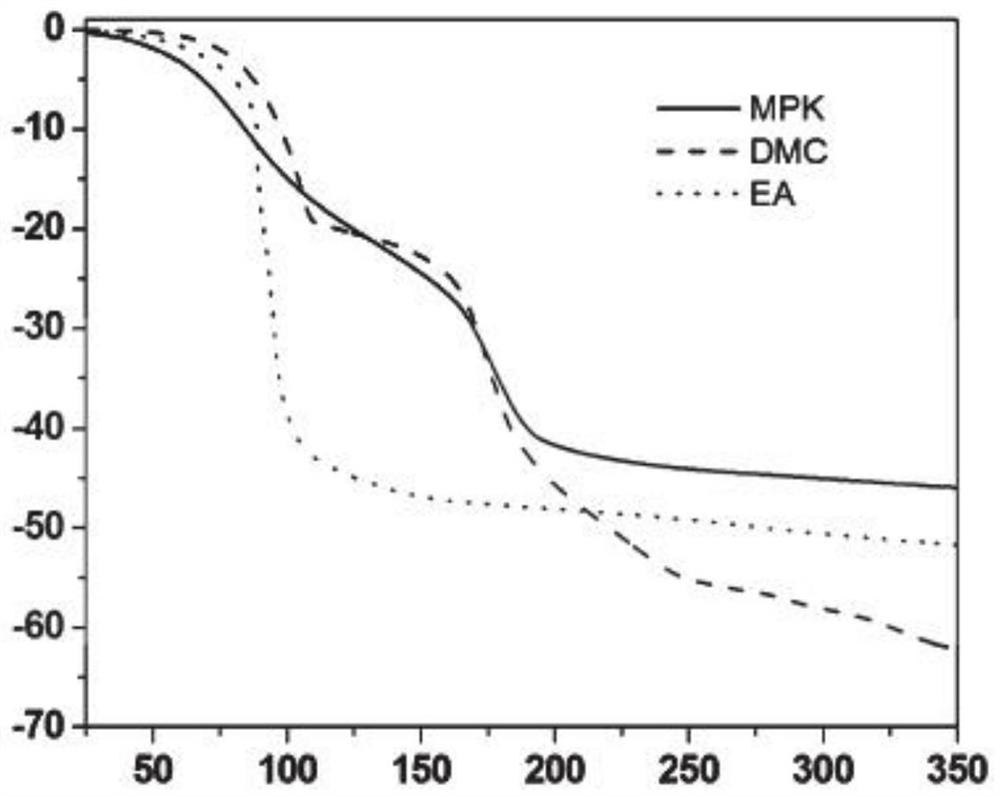

[0062] (1) Thermogravimetric (TG) analysis

[0063] The TG curves of the samples prepared using MPK, EA and DMC are plotted in the attached figure 2 , where the horizontal axis is temperature (°C), and the vertical axis is weight change (%). At 250 °C, the weight losses of MPK, EA and DMC samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com