A kind of Ga, Al co-doped llzo solid electrolyte, multi-element solid battery and preparation method thereof

A solid-state battery, solid electrolyte technology, used in electrolytes, electrical components, secondary batteries, etc., can solve the problems of high electrolyte strength and brittleness, irregular deposition of lithium ions, and inability to operate solid batteries, to ensure normal performance and reliability. Cycling, preventing the formation of lithium dendrites, and slowing down the decay of discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

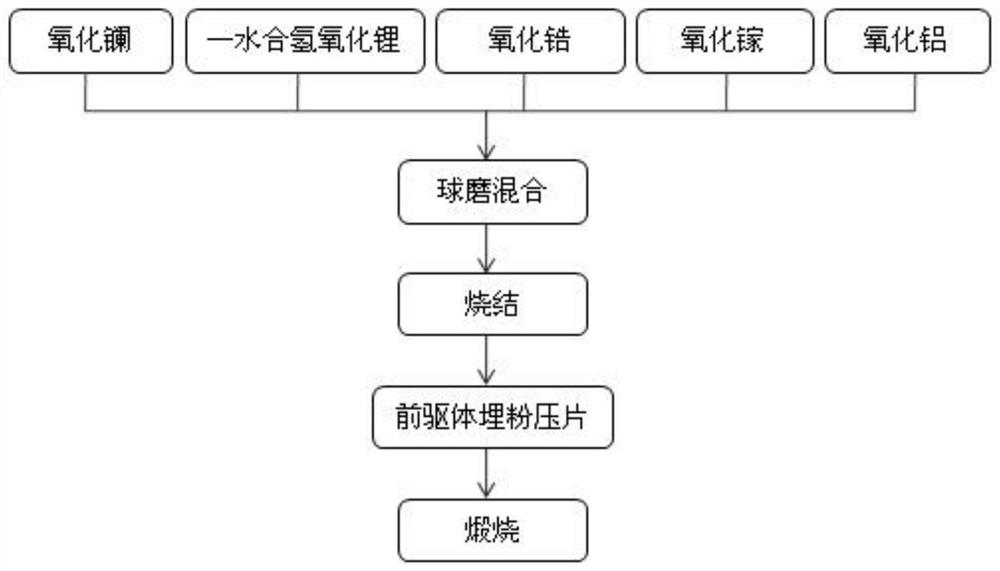

[0053] Embodiment 1 (preparation of Ga, Al co-doped LLZO solid electrolyte)

[0054] According to the chemical formula Li 7-3x-3y al x Ga y La 3 Zr 2 o 12 , (wherein x=0.15, y=0.15) molar ratio weighs lithium hydroxide monohydrate (LiOH·H 2 O), lanthanum trioxide (La 2 o 3 ), zirconium dioxide (ZrO 2 ), gallium trioxide (Ga 2 o 3 ), aluminum oxide (Al 2 o 3 ), the La 2 o 3 Sinter in a muffle furnace at 900°C for 12 hours. After sintering, mix it with lithium hydroxide monohydrate, zirconium dioxide, gallium trioxide, and aluminum trioxide. The raw materials are wet ball milled for 10 hours (the balls and jars are both made of zirconia) to ensure that the raw materials are mixed evenly; the raw materials mixed by ball milling are dried in a vacuum oven at 80°C for 12 hours; the dried and evenly mixed raw materials are ground Thinning, pre-sintering at 950°C for 6 hours to obtain the precursor material; weigh a certain mass of the precursor material obtained by pr...

Embodiment 2

[0055] Embodiment 2 (preparation of positive electrode sheet)

[0056] The starch was dried at 100°C for 24 hours in an air atmosphere, and then the dried starch was ball milled at a speed of 300r / min, and the ball milling time was 6 hours. Finally, the ball milled starch was put into a quartz tube furnace. Under the protection of nitrogen atmosphere, at a heating rate of 10°C / min, the first step is to 200°C, and the temperature is kept at 200°C for 1 hour, and then the temperature is kept at 500°C for 1 hour, and the positive electrode active material is obtained in the natural cooling zone to room temperature. . Coating the cathode active material slurry on the quantum carbon-based film coated with a layer of nano-silver metal protection to obtain two coating materials, and then hot-compressing the two coating materials to form a quantum carbon-based film / metal protection Layer / positive electrode material / metal protective layer / quantum carbon-based film multilayer composite...

Embodiment 3

[0057] Embodiment 3 (preparation of multi-component negative pole sheet)

[0058] Below -50°C, under vacuum conditions, 90% by weight of metal lithium is placed in a molten alloy bath, and then gold lithium is heated to 300°C to melt metal lithium; then according to the weight ratio of 5% nickel, Add 3% manganese into the molten bath and stir for 30 minutes; then add 2% gallium into the molten bath and keep stirring for 30 minutes to completely dissolve the gallium particles and homogenize the liquid mixture to form a molten alloy, then cool to room temperature, A gallium-doped lithium-nickel-manganese multi-element active material is prepared.

[0059] Coat the negative electrode active material slurry on the quantum carbon-based film coated with a layer of nano-silver metal protection to obtain two coating materials, and then heat-compress the two coating materials to form a quantum carbon-based film / metal Multi-layer composite multi-element negative electrode sheet of prot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| shear modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com