Single atom pt counter electrode and its preparation method and application

An atomic and electrode technology, applied in the field of single-atom Pt counter electrode and its preparation, can solve the problems of decreased stability, inability to significantly reduce the amount of Pt used, and increase of metal surface free energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

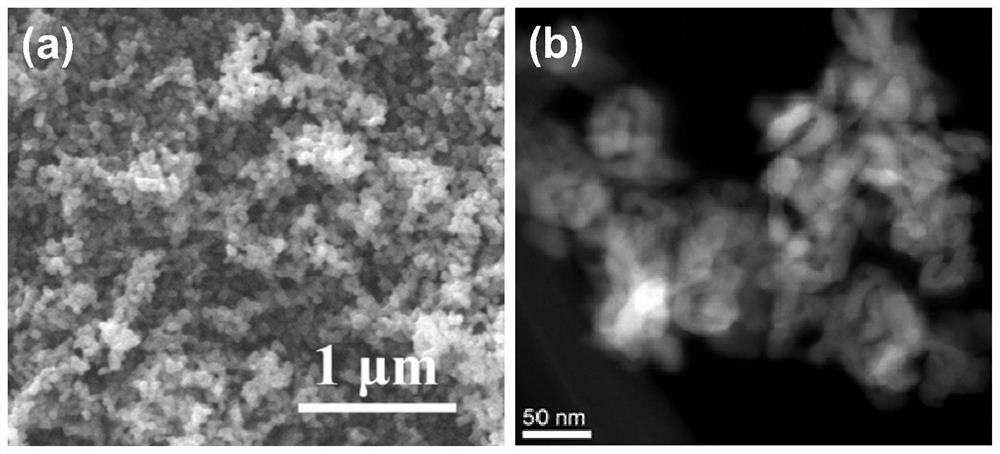

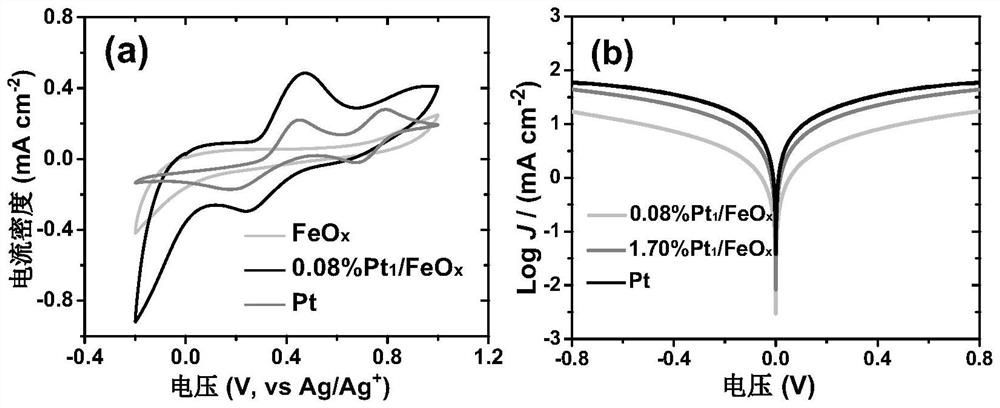

[0057] 1. Single-atom Pt catalytic material Pt 1 / FeO x preparation of

[0058] First, two single-atom catalysts with different Pt contents were prepared by co-precipitation method (refer to "Nature Chemistry", 2011, 3, p634–641 for details) (the mass percentages of Pt in the two samples were 0.08% and 1.70%, respectively). The preparation of the sample is carried out in aqueous solution. The precursors include chloroplatinic acid solution, ferric nitrate solution and sodium carbonate solution. The pH of the reaction system is controlled at about 8.0. When preparing samples with a Pt content of 0.08%, the concentration of chloroplatinic acid was 2.12×10 -2 M, the concentration of ferric nitrate is 1.0M, the concentration of sodium carbonate solution is 1.0M, and the reaction temperature is 50°C; when preparing a sample with a Pt content of 1.70%, the concentration of chloroplatinic acid is 0.36 M, the concentration of ferric nitrate is 1.0M, and the concentration of sodium c...

Embodiment 2

[0069] The opposite electrode prepared by the sample with a Pt mass percentage content of 0.08% in Example 1 is assembled into a complete DSCs device, and the photoelectric conversion performance of the device is tested

[0070] (1) draw a regular square on the counter electrode prepared by the sample whose Pt mass percentage content is 0.08% in embodiment 1, and the area of the square is consistent with the active area of the photoanode; on the diagonal apex of the square Drill a small hole each with a diameter of about 0.5mm.

[0071] (2) Take the dye-sensitized photoanode, cover it completely with sarin film outside the active area of the photoanode, and then cover the counter electrode and heat seal it to ensure that the photoanode and the counter electrode are tightly connected.

[0072] (3) Connect the air pump with an elastic plastic tube. One end of the plastic tube is close to the small hole on the counter electrode. The electrolyte is perfused from another sma...

Embodiment 3

[0076] 1. Preparation of Pt with a Pt content of 2.32% 1 / FeO x

[0077] The method used is the co-precipitation method (references Nature Chemistry, 2011, 3, 634-641). The preparation of the samples was carried out in aqueous solution, the concentration of chloroplatinic acid was 4.09×10 -2 M, the concentration of ferric nitrate is 1.0M, the concentration of sodium carbonate solution is 1.0M, and the reaction temperature is 50°C. After the precipitation reaction has completely occurred (this process takes about 1h), the sample is centrifuged, dried at 60°C for 5h, and then sintered in a muffle furnace at 400°C for 5h; before preparing the counter electrode, the sintered sample is reduced by hydrogen, The specific process is to introduce a mixed gas containing 10% hydrogen at 200°C (the other component in the mixed gas is He gas, which acts as a carrier gas) for 0.5h reduction

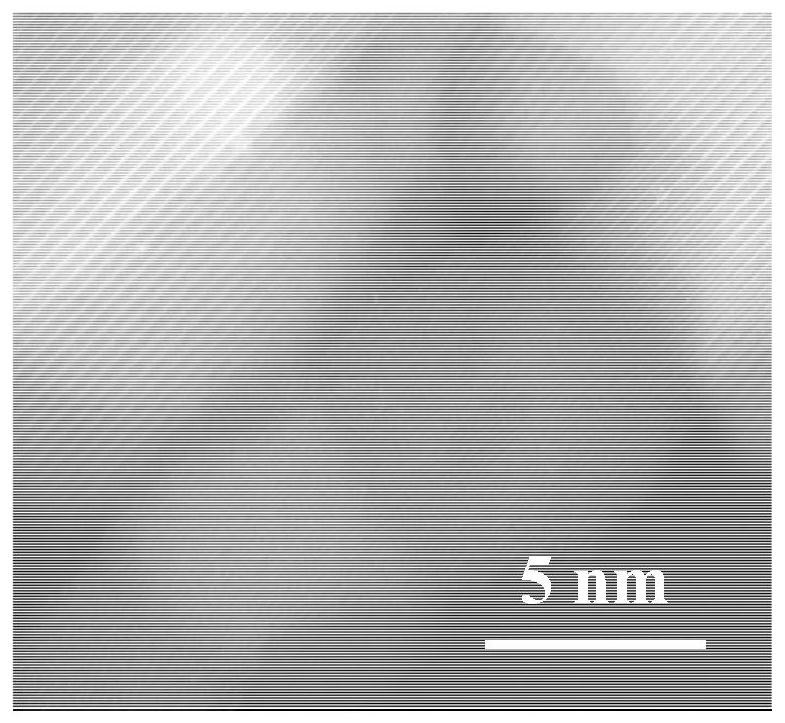

[0078] The prepared Pt content was 2.32% Pt 1 / FeO x The high-resolution spherical aberration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com