Pure epoxy system low-temperature curing coating material composition for carbon fiber substrate, and coating material thereof

A carbon fiber substrate and curing coating technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of high melt viscosity, poor powder storage stability, difficult flow of coating films, etc., and achieve high hardness and good anti-corrosion performance. , The effect of low temperature fast curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034]The present invention further provides a method for preparing a low-temperature curing flat coating material, which is characterized in that it is prepared by using the low-temperature curing flat coating composition of the present invention, which includes the following steps: a surface pretreatment step, a spraying step, and a curing step.

[0035] In the surface pretreatment step, conventionally used methods can be used, as long as the sprayable conditions of the powder coating composition can be achieved, there is no special requirement.

[0036] The spraying step is carried out at 40-90° C.; it can be carried out by using conventional spraying equipment, but as long as a flat coating can be obtained, it can be used.

[0037] Curing step, rapid curing in 3 minutes at a temperature below 130°C.

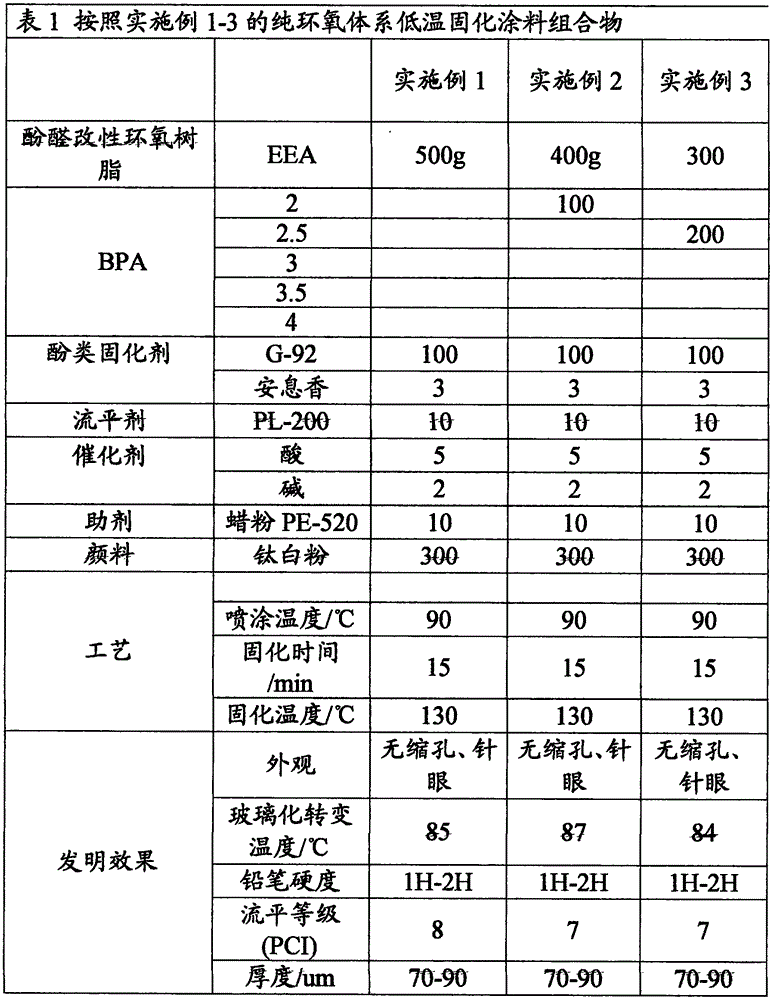

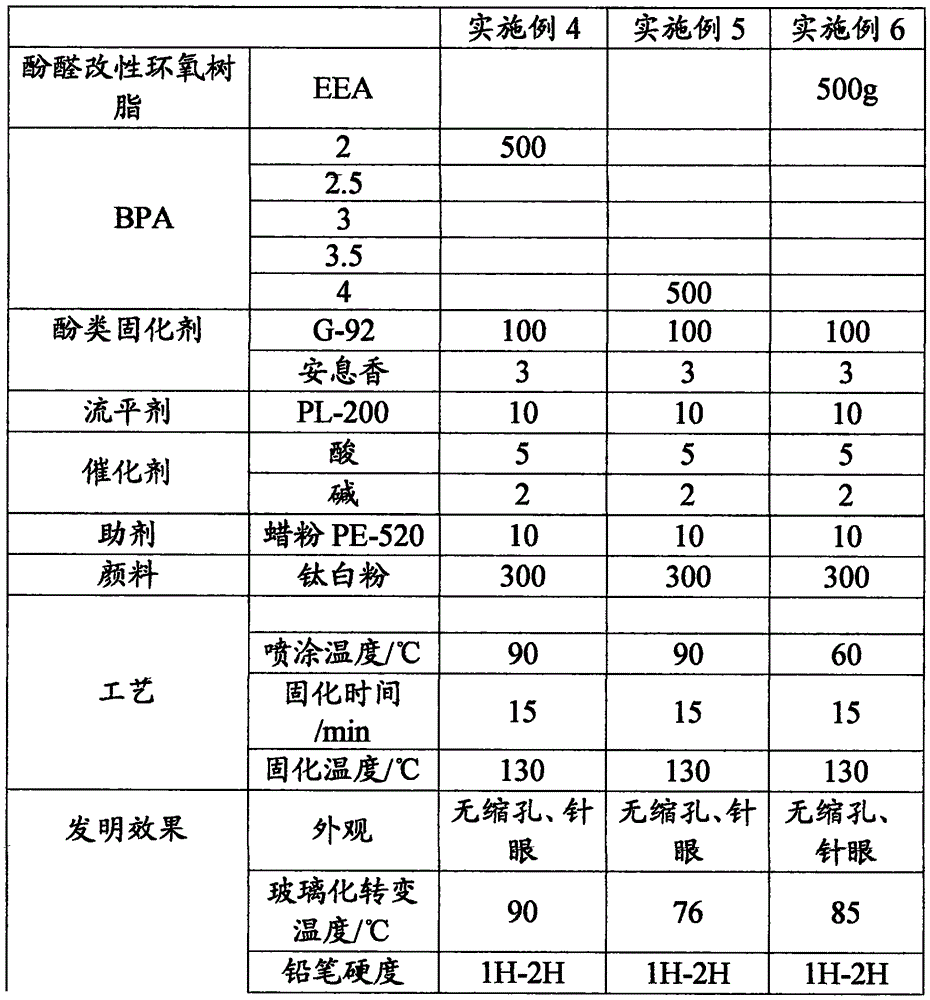

Embodiment 1

[0040] First, take 500g as modified epoxy resin EEW, 100g as phenolic curing agent G-92, 10g as leveling agent PL-200, 3g benzoin, 5g acid catalyst, 2g alkali catalyst, 10g wax powder ( PE-520), 300g of titanium dioxide are put into the mixing tank; after being co-extruded by the melt extruder, and then cooled by the blower fan, the tablet material is obtained; the obtained tablet material is pulverized and ground twice to obtain a fine powder, In the secondary grinding process, a heat exchanger is used to convey cold air for cooling to obtain a fine powder; after being separated by a cyclone separator, it is sieved through a sieve to detect a finished product. Secondly, the carbon fiber is pretreated, and the coating composition is sprayed on the carbon fiber pretreated at 90° C., and cured at 130° C. for 15 minutes in a curing oven with hot air circulation to obtain a coating material.

[0041] According to the method of Example 1, the coating material is obtained. Visually ...

Embodiment 2

[0043] First, weigh 400g of EEW as modified epoxy resin, 100g of type 2 BPA, 100g of G-92 as phenolic curing agent, 10g of PL-200 as leveling agent, 3g of benzoin, 5g of acid catalyst, 2g of base catalyst , 10g of wax powder (PE-520), and 300g of titanium dioxide are put into the mixing tank; after being co-extruded by the melt extruder, and then cooled by the blower fan, the tablet material is obtained; the obtained tablet material is pulverized twice Grind to obtain fine powder, and use heat exchanger to transport cold air to cool in the secondary grinding process to obtain fine powder; after being separated by cyclone separator, and then sieved through sieve, the finished product is detected. Secondly, the carbon fiber is pretreated, and the coating composition is sprayed on the carbon fiber pretreated at 90° C., and cured at 130° C. for 15 minutes in a curing oven with hot air circulation to obtain a coating material.

[0044] According to the method of Example 2, the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com