Safe stopping device, working method thereof and honing machine

A technology of safety stop and honing machine, which is applied in the direction of grinding/polishing safety device, honing machine tool, grinding frame, etc. It can solve the problems of loading and unloading and maintenance difficulties, and achieve the effect of reducing motion impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

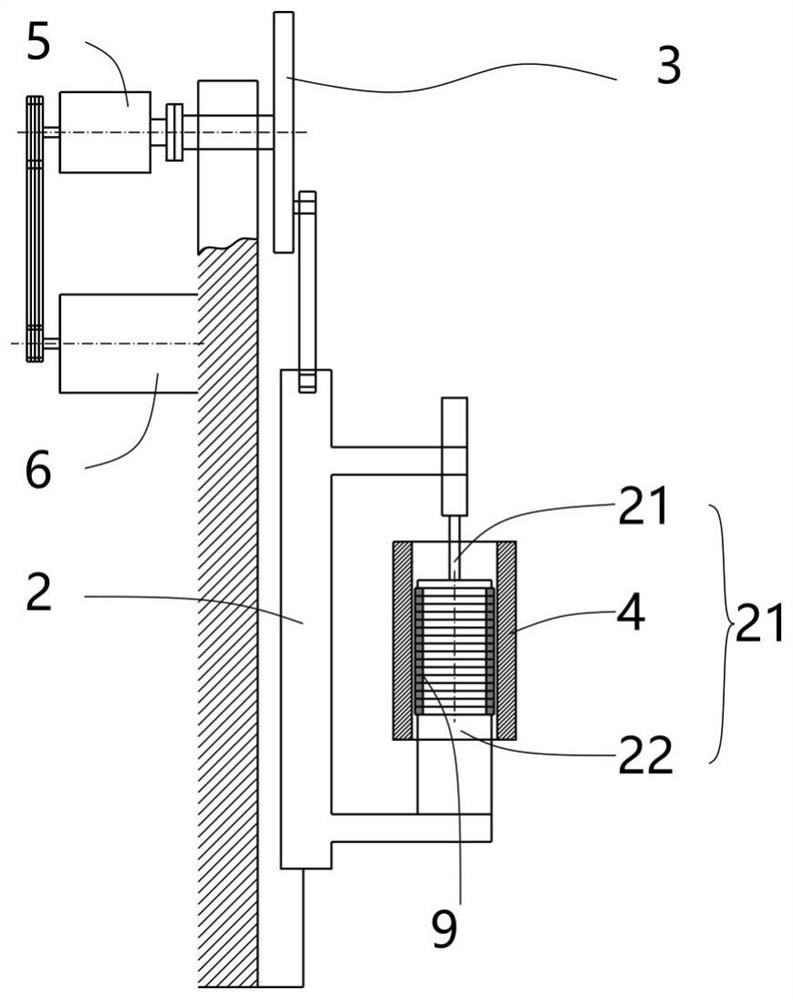

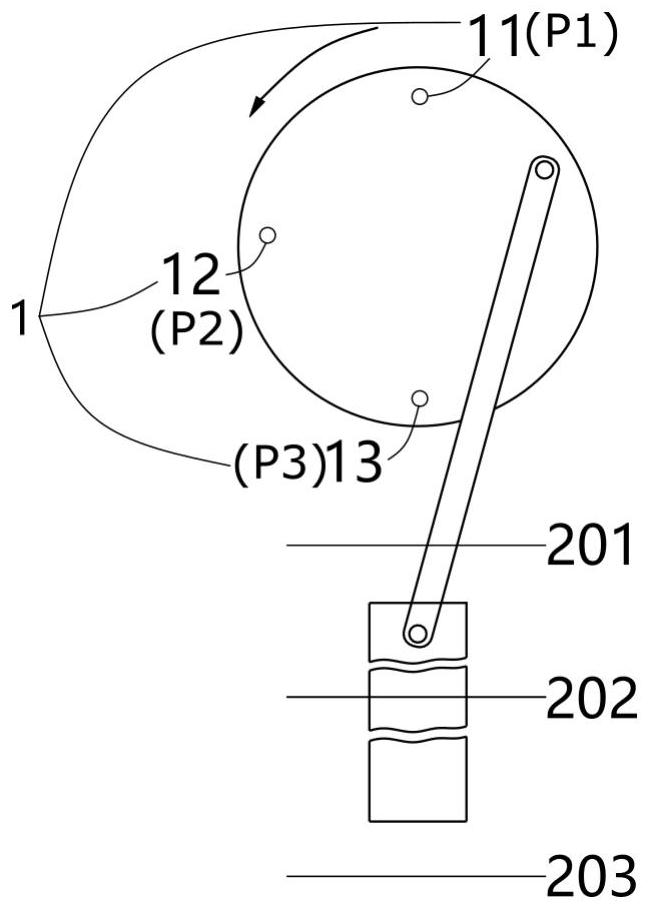

[0019] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. In this specification, the size ratio of the drawings does not represent the actual size ratio, but is only used to reflect the relative positional relationship and connection relationship between the components, and the names are the same Or identically numbered components represent similar or identical structures and are for illustrative purposes only.

[0020] The safety stop device of the present invention is installed on the piston ring honing machine to realize the safety stop function of the piston ring honing machine. Specifically, it is realized that the sliding plate of the piston ring honing machine can stop at the top dead center when it stops, so as to facilitate loading and unloading and equipment maintenance, and ensure that the sliding plate can be reliably stopped at the top dead center in the event of a power failure, program err...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com