Multi-nozzle printing method of 3d printer

A technology of 3D printers and printing nozzles, applied in the direction of digital output to printing units, machine learning, instruments, etc., can solve the problems of affecting the experience of staff, low efficiency of 3D printer data reception, low efficiency of data transmission, etc., to avoid transmission The effect of blocking, ensuring the efficiency of data reception, and improving the efficiency of data transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

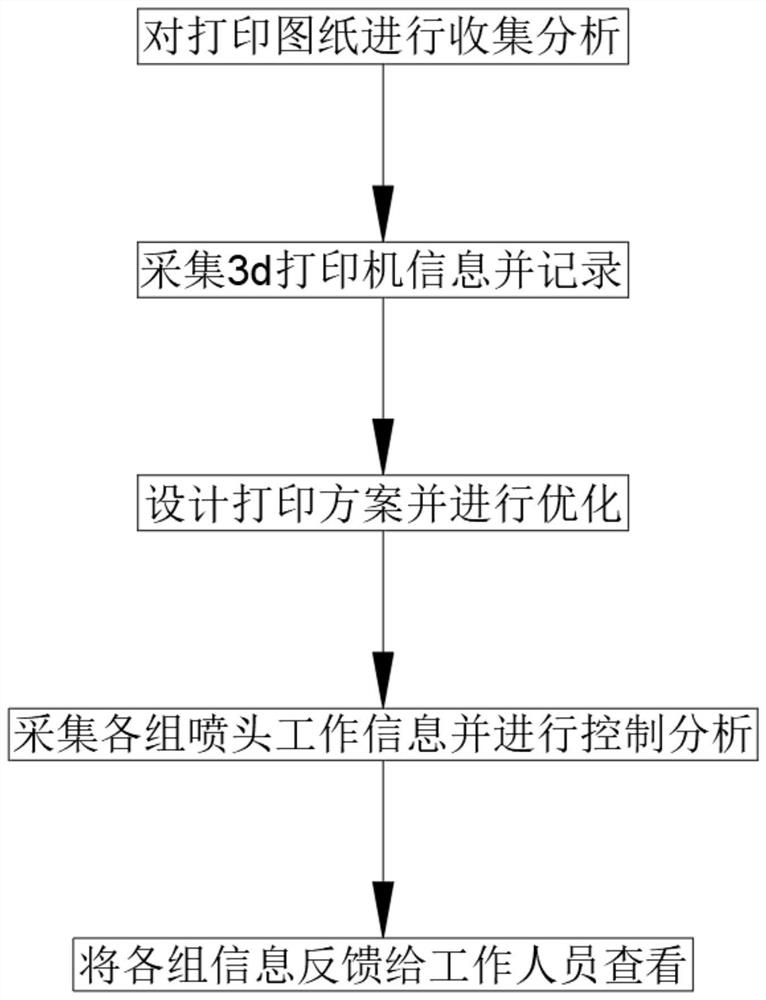

[0039] see figure 1 As shown, the present invention is a multi-nozzle printing method for a 3D printer, and the specific steps of the printing method are as follows:

[0040] Collect and analyze printed drawings: The computer receives one or more groups of printed drawings uploaded by the staff, and classifies and analyzes the collected groups of printed drawings.

[0041] Specifically, after the computer receives each group of printed drawings uploaded by the staff, it searches whether there are the same drawings in each group of drawings. If there are identical drawings, the number of the drawings is counted, and the redundant drawings are filtered out. After completion, count the number of nozzles required for printing each group of drawings, and classify them according to 1 to N, where N is the total number of nozzles of the 3D printer.

[0042] Collect 3D printer information and record: The computer communicates with the 3D printer, collects each group of information on ...

Embodiment 2

[0044] see figure 1 As shown, the present invention is a multi-nozzle printing method for a 3D printer, and the specific steps of the printing method are as follows:

[0045] Design and optimize the printing scheme: The computer is connected to the cloud database and the Internet, and collects each group of scheme data. At the same time, the collected data is screened and classified, and the system default or user-set printing scheme is optimized.

[0046] Specifically, when the relevant application software receives each group of program data, it constructs a data filter by itself, and at the same time imports the collected program data of each group into the data filter. Classification, export each group of program data from different data sources into text files in a specified format or file types in other formats, and then extract the obtained program data, and then deal with missing data, duplicate data, abnormal data, and inconsistent data. The program data is processed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com