Three-phase electric energy meter automatic assembly line multi-task alternate feeding and discharging system and method

A three-phase electric energy meter, assembly line technology, applied in transportation and packaging, conveyor objects, conveyor control devices, etc., can solve the problem of affecting production capacity, not having three-phase loading and unloading double-claw robots, and unable to meet the continuity of system operation and other problems to achieve the effect of accurate and fast sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below with reference to the accompanying drawings and embodiments.

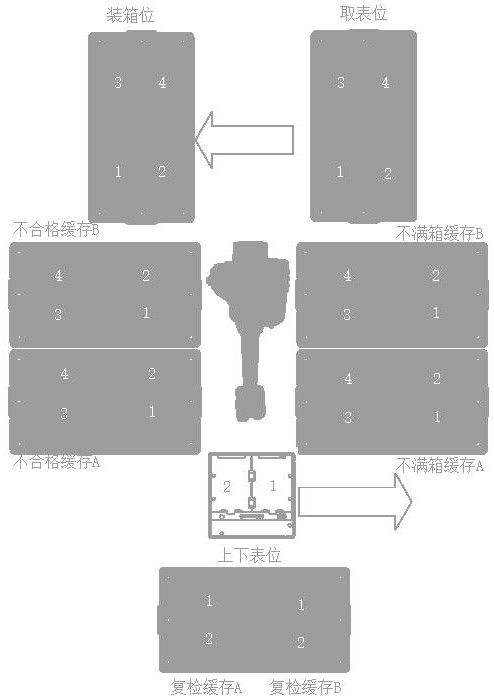

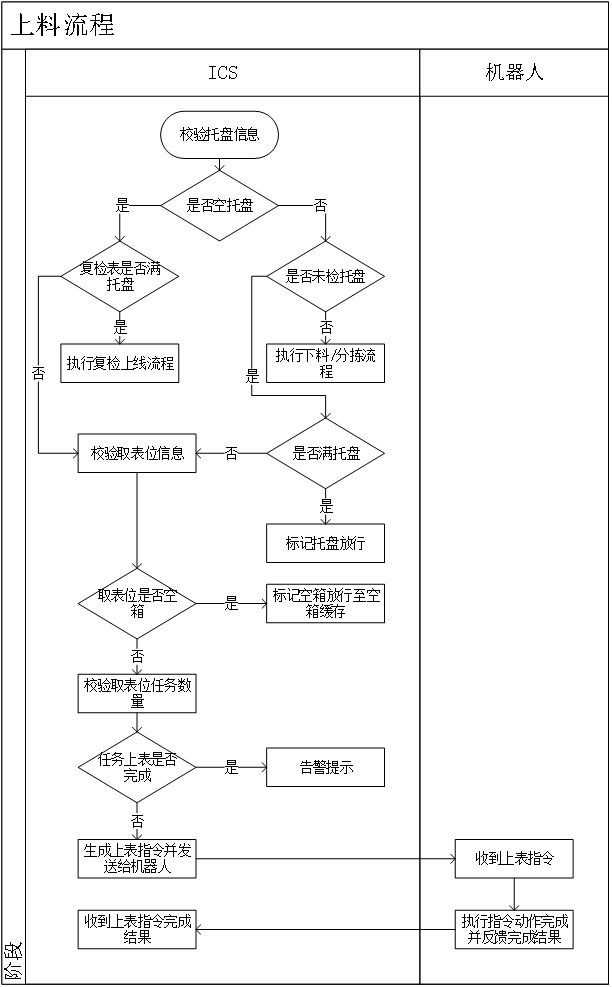

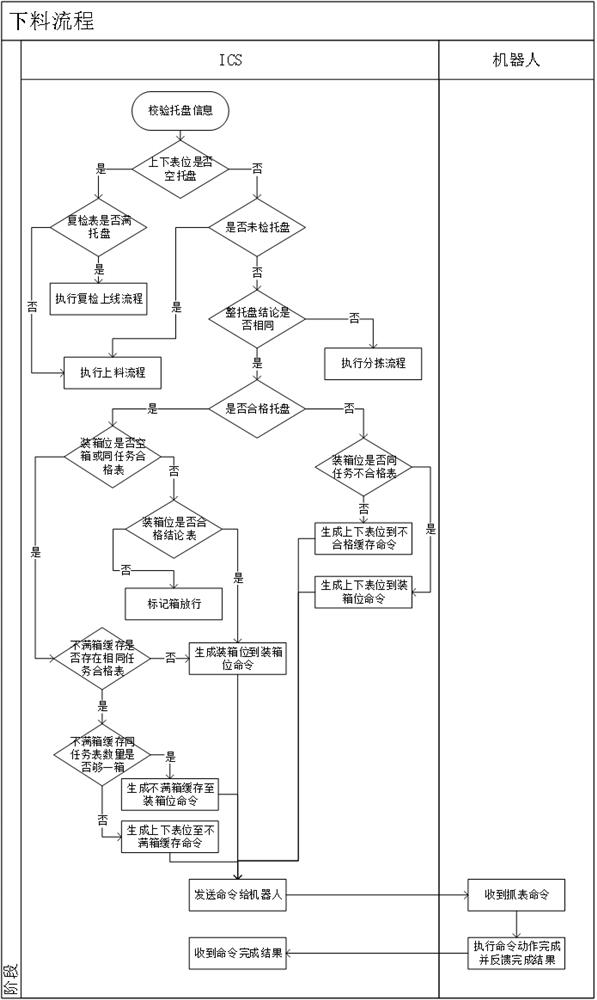

[0036] Please refer to figure 1 , the present invention provides a multi-task interspersed loading and unloading system for an automatic assembly line of a three-phase electric energy meter, including a drum line unit, a doctor line unit, a buffer area unit and a robot; the drum line includes a table taking position and a boxing position; the doctor The line unit includes upper and lower bits: the buffer area unit includes an unsatisfactory box buffer, an unqualified buffer, and a recheck buffer; the upper and lower bits, the unsatisfactory box buffer, the table fetching bit, the boxing bit, and the unqualified buffer are in counterclockwise order. setting; the recheck buffer is arranged on the side of the upper and lower bits.

[0037] Preferably, the robot adopts a double-claw loading and unloading sorting robot.

[0038] In this embodiment, there is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com