Laser corneal cutting system and method for treating xerophthalmia

A cutting method, dry eye technology, applied in laser surgery, ophthalmology treatment, equipment for testing eyes, etc., can solve problems such as unaware, unaware corneal surface dry eye

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

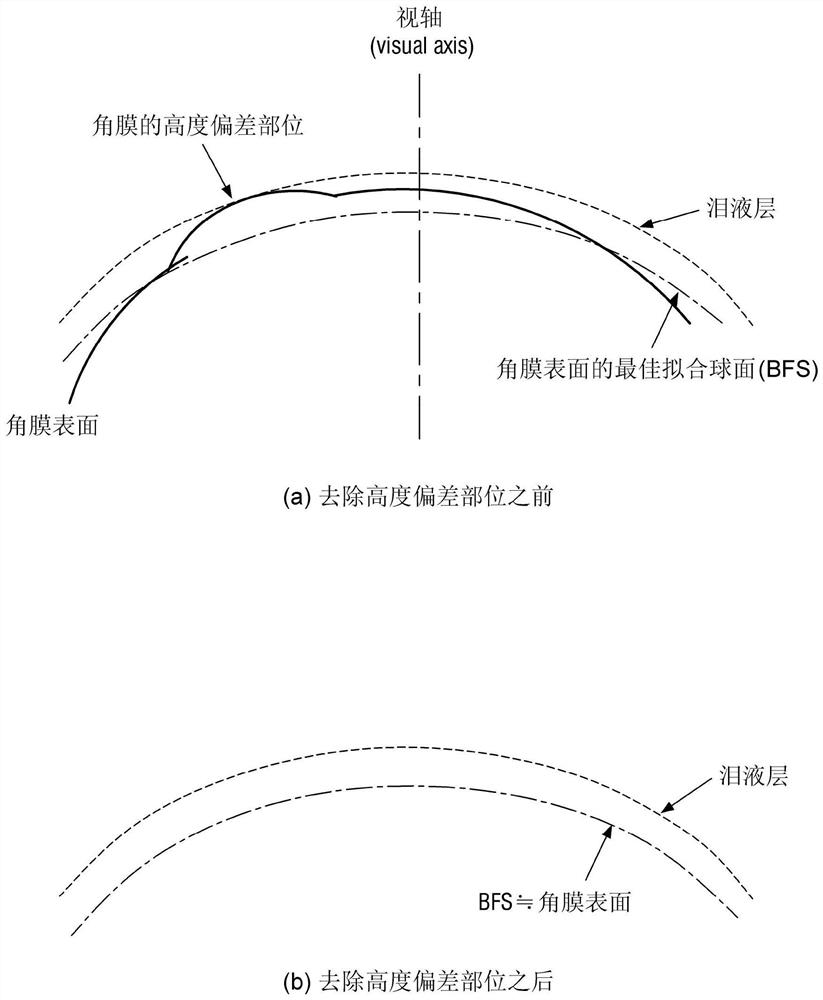

[0088] Image 6 It is a four-phase map of the cornea taken by Anterior Segment Tomography. available through the Image 6 Corneal surface height map on the upper left side (map labeled Anterior Float) to confirm the surface height deviation of the cornea.

[0089] Figure 7 For cutting from 0 degrees to 180 degrees Image 6 The cross-sectional view of the four-phase diagram. through the Figure 7 The cross-sectional view of the corneal surface height map on the upper left side can easily confirm the corneal BFS and the corresponding corneal surface height deviation.

[0090] like Image 6 As shown in the corneal surface height map on the upper left side, the arithmetic unit extracts and confirms the surface height deviation position using the corneal surface height map obtained from the cornea measurement unit, and the result is a slightly deviated part in the direction of 225 degrees from the center of the cornea, as shown in the figure. Based on BFS, there is a part w...

Embodiment 2

[0094] Figure 9 Four-phase map of the cornea taken and analyzed by Anterior Segment Tomography. available through the Figure 9 Corneal surface height map on the upper left side (map labeled Anterior Float) to confirm the surface height deviation of the cornea.

[0095] Figure 10 For cutting from 0 degrees to 180 degrees Figure 9 A cross-sectional view of the corneal tetraphasic diagram. through the Figure 10 The cross-sectional view of the corneal surface height map on the upper left side can easily confirm the corneal BFS and the corresponding corneal surface height deviation.

[0096] like Figure 9 As shown in the corneal surface height map on the upper left side, the arithmetic unit uses the corneal surface height map obtained from the cornea measurement unit to extract and confirm the surface height deviation position. In addition, the right side is outside the 2 mm area, and there is a portion (dark yellow) with a surface height of 30 μm based on BFS.

[009...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com