Novel industrial wastewater treatment system

A technology for treating system and industrial wastewater, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of inability to treat industrial wastewater, filter clogging, time-consuming and labor-intensive, etc., to improve fluency and prevent clogging , to ensure the effect of processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

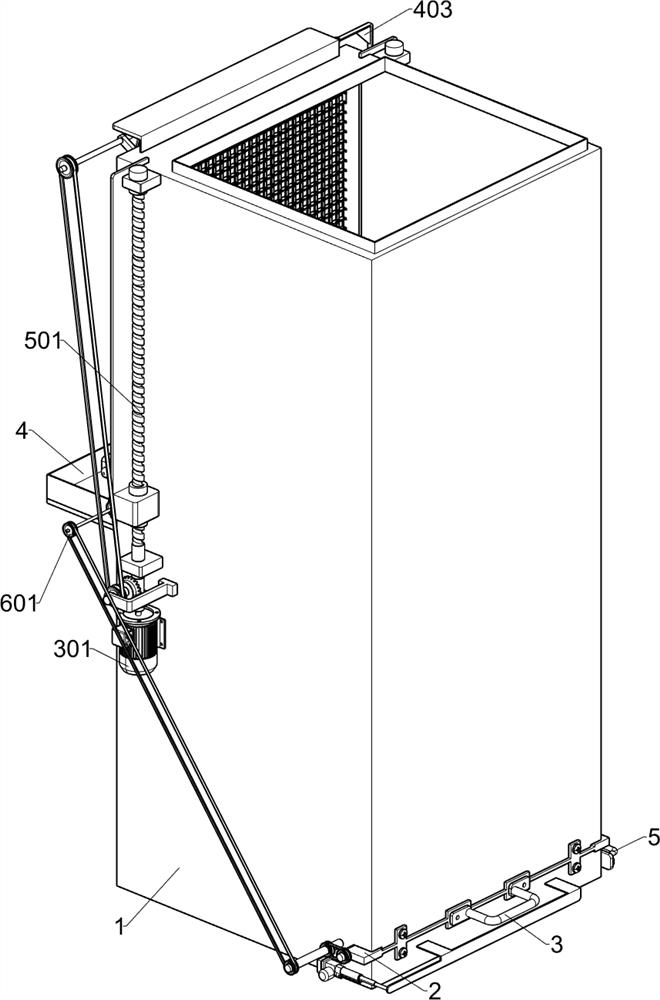

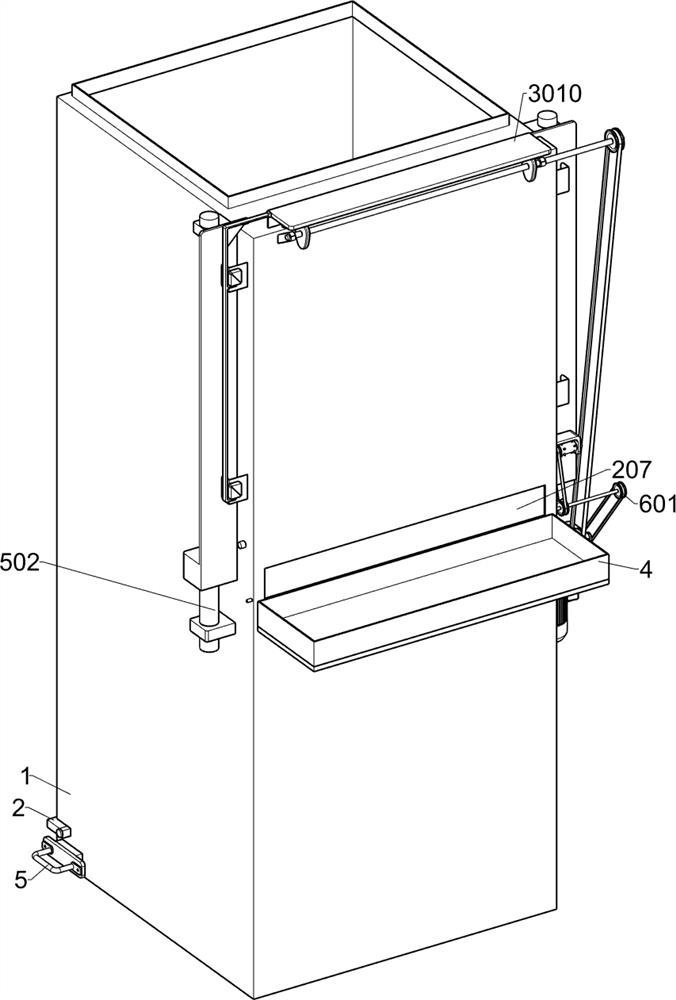

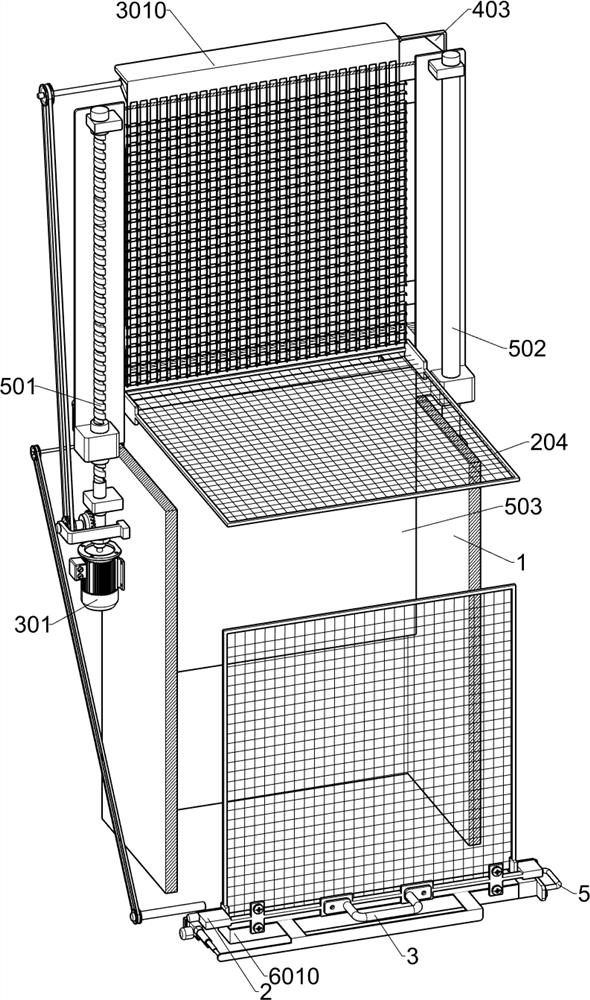

[0030] A new type of industrial wastewater treatment system, such as Figure 1-Figure 8As shown, it includes a filter frame 1, a sealing frame 2, a first handle 3, a first collection frame 4, a second handle 5, an electromagnetic processing system, a primary cleaning system, a secondary cleaning system and a magnetic cleaning system; filter frame 1 right A sealing frame 2 is bolted to the lower part of the side surface; a first collection frame 4 is installed in the middle of the left side of the filter frame 1; a second handle 5 is installed at the lower part of the rear side of the filter frame 1; An electromagnetic treatment system is installed in the middle of the inner side of the filter frame 1 to adsorb and collect harmful metal particles in industrial waste water; a first-level cleaning system is installed on the left side of the upper side of the filter frame 1; System; a magnetic cleaning system is installed on the lower left of the filter frame 1; through the cooper...

Embodiment 2

[0043] On the basis of Example 1, as figure 1 and Figure 9 and Figure 10 As shown, it also includes a continuous treatment system, a continuous treatment system is installed on the lower right side of the filter frame 1, the first drive shaft 205 is connected to the continuous treatment system; the sealing frame 2 is connected to the continuous treatment system; the second handle 5 is connected to the continuous treatment system; continuous The processing system includes a fifth transmission wheel 601 , a fourth transmission shaft 602 , a sixth transmission wheel 603 , a seventh transmission wheel 604 , a second connecting rod 605 , an eighth transmission wheel 606 , a second electromagnetic filter 607 , and a driving member 608 , a sealing cover plate 609 and a second collecting frame 6010; a fifth transmission wheel 601 is fixedly connected to the front side of the outer surface of the first transmission shaft 205; a fourth transmission shaft 602 is rotatably connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com