High-performance green and environment-friendly composite mineral admixture applicable to cement and concrete

A green and environmentally friendly technology for compounding minerals, which is applied in the field of mineral admixtures to reduce preparation costs, ensure water retention and fluidity, and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The environment-friendly composite mineral admixture of the present invention mainly consists of 45 parts of SiO 2 , 18 parts of Al 2 o 3 , 17 parts of CaO, 9 parts of MgO, 7 parts of Fe 2 o 3 , 1.5 parts of SO 3 and 0.05 Cl - Composition, the components of the present invention are used in parts by weight. Among them, the Cl - It is self-contained in various raw materials, and its content is less than 0.06 parts by mass to meet the index standard of concrete. The raw materials of the admixture in this embodiment are wastes such as water-quenched slag from steel mills, fly ash, water-quenched phosphorus slag, silicon dioxide and hemihydrate gypsum, so the cost is quite low. For the convenience of explanation, the raw materials of the admixture in all the embodiments of the present invention are illustrated by taking water-quenched slag, fly ash, water-quenched phosphorus slag and other wastes, silicon dioxide and hemihydrate gypsum as examples. The raw material ...

Embodiment 2

[0036] This embodiment is basically the same as Embodiment 1, and its difference is that the environment-friendly composite mineral admixture in the present embodiment mainly consists of 47 parts of SiO 2 , 16 parts of Al 2 o 3 , 16 parts of CaO, 7 parts of MgO, 5 parts of Fe 2 o 3 , 1.4 parts of SO 3 and Cl of 0.04 - Composition, what the component of this embodiment adopts is by weight. The raw materials used in this embodiment are: 42 parts of water-quenched slag from steel mills, 35 parts of fly ash, 10 parts of water-quenched phosphorus slag, 4 parts of silicon dioxide and 0.08 part of hemihydrate gypsum, Wherein the weight of each raw material used is in parts by weight.

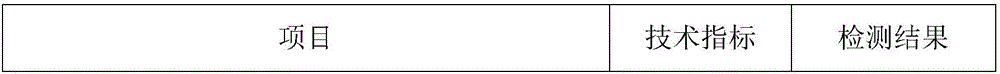

[0037] The present invention detects according to GB / T 51003-2014 "Technical Specifications for the Application of Mineral Admixtures", and its relevant detection indicators are shown in Table 3.

[0038]

[0039] Table three

[0040] As can be known from the final test data in Table 3, the ...

Embodiment 3

[0043] This embodiment is basically the same as Embodiment 1, and its difference is that the environment-friendly composite mineral admixture in the present embodiment mainly consists of 48 parts of SiO 2 , 15 parts of Al 2 o 3 , 14 parts of CaO, 5 parts of MgO, 4 parts of Fe 2 o 3 , 1 part of SO 3 and 0.03 Cl - Composition, what the component of this embodiment adopts is by weight. The raw materials used in this embodiment are: 34 parts of water-quenched slag from steel mills, 40 parts of fly ash, 15 parts of water-quenched phosphorus slag, 6 parts of silicon dioxide and 0.12 parts of hemihydrate gypsum, Wherein the weight of each raw material used is in parts by weight.

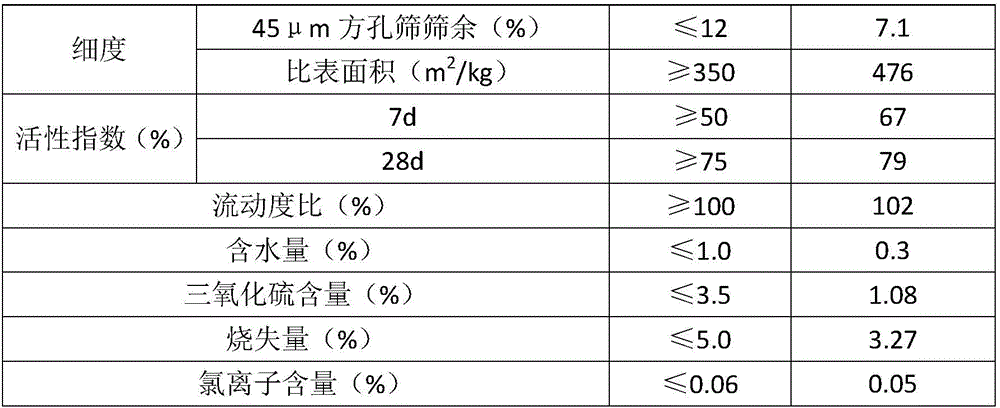

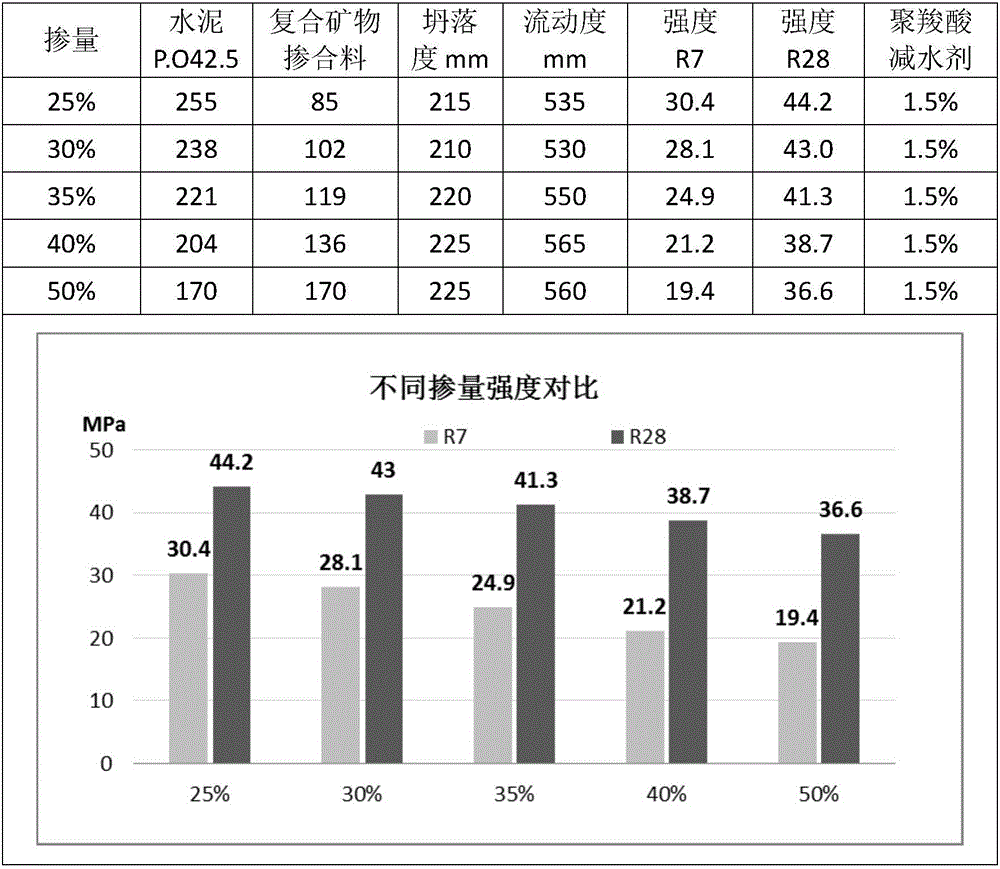

[0044] The present invention detects according to GB / T 51003-2014 "Technical Specifications for the Application of Mineral Admixtures", and its relevant detection indicators are shown in Table 4.

[0045]

[0046] Table four

[0047] As can be known from the final test data in Table 4, the admixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com