Patents

Literature

67 results about "Hazardous metals" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Among the list of wastes considered hazardous because of their toxicity, you’ll find heavy metals. RCRA monitors eight different metallic elements, commonly referred to as the “RCRA 8’s”. These heavy metals include: arsenic, barium, cadmium, chromium, lead, mercury, selenium, and silver.

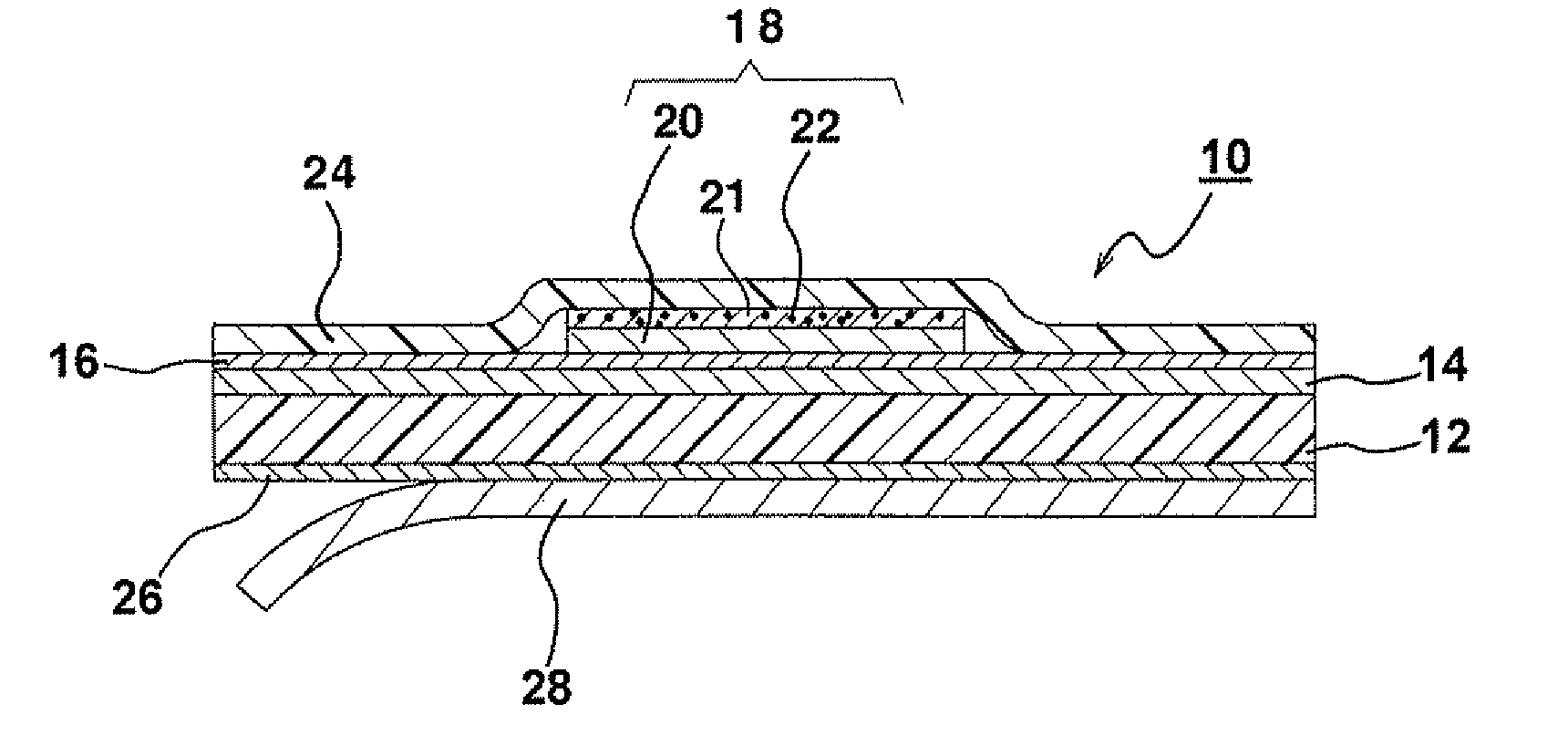

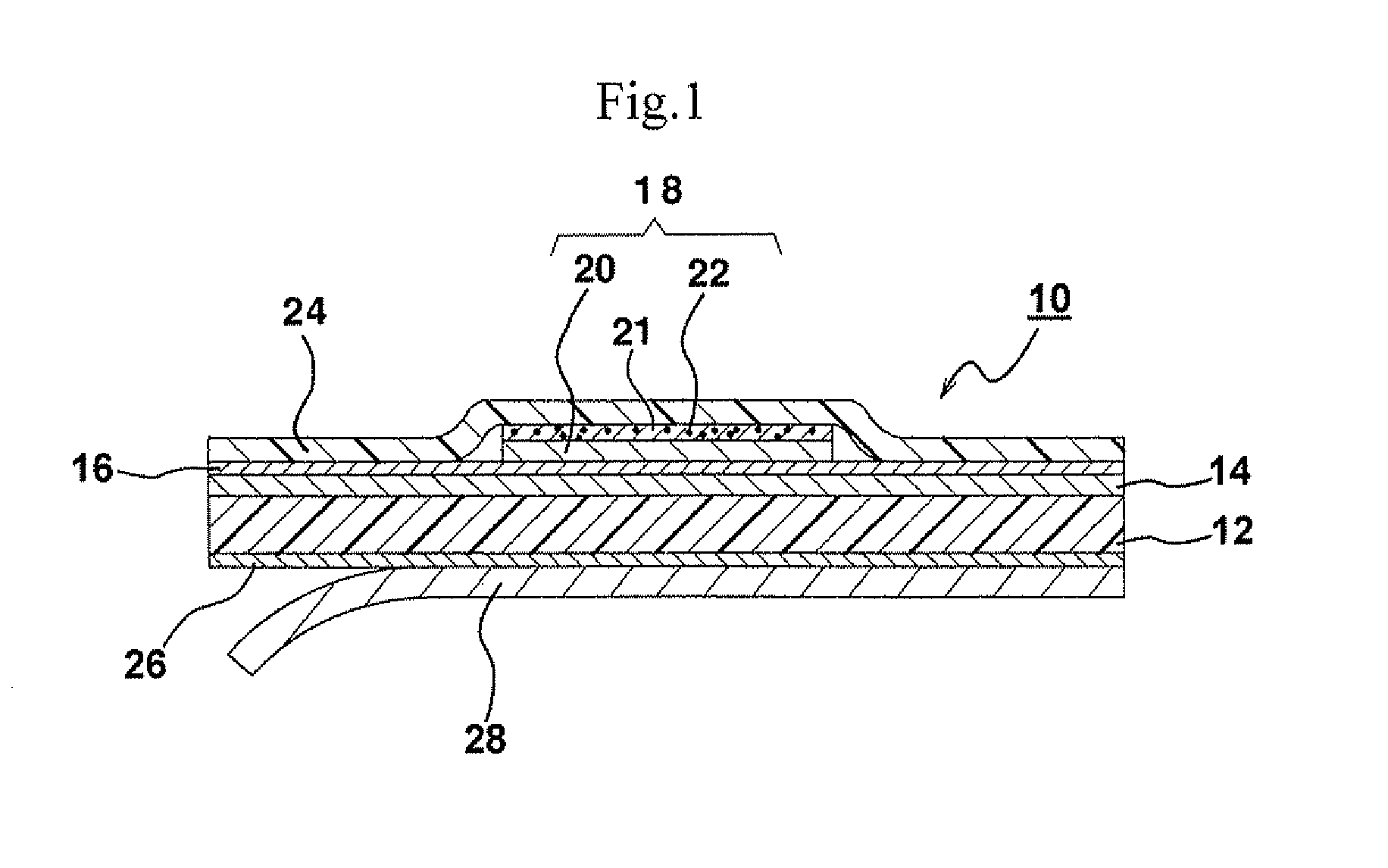

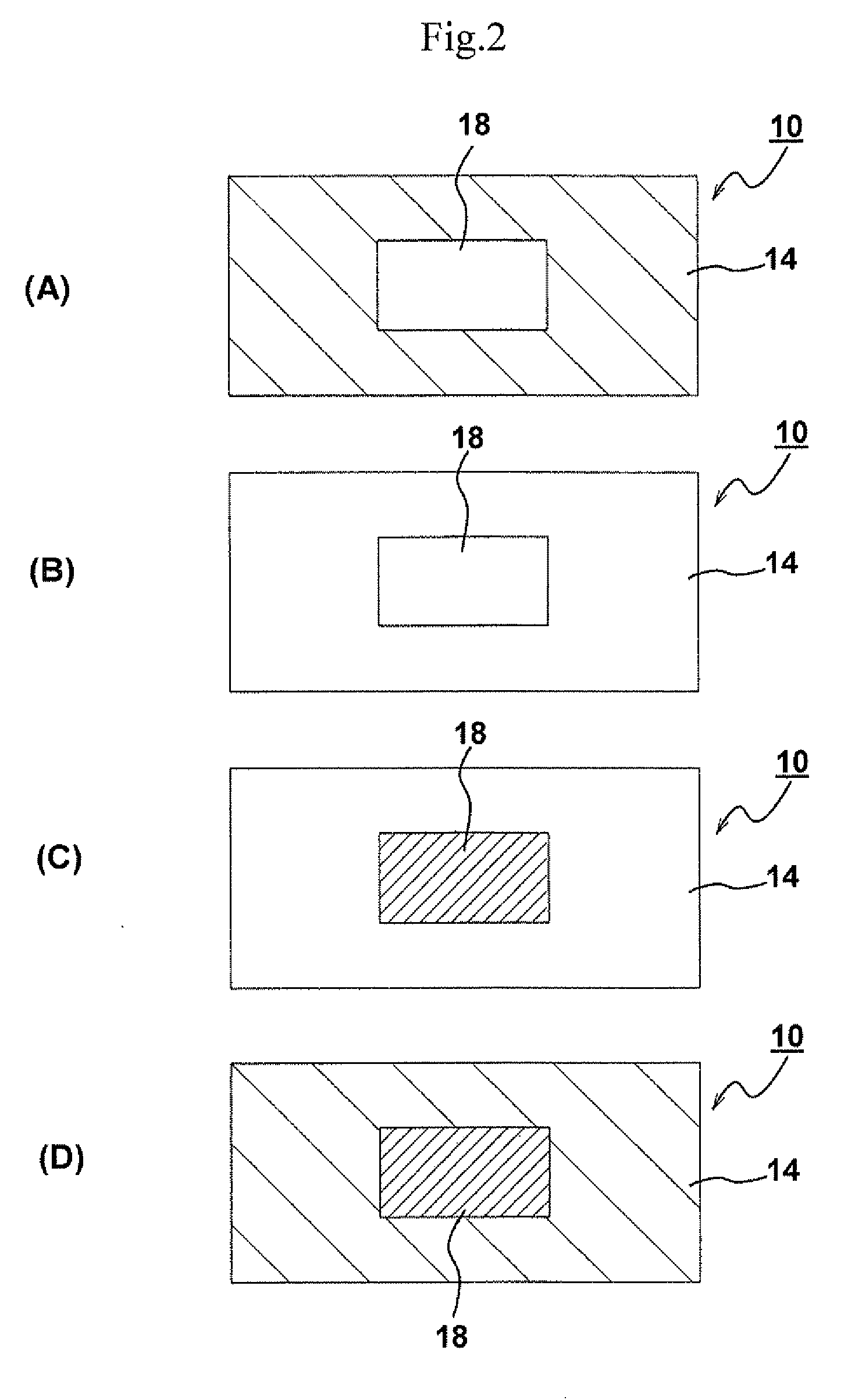

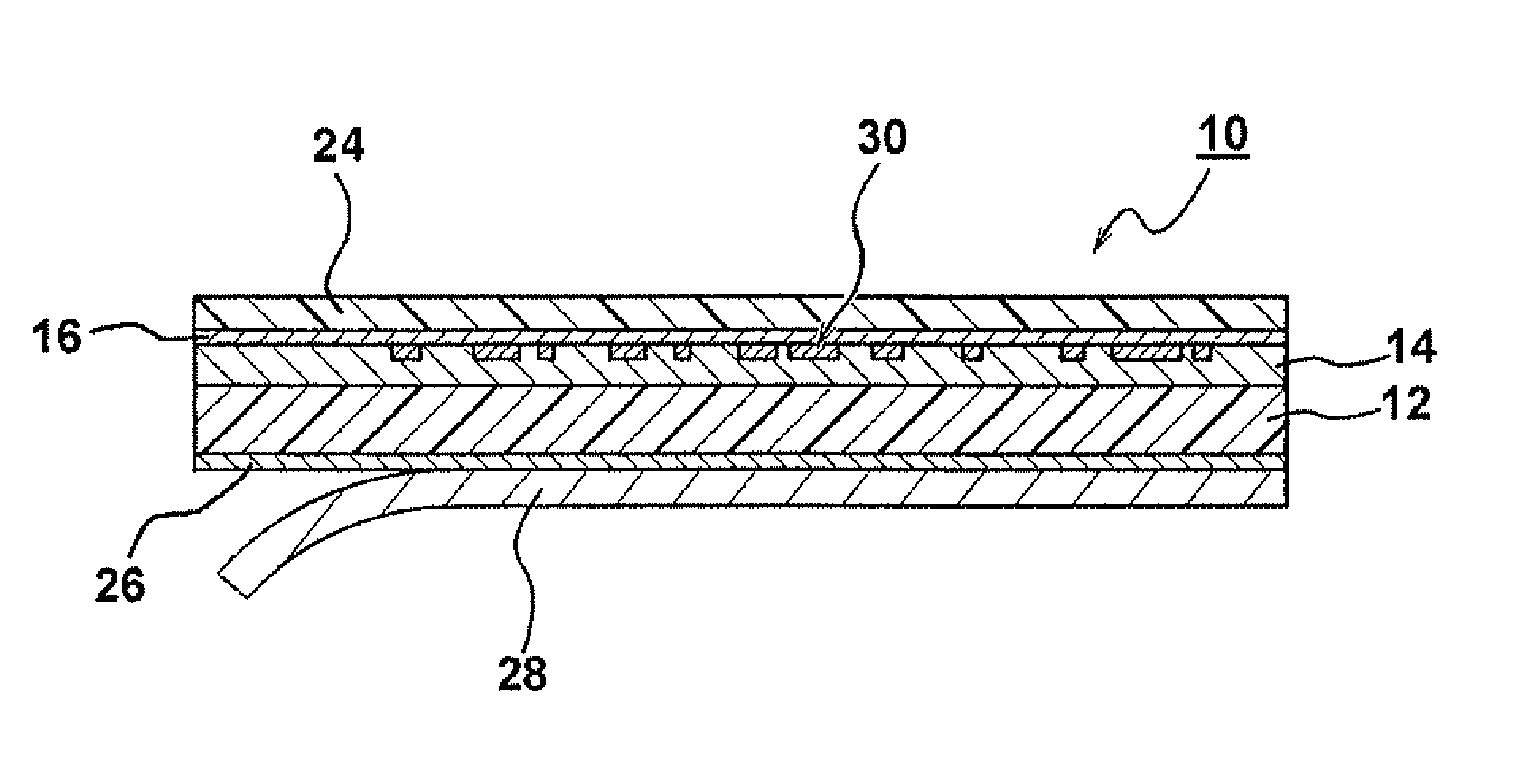

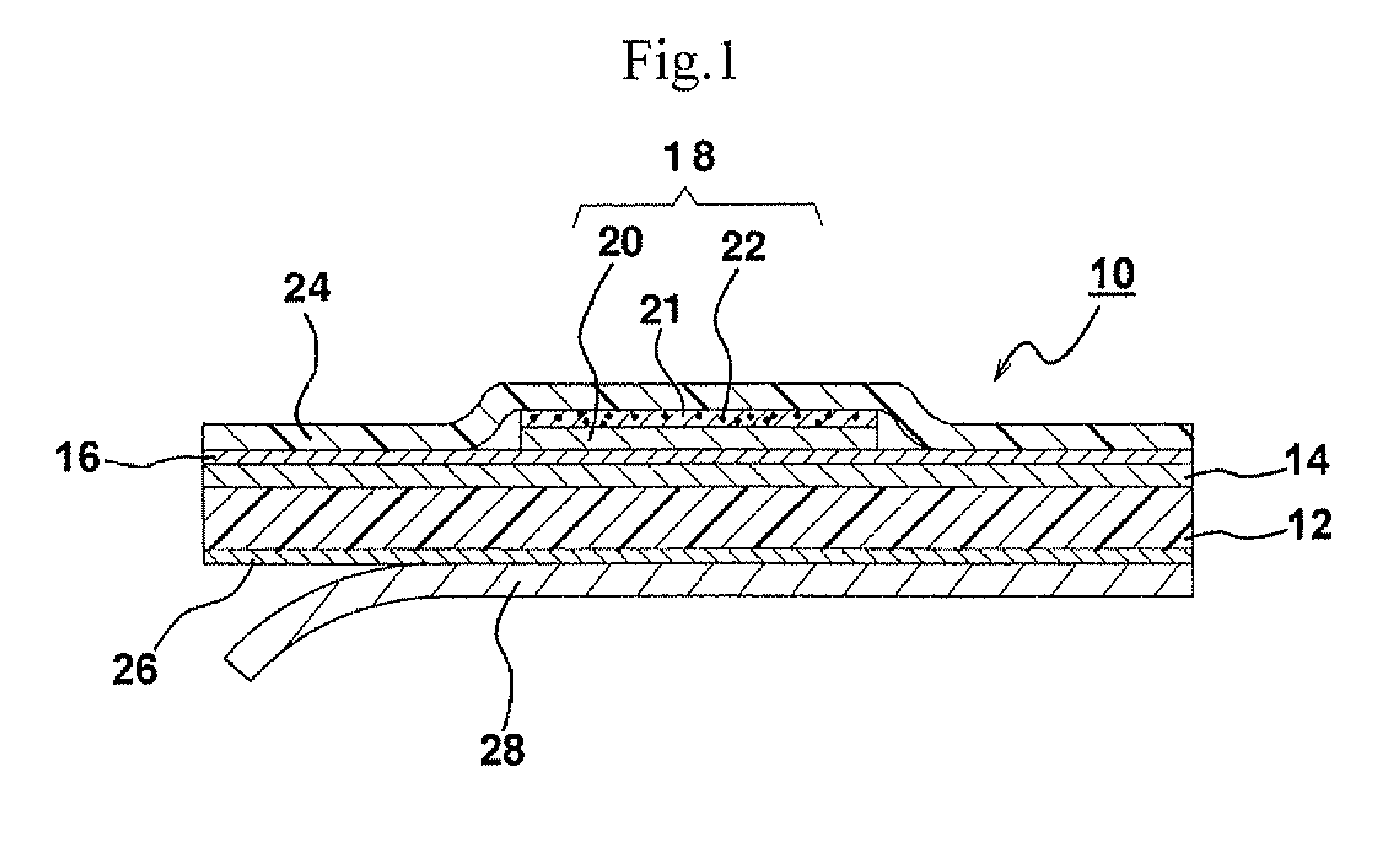

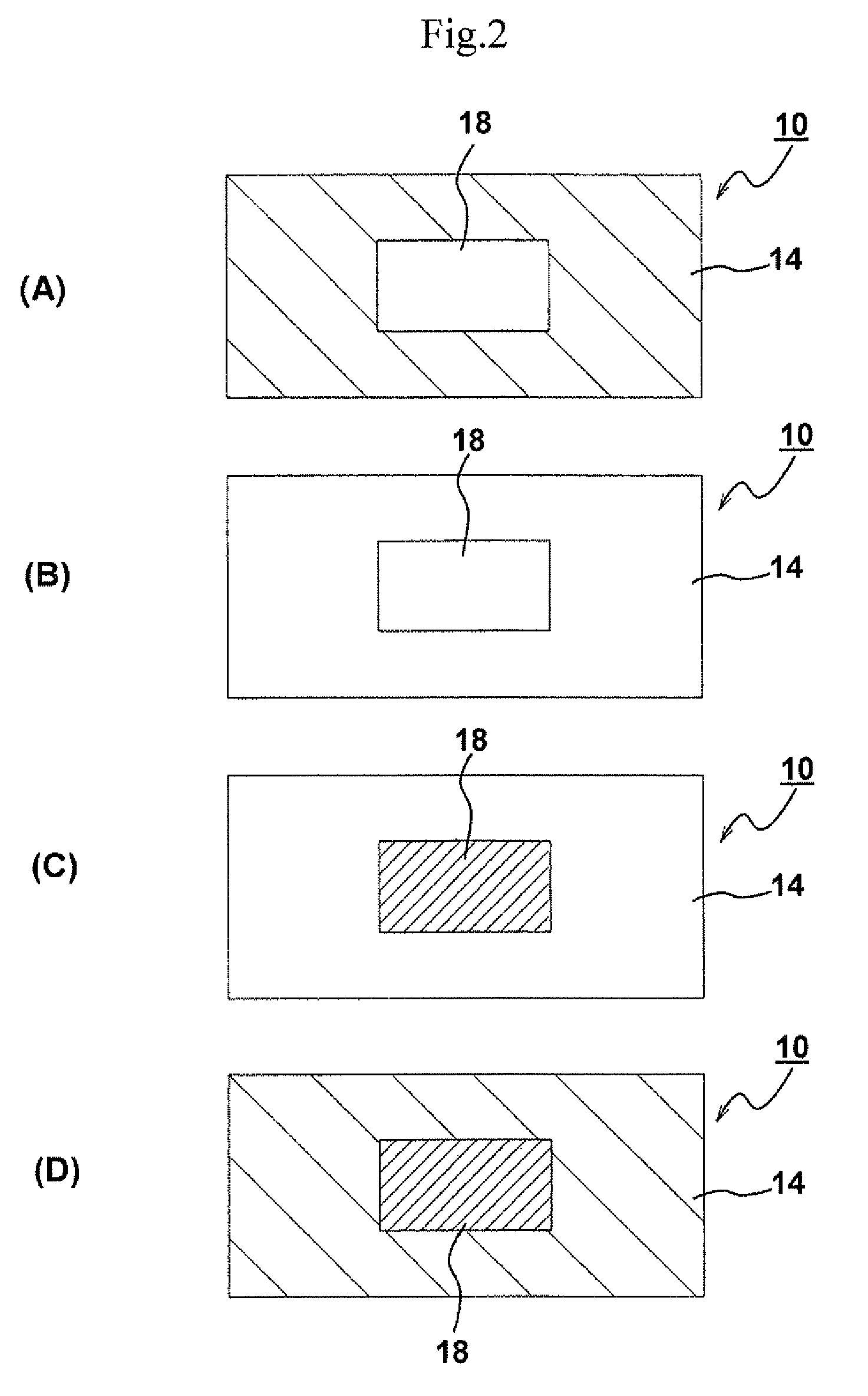

Temperature management indicator and structure having the same attached

ActiveUS20130014690A1Excellent in anti-light durability durabilityLong effective life-timeThermometers using mean/integrated valuesThermometers using physical/chemical changesManagement indicatorsColor changes

A temperature management indictor having simple structure is provided, which, not containing a hazardous metal, especially mercury among others, is safe and excellently durable, especially durable against light and repetition of heating and cooling cycle, is capable of indicating specific temperature ranges by means of reversible color changes, and also is able, as need be, to indicate an arrival at a specific temperature by means of an irreversible color change. A temperature management indicator 10 comprises; a reversible temperature indicating member 14 including reversible temperature indicating pigment particles devoid of mercury, which reversibly undergoes color changes at a predetermined temperature, wherein in the reversible temperature indicating member 14, the reversible temperature indicating pigment particles contain an iron-containing complex compound and are dispensed to be dispersed in a resin thereof.

Owner:NICHIYU GIKEN KOGYO CO LTD

Combinations of liquid filtration media and methods for enhanced filtration of selected water contaminants

InactiveUS20130022686A1Solve Porosity InsufficiencyAvoid bleedingBiocideInorganic active ingredientsFiltrationManganese

By sequentially aligning various filtration media and delivery systems, enhanced synergistic reduction of water contaminants is obtained compared to the prior art or separate use of the individual media / filters. Specific filtration media are formulated with proper proportioning and sequencing to enhance the ability to reduce metals that cause staining, odors and bad taste such as iron, copper and manganese. Also disclosed is the reduction of potentially hazardous metal radionuclides metals such as uranium, iodine, cesium, plutonium and radium. Also disclosed is improved removal of heavy metals such as arsenic, lead, chromium, and mercury as well as organic compounds such as halogenated carcinogenic compounds. The present devices and methods remove specific bacteria and their toxins from water to reduce the risk of dermatitis. Thus, the present invention enhances our ability to achieving cleaner and safer water for drinking, swimming, washing, bathing and cooking.

Owner:HYDROPURE TECH

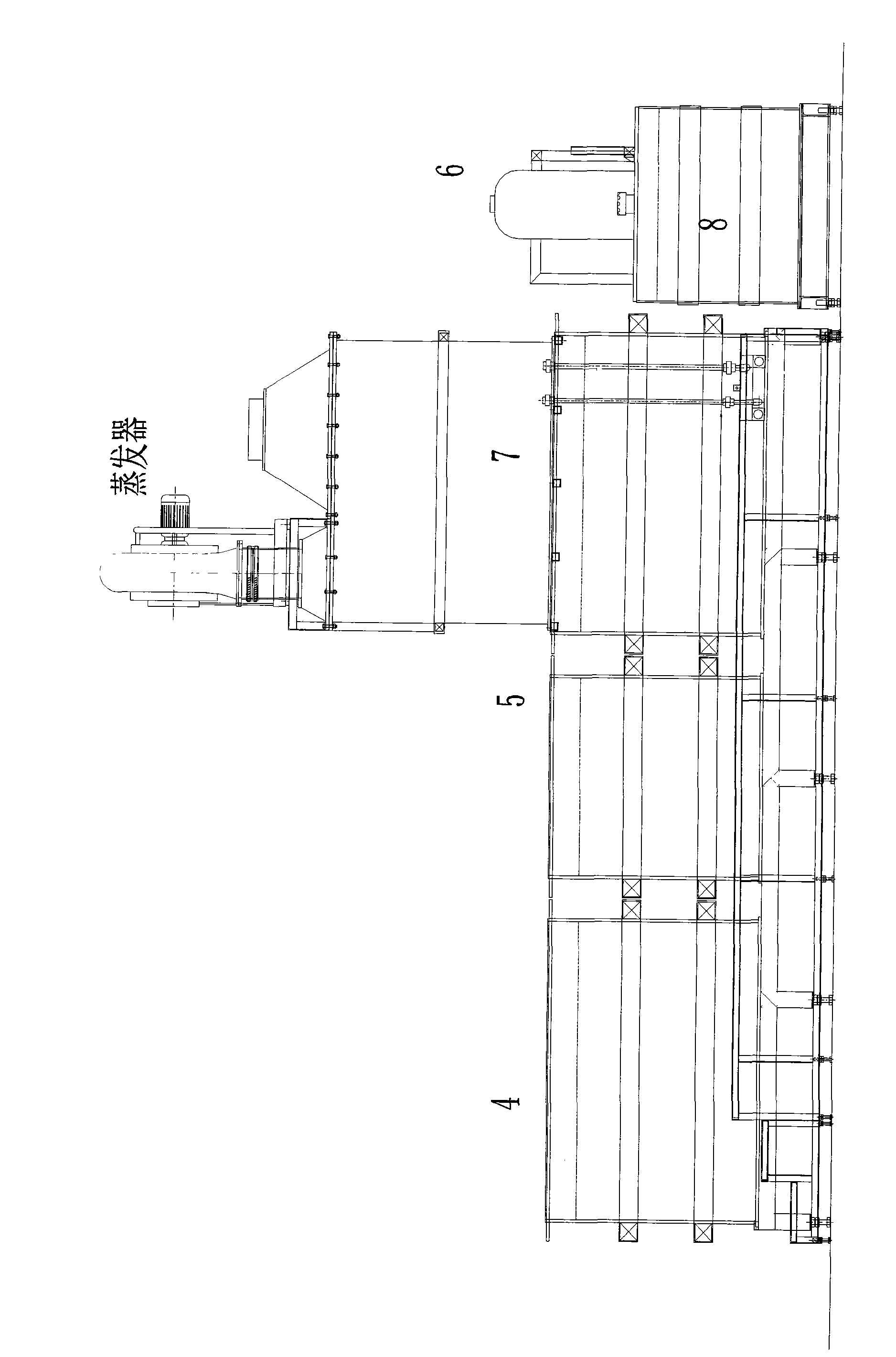

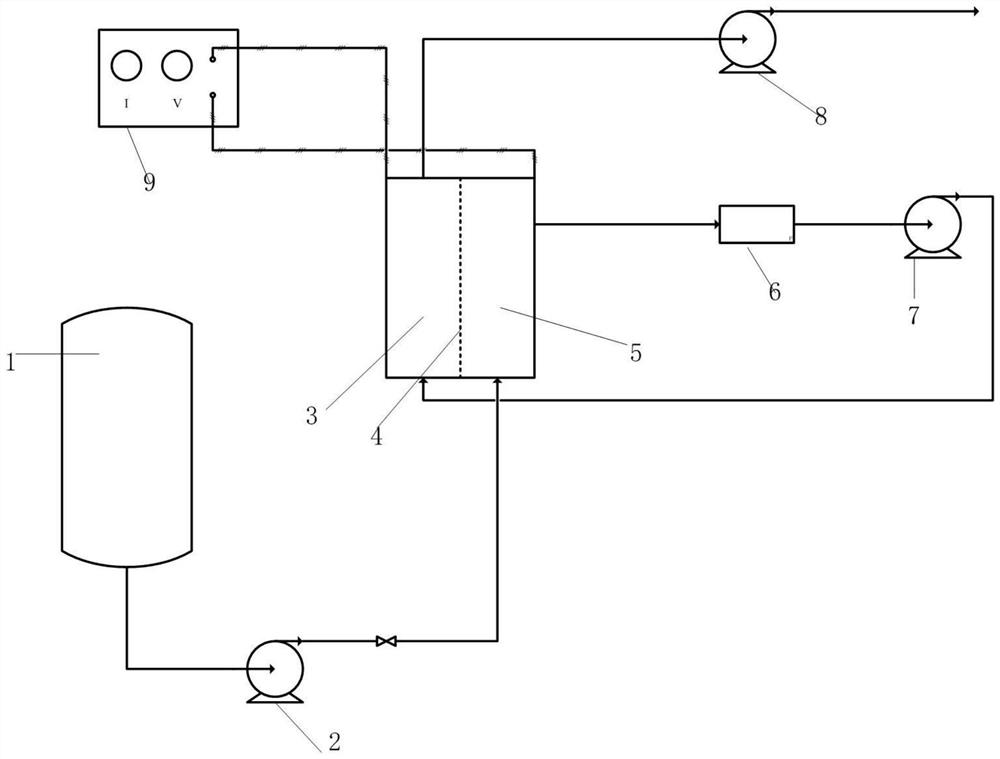

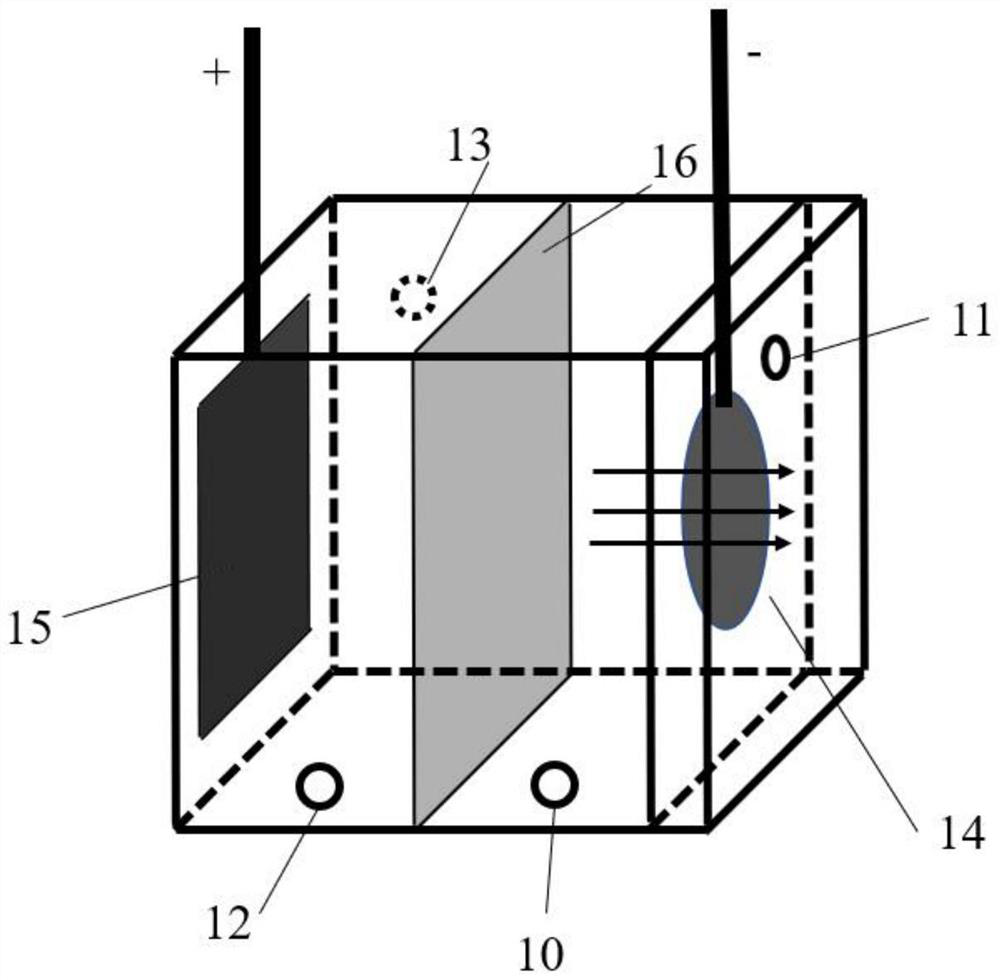

Apparatus and technology for controlling and improving plating solution PH value on fingerprint resistant production chain

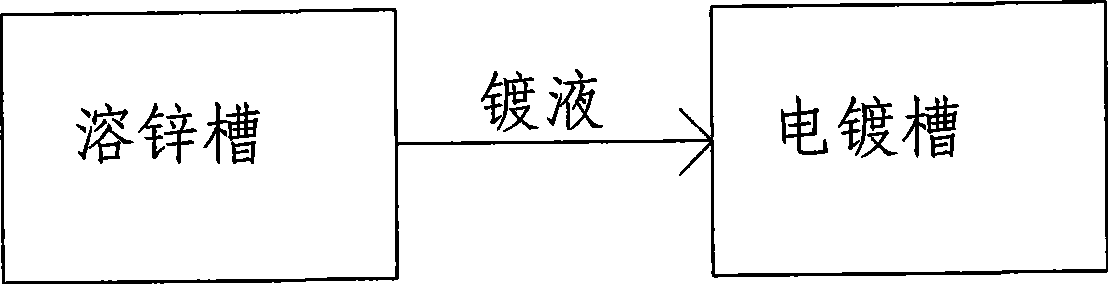

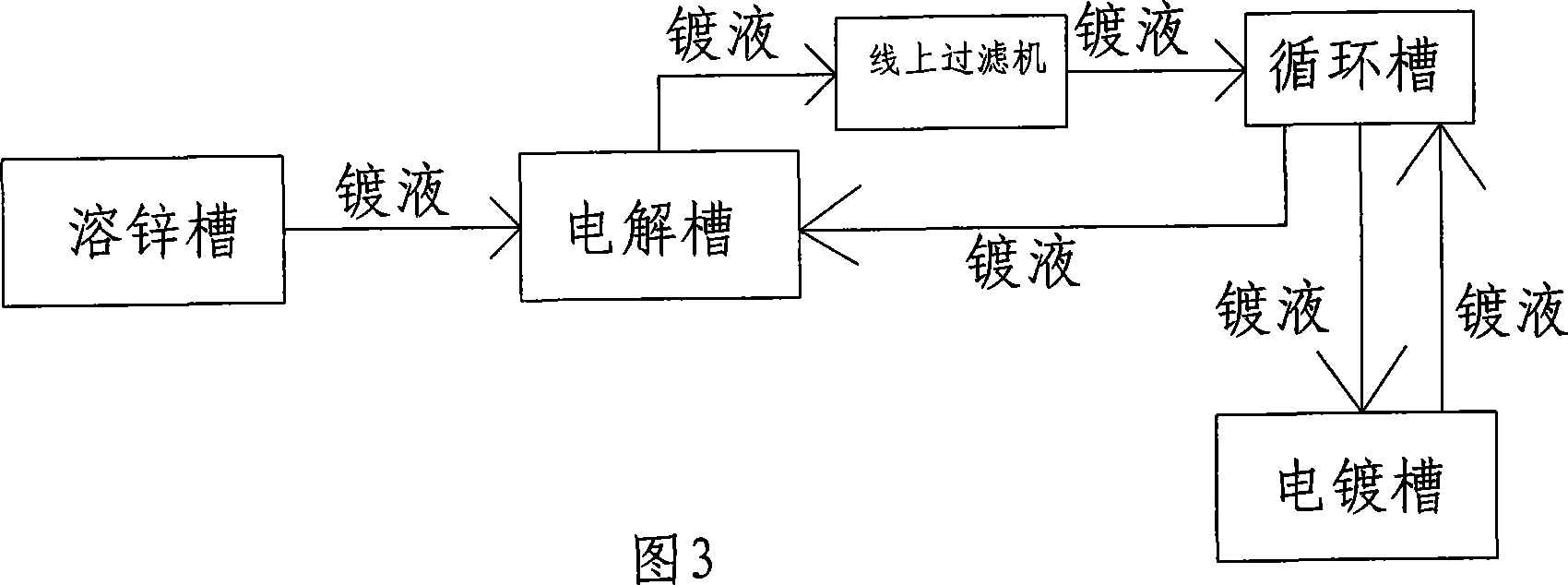

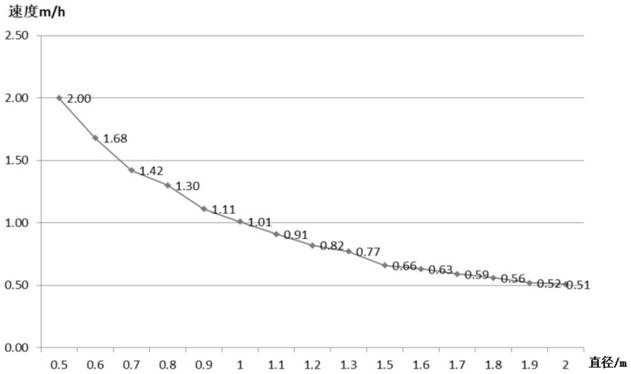

The invention provides a technical method for controlling and raising the PH value of galvanizing solution on a fingerprint resistant continuous and automatic production line of the electro-galvanizing and roller coating of a rolled plate; the galvanizing solution rich in zinc ions enters a galvanizing bath from a dezincification bath; the technique is characterized in that: after entering the galvanizing bath from the dezincification bath, the galvanizing solution enters a circulating tank after going through an on-line filtering machine and then enters the galvanizing bath from the circulating tank; the galvanizing solution in the galvanizing bath returns to the galvanizing bath through the circulating tank; and the galvanizing solution is electrolyzed by the current density of 0.1A / dm<2> to 0.3A / dm<2> in an electrobath. The electrobath is internally provided with three anodes and two cathodes at intervals. The technical proposal has the advantages of not only removing hazardous metal impurities, but also increasing dezincification speed, particularly properly raising the PH value, increasing the overpotential of hydrogen, reducing hydrogen evolution, fining electro-galvanizing layers and reducing electric energy consumption, thereby greatly improving product quality.

Owner:长江润发(江苏)薄板镀层有限公司

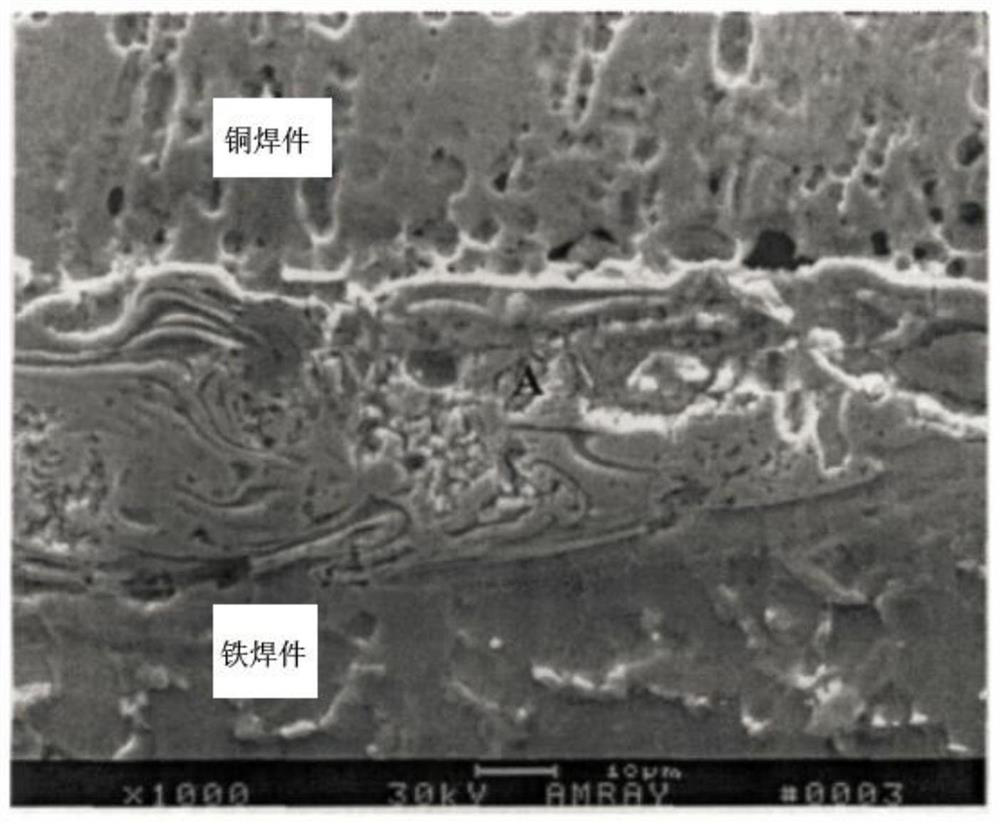

Heat releasing welding powder formula

InactiveCN104107990AQuality assuranceEnsure safetyWelding/cutting media/materialsSoldering mediaIron powderAluminium powder

The invention provides a heat releasing welding powder formula. The basic components of the formula of heat releasing welding powder are mixed copper oxide powder, aluminum powder and other auxiliary materials. One kind of the mixed copper oxide powder is copper oxide sheets with the oxidation rate being over 80%, the oxygen content being 13.5% and the particle size ranging from 30 meshes to 100 meshes, and the other kind of the mixed copper oxide powder is the mixed copper oxide powder with the oxidation rate being 50% to 75% and the particle size ranging from 30 meshes to 100 meshes obtained by mixing copper oxide wires with the oxidation rate being 40% to 60%. The aluminum powder is flaky atomizing aluminum powder with the particle size ranging from 40 meshes to 60 meshes. The other auxiliary materials are mixed powder of iron powder, fluorite powder, silicon iron powder and silicon dioxide powder, and the particle size ranges from 100 meshes to 200 meshes. The heat releasing welding powder formula does not contain phosphorus, sulfur, lead, tin, magnesium and other poisonous metal. The heat releasing welding powder formula adjusts the reaction speed and the reaction temperature by adjusting the oxidation rate and the particle size of the mixed copper oxide powder, and is stable in welding, free of splashing and free of welding seam defect.

Owner:江苏安荣电气设备有限公司

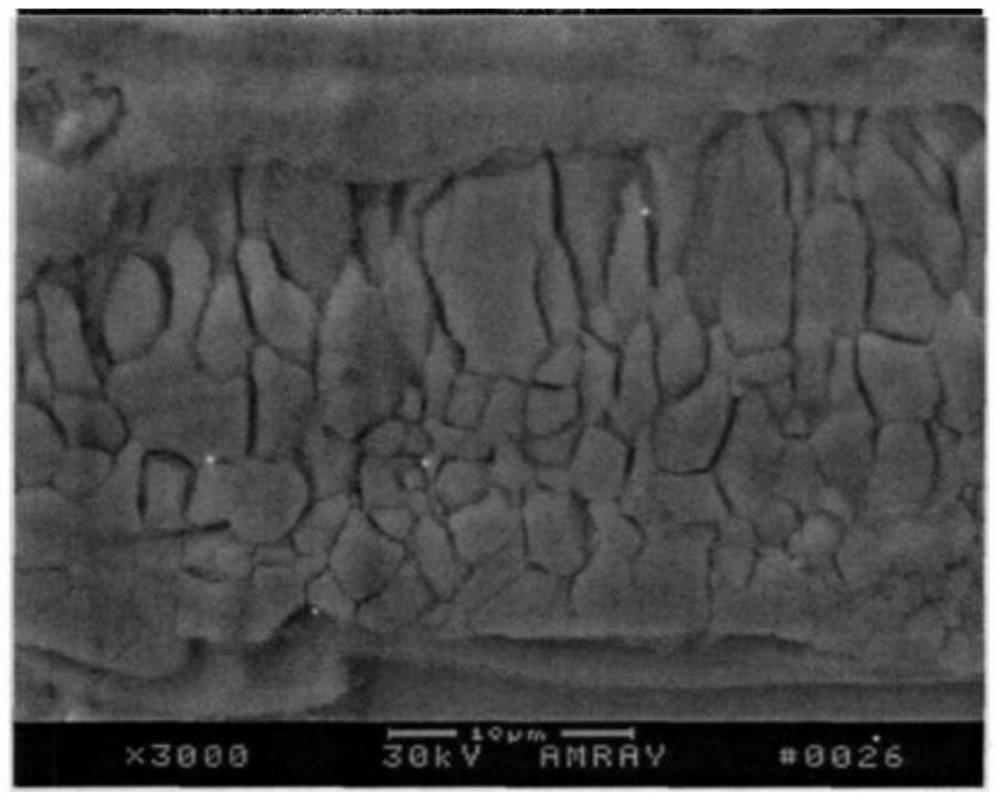

Method for removing aging copper foil plating solution detrimental impurities

InactiveCN101245486AEfficient removalBath Performance RecoveryCellsHigh concentrationActivated carbon

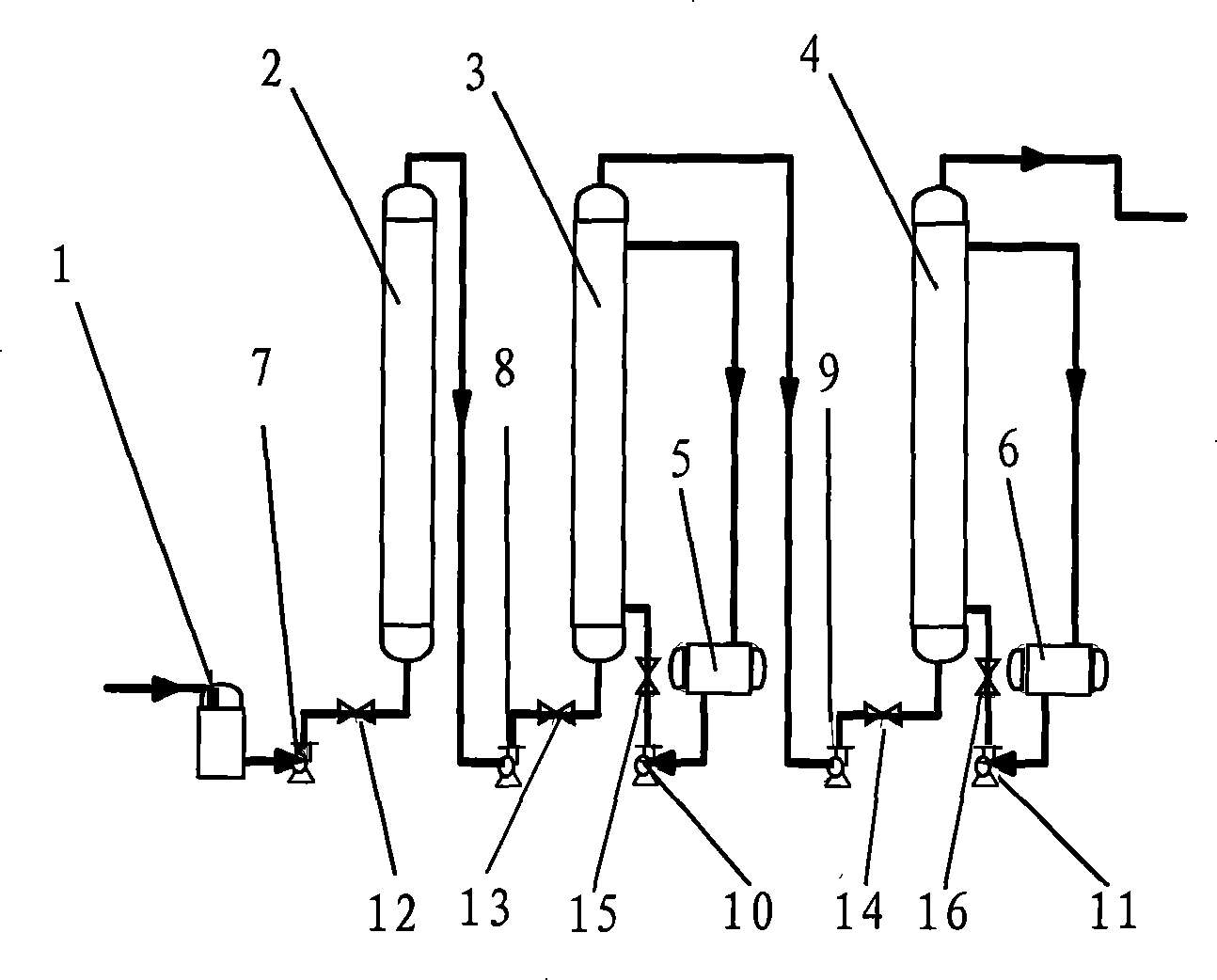

The invention provides a method for removing hazardous matters in plating bath of an ageing copper foil, aiming at overcoming the defects of the traditional industrial processing method that ageing plating bath is discharged, which seriously pollutes environment and activated carbon has poor absorbability for CI<-> and poisonous metal and the absorption of the activated carbon does not have selectivity and copper sulphate with high concentration in the plating bath is also absorbed, thus being easily saturated, having short period, etc. The method uses a purification processing unit, adopts absorption combining activated carbon and ion exchange resin. On the premise that the plating bath is not discarded, hazardous metal ions such as Zn, Fe, Cr, Pb, Sb, As, etc. and organic pollutants with comparatively high concentration in the plating bath are removed. Highly acidic ion exchange resin and weakly alkaline ion exchange resin are respectively contacted with a regenerant and are produced after reaching saturated absorption. The method for removing hazardous matters in plating bath of the ageing copper foil has the advantages that on the premise that the plating bath is not discarded, the hazardous metal ions, Cl<->, organic pollutants with comparatively high concentration in the plating bath are removed; the method for removing hazardous matters in plating bath is characterized by high purification rate, strong selectivity and having resin reproduced that can be reused and does not pollute environment, etc., thus having good economic benefits.

Owner:SHENYANG NORMAL UNIV

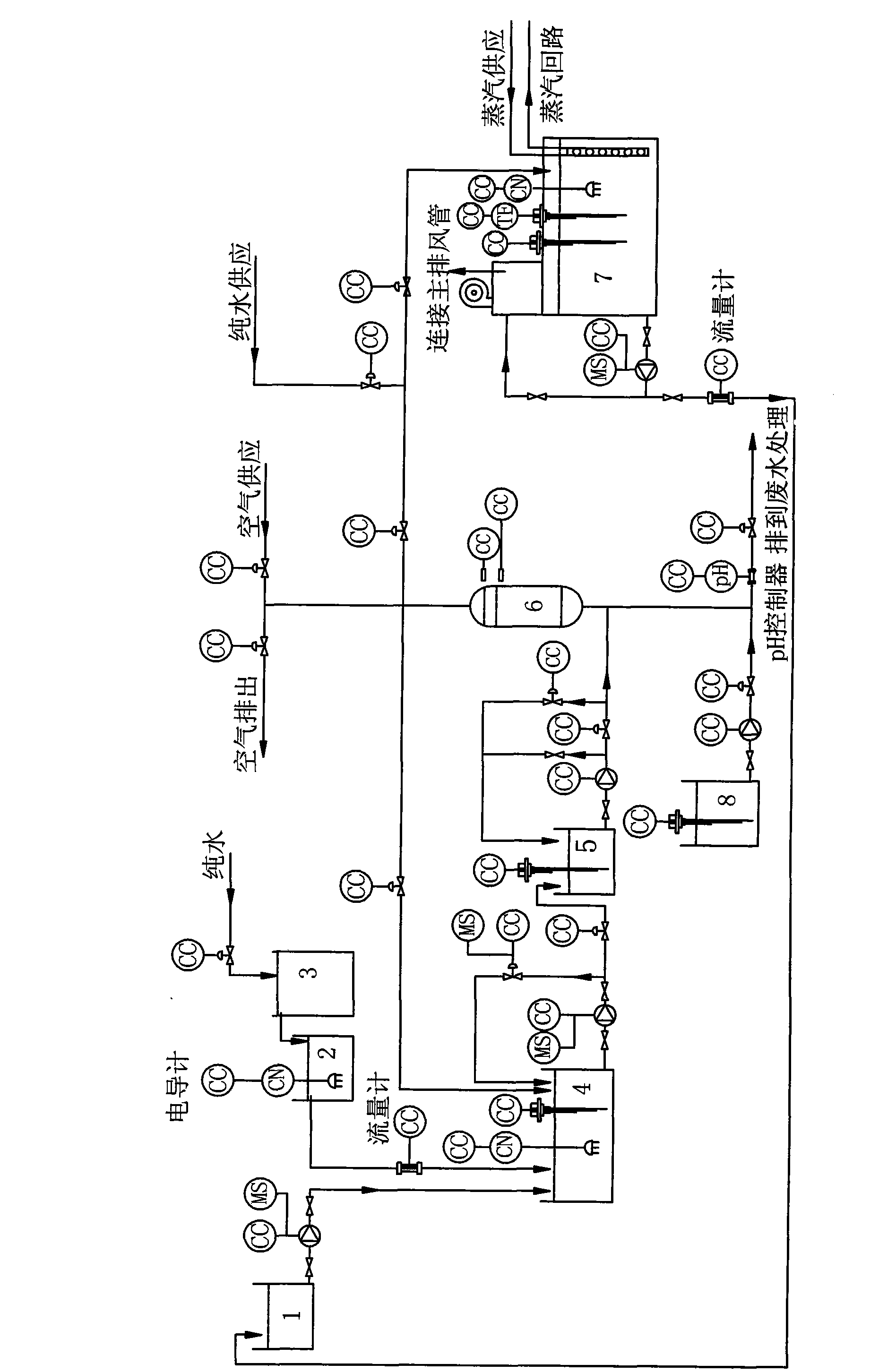

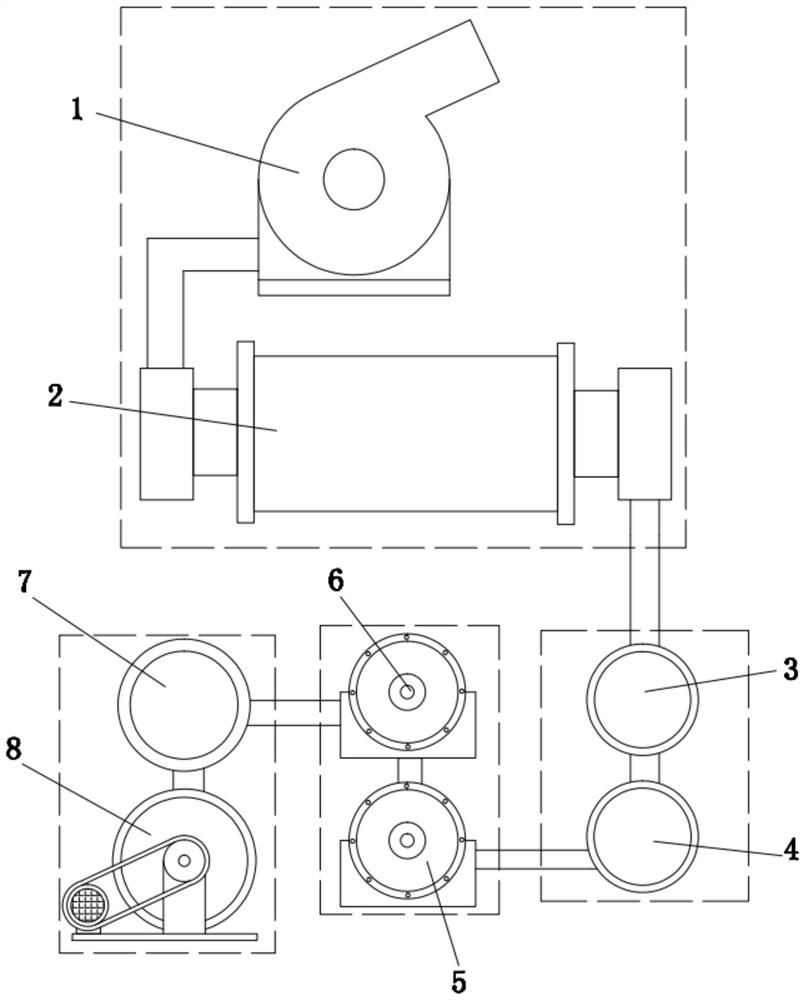

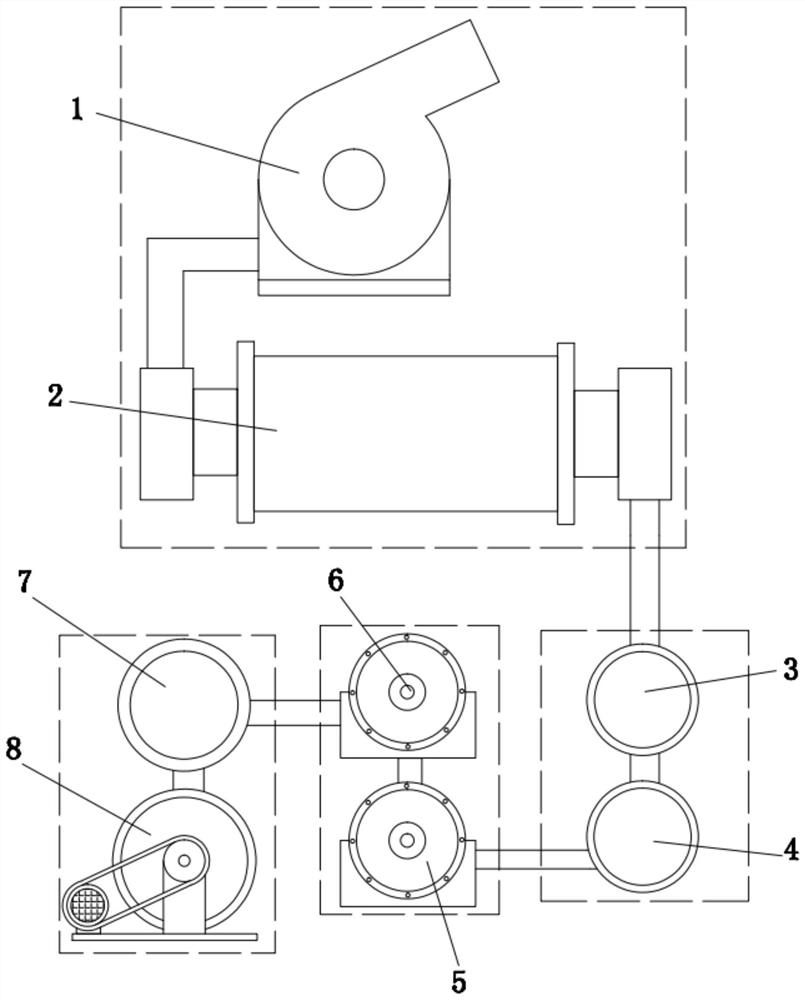

Method and device for purifying and recycling chromium electroplating solution and waste solution thereof

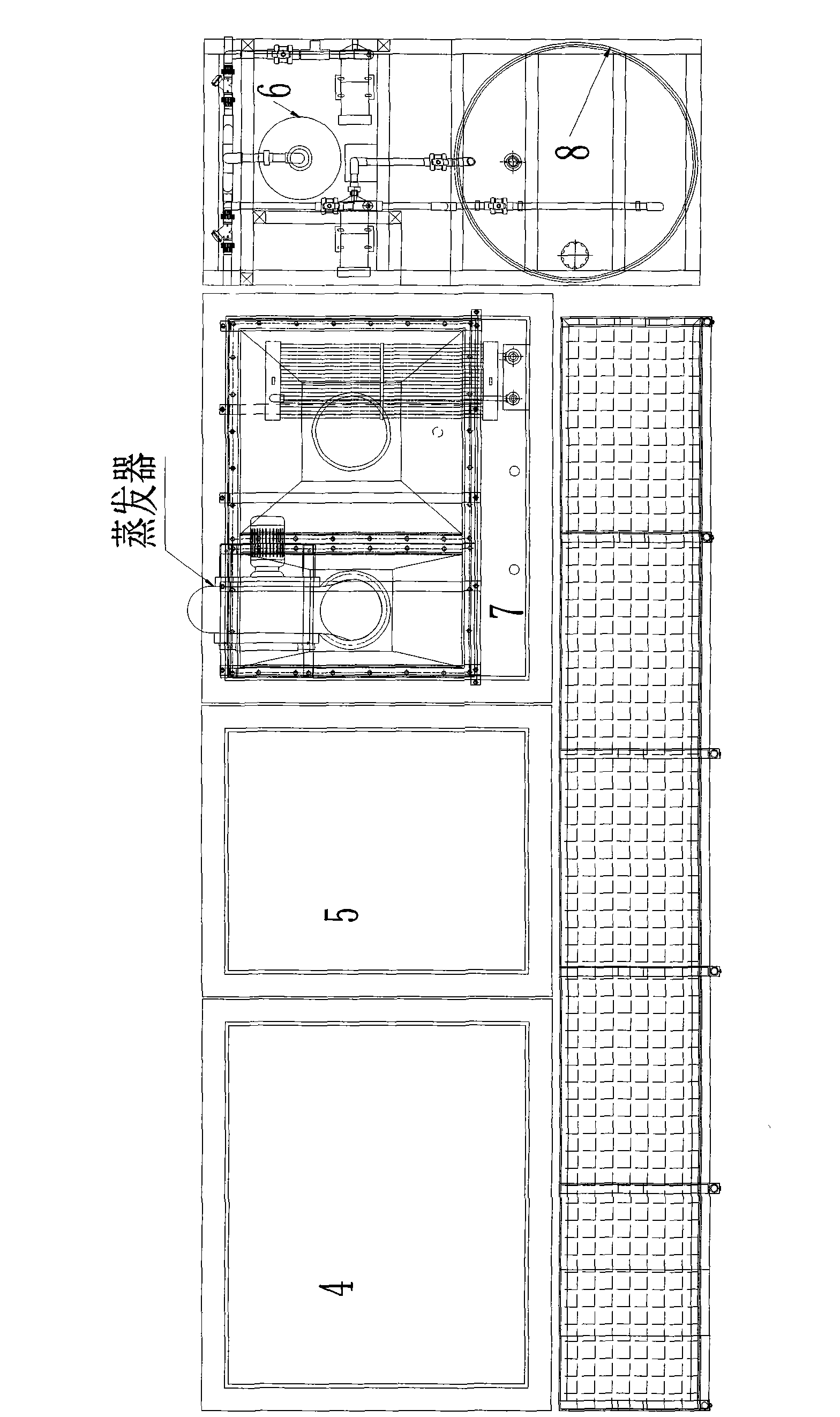

The invention discloses a method and a device for purifying and recycling a chromium electroplating solution and a waste solution thereof. The method directionally solves the problem of metal pollutions and comprises the following steps: adopting a purification apparatus to effectively eliminate various harmful metallic impurities such as copper, zinc, nickel, iron and the like; concentrating the solution after the purification; and finally recycling the solution into an electroplating bath, wherein the recycling rate reaches more than 95 percent. Simultaneously, through an automatic control system, the electroplating bath, a recovery tank, the purification apparatus, a concentrating device, an analysis meter and the like are combined together organically to achieve full automatic operation. The method and the device solve the problem that the chromium electroplating solution cannot be recycled in clean production for years in China. The method avoids a large quantity of chromium-containing wastewater discharges, effectively saves additional supplementation of chromic anhydride at the same time, and obtains double produce effects of recycling economy and clean production.

Owner:东莞庞思化工机械有限公司

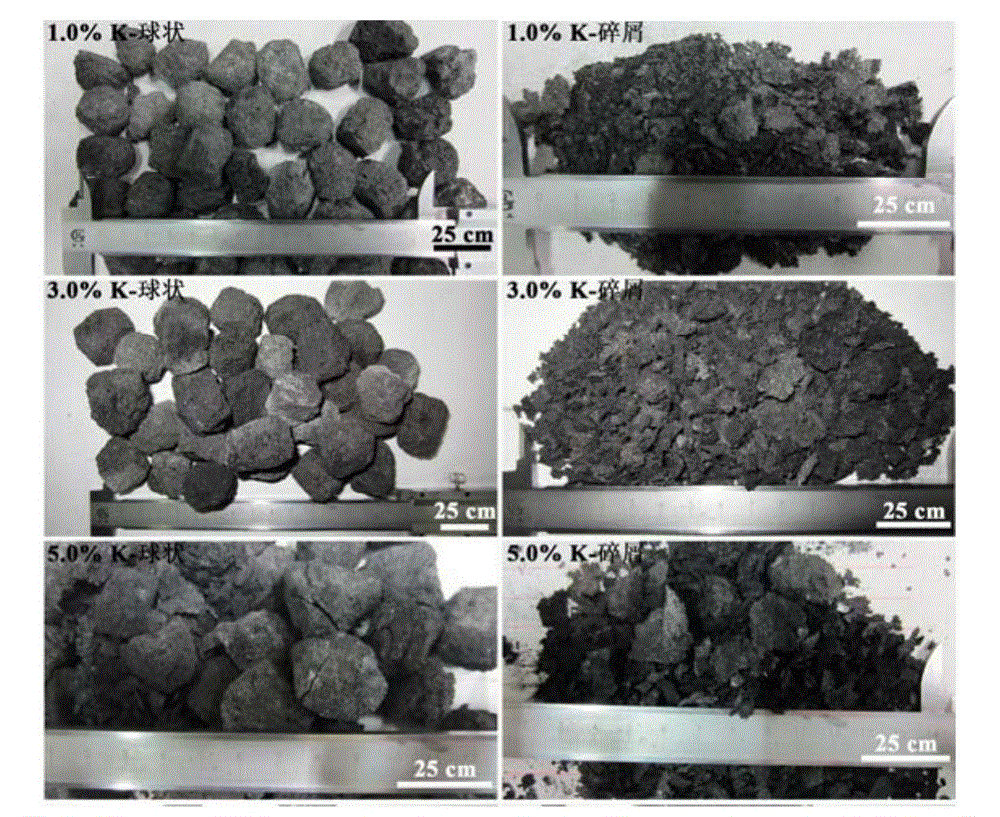

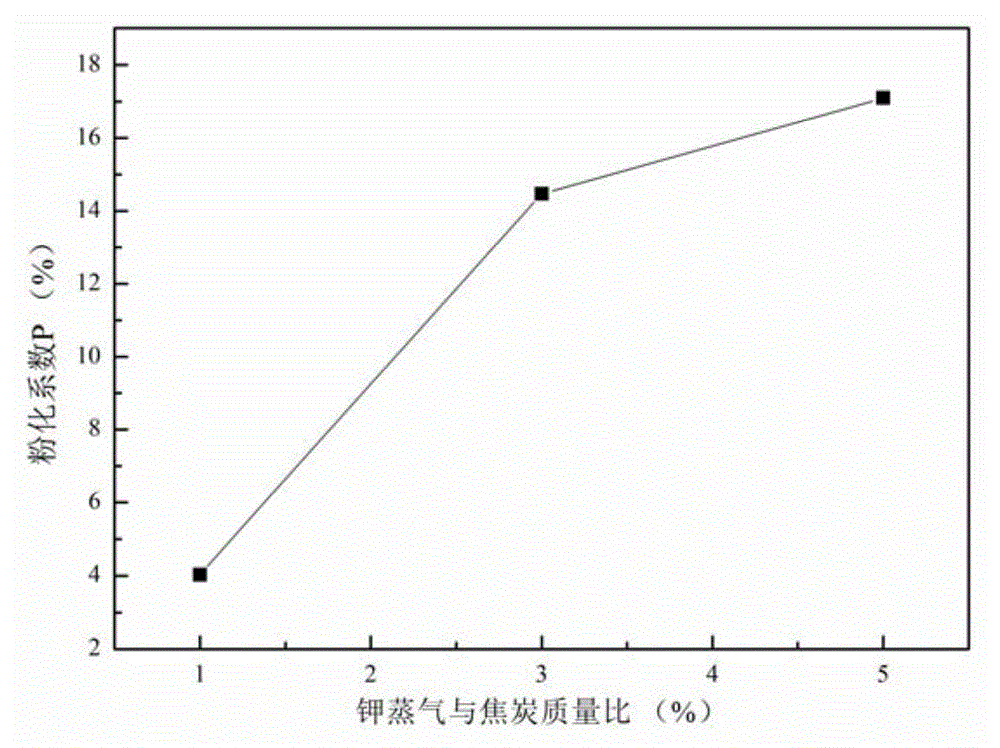

Method for testing destructive effect and performance impact of alkali metal and zinc vapor to coke

ActiveCN104316429ADistinguishing direct destructive effectsDistinguishing the degree of impact of deteriorationWeighing by removing componentWeather/light/corrosion resistanceThermal stateMuffle furnace

The invention discloses a method for testing the destructive effect and the performance impact of alkali metal and zinc vapor to coke. The method comprises the following steps: uniformly mixing excessive active carbon powder and alkali metal carbonate or zinc oxide, arranging the mixture in a corundum crucible internally provided with a step, arranging a porous corundum gasket on the step in the crucible, arranging a reacting coke sample on the gasket, covering a cover, keeping a container in a sealing state; arranging the container in a constant-temperature region of a muffle furnace, raising the temperature to 1300 DEG C at a certain rate, keeping the temperature for 90min to ensure that metal steam is completely absorbed by coke; after reacting, recording the mass of a coke sample with the particle size being more than 23mm, calculating the specific gravity of the pulverized coke; and testing a thermal state performance of a sample which is eroded by metal vapor. The method is capable of singly representing a direct destructive effect of the metal vapor to the coke, is beneficial to finding a relationship between the steam enrichment and the coke performance, and provides a quantization basis for reasonably controlling an alkali load and a zinc load which are charged in a blast furnace.

Owner:UNIV OF SCI & TECH BEIJING

Temperature management indicator and structure having the same attached

ActiveUS9145514B2Excellent in anti-light durability and durabilityLong effective life-timeThermometer detailsThermometers using mean/integrated valuesManagement indicatorsColor changes

A temperature management indictor having simple structure is provided, which, not containing a hazardous metal, especially mercury among others, is safe and excellently durable, especially durable against light and repetition of heating and cooling cycle, is capable of indicating specific temperature ranges by means of reversible color changes, and also is able, as need be, to indicate an arrival at a specific temperature by means of an irreversible color change. A temperature management indicator 10 comprises; a reversible temperature indicating member 14 including reversible temperature indicating pigment particles devoid of mercury, which reversibly undergoes color changes at a predetermined temperature, wherein in the reversible temperature indicating member 14, the reversible temperature indicating pigment particles contain an iron-containing complex compound and are dispensed to be dispersed in a resin thereof.

Owner:NICHIYU GIKEN KOGYO CO LTD

Method for treating incinerated fly ash with harmful heavy metals

The invention relates to a method for treating incinerated fly ash with harmful heavy metals, and provides a method capable of enabling waste particularly harmful heavy metals especially to be separated from the fly ash generated by a garbage incinerator. The invention is characterized in that quartz sand and water are added in the waste incinerated fly ash with harmful heavy metals, and using a wet turbine taper for screening and separating the harmful heaving metals.

Owner:YING CHENG ENVIRONMENTAL TECH +1

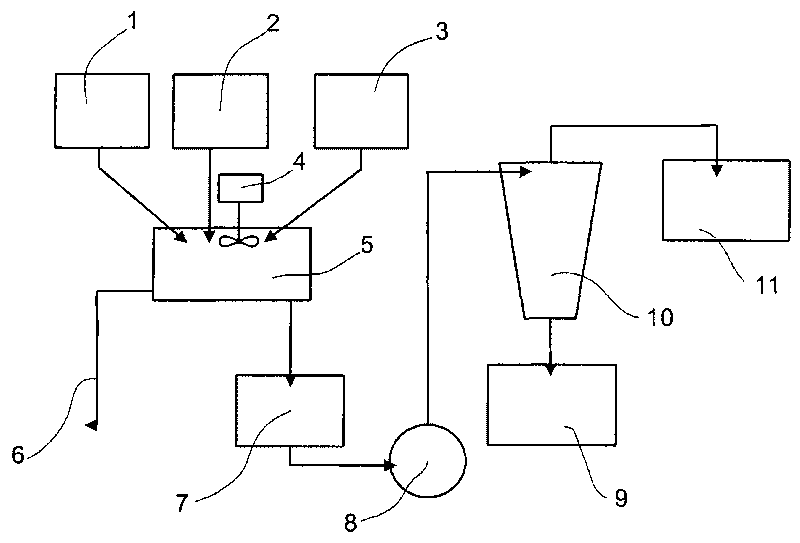

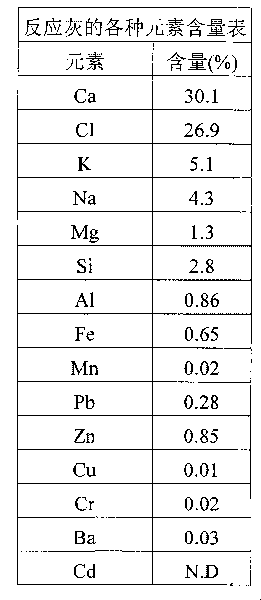

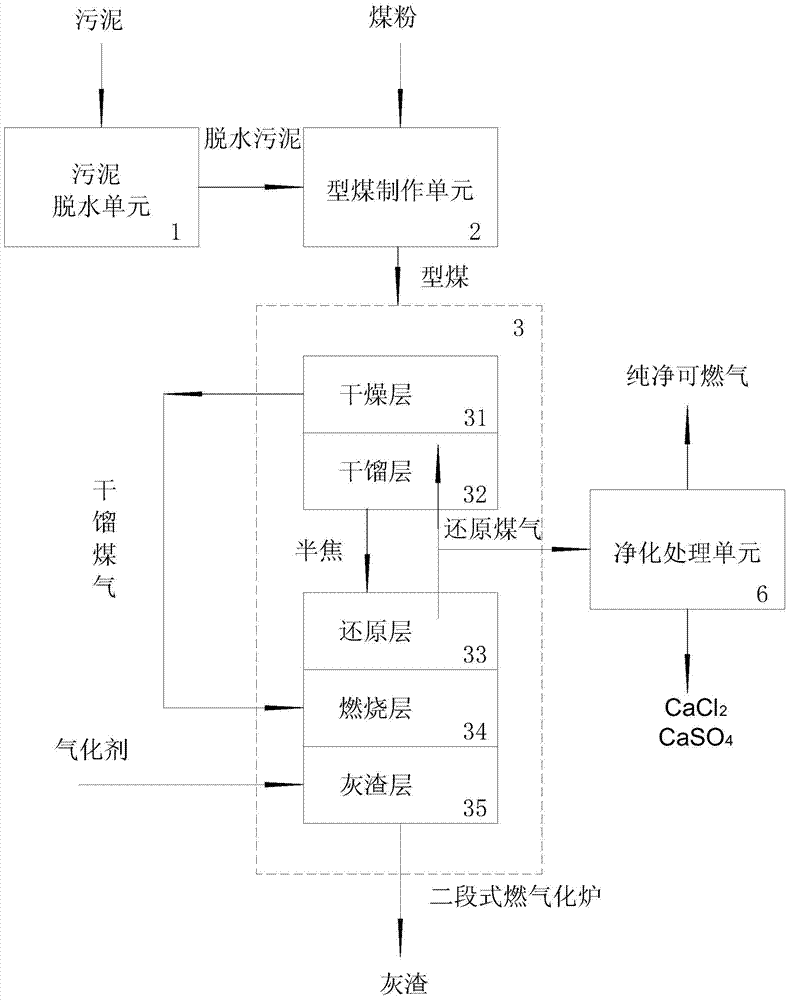

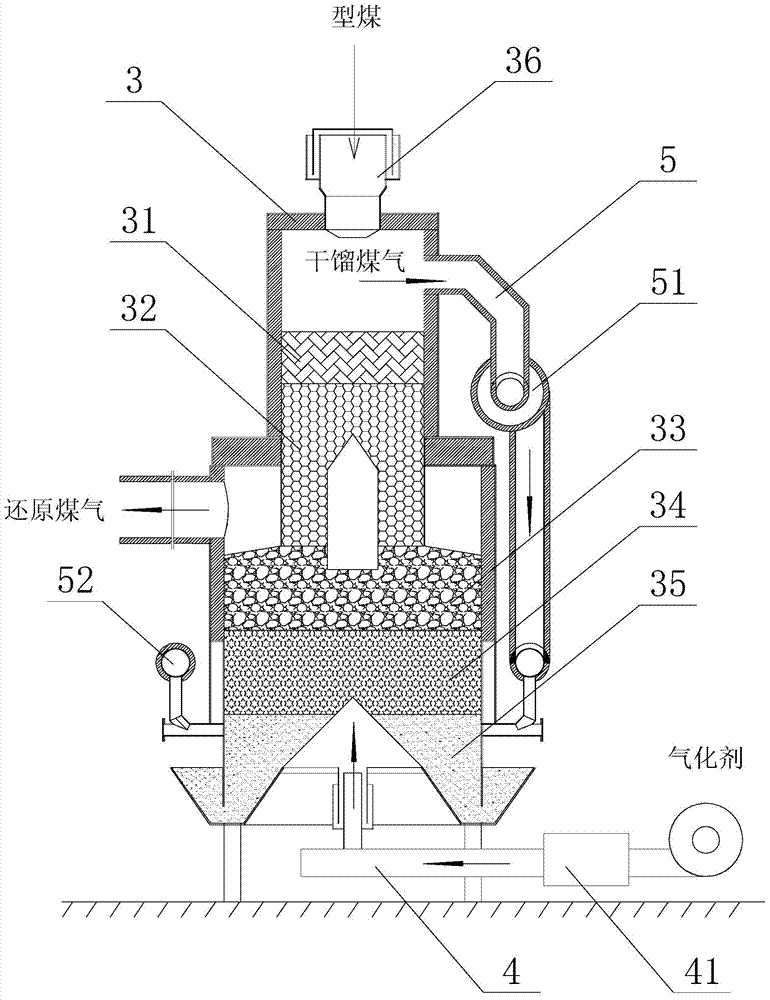

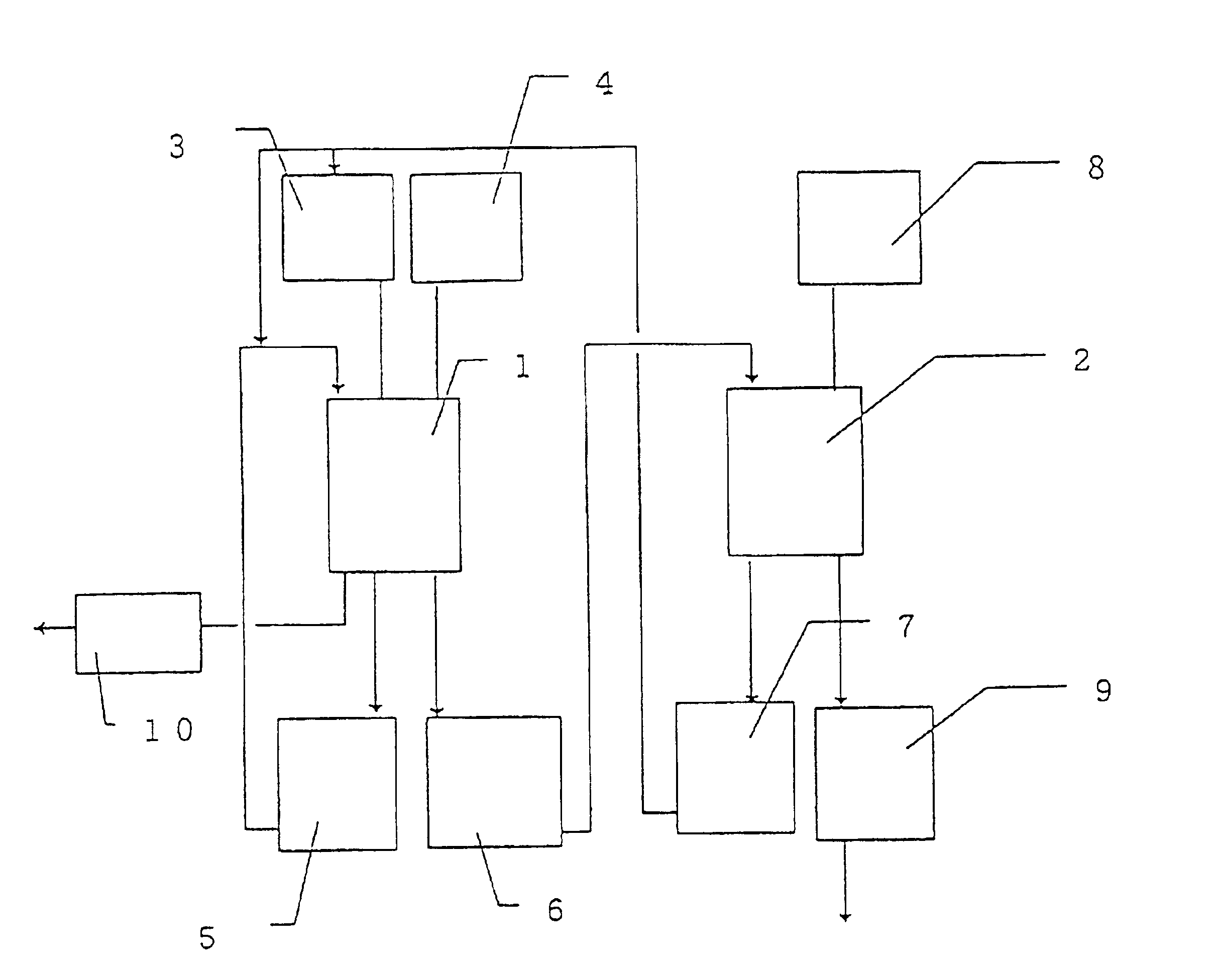

Two-section sludge gas-generating treatment method and two-section sludge gas-generating treatment device

InactiveCN104211271ASatisfy requirements for safe handlingIncrease profitSludge treatmentSpecial form destructive distillationCoal briquetteDewatered sludge

The invention discloses a two-section sludge gas-generating treatment method and a two-section sludge gas-generating treatment device. The treatment device includes a sludge dewatering unit, a coal briquette manufacturing module and a sludge combustion treatment unit. In the invention, dewatered sludge is mixed with pulverized coal to manufacture coal briquettes and the coal briquettes are subjected to high-temperature pyrolysis in a two-section gas-generating furnace so that reduced coal gas can be produced through combustion of the sludge fully. Meanwhile, the coal briquettes are subjected to further dehydration and drying and anaerobic destructive distillation through high-temperature reduced coal gas. Destructive-distilled coal gas generated in the destructive distillation process is fed into the gas-generating furnace again for being used in combustion so that toxic and harmful substances in the destructive-distilled coal gas are completely eliminated. Meanwhile, harmful metal elements, such as copper, zinc, lead, chromium, arsenic and the like, which are not easy to deform, in the sludge enter into fused ash residue and are solidified after temperature decreasing, thereby satisfying a requirement of safe treatment.

Owner:ZHEJIANG DEQIAN ENERGY SAVING TECH

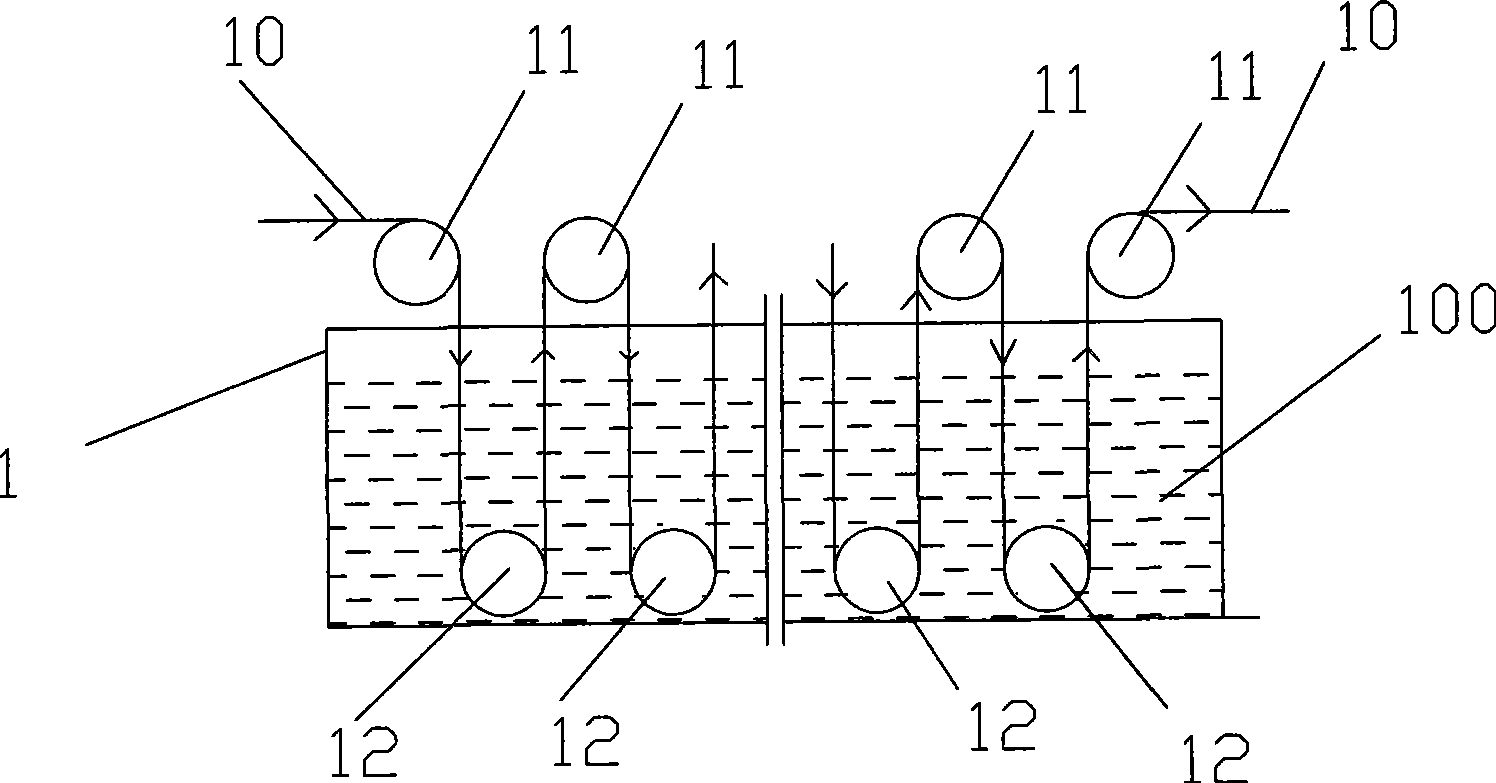

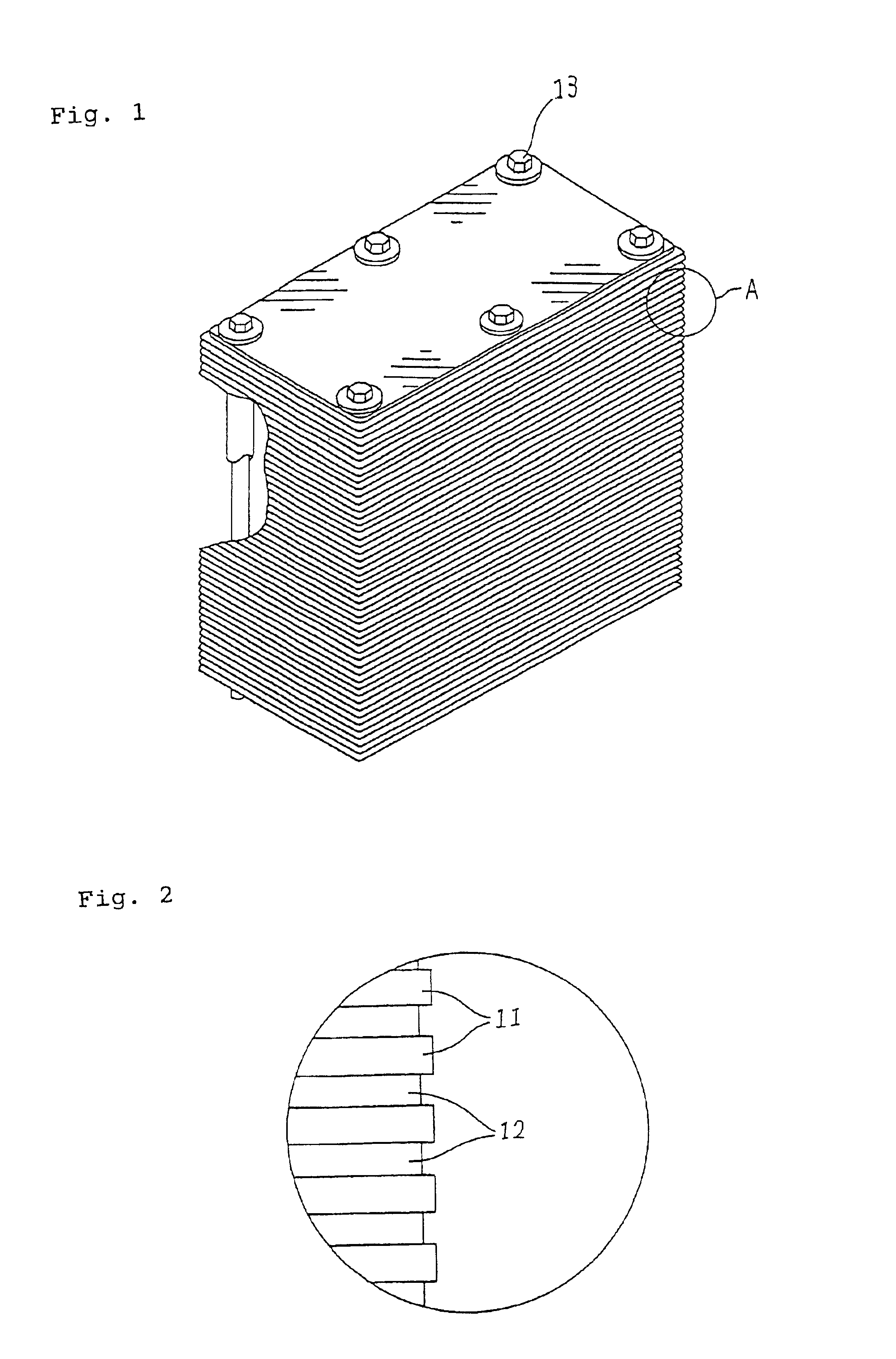

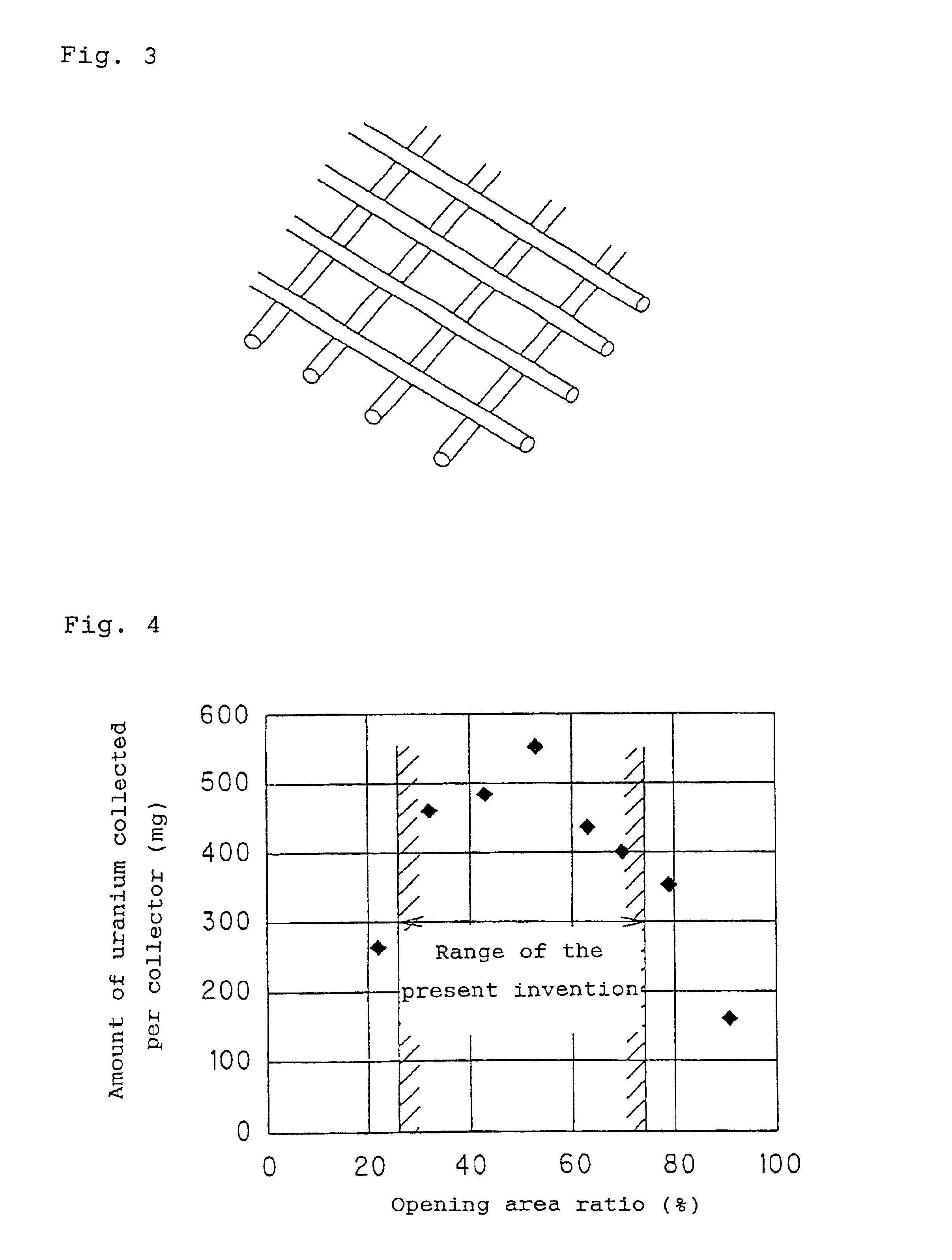

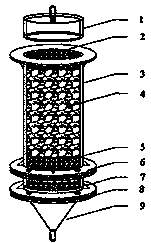

Metal-collecting apparatus and method for elution and recovery of metal from metal-collecting material

An object of the present invention is to provide a structure of a metal collecting material for use in seawater or river water or industrial wastewater to give the most excellent adsorption efficiency. Another object of the present invention is to provide a process for efficiently separating and recovering valuable metals or noxious metals from a metal collecting material having collected said valuable metals from seawater or noxious metals from river water or wastewater with the least possible waste generation.A metal collector according to an aspect of the present invention is formed by stacking at least partially alternate layers of a fibrous metal collecting material with a spacer for introducing a liquid to be treated into said collecting material, wherein the area of spacer side faces represents 25-75% of the total area of collecting material side faces and spacer side faces in the side faces of the stack. A process for eluting and recovering a metal from a metal collecting material according to another aspect of the present invention comprises the steps: (1) contacting the metal collecting material having absorbed a metal with a dilute eluent, (2) contacting the metal collecting material with an eluent more concentrated than in step 1 to recover the metal into the eluent; and (3) contacting a metal resorbing material with the eluate from step 2 to resorb the metal.

Owner:EBARA CORP

Each kind discarded resource mark color and corresponding refuse classification method

InactiveCN101236710AEasy to rememberEasy to identifyStampsIdentification meansLitterClassification methods

The invention provides a various resource wastes signal coloration, comprising a primary signal coloration and a secondary signal coloration, wherein, the primary category comprises twelve classes, the colors of red, orange, yellow, green, blue-green, blue, purple, pink, white, grey, brown and black are respectively taken as the signal coloration of hazardous and noxious substances, metal, wood-bamboo, glass, paper, appliance, seeds, textile products, plastic, masonry terracotta, compost and rubber; the secondary category is the close category of waste resources including various substances in the primary category according to the needs of waste product purchase and the waste circulation. The invention classifies the seven kinds of the primary category resources again and designs the secondary signal coloration which can be increased, decreased, separated and jointed. The signal coloration of each small category consists of the primary signal coloration of category and the secondary signal coloration representing the small category; the secondary signal coloration and the primary signal coloration can be distinguished by the rich color or light color, or the shape, the area and the combination. The general principle is to give prominence to the primary signal coloration in order to ensure that the people who drop litter can rapidly find out the primary category container and then the secondary category container.

Owner:于俊清

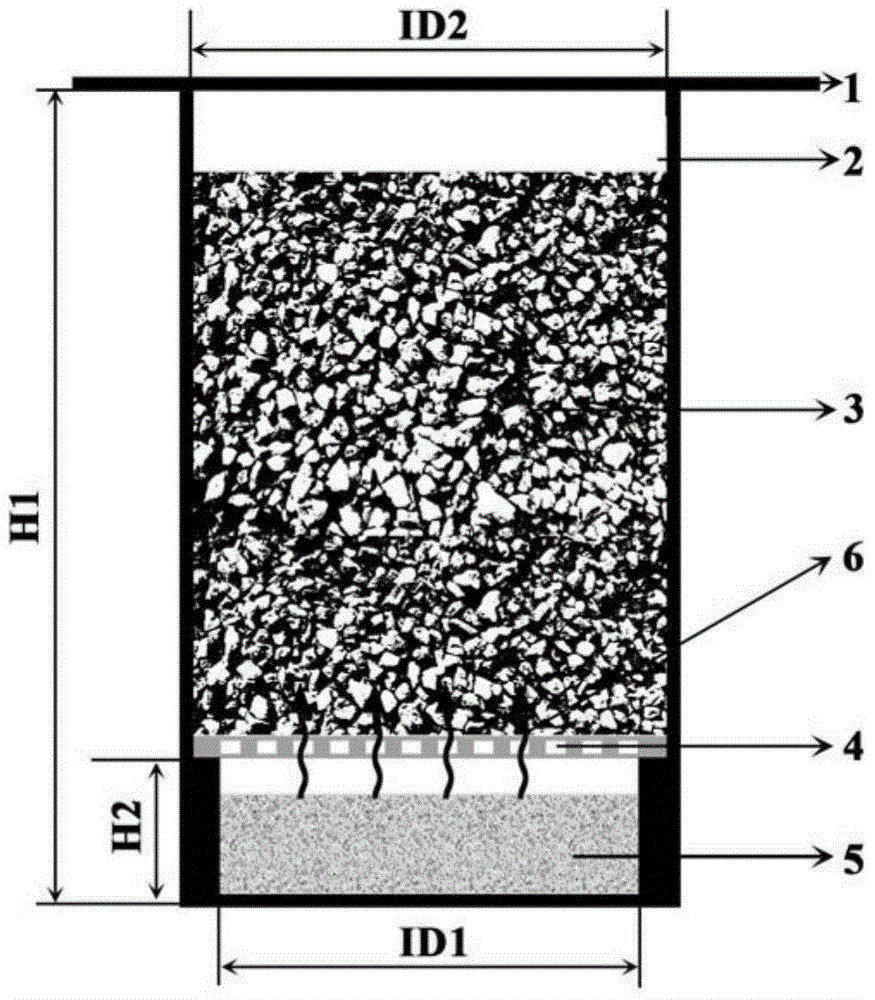

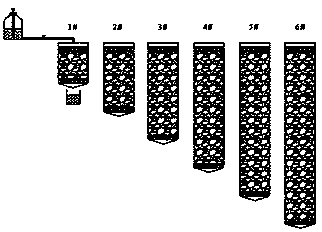

Method for measuring leaching parameters of dump leaching mineral pile at different depths

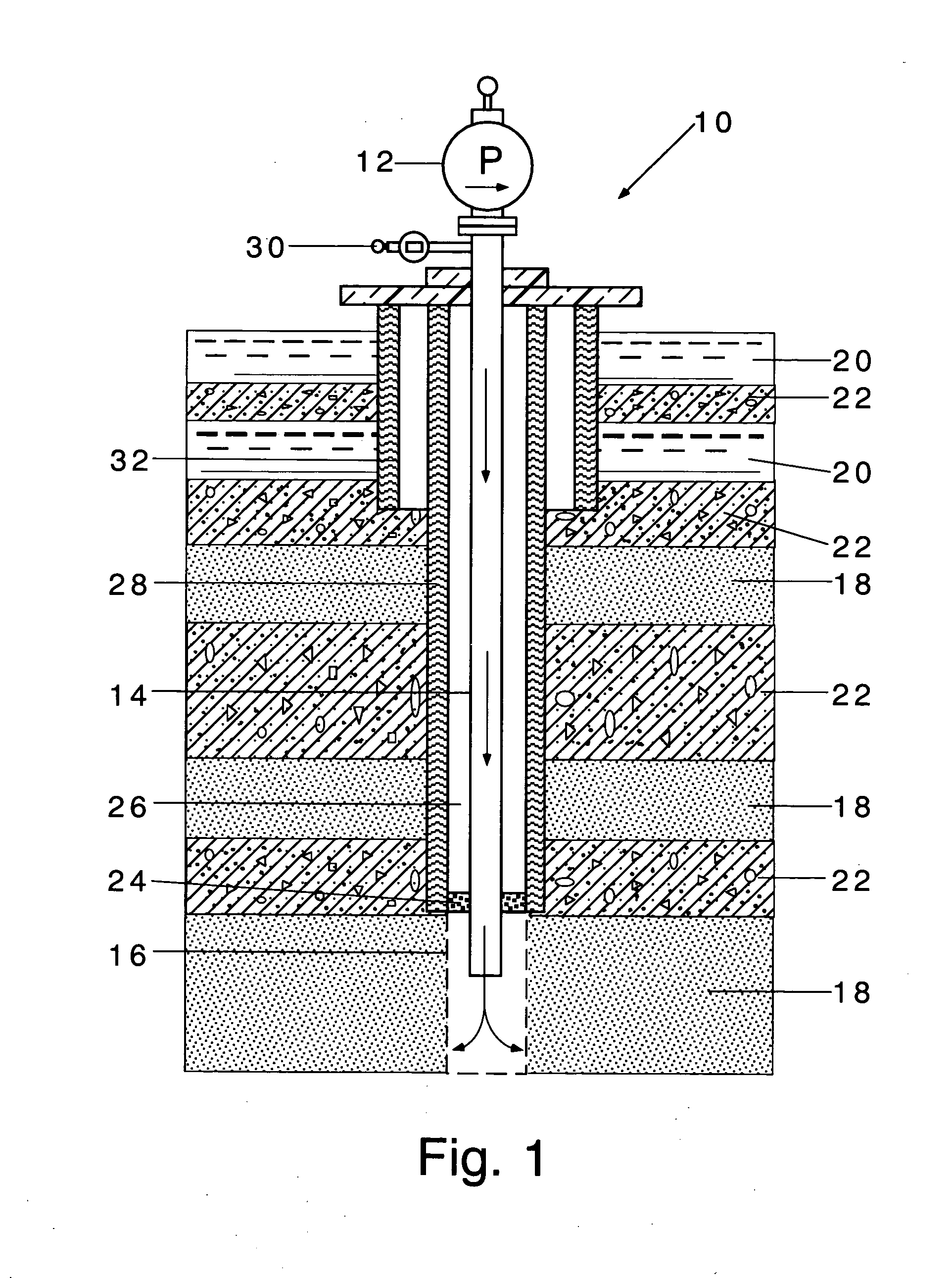

InactiveCN103409620AEnsure consistencyReflect the law of space-time distributionProcess efficiency improvementPregnant leach solutionSoil science

The invention relates to a method for measuring leaching parameters of a dump leaching mineral pile at different depths. A parallel column leaching test system is formed by using two or more test columns with different lengths, wherein the number of the test columns and the number of measuring points of leaching parameters of a dump leaching mineral pile to be measured are the same; the ore loading height of each test column and the depths of the measuring points of the leaching parameters of the dump leaching mineral pile to be measured are the same. According to the method provided by the invention, a leaching solution and test ore samples of the dump leaching mineral pile at the different depths can be conveniently obtained, so that the leaching parameters, such as leaching rates of useful metals, concentrations, pH values and Eh values of a leaching agent and an oxidizing agent at different depths of the dump leaching mineral pile and the variation of the parameters along with the time are detected. Meanwhile, the invention further provides a method for detecting the leaching parameters, such as removal rates of harmful metals, recovery rates of the useful metals, concentrations, pH values and Eh values of the leaching agent and the oxidizing agent at different depths of the dump leaching mineral pile and the variation of the parameters along with the time for dump leaching treatment of solid wastes, harmful metal contamination soil and electronic wastes.

Owner:NANHUA UNIV

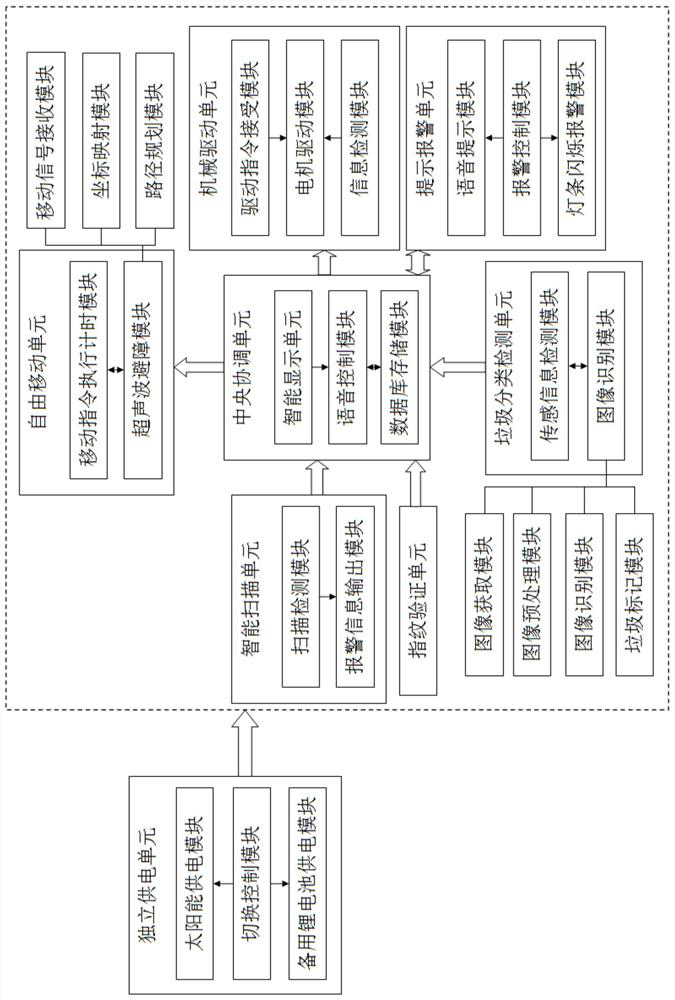

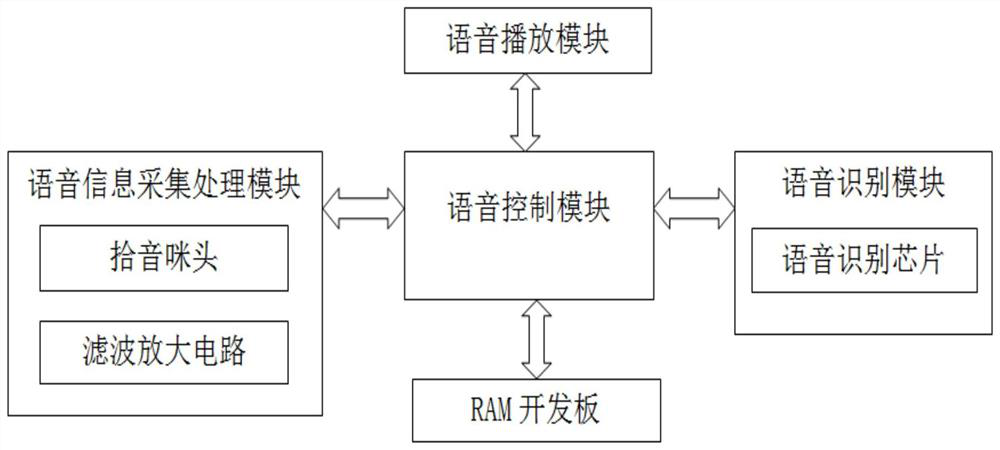

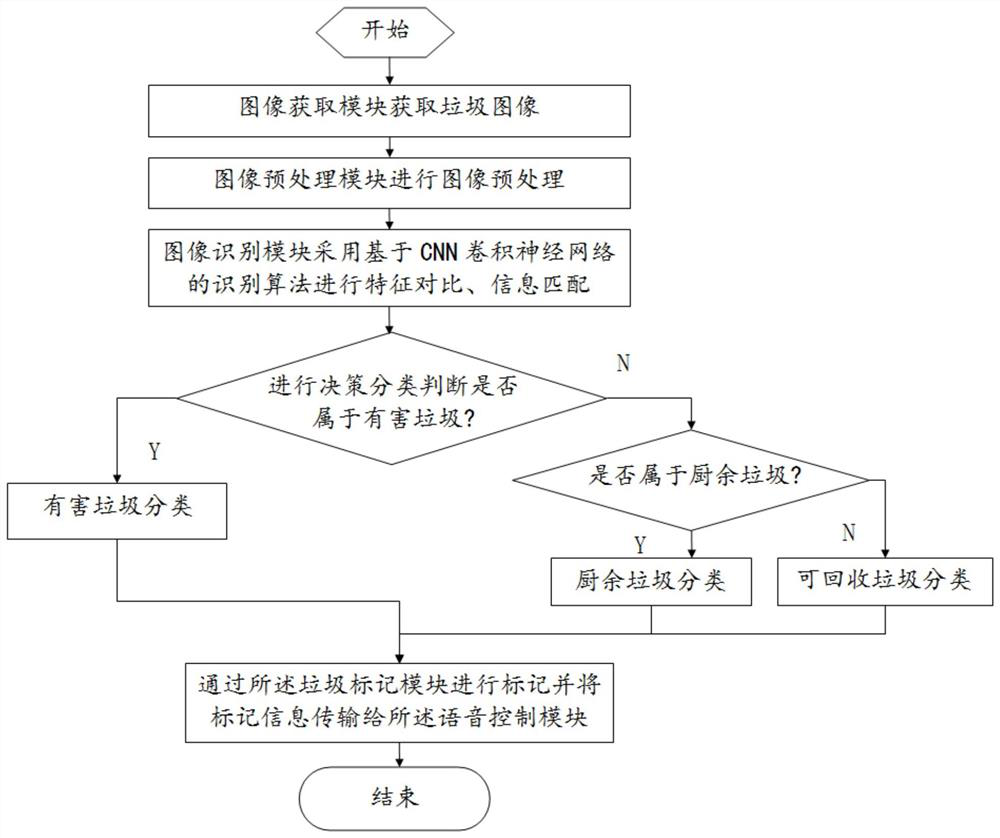

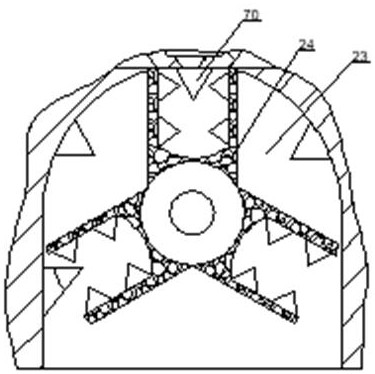

Voice control intelligent garbage can capable of achieving classification

ActiveCN112046962AImprove classification efficiencyImprove user experienceWaste collection and transferRefuse receptaclesMechanical driveEmbedded system

The invention provides a voice control intelligent garbage can capable of achieving classification. The voice control intelligent garbage can comprises an intelligent scanning unit, a garbage classification detection unit, a mechanical drive unit, a prompt alarm unit, a central coordination unit, an independent power supply unit and a free moving unit. The intelligent scanning unit is used for scanning whether harmful metal exists in garbage or not. The garbage classification detection unit is used for detecting the dryness, wetness and rotting degree and weight of the garbage and conducting recognition and classification on the garbage. The mechanical drive unit is used for driving a movable base arranged at the bottom of the garbage can to move, a garbage can cover to be opened and closed and moving wheels to move. The central coordination unit is used for receiving a voice control instruction of a user and then sending the control instruction to the mechanical drive unit to controlthe opening and closing of the garbage can cover and the moving distance and direction of the garbage can. The free moving unit comprises the multiple moving wheels and an ultrasonic obstacle avoidingmodule. According to the voice control intelligent garbage can, the garbage classification efficiency is improved, intelligent putting is achieved, and the usage experience of the user is improved.

Owner:浙江始祖鸟科技有限公司

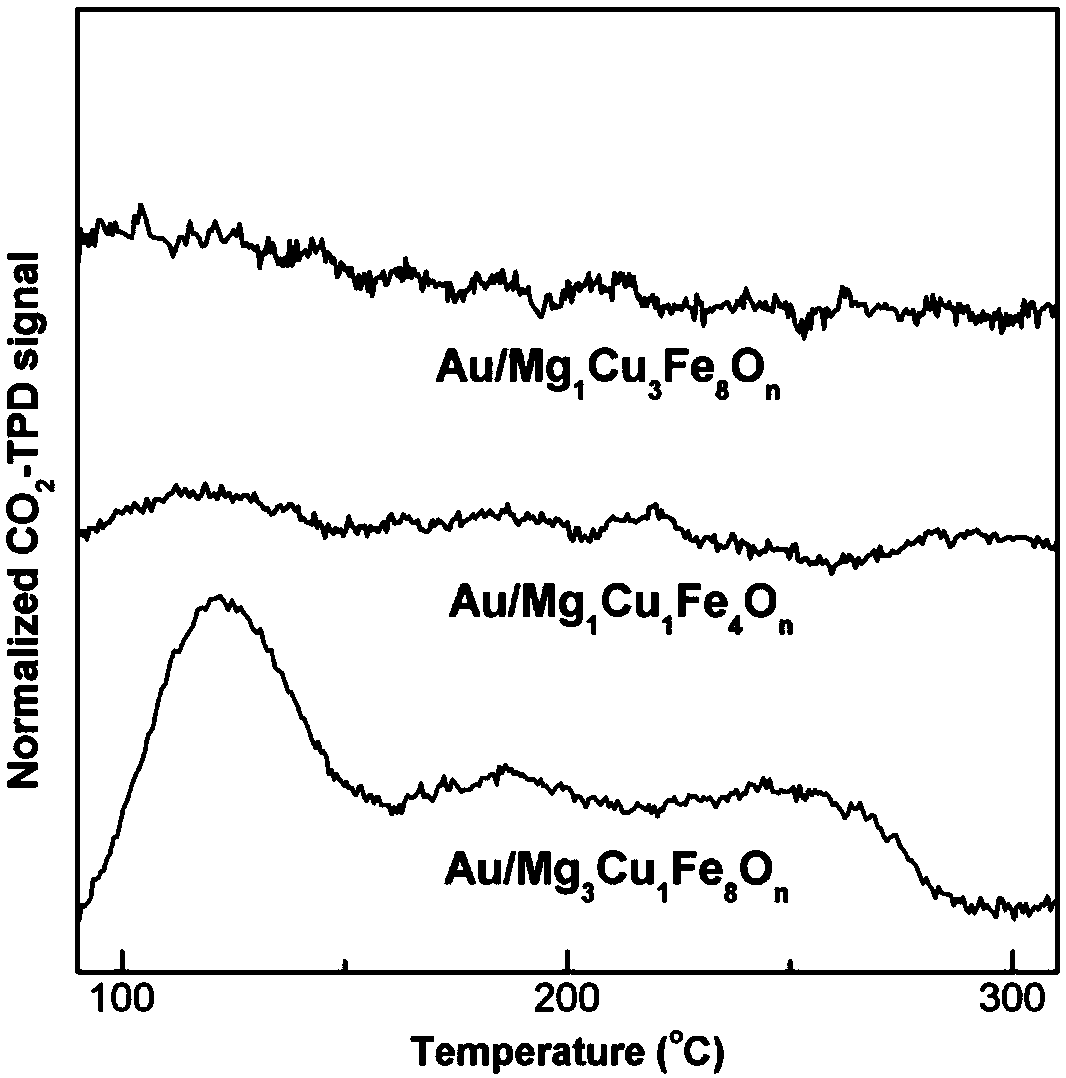

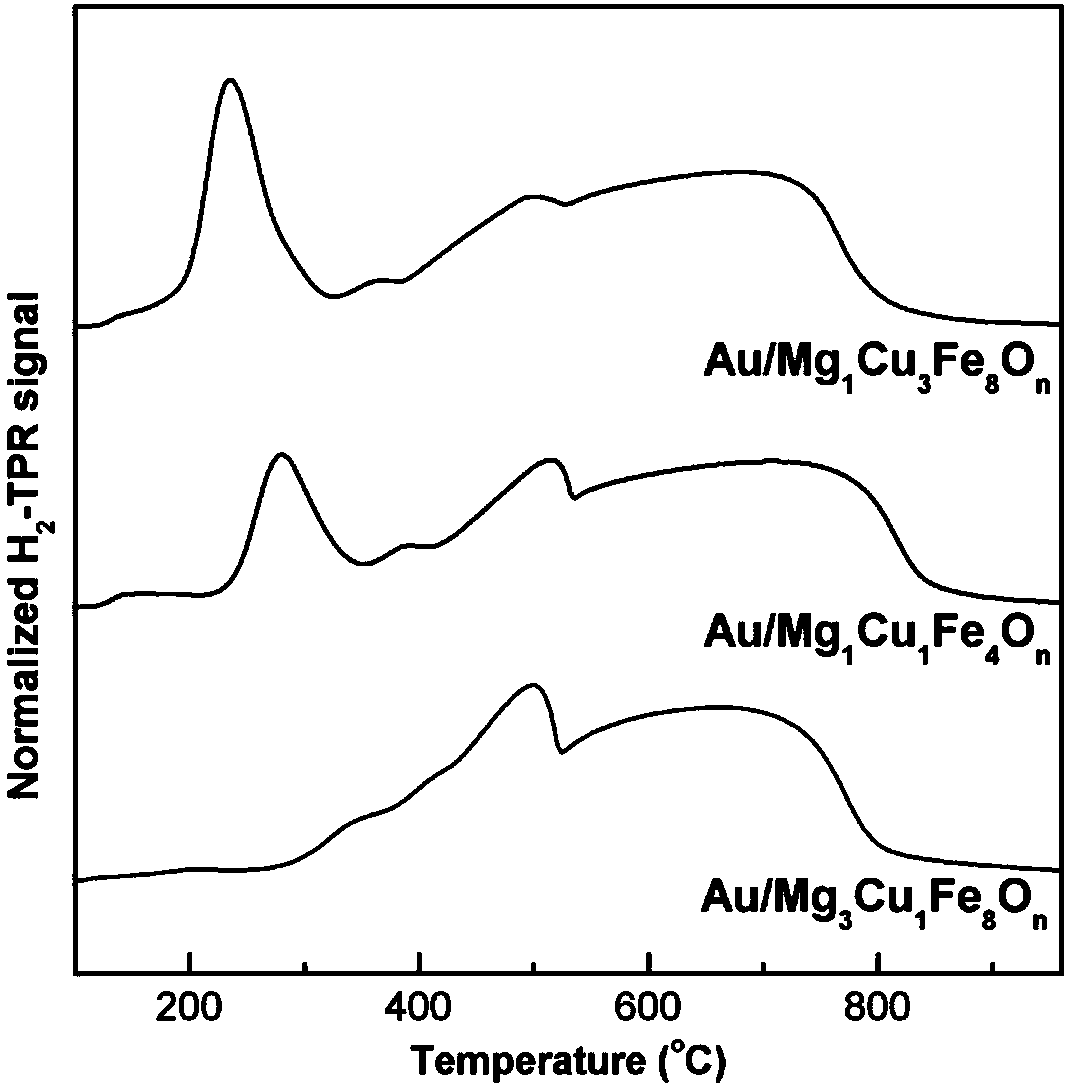

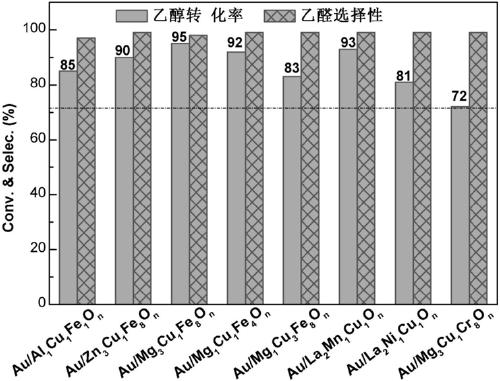

Ethanol gas phase oxidation acetaldehyde preparation catalyst and preparation and application methods thereof

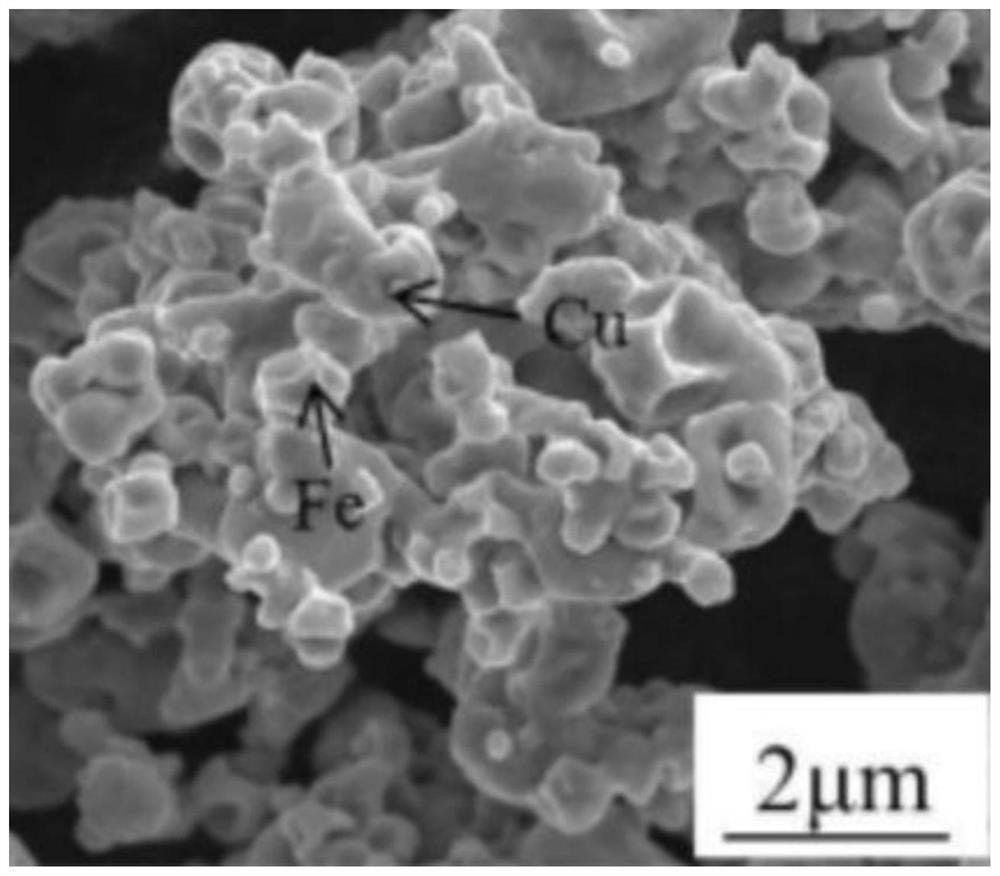

ActiveCN109569647AHigh catalytic activityInhibit deep oxidationOrganic compound preparationHeterogenous catalyst chemical elementsGas phaseCatalytic effect

The invention belongs to the field of catalysts and particularly relates to an ethanol gas phase oxidation acetaldehyde preparation copper oxide-supported nanogold catalyst and preparation and application methods thereof. The ethanol gas phase oxidation acetaldehyde preparation copper oxide-supported nanogold catalyst is composed of Au / AxByCuzOn, wherein A is a valent non-changeable metal ion, andB is a valent changeable metal ion; a carrier is efficiently synthesized through a simple low-temperature combustion-roasting method, and the surface acidity and the oxidation-reduction characteristics of the carrier can be adjusted by adjusting the variety and composition of metal elements to further enhance the synergic catalytic effects between nanogold and the carrier and accordingly to achieve stable and efficient ethanol gas phase selective oxidation acetaldehyde preparation. The ethanol gas phase oxidation acetaldehyde preparation copper oxide-supported nanogold catalyst has the advantages of being simple in preparation process, free from toxic and hazardous metals, high in low-temperature catalytic activity and acetaldehyde selectivity and the like and can maintain performance stability for a long time, avoid obvious carbon deposition and sintering and have a potential industrial application prospect.

Owner:HUAZHONG UNIV OF SCI & TECH

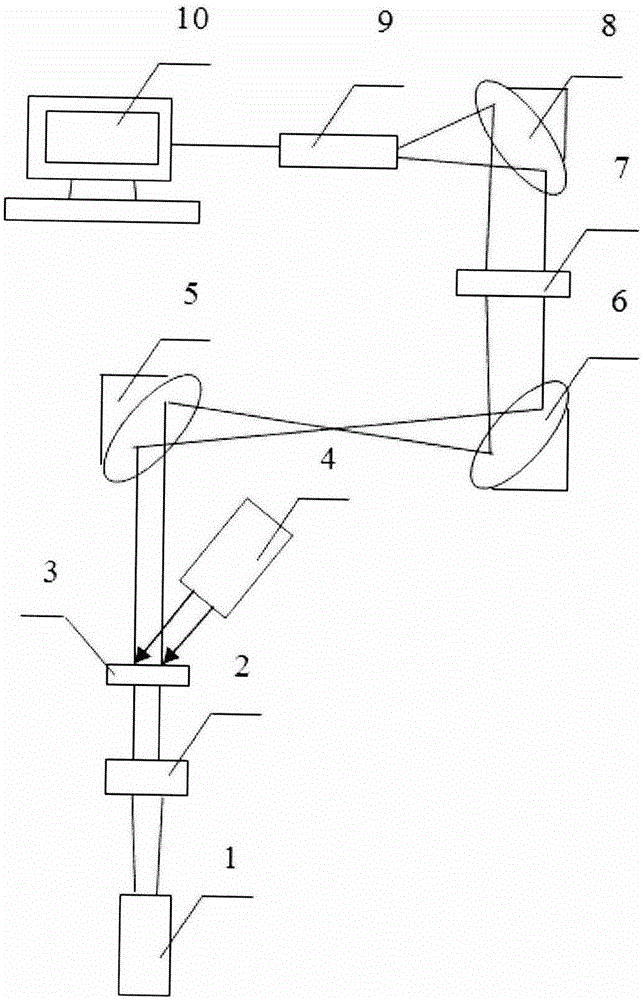

Detecting device and method for continuous wave terahertz real-time watermark imaging

InactiveCN105181697AControl the number of displayed image framesHigh detection sensitivityPaper-money testing devicesMaterial analysis by optical meansHigh resistanceNon destructive

The invention discloses a detecting device and method for continuous wave terahertz real-time watermark imaging. The detecting device comprises a continuous wave terahertz radiation source, a collimating beam-expanding system, a high-resistance silicon wafer, an argon ion laser, an off-axis parabolic lens, a sample platform, a terahertz wave detector and a computer. According to the detecting device provided by the invention, the collimating beam-expanding system is utilized to collimate the terahertz wave into parallel beams; the off-axis parabolic lens is used for expanding the beams for the second time; after the beams penetrate through a sample, the beams are focused on the terahertz wave detector; the computer is used for performing real-time imaging display on the image; the turning-on / off control on the detecting device is realized by utilizing a fact that whether the argon ion laser beam illuminates on the high-resistance silicon wafer or not. The detecting device for continuous wave terahertz real-time watermark imaging provided by the invention has the advantages of compact structure, high response speed, convenient switching, real-time watermark imaging and significant practical application value, and is also capable of performing non-destructive detection on the hazardous metal hidden in the packaging articles such as newspaper, fabrics and plastics.

Owner:CAPITAL NORMAL UNIVERSITY

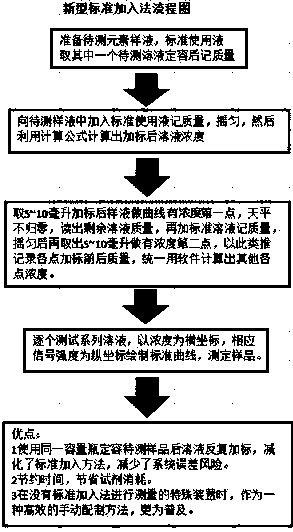

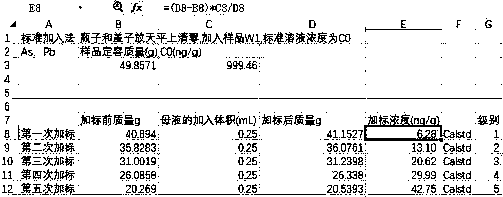

Method for performing accurate quantitative analysis on metal elements

ActiveCN110132916AReduce consumptionReduce system errorPreparing sample for investigationMaterial analysis by electric/magnetic meansQuantification methodsStandard methods

The invention relates to the field of analytical chemistry, in particular to a method for performing accurate quantitative analysis on metal elements by a patent technology combining a standard addition method and a differential method during accurate quantification. According to the analysis method, the standard addition method and the differential method are combined; a standard curve concentration calculation formula based on the differential method is designed; in combination with software calculation, a standard curve is established by using the standard addition method; the efficiency ofpreparing the standard curve is improved; and the interference caused by the matrix effect is effectively reduced, so that accurate quantification of the metal elements is realized. According to themethod, the calculated amount of preparing the standard curve by using the traditional standard addition method is greatly reduced, so that the quantitative analysis precision and speed of the harmfulmetal elements are improved; the standard addition method can replace the standard curve method (an external standard method); the accurate quantification method for the metal elements can be appliedto the detection of batch samples; and the method serves as a method for efficiently measuring the element concentration when a used instrument measures a special device without using the standard addition method.

Owner:李蒙

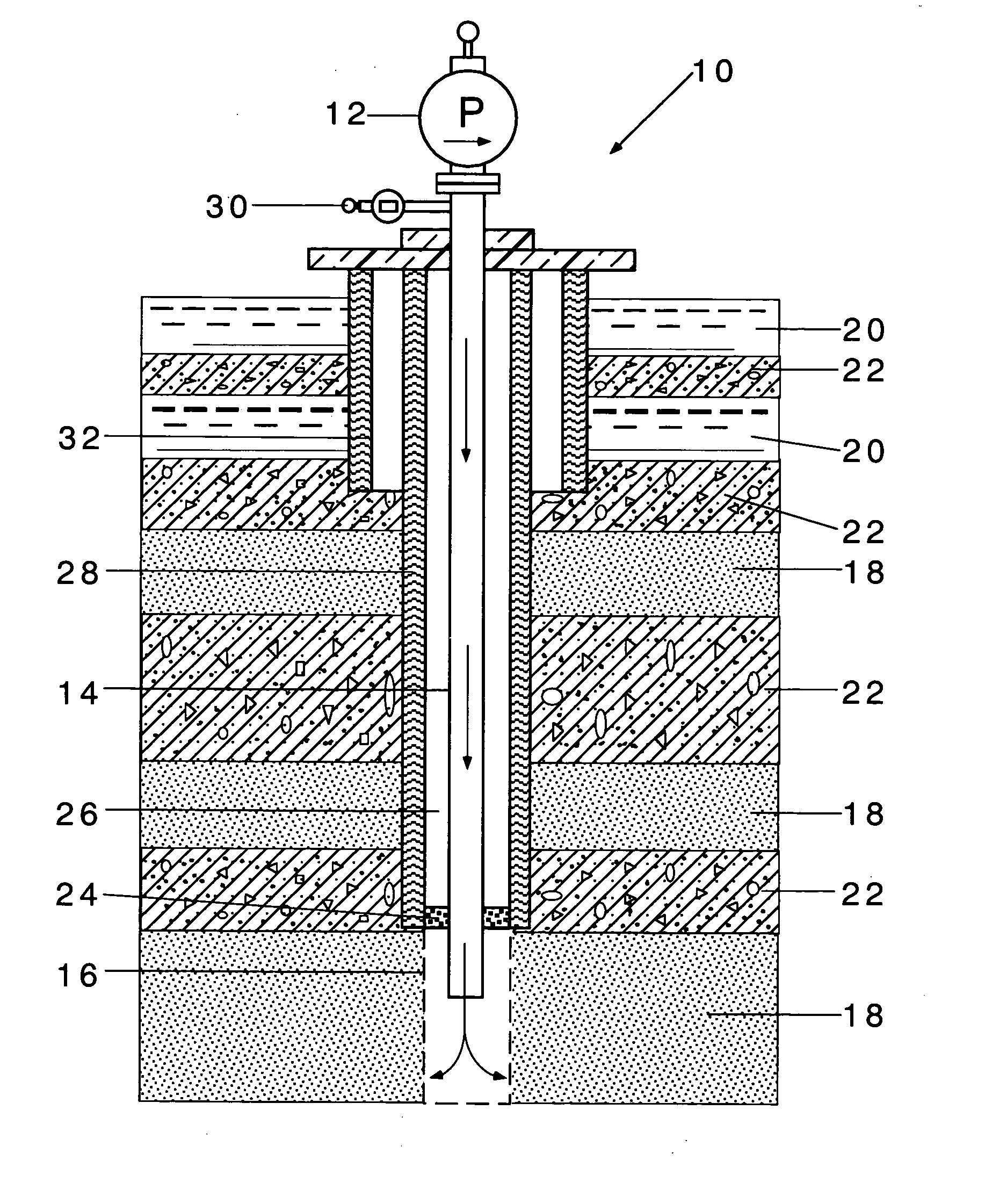

Disposal of accumulated waste solids from processing of titanium-bearing ores

A process for treating neutralized waste solids from the processing of titanium-bearing ores, whereby the neutralized waste solids are contacted with an acid under conditions effective to dissolve at least some of the waste solids, and then residual undissolved solids are separated out prior to injection of the remainder into a subterranean waste disposal well. The process is particularly adapted to disposal of hazardous metal waste solids which have been deposited over time in a waste disposal pond but which are judged as posing a hazard for migration from the pond to surface and subterranean waters.

Owner:ALEXANDER SAMUEL R

Rust-Proof Paint Composition and Method of Manufacturing a Member Having a Rust-Proof Coating Using the Rust-Proof Paint Composition

ActiveUS20100285226A1Long application periodEasy to operateOther chemical processesPretreated surfacesOrganic solventOrganotitanium compound

A rust-proof coating, which does not contain a hazardous metal such as chromium and is able to form a thin coating in which crack generation is inhibited even after a baking treatment at a high temperature, including based on the whole composition, 5 to 40% by weight of an organic silicon compound, 0.05 to 5.0% by weight of an organic titanium compound, 20 to 60% by weight of one or more metal powders selected from the group of zinc powder, zinc alloy powder, and aluminum powder, and 10 to 60% by weight of an organic solvent. A coating having excellent anticorrosive properties can be formed by coating the above-mentioned paint composition followed by heating at a temperature of from 200 to 400 degrees C.

Owner:YUKEN KOGYO

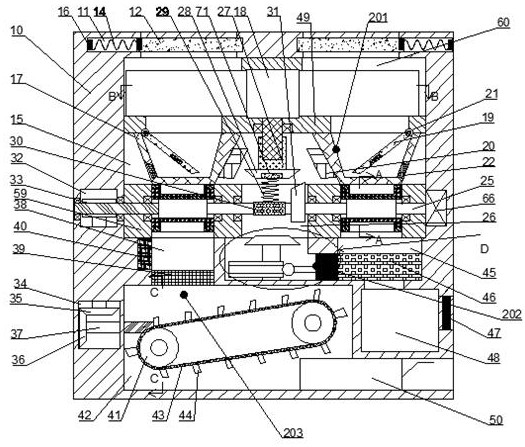

Classification device for plastic garbage treatment and recovery

InactiveCN112677369AGuaranteed recyclabilitySolid waste disposalPlastic recyclingMicroorganismThermodynamics

The invention relates to the field of garbage classification equipment, in particular to a classification device for plastic garbage treatment and recovery. The classification device comprises a machine body and a classification cavity located in the machine body and provided with an upward opening, moving grooves in bilateral symmetry are formed in the end wall of the upper side of the classification cavity, baffles capable of moving left and right are arranged in the moving grooves, and first electromagnets which are in bilateral symmetry and attract each other after being powered on are arranged on the outer walls of the baffles and the moving grooves. The invention provides the classification device for plastic garbage treatment and recovery. According to the classification device, the amount of harmful metal elements such as mercury in the plastic garbage is detected through a metal detector, the harmful metal elements are classified into the corresponding garbage baskets to be treated through rotation of classification wheels, the plastic without metal parts is sealed in a closed space after being crushed, nutrient solution is supplied to plastic decomposition microorganisms in the plastic at intervals through extrusion of sponge blocks, the plastic containing metal is heated and decomposed through crushing and heating and then recycled in a unified mode, and the recyclability of the device is guaranteed.

Owner:南京海薇兰贸易有限公司

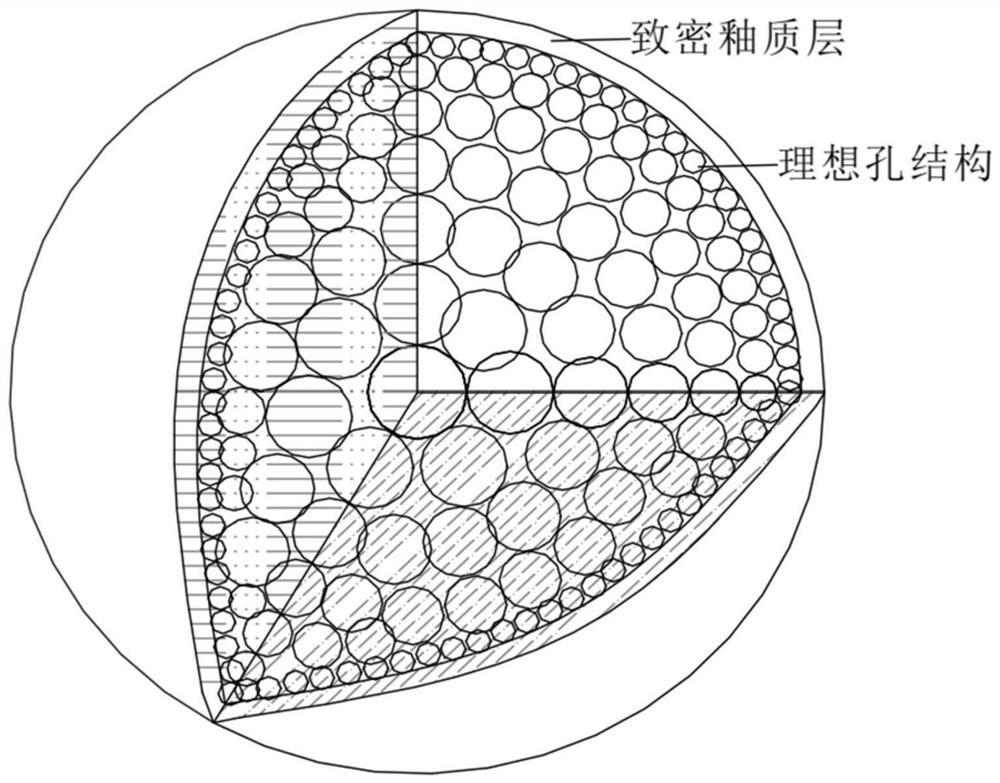

Preparation method of ceramsite by using river sediment as raw material

The invention provides a preparation method of ceramsite by using river sediment as a raw material. The method comprises the following steps: adding excitable solid powder wastes (such as fly ash, slag and volcanic ash), strong alkali materials (such as quick lime and sodium hydroxide) and other substances into the river sediment to prepare residual soil, and carrying out multi-stage granulation; then, coating the surface of the ceramsite obtained through multi-stage granulation by adopting a sulphoaluminate cement-based material with rapid hardening, early strength and low porosity, so that the sulphoaluminate cement coated ceramsite with the porous interior and the compact shell structure is prepared, and the negative effects of the unfired ceramsite on the aspects of harmful metal migration and odor volatilization are reduced; and meanwhile, the compressive strength of the single ceramsite is improved. The method provided by the invention has the advantages of low energy consumption, no tail gas pollution, low equipment investment, high production efficiency, easily controllable production process and good industrialization prospect.

Owner:ZHEJIANG SHUREN COLLEGE ZHEJIANG SHUREN UNIV

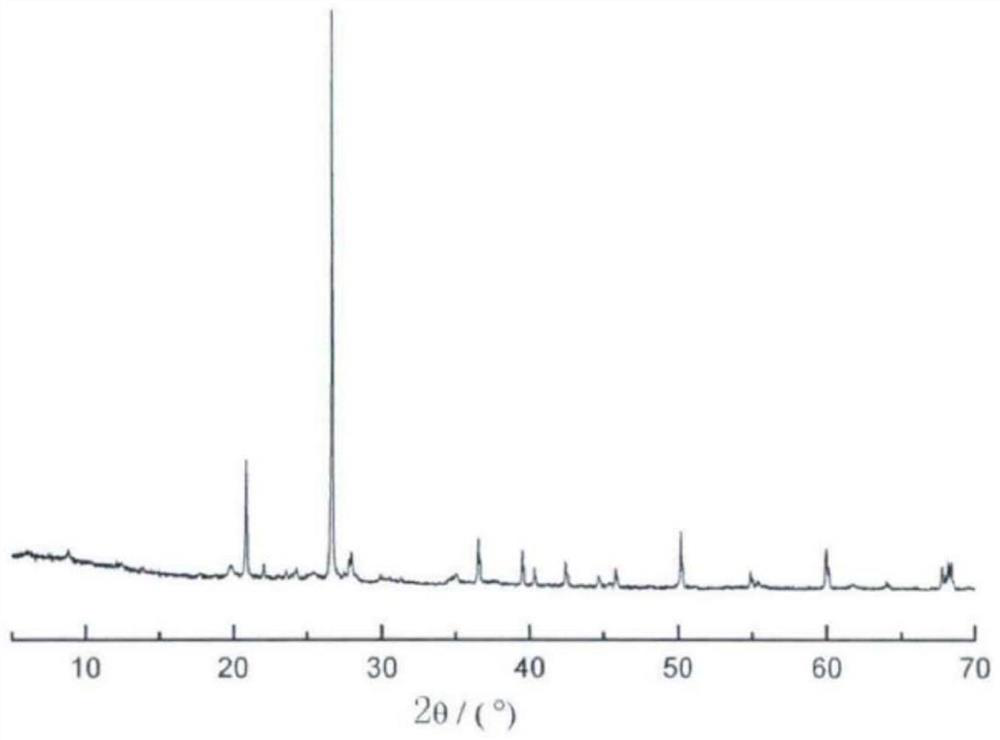

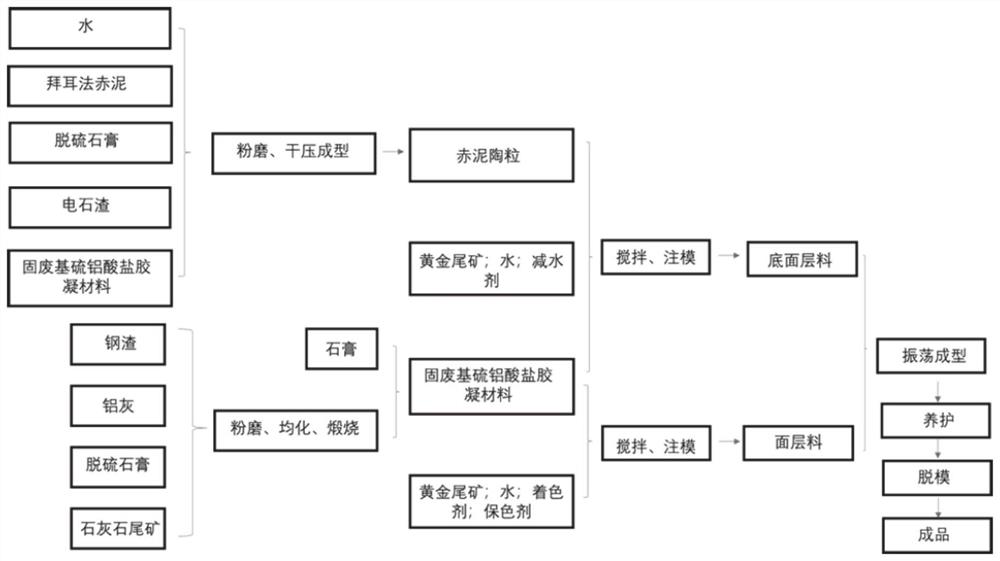

Red mud ceramsite-gold tailing sand-based color brick as well as preparation method and application thereof

PendingCN113480278ALight in massImprove insulation effectSingle unit pavingsAluminateEarthquake resistance

The invention relates to the technical field of color bricks, in particular to a red mud ceramsite-gold tailing sand based color brick and a preparation method and application thereof. The color brick comprises a base layer and a surface layer. The base layer is prepared from, by mass, 15-25 parts of a solid waste based sulphoaluminate cementing material, 50-80 parts of red mud ceramsite and 25-30 parts of gold tailing sand, and the water-binder ratio is 0.30-0.35. The surface layer comprises, by mass, 15-25 parts of a solid waste-based sulphoaluminate cementing material, 22-38 parts of gold tailing sand, 0.2 parts of a color retention agent and 1-1.6 parts of a coloring agent, and the water-binder ratio is 0.35-0.4. The prepared color brick is light in weight, and the thermal insulation and anti-seismic properties are improved. All the raw materials are solid wastes, so that the color brick is more energy-saving and environment-friendly. In the base layer of the color brick, the gold tailing sand and the red mud ceramsite are jointly used as aggregate and compounded with the solid waste-based sulphoaluminate cementing material, harmful metal elements and the like in the gold tailing sand are hydrated and fixed through the hydration effect of the solid waste-based sulphoaluminate cementing material, and pollution of the gold tailing sand to the environment is reduced.

Owner:SHANDONG UNIV

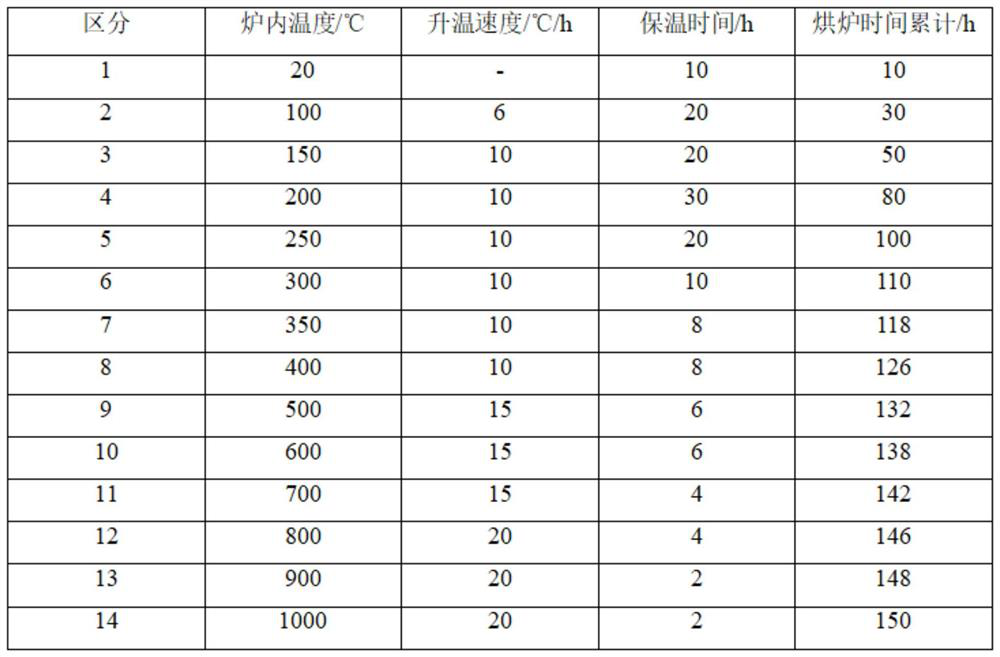

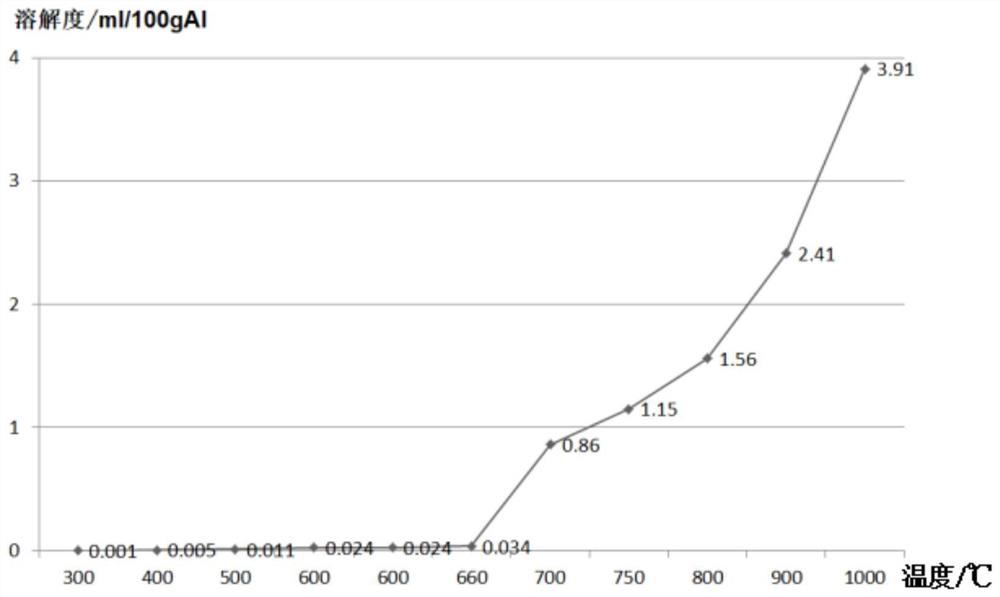

Production method of high-performance special aluminum alloy profile

InactiveCN113846241AAvoid crackingAvoid damageCasting safety devicesFoundry mouldsMetal impuritiesHydrogen content

The invention provides a production method of a high-performance special aluminum alloy profile and belongs to the technical field of aluminum alloy processing. The method comprises the following steps: step 1, furnace baking; step 2, burdening / feeding, wherein raw materials are fed into a furnace according to the proportion requirement; step 3, smelting, wherein solid raw materials are subjected to homogenization heat treatment; step 4, filtering, wherein the gas content in the melt is further reduced, and non-metallic inclusions and various harmful metal impurities are reduced; and step 5, casting. According to the method, furnace baking operation is carried out according to parameters such as preset time and speed before smelting, so that the temperature of a furnace body is uniformly and slowly increased, and cracking of a furnace lining due to rapid cooling and rapid heating is avoided. In the four stages, i.e., before / during smelting, during filtering and during casting, the production process of the aluminum alloy profile is optimized and the hydrogen content is reduced to be less than 0.1 cm<3> / 100g by controlling parameters such as furnace baking time, smelting temperature, casting speed / temperature, cooling speed and the like, so that cast ingot grains are refined and the performance of the alloy profile is improved.

Owner:DONGLIANG ALUMINIUM CO LTD

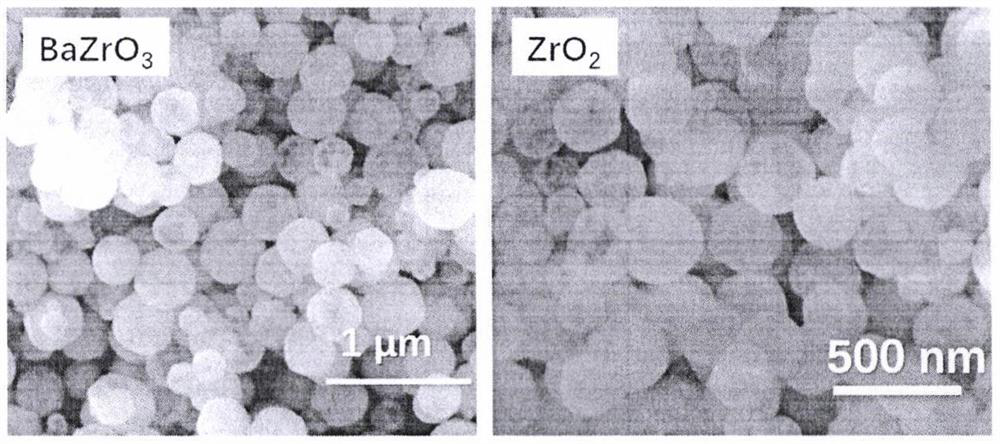

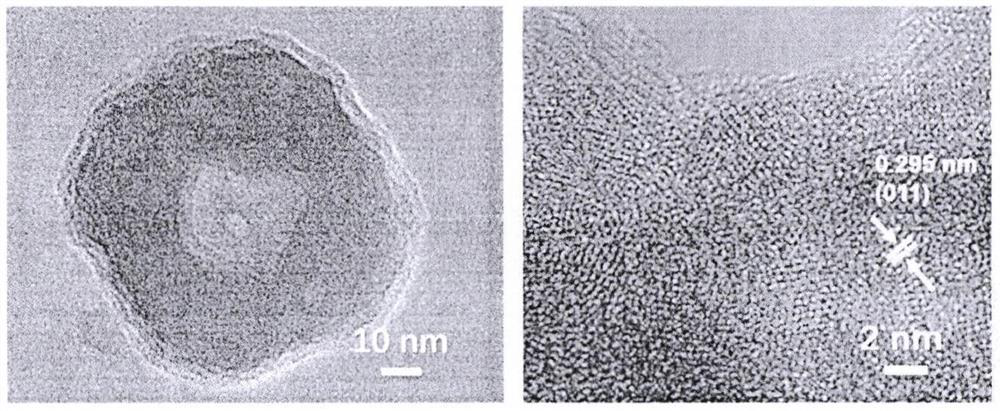

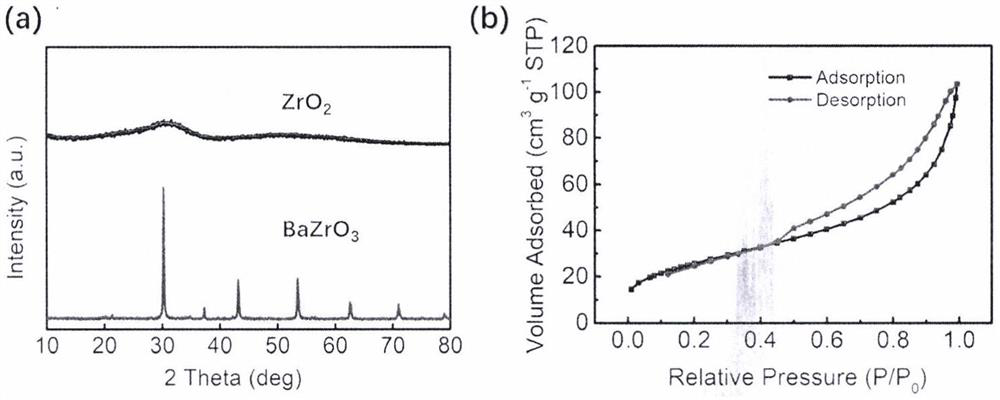

Porous oxide adsorbing material for efficiently removing harmful ions in water

PendingCN112206742AImprove adsorption capacityOther chemical processesSpecific water treatment objectivesEtchingSorbent

The invention relates to a transition metal oxide material for water pollution treatment. The transition metal oxide material can remove harmful metal ions such as chromium (VI), arsenic (V), lead (I1), uranium (VI) and cadmium (I1) in water to reach the drinking water standard. Chromium (VI) and arsenic (V) can be adsorbed to 10 ppb or below, and lead (II), cadmium (II) and uranium (VI) can be adsorbed to 1 ppb or below. The general formula of the adsorbent is MxOy, wherein M is selected from one or two transition metal elements of Zr, Ti, Fe, Mn, Mo, W and the like; and 1 < = x < = 2 and 1 <= y < = 5. The material is prepared by adopting a micro-etching technology, and has the characteristics of rich pore structures, high-density hydroxyl, high specific surface area and the like throughaccurate selective etching, so that the adsorbent has strong adsorption capacity on harmful ions, and an efficient removal effect is achieved. In addition, the material has good cyclic utilization performance, the synthesis process is simple, the cost is low, and the material has a wide prospect in the aspect of water pollution treatment.

Owner:PEKING UNIV

High-purity molybdenum filament and production method thereof

The invention discloses a high-purity molybdenum filament and a production method thereof, relates to a metal material production process, in particular to a method for producing the high-purity molybdenum filament. The production method comprises the following steps: dissolving TMA-52 chelon into deionized water to form a TMA-52 chelon solution as a MoO2 raw material cleaner; drying the washed MoO2; sequentially performing molybdenum powder reduction, molybdenum bank strip pressing, molybdenum bank strip sintering, and molybdenum rod forging and rolling; and finally forming more than or equal to 99.984 percent of molybdenum filament through wiredrawing. The invention can effectively remove Fe, Ni and Mg and the other harmful metallic impurities in the MoO2 so as to guarantee that the produced molybdenum filament has high molybdenum content. The TMA-52 chelon solution is used as the cleaner, which ensures that the whole production process achieves green, environmental protection, and great conservation of the energy and the materials.

Owner:盛华伟

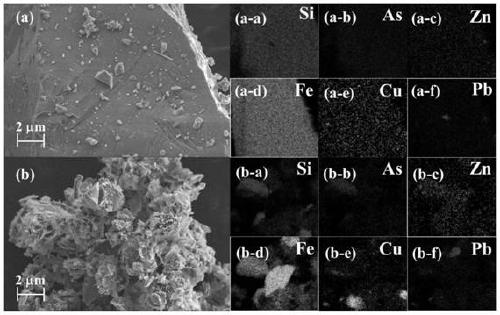

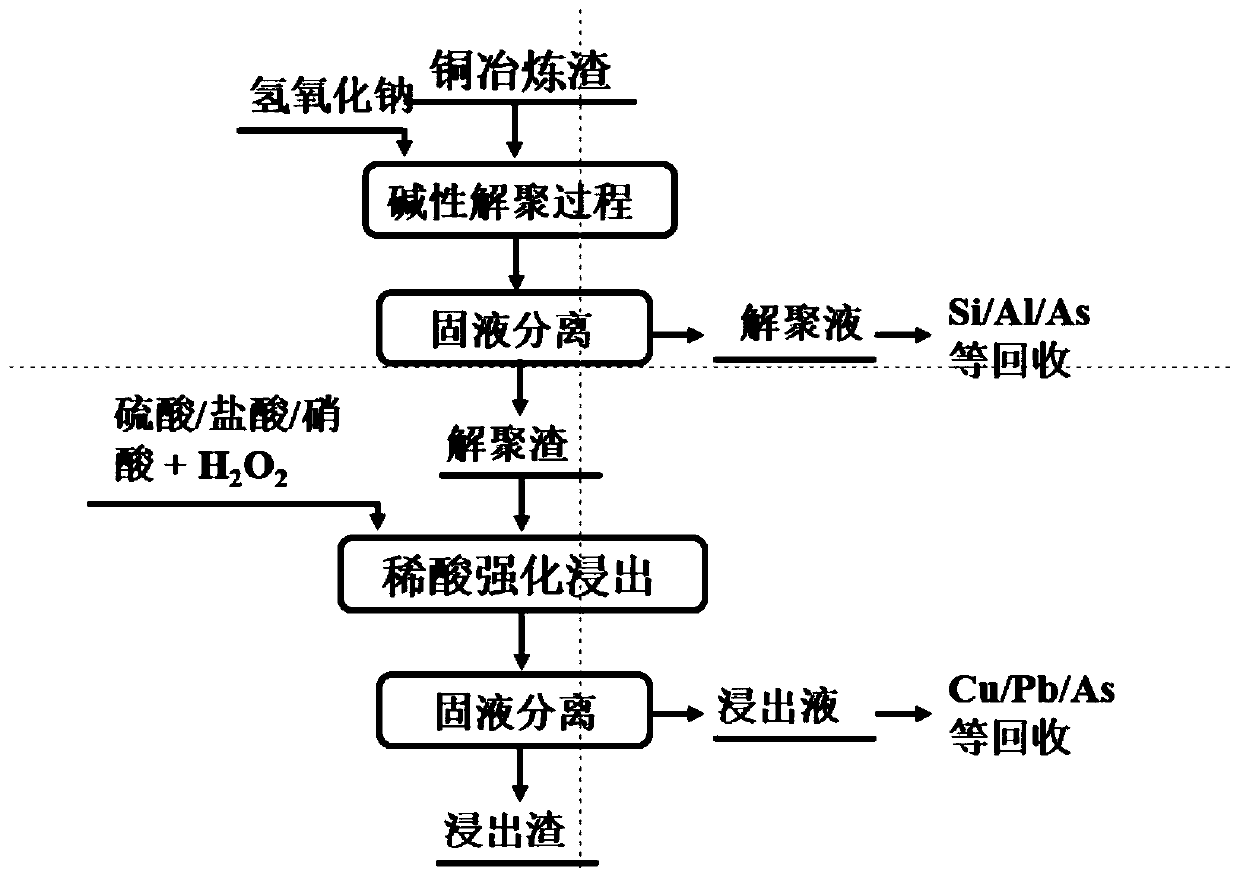

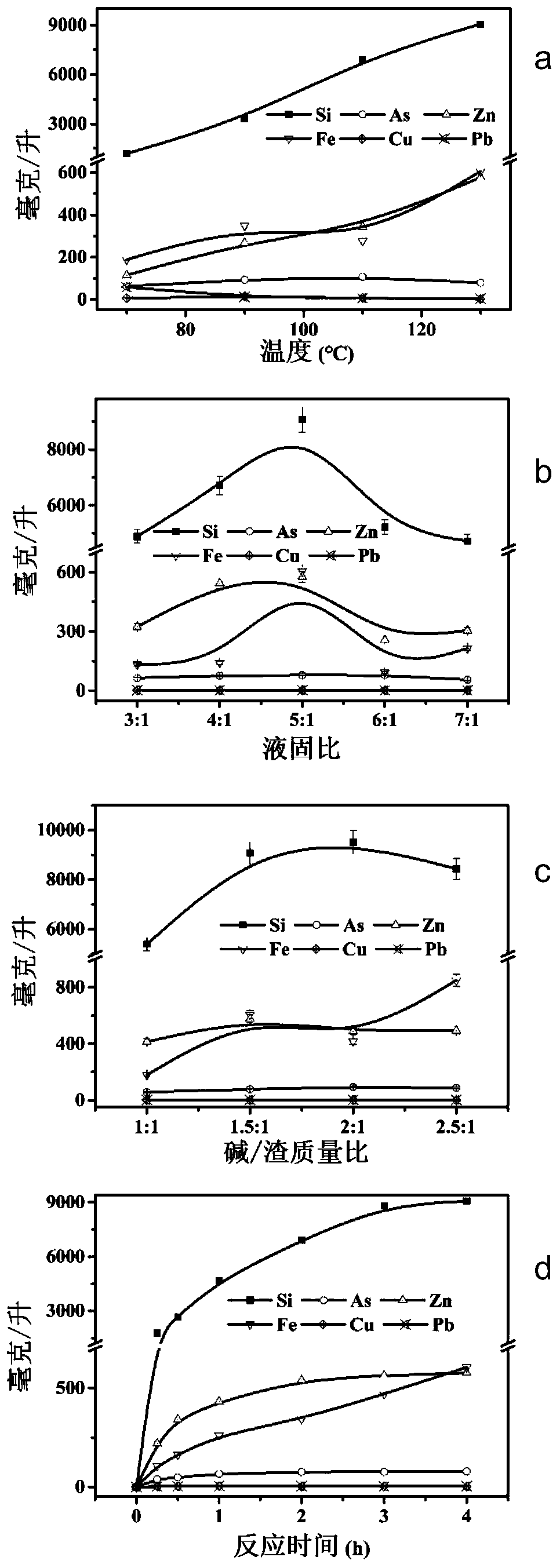

Harmless and reduction method of smelting slag rich in fayalite

InactiveCN111185463AEffective destructionReduce the risk of contaminationSolid waste disposalTransportation and packagingFayalitePregnant leach solution

The invention belongs to the technical field of harmlessness and recycling of metallurgical and bulk industrial smelting slag waste, and discloses a harmless and reduction method of smelting slag richin fayalite. The harmless and reduction method mainly adopts a hot alkali depolymerization-diluted acid enhanced leaching process, and includes the following steps that (1) the smelting slag rich infayalite is crushed and pulverized into powder, and the smelting slag is depolymerized with a hot alkaline solution to obtain depolymerized slag; and the alkaline solution is a sodium hydroxide solution or a potassium hydroxide solution; and (2) the depolymerized slag in the step (1) is subjected to agitation leaching reaction with a mixed system of diluted acid and oxidant to obtain a leaching solution and harmless and reduced slag. The test results show that the harmless and reduction method treats copper smelting slag rich in fayalite, harmful metals in the copper smelting slag are extracted, the leaching rate of the harmful metals As and Pb in the treated copper smelting slag reaches 99.7% and 99.9%, and the reduction rate of the copper smelting slag can reach 57%.

Owner:SOUTH CHINA UNIV OF TECH

Method for treatment of waste material

InactiveCN1091662CReduce concentrationImprove stabilityWaste processingSolid waste disposalFly ashMetal

The present invention relates to providing a treatment method capable of stabilizing harmful metals, especially lead, in waste materials, especially fly ash. It is characterized in that adding and mixing water glass and water to waste containing harmful metals and stirring.

Owner:KYOWA CHEM IND

Electric microfiltration device system for synchronously removing hardness and harmful metal of drinking water

ActiveCN113461119AWith backwash self-cleaning functionNo secondary pollutionWater treatment parameter controlSpecific water treatment objectivesMicrofiltration membranePotable water

The invention relates to the field of drinking water safety guarantee, in particular to an electric microfiltration device system for synchronously removing hardness and harmful metal in drinking water. In the electric microfiltration device system for synchronously removing the hardness and the harmful metal in the drinking water, a feed liquid pool is connected with a first pump body through a guide pipe, the first pump body is connected with a cathode chamber through a guide pipe, the cathode chamber is connected with a pressure gauge through a guide pipe, the pressure gauge is connected with a second pump body through a guide pipe, and the second pump body is connected with an anode chamber through a guide pipe; and the anode chamber is connected with the third pump body through a conduit. According to the invention, calcium carbonate is precipitated by using the strong alkaline atmosphere in the cathode chamber, the membrane surface and the membrane holes, harmful metal ions generate co-precipitation in the precipitation process, and generated insoluble crystals are synchronously intercepted by the microfiltration membrane. And the cathode effluent flows through the anode chamber to ensure that the overall effluent is neutral and reaches the drinking water standard. When the membrane flux is obviously reduced, the cathode and the anode can be reversed, and reverse water flow is applied to the membrane electrode, so the membrane flux can be completely recovered.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Heat release welding flux based on copper-iron alloy

ActiveCN113996968AImprove mechanical propertiesImprove conductivityWelding/cutting media/materialsSoldering mediaAl powderIron powder

The invention discloses a heat release welding flux based on a copper-iron alloy, and relates to the technical field of welding. The heat release welding flux comprises the following components: 10-25 parts of copper oxide, 35-50 parts of copper powder, 5-12 parts of iron powder, 20-50 parts of aluminum powder, 0.5-1 part of tungsten powder and 0.2-0.4 part of silicon powder. The copper-iron alloy is generated after the heat release welding flux is ignited; the copper-iron alloy has good mechanical property, conductivity and corrosion resistance, does not contain harmful metals such as phosphorus, sulfur, lead, tin and magnesium and is good in welding quality; and welding points are not prone to rusting and cracking, and the welding points can endure repeated large surge current without degradation.

Owner:绍兴十目科技有限公司

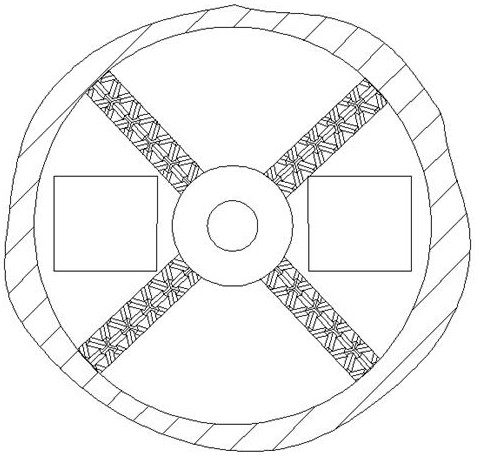

Ceramic body raw material processing device and processing process thereof

PendingCN113953059AMeets requirementsCompliant with application standardsMagnetic separationGrain treatmentsMagnetic separationDehydration

The invention relates to the technical field of ceramic production, and particularly relates to a ceramic body raw material processing device. The device comprises a crushing and pulping module, a precipitation module, a magnetic separation module and a dehydration module connected in sequence. The invention further provides a processing process of the ceramic body raw material processing device. The processing process comprises the following steps: S1, crushing and filtering raw materials; S2, performing ball milling treatment on the raw materials to obtain mud; S3, injecting the mud into an overground mud pit; S4, precipitating the mud in the mud pit on the ground; S5, carrying out magnetic separation treatment on the precipitated materials; S6, inputting the materials obtained after magnetic separation into a mud transfer pit to be stirred; and S7, carrying out dehydration treatment on the materials. According to the device and the processing process thereof, the crushed and filtered raw materials are subjected to ball milling treatment to form the mud, and then the mud is sequentially subjected to precipitation, magnetic separation and the like so that most of harmful metal oxides in the raw materials of the ceramic body can be removed, and the influence of the harmful metal oxides in the raw materials on the product quality can be greatly reduced.

Owner:宁夏科豪陶瓷科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com