Harmless and reduction method of smelting slag rich in fayalite

A technology of smelting slag and olivine, which is applied in the fields of metallurgy, reduction and recycling, and the harmless treatment of bulk industrial smelting slag waste, can solve problems such as ignoring environmental risks, and achieve the effect of reducing environmental pollution risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

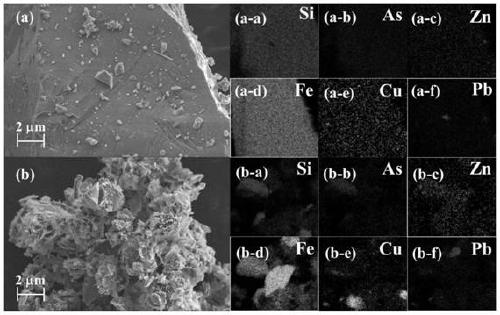

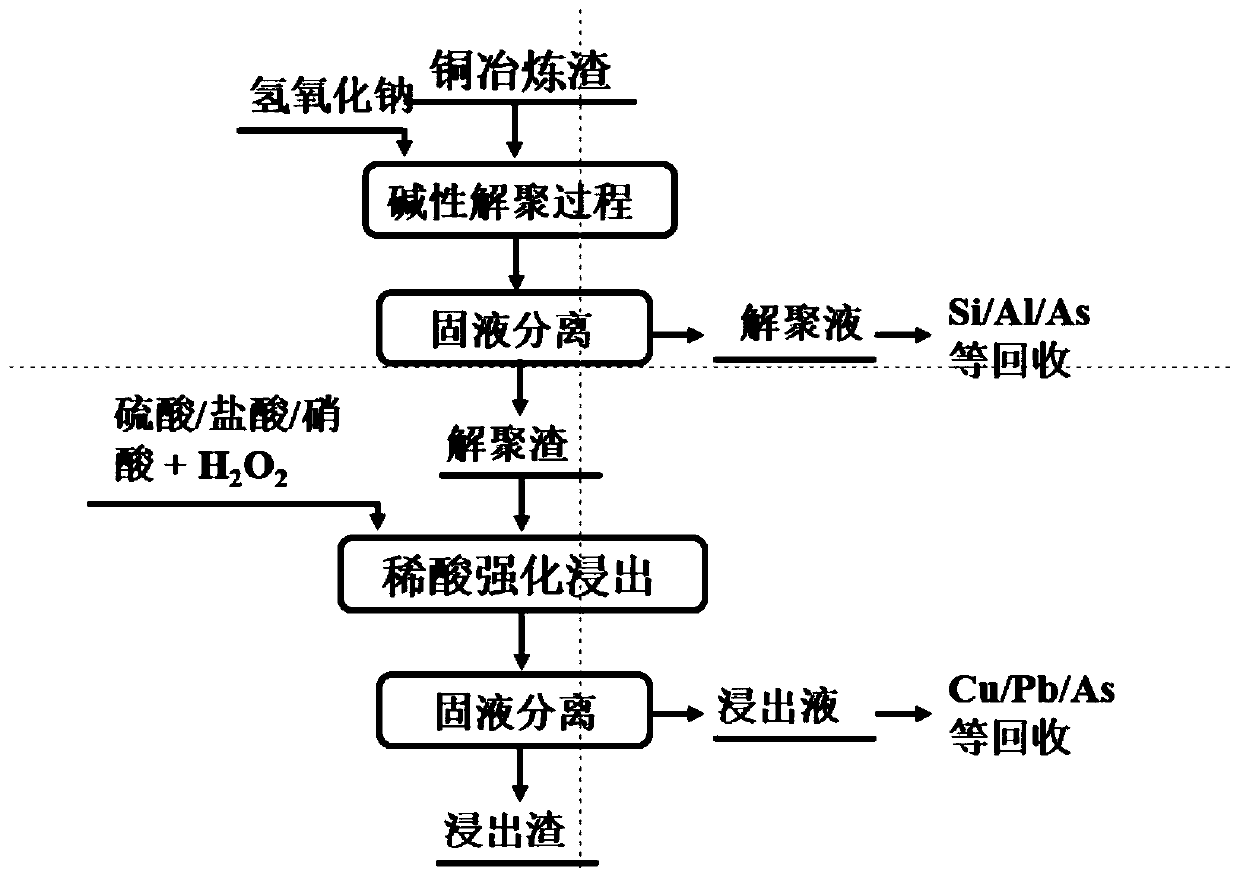

[0041] Depolymerization of fayalite in copper smelting slag in hot alkali system

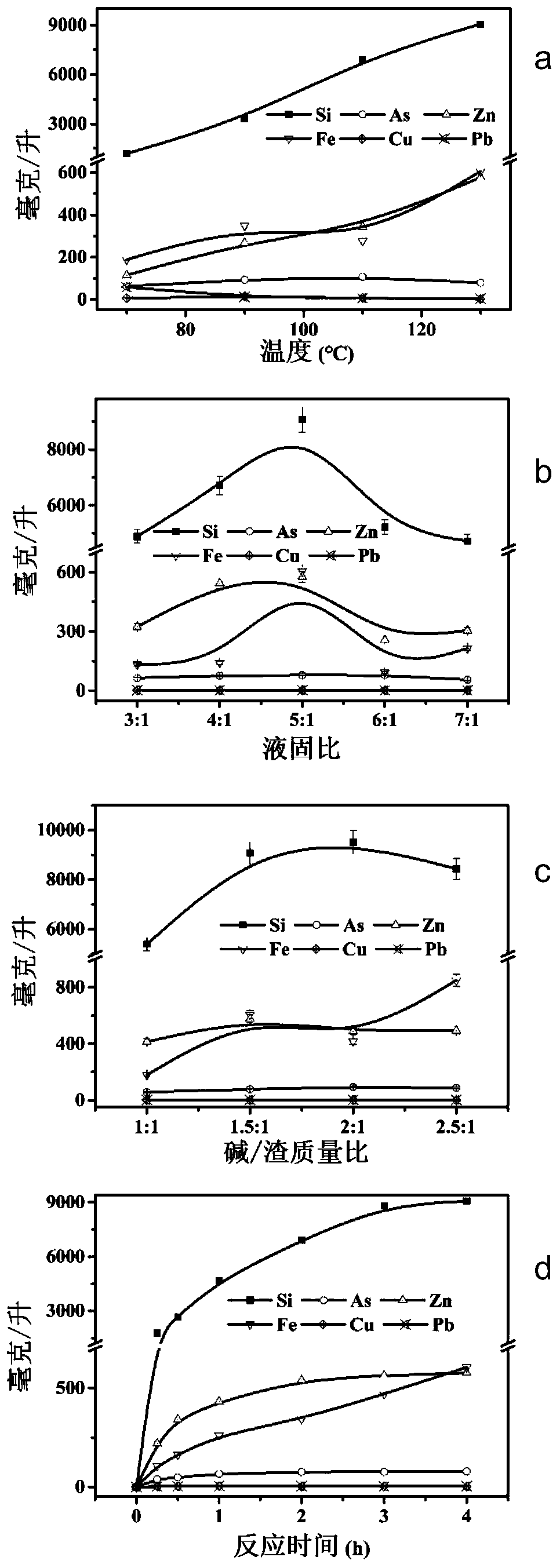

[0042] The copper smelting slag is crushed and sieved, the particle size of the sieved copper smelting slag is 50-250 mesh, the consumption of sodium hydroxide is 30-75g and dissolved in 150 ml of deionized water, and the lye and lye are controlled. The liquid-solid ratio in the copper smelting slag is 3:1-7:1, the stirring rate is 400rpm, and the heating temperature is set on the heating plate at 70, 90, 110, 130°C and 0.5, 1, 2, 3, 4h, etc. Depolymerization effect of copper smelting slag (in terms of silicon leaching) under different time series conditions to determine the best experimental conditions. The depolymerized slag is washed, dried and set aside.

[0043] Under specific time series conditions, a part of the liquid is taken out with a syringe and subjected to high-speed centrifugation to achieve solid-liquid separation. The obtained depolymerization solution was diluted with 5 (v / v)...

Embodiment 2

[0048]The depolymerized slag is extracted at a liquid-solid ratio of 10:1, and 0.4-1.4M sulfuric acid and 0.3-0.7M hydrogen peroxide are used for intensive leaching, and the leaching is stirred and leached for 4 hours at a stirring rate of 400rmp. Such as image 3 , the preferred implementation conditions in the examples are a liquid-solid ratio of 10:1, 1.2M sulfuric acid, 0.6M hydrogen peroxide, a stirring rate of 400rmp, and a reaction time of 4h. After calculation, the total leaching rate of arsenic is 99.7%, the total leaching rate of lead is 1.61%, and the reduction rate is 57.1%.

Embodiment 3

[0050] The depolymerized slag was leached with a liquid-solid ratio of 10:1, 0.4-1.8M dilute hydrochloric acid and 0.6M hydrogen peroxide for enhanced leaching, and stirred and leached for 4 hours at a stirring rate of 400rmp. Such as Figure 4 , the preferred implementation conditions in the examples are a liquid-solid ratio of 10:1, 1.8M hydrochloric acid, 0.6M hydrogen peroxide, a stirring rate of 400rmp, and a reaction time of 4h. After calculation, the total leaching rate of arsenic is 99.7%, the total leaching rate of lead is 99.9%, and the reduction rate is 46.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com