Method for measuring leaching parameters of dump leaching mineral pile at different depths

A heap leaching and parameter technology, which is applied in the fields of solution mining and environmental protection, can solve problems such as errors, failure to maintain the consistency of heap leaching ore piles, and inability to obtain test column leaching liquid samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

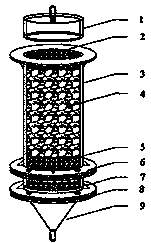

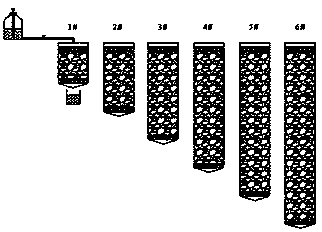

[0036] The present invention provides a method for measuring leaching parameters at different depths of heap leaching ore piles. The method uses a set of parallel column leaching test systems composed of two or more test columns of different lengths, wherein the number of test columns is according to needs The number of measuring points for measuring heap leaching parameters is determined, which is consistent with the number of measuring points; the loading height of each test column is consistent with the depth of the measuring points required to determine the leaching parameters. Follow the instructions attached figure 1 And figure 2 After completing the installation of the parallel column leaching test system, use the on-site heap leaching solution concentration, oxidant concentration, liquid distribution strength, liquid-solid ratio, liquid distribution time and other parameters for liquid distribution, and collect the leaching liquid.

[0037] If you need to know the leachin...

Embodiment 1

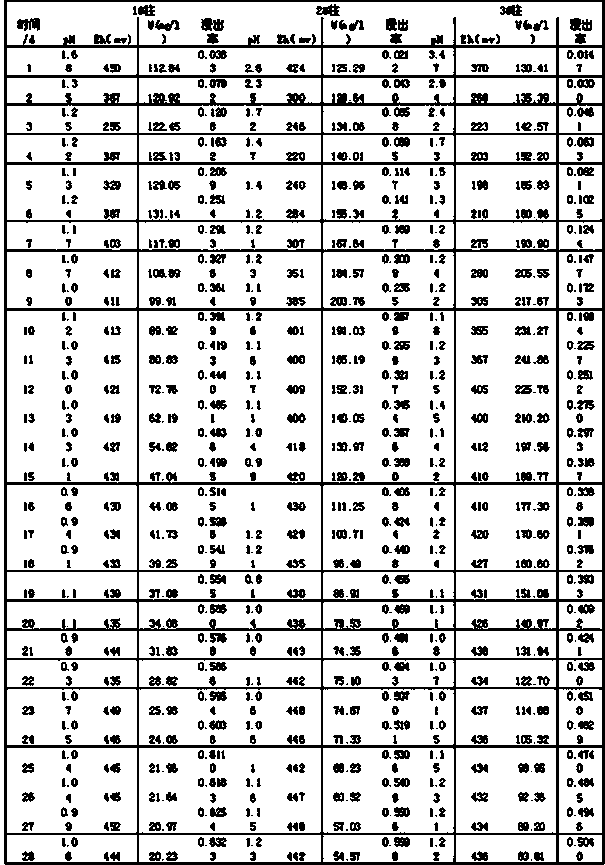

[0041] For a mine pile with a height of 3 m, the concentration of useful metals in the leaching solution at a depth of 0.5 m, 1.0 m, 1.5 m, 2.0 m, 2.5 m, and 3.0 m, pH, Eh, and leaching rate and other leaching parameters over time need to be measured Variety.

[0042] Using 6 test columns to form a parallel column leaching test system, 1 # -6 # The loading heights of the test pillars are 0.5 m, 1.0 m, 1.5 m, 2.0 m, 2.5 m, and 3.0 m, respectively, which are used to simulate the pile depth at 0.5 m, 1.0 m, 1.5 m, 2.0 m, 2.5 m, and 3.0 m. The leaching parameters.

[0043] Prepare test uranium ore with a particle size distribution of 0-9 mm and mix it evenly. A layer of quartz sand with a thickness of 3 cm was laid on the bottom of the buffer space, and then a layer of test ore with a thickness of 2 cm was laid on it, and the conical funnel and the buffer space were connected and fixed on the support. Pass the plexiglass column tube through the round holes on the bracket and connect ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com