Two-section sludge gas-generating treatment method and two-section sludge gas-generating treatment device

A treatment method and technology of treatment devices, which are applied in the fields of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as the inability to completely eliminate the cost of toxic and harmful gas treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

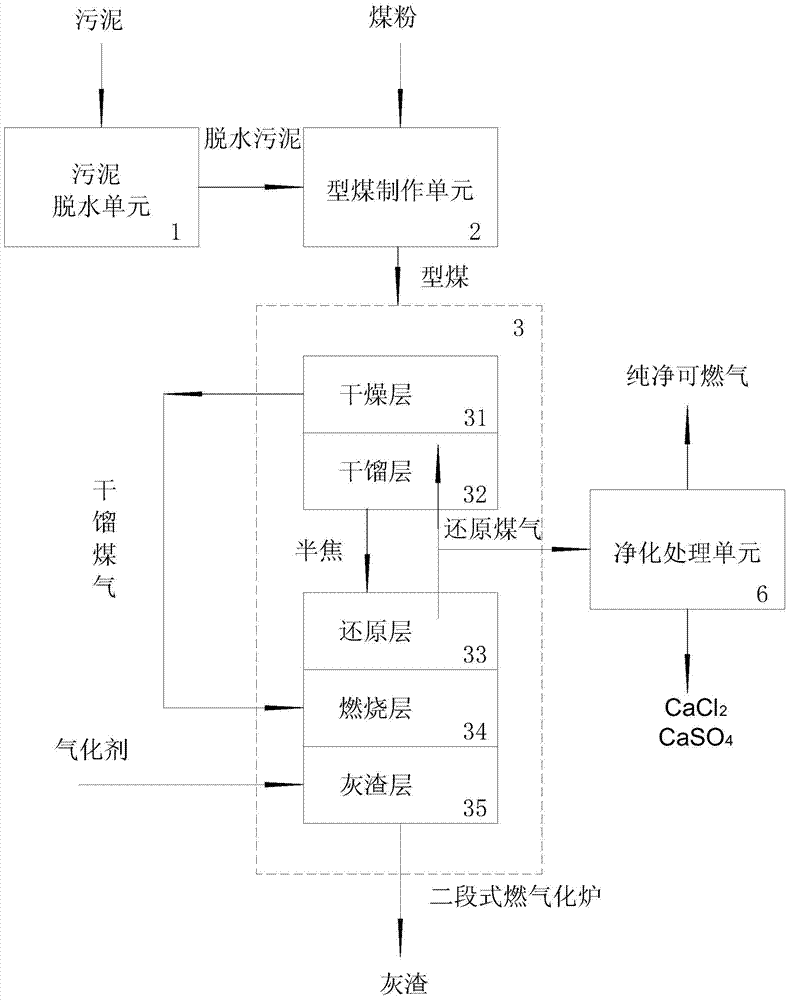

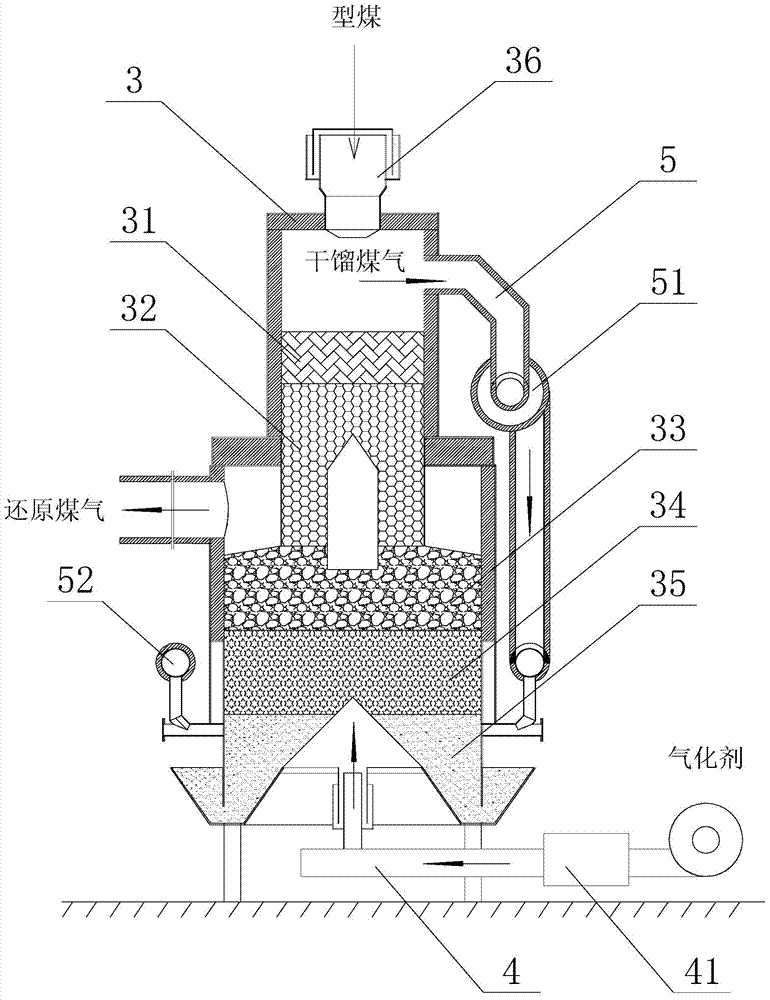

[0027] Embodiment: A kind of two-stage sludge gasification treatment method of this embodiment, such as figure 1 As shown, the process steps are as follows:

[0028] First, mechanically dehydrate the sludge with high water content, and mix the dehydrated sludge with a water content of less than 50% and coal powder at a ratio of 1:2 and press briquette coal;

[0029] Secondly, the briquettes are put into the furnace from the feeding port on the top of the two-stage gasification furnace. Since the high-temperature reduction gas generated at the bottom of the gasification furnace rises as a heat carrier and passes through the stacked briquettes, the briquettes are dried and dehydrated in the drying layer. Moreover, due to the airtightness of the furnace, the briquettes in the retort layer can be retorted in an oxygen-free state at 400°C to 550°C to form semi-coked briquettes and retort gas, which contains more toxic and harmful substances. Water vapor is mixed with a temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com