Ethanol gas phase oxidation acetaldehyde preparation catalyst and preparation and application methods thereof

A gas-phase oxidation and catalyst technology, which is used in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., and can solve the problems of high reaction temperature, low catalytic activity, and complicated preparation. , to achieve the effect of simple preparation process, strong controllability and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of above-mentioned catalyst comprises the steps:

[0040] (1) according to the metered molar ratio of A, B and Cu, the metal nitrate of A, B and Cu is dissolved, and the valence state of metal in the metal nitrate here can be the highest valence, also can be the low valence state, to the metal that obtains After adding citric acid and ethylene glycol to the nitrate solution, ultrasonically treat it for 0.5-1 h to obtain a uniform mixed solution a; the total metal concentration of the metal nitrate solution is 2-5 mol / L, and the total molar number of citric acid and the metal is The ratio is 0.1~0.3:1; the volume ratio of ethylene glycol to the metal nitrate solution is 0.05~0.2:1

[0041] (2) Heat the solution a obtained in step (1) in a sand bath at 130-200°C until spontaneous combustion, and the obtained fluffy solid b is roasted in an oxygen-containing atmosphere at 600-1000°C for 3-10 hours to obtain carrier A x B y Cu z o n ;

[0042] (3...

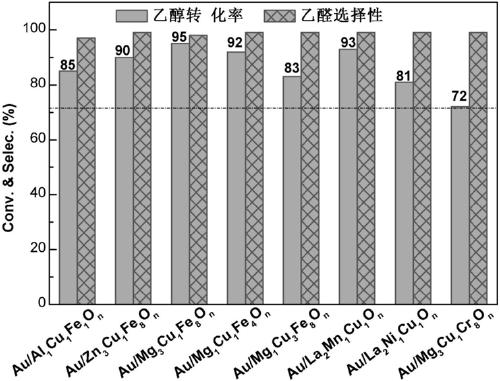

Embodiment 1

[0049] Au / Al for the Production of Acetaldehyde by Gas-Phase Oxidation of Ethanol 1 Cu 1 Fe 1 o n preparation of

[0050] Weigh 7.51g of aluminum nitrate, 4.84g of copper nitrate and 8.08g of ferric nitrate and dissolve them in 25mL of deionized water, then add 3.0g of citric acid and 2mL of ethylene glycol, mix and stir and sonicate for 0.5h, and put the mixed solution at 170°C Heating in a sand bath until spontaneous combustion, grinding the obtained fluffy solid and roasting in a muffle furnace at 900°C for 6 hours, the Al 1 Cu 1 Fe 1 o n carrier. Take out 1.0g carrier and place it in a 50mL round bottom flask, add 30mL deionized water and 0.20g urea, place the flask in a 100°C oil bath and stir for 10min, add 5mL of 10mM HAuCl dropwise 4 Aqueous solution, reflux reaction for 4 hours, after cooling, suction filtration, washing, drying, and calcination in a muffle furnace at 300°C for 4 hours, Au / Al with Au loading of ~1% can be obtained 1 Cu 1 Fe 1 o n catalyst....

Embodiment 2

[0052] Au / Zn for Ethanol Vapor Phase Oxidation to Acetaldehyde 3 Cu 1 Fe 8 o n preparation of

[0053] Weigh 4.46g of zinc nitrate, 1.21g of copper nitrate and 16.16g of ferric nitrate and dissolve them in 25mL of deionized water, then add 3.1g of citric acid and 2mL of ethylene glycol, mix and stir and sonicate for 0.5h, and put the mixed solution at 180°C Heating in a sand bath until spontaneous combustion, grinding the obtained fluffy solid and roasting in a muffle furnace at 800°C for 7 hours, the Zn 3 Cu 1 Fe 8 o n carrier. Take out 1.0g of the carrier and place it in a 50mL round bottom flask, add 30mL of deionized water and 0.20g of urea, place the flask in a 100°C oil bath and stir for 10min, then add 5mL of 10mM HAuCl dropwise 4 Aqueous solution, reflux reaction for 4 hours, after cooling, suction filtration, washing, drying, and roasting in a muffle furnace at 350°C for 3 hours, Au / Zn with Au loading of ~1% can be obtained 3 Cu 1 Fe 8 o n catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com