Method for removing aging copper foil plating solution detrimental impurities

A technology of harmful impurities and electroplating solution, applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of serious pollution of the environment, poor adsorption of harmful metals, short service cycle, etc., to achieve high adsorption purification rate, good economic benefits, selection strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

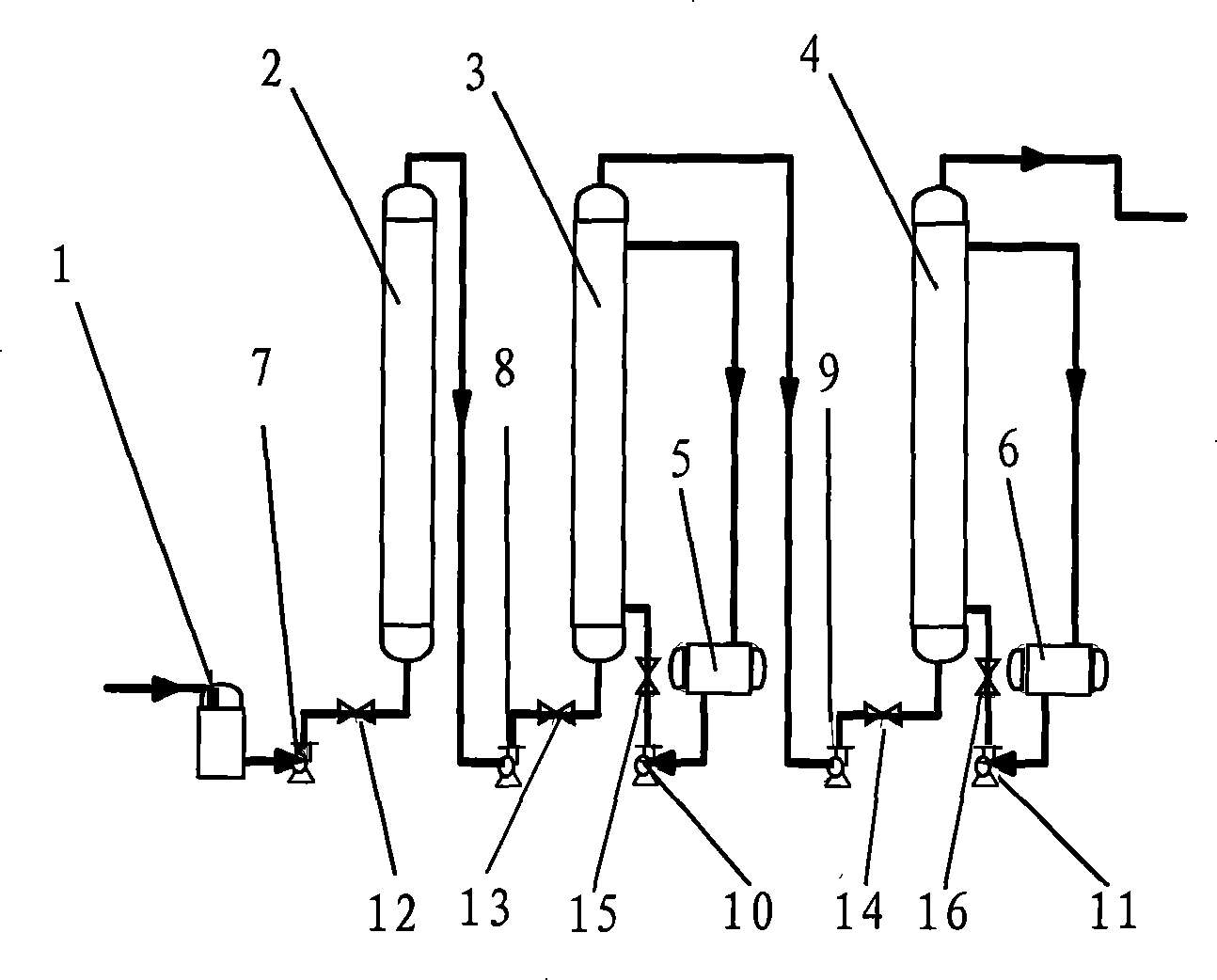

[0020] First make the valves on each pipeline in the purification treatment process device be in a closed state, store the processed aging electroplating solution in the storage tank 1, start the corrosion-resistant pumps 7, 8, 9, and turn the corresponding valves 12, 13, 14 Open, the processing speed is controlled at 0.3m 3 / h;

[0021] The electroplating solution flows through the activated carbon column 2 (using coconut shell granular activated carbon 10-20 mesh) in the pipeline for adsorption to remove organic impurities and a small amount of harmful metal ions;

[0022] After the electroplating solution flows out from the activated carbon adsorption column 2, it enters the strong acid resin column 3 (resin model used: strong acid 001×7), so that the higher concentration of Zn, Fe, Cr, Pb, Sb, As and other trace metal ions in the plating solution remove;

[0023] The electroplating solution enters the weak base resin column 4 after flowing out from the strong acid resin ...

Embodiment 2

[0025] First make the valves on each pipeline in the purification treatment process device be in a closed state, store the processed aging electroplating solution in the storage tank 1, start the corrosion-resistant pumps 7, 8, 9, and turn the corresponding valves 12, 13, 14 Open, the processing speed is controlled at 0.4m 3 / h;

[0026] The electroplating solution flows through the activated carbon column 2 (using coconut shell granular activated carbon 10-20 mesh) in the pipeline for adsorption to remove organic impurities and a small amount of harmful metal ions;

[0027] After the electroplating solution flows out from the activated carbon adsorption column 2, it enters the strong acid resin column 3 (resin type: strong acid 001×10;), so that the higher concentration of Zn, Fe, Cr, Pb, Sb, As and other trace metals in the plating solution ion removal;

[0028] The electroplating solution enters the weak base resin column 4 after flowing out from the strong acid resin col...

Embodiment 3

[0030] First make the valves on each pipeline in the purification treatment process device be in a closed state, store the processed aging electroplating solution in the storage tank 1, start the corrosion-resistant pumps 7, 8, 9, and turn the corresponding valves 12, 13, 14 Open, the processing speed is controlled at 0.5m 3 / h;

[0031] The electroplating solution flows through the activated carbon column 2 (using coconut shell granular activated carbon 10-20 mesh) in the pipeline for adsorption to remove organic impurities and a small amount of harmful metal ions;

[0032] After the electroplating solution flows out from the activated carbon adsorption column 2, it enters the strong acid resin column 3 (resin type: strong acid 001×8;), so that the higher concentration of Zn, Fe, Cr, Pb, Sb, As and other trace metals in the plating solution ion removal;

[0033] The electroplating solution enters the weak base resin column 4 after flowing out from the strong acid resin colu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com