Red mud ceramsite-gold tailing sand-based color brick as well as preparation method and application thereof

A technology of gold tailings sand and red mud ceramsite, which is applied to pavement, roads, buildings and other directions paved with prefabricated blocks, can solve the problems of unfavorable sustainable development, poor thermal insulation performance, excessive specific gravity, etc., and achieve light weight and high Thermal insulation and shock resistance, effect of reducing dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

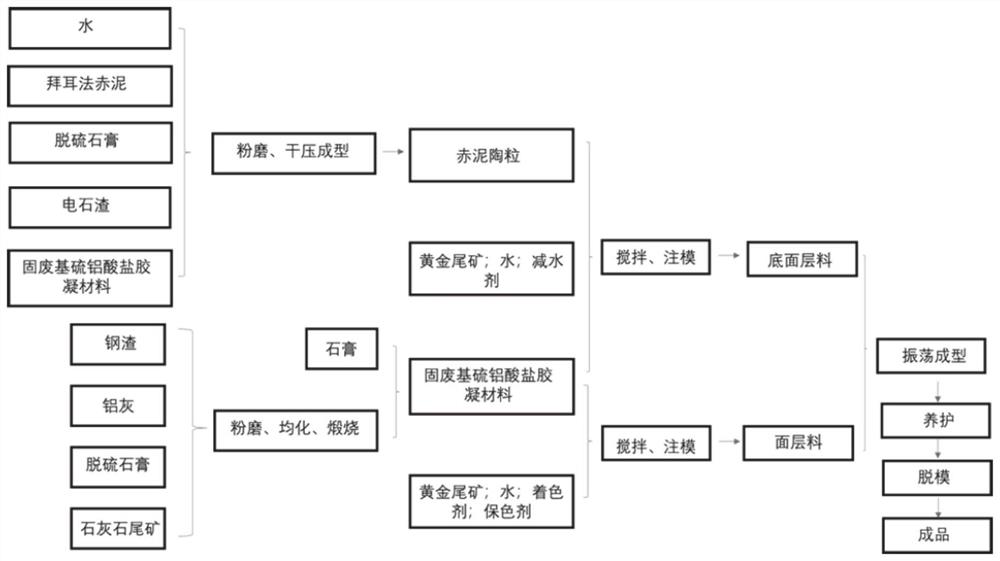

[0039] In the present invention, red mud is applied to the preparation of colored bricks. Firstly, red mud needs to be prepared into red mud ceramsite aggregate. In the present invention, red mud and solid waste-based sulphoaluminate cementitious materials, carbide slag and desulfurized gypsum are used Compounding, red mud ceramsite is made by dry pressing, the ceramsite is light in weight and has good mechanical properties.

[0040] In one or more embodiments, the curing temperature is 15 to 25°C, preferably 20°C, the air humidity is 93% to 97%, preferably 95%, and the curing time is 26 to 30 days, preferably 28 days, so as to fully Hydration ensures the performance of red mud-based aggregate.

[0041] In an embodiment of the present invention, the particle size distribution of the gold tailings sand is 100mm-200mm.

[0042] In an embodiment of the present invention, the colorant is an iron oxide pigment.

[0043] In an embodiment of the present invention, the water reducer...

Embodiment 1

[0054] Preparation of solid waste-based sulfoaluminate cementitious material:

[0055] Steel slag 20.61%, aluminum ash 24.74%, desulfurized gypsum 29.38%, limestone tailings 25.26%, the raw materials after grinding and homogenization are calcined at 1220°C in the kiln, and the holding time is 30min to obtain solid waste-based sulfoaluminate Cement clinker, the obtained solid waste-based sulphoaluminate cement clinker is ground with 4% desulfurized gypsum, and the solid waste-based sulphoaluminate cementitious material is prepared, which has the advantages of early strength, rapid hardening, low cost and environmental protection features.

[0056] Preparation of red mud ceramsite: 30% solid waste-based sulphoaluminate cementitious material, 60% Bayer red mud, 5% desulfurized gypsum, 5% carbide slag; 8% water of the total mass of solid waste raw materials; solid waste Sulphoaluminate-based cementitious material, Bayer red mud, desulfurized gypsum, and calcium carbide slag are m...

Embodiment 2

[0058] A preparation method of red mud ceramsite-gold tailing sand-based colored brick is as follows: use 15 parts of solid waste-based sulfoaluminate cementitious material, 78 parts of red mud ceramsite, 25 parts of gold tailing sand, and configure with a water-binder ratio of 0.30 The raw materials of the bottom layer are prepared according to 15 parts of solid waste-based sulfoaluminate cementitious materials, 38 parts of gold tailings, 0.2 parts of color retention agent, 1.5 parts of coloring agent, and 0.35 water-to-binder ratio. First add the material of the fabric layer to the bottom mold of the oscillating table, vibrate to make it dense, then add the raw material of the bottom layer, vibrate to make it dense, the thickness of the bottom layer is 55mm, and the thickness of the surface layer is 5mm; the standard curing temperature of the brick sample after demoulding is 20 ±0.5°C, humidity 98%, after curing for 28 days, perform performance test.

[0059] Performance tes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Surface thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com