Porous oxide adsorbing material for efficiently removing harmful ions in water

An oxide and water removal technology, applied in the directions of alkali metal oxides/hydroxides, water pollutants, alkali metal compounds, etc., can solve the problems of insufficient adsorption performance, limited adsorption capacity, adsorption rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

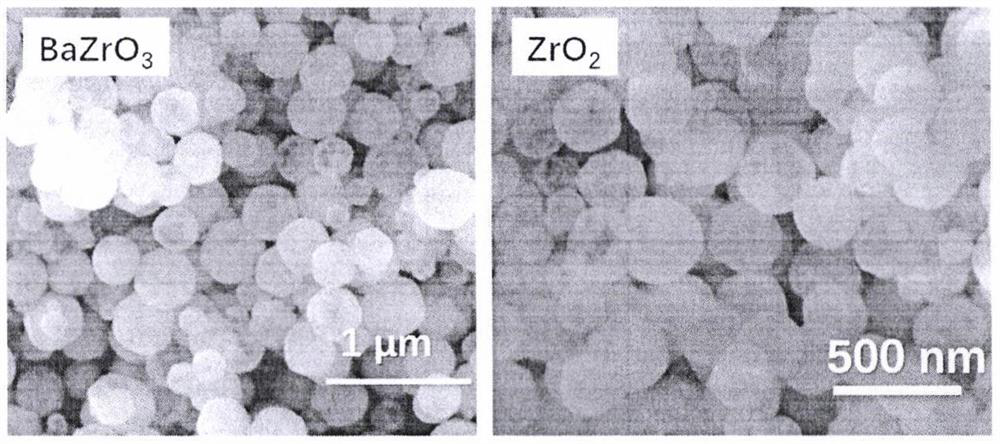

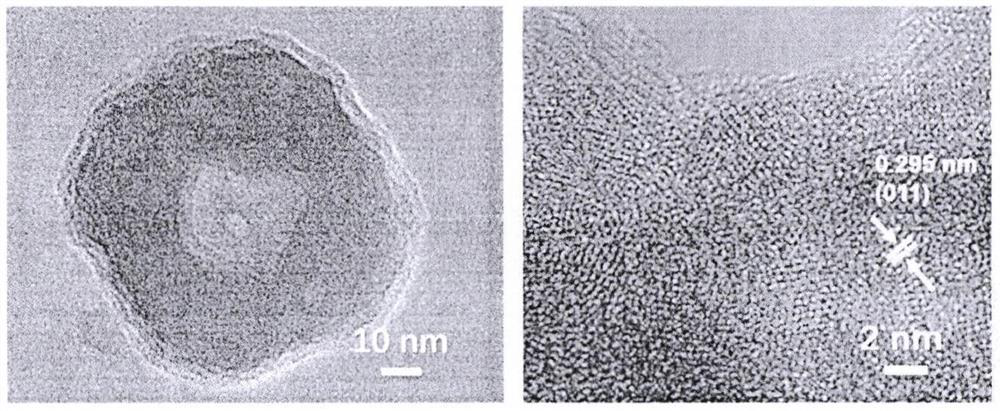

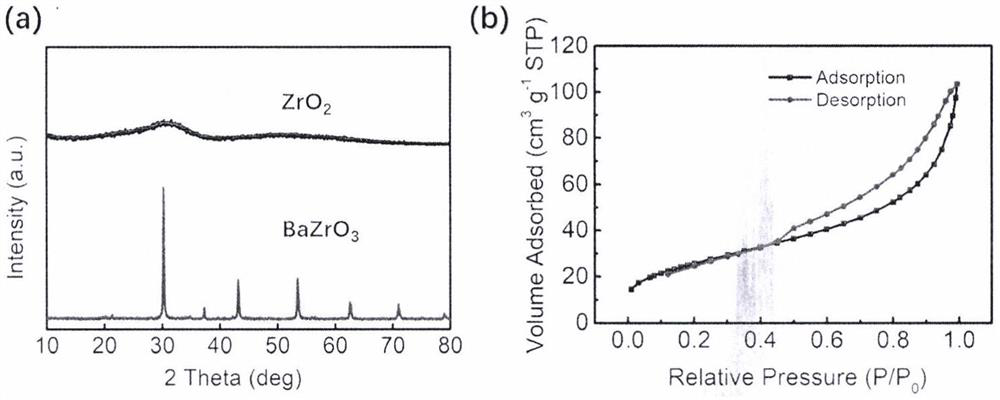

[0040] BaZrO with hollow spherical morphology was first prepared by hydrothermal method 3 Precursor, the reaction condition is Ba(OH) 2 , ZrOCl 2 ·8H 2 O, KOH and H 2 O is fully stirred according to the molar ratio of 1:1:10:100, placed in a hydrothermal device, and reacted at 150°C for 3 days to prepare hollow BaZrO 3 . Precursor hollow BaZrO 3 , hydrochloric acid and water were mixed according to the molar ratio of 1:10:100, placed in a high-pressure reaction vessel, first reacted at 100°C for one day, and then transferred to an oven at 150°C for 3 hours. After this step of reaction, all Ba is stripped out and transformed into the product ZrO 2 . The product was separated by centrifugation and washed with deionized water, and dried in an oven at 70 °C. This product retains the hollow spherical characteristics of the precursor, which is determined by figure 1 Visible, the precursor BaZrO 3 and product ZrO 2 They are all hollow spherical. figure 2 shows ZrO 2 Th...

Embodiment 2

[0042] Firstly, star-shaped BaZr was prepared by hydrothermal method x Ti 1-x o 3 (x=0.2-0.8) precursor, the reaction condition is that Ba(OH) 2 , ZrOCl 2 ·8H 2 O, TiCl 4 and H 2 O according to the molar ratio of 1:x:(1-x):100, (x=0.2-0.8) is fully stirred and placed in a hydrothermal device, and BaZr can be prepared by reacting at 120°C for 1 day x Ti 1-x o 3 . Precursor BaZr x Ti 1-x o 3 , hydrochloric acid and water were mixed according to the molar ratio of 1:12:100, placed in a high-pressure reaction vessel, first reacted at 110°C for one day, and then transferred to an oven at 140°C for 2 hours. After this step of reaction, Ba is all dissolved and converted into the product Zr x Ti 1-x o 2 (x=0.2-0.8). The product was separated by centrifugation and washed with deionized water, and dried in an oven at 70 °C. Product Zr x Ti 1-x o 2 (x=0.2-0.8) has the same star-shaped characteristics as the precursor, by Figure 5 confirmed by scanning electron micro...

Embodiment 3

[0044] BaZrO with truncated octahedral morphology was first prepared by hydrothermal method 3 Precursor, the reaction condition is Ba(OH) 2 , ZrOCl 2 ·8H 2 O and H 2 O is fully stirred according to the molar ratio of 1:1:100, placed in a hydrothermal device, and reacted at 130°C for 1 day to prepare truncated octahedral BaZrO 3 . The precursor BaZrO 3 , hydrochloric acid and water were mixed according to the molar ratio of 1:10:100, placed in a high-pressure reaction vessel, first reacted at 110°C for one day, and then transferred to an oven at 130°C for 3 hours. After this step of reaction, all Ba is dissolved and transformed into truncated octahedral ZrO 2 . The product was separated by centrifugation and washed with deionized water, and dried in an oven at 70 °C. The process and mechanism of the preparation reaction are consistent with Example 1. X-ray powder diffraction showed that the zirconium dioxide had an amorphous phase. The zirconium dioxide is used to pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com