Method and device for purifying and recycling chromium electroplating solution and waste solution thereof

A technology for purifying device and chrome plating solution, applied to cells, electrolysis process, electrolysis components, etc., can solve the problems of limited chrome plating tank capacity, tank liquid pollution, accelerated accumulation of metal impurities, etc. The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

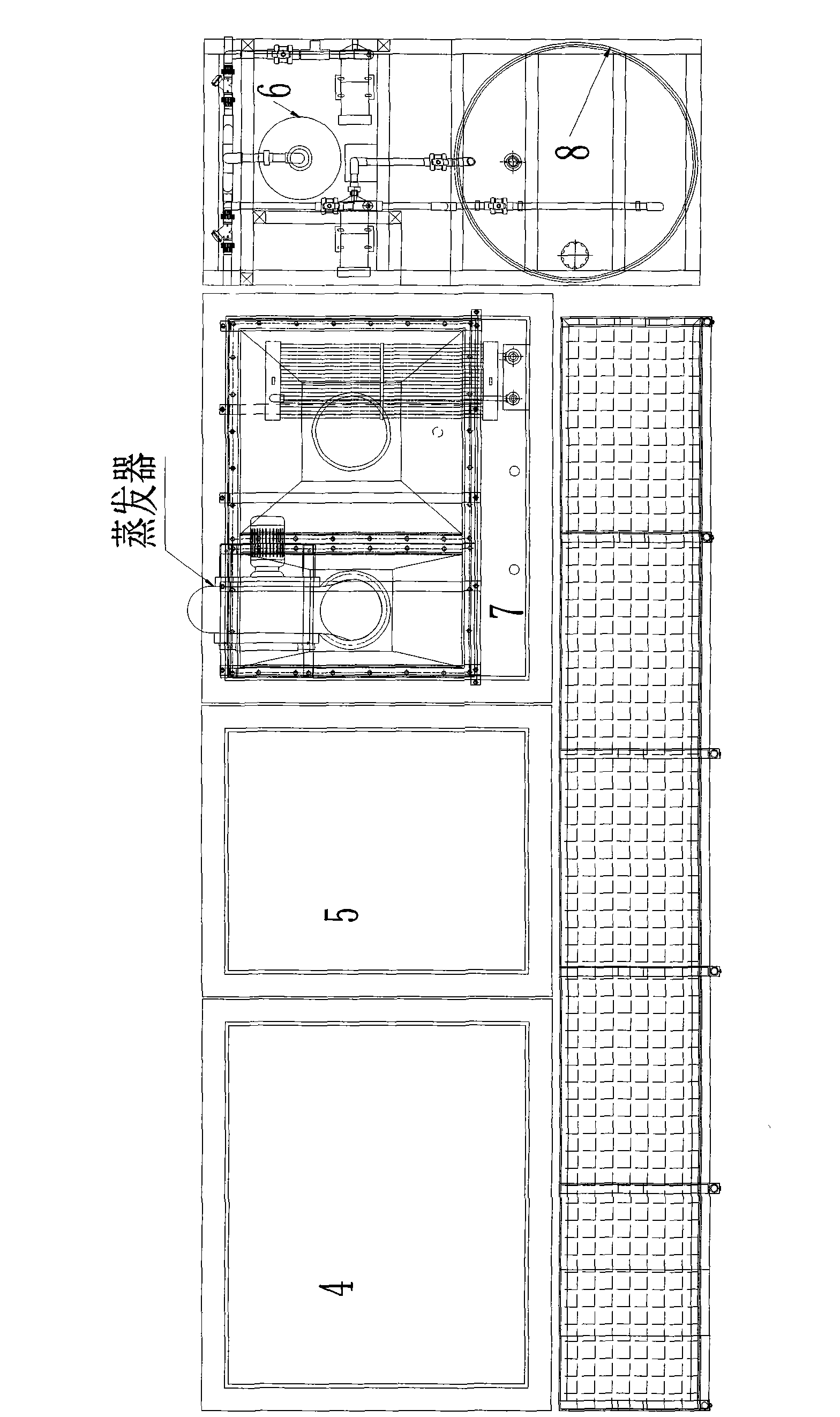

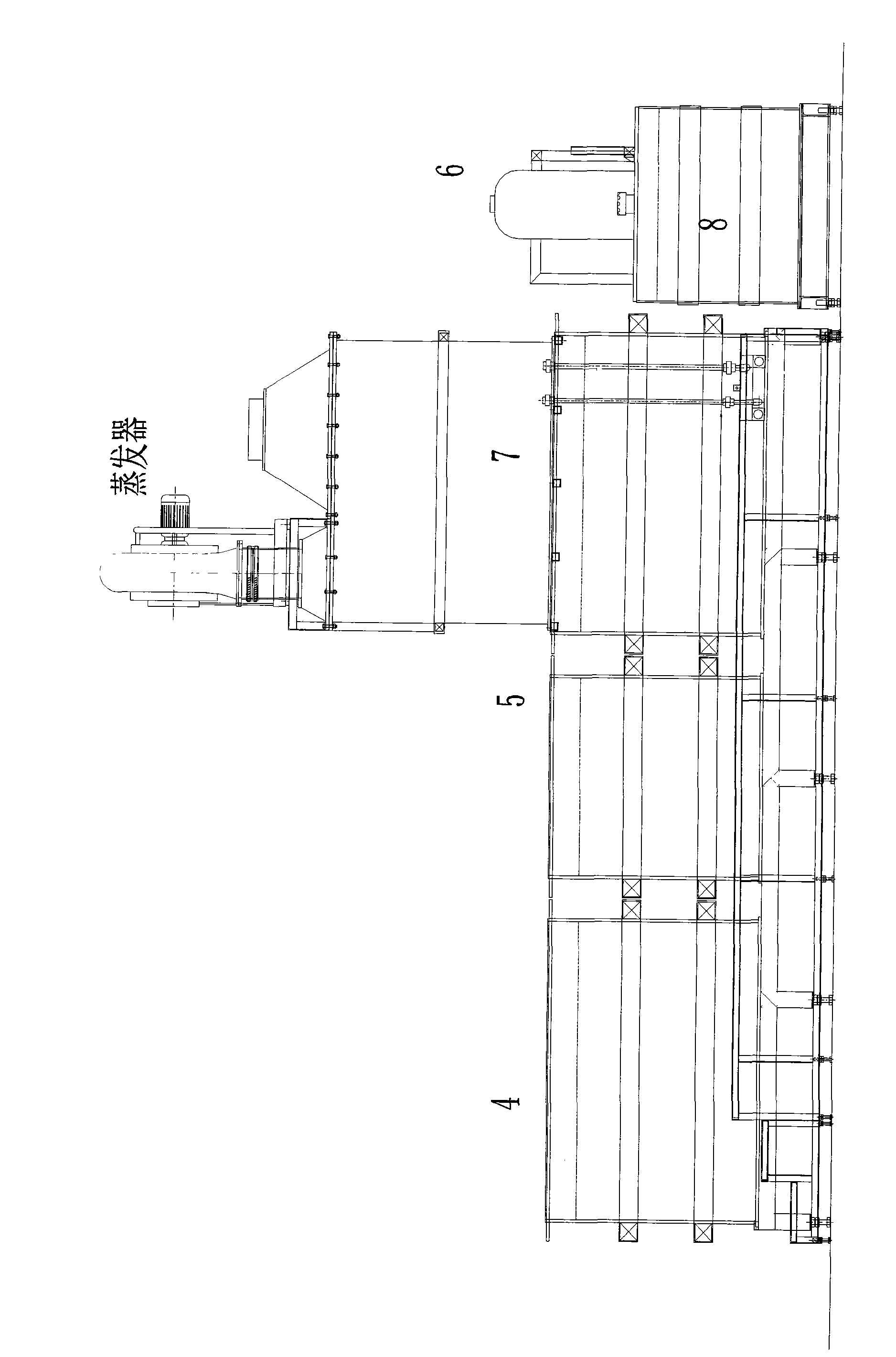

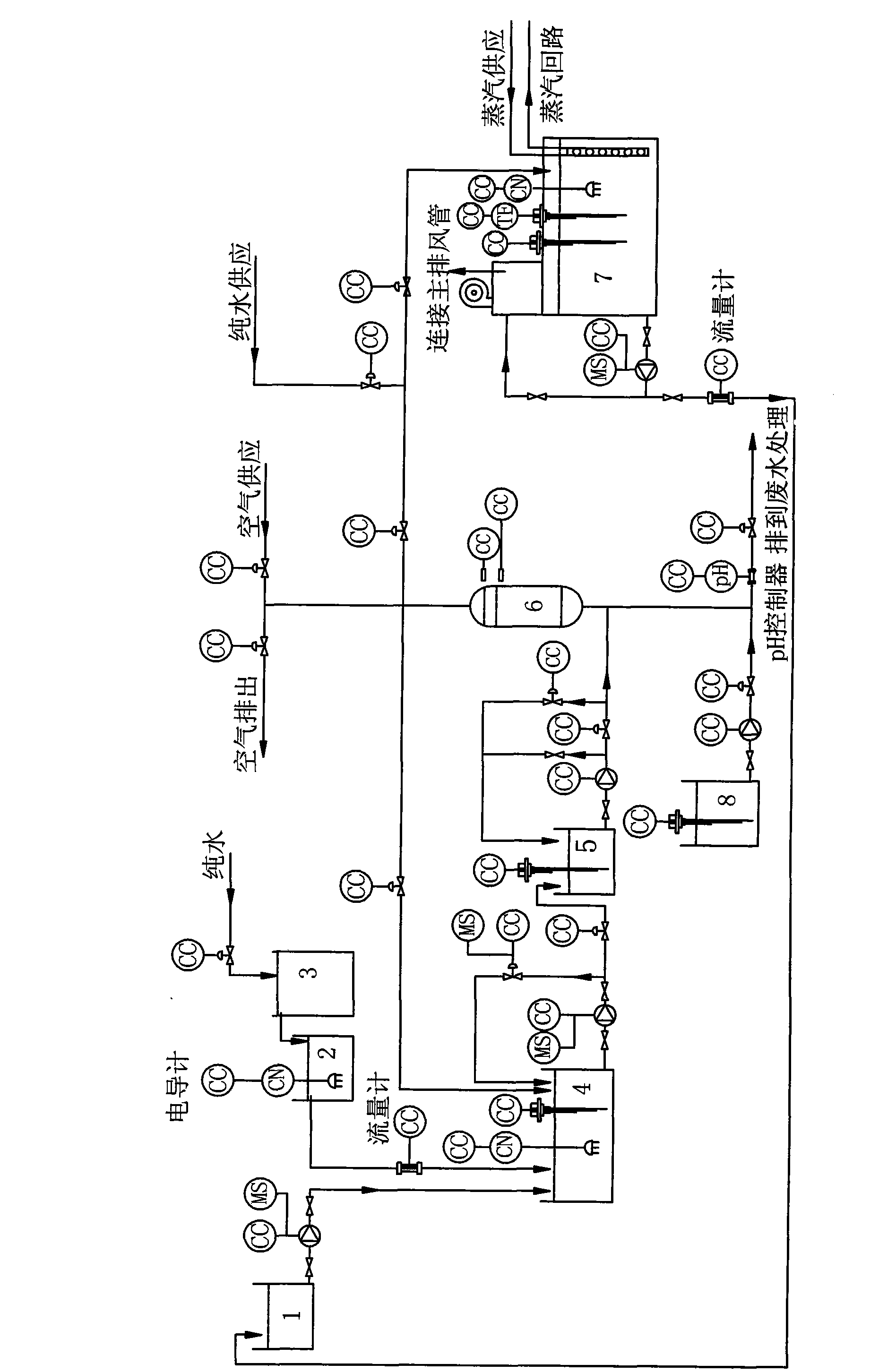

[0037] Such as image 3 As shown, the device for realizing the purification and reuse method of the chromium plating solution includes: a chromium solution storage tank 4, a purification device buffer tank 5, a cationic resin column 6, a concentration device 7 and a PLC controller; a chromium solution storage tank 4 The pipelines are respectively connected to the first recovery tank 2 and the electroplating tank 1 in the electroplating production line. The chromium solution storage tank 4 is connected to the buffer tank 5 of the purification device through a pump and pipeline, and the buffer tank 5 of the purification device is connected to the cation through a pump and a valve. Resin column 6 is connected, cationic resin column 6 is connected with concentrator 7 by pipeline, sulfuric acid tank 8 is connected to cationic resin column 6 by the pipeline that is connected with pump and valve, and concentrator 7 is connected by the pipeline that is connected with valve and flow met...

Embodiment 2

[0042] After the workpiece is chrome-plated in the electroplating tank 1, the workpiece brings the chromium plating solution into the first recovery tank 2. After the solution in the first recovery tank 2 is measured by the conductivity meter to 10 g / liter of chromic acid, control the solenoid valve for adding water, and add water to the second recovery tank. Groove 3, the water of the second recovery tank 3 overflows to the first recovery tank 2, and then the solution of the first recovery tank 2 overflows to the chrome solution storage tank 4;

[0043] After the terminal liquid level instrument measures that the solution in the chromium solution storage tank 4 reaches 80% of the volume, the PLC controller sends the solution in the chromium solution storage tank 4 in batches and quantitatively to the purification device for processing according to the concentration of the solution. Exchange the resin, pump the solution to be purified into the buffer tank 5 of the purification ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com