Patents

Literature

51results about How to "Achieve eco-efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

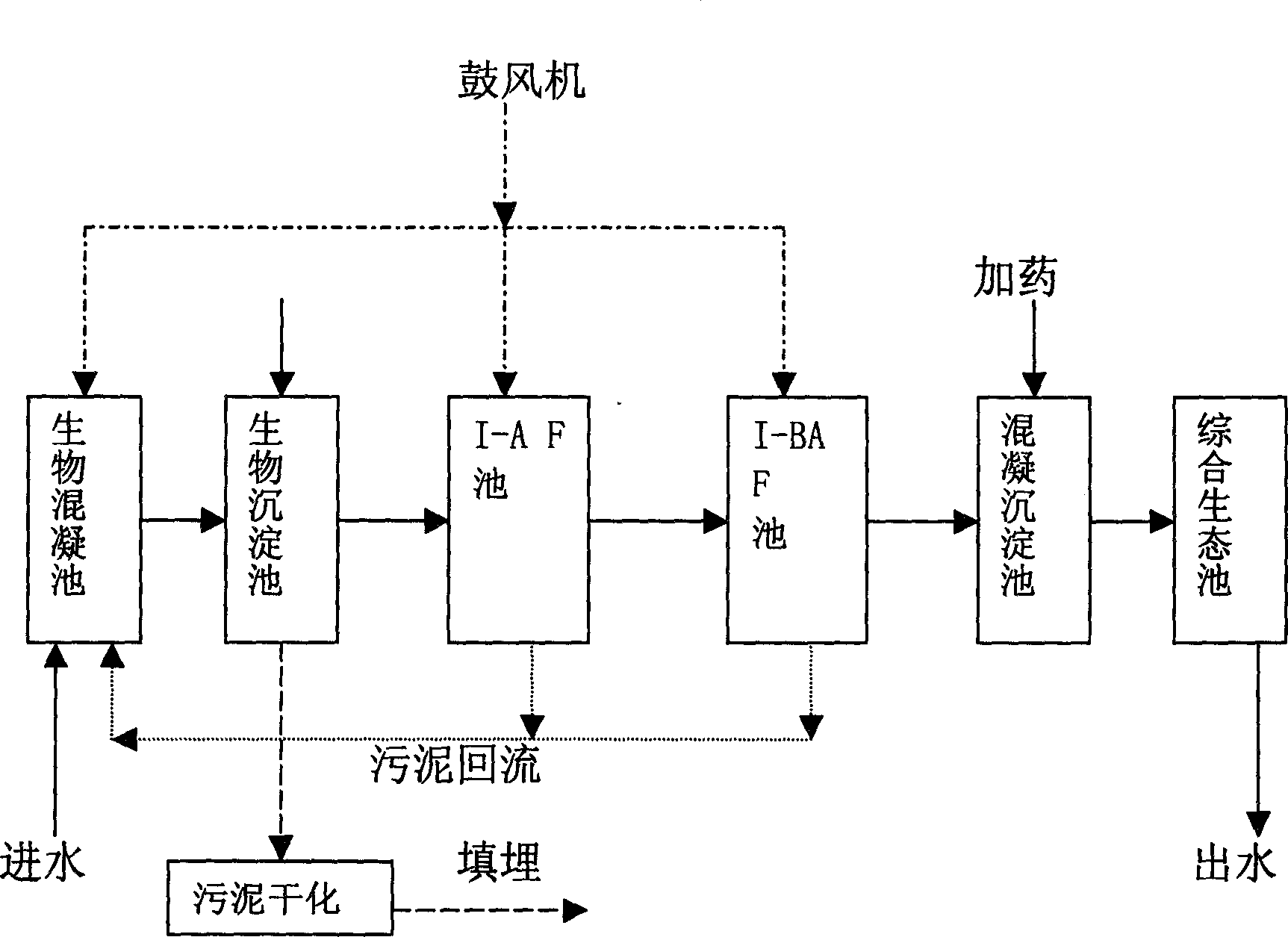

Combined treatment method and system for landfill leachate

InactiveCN1631820AEasy to handleStabilizationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentFiltrationWater quality

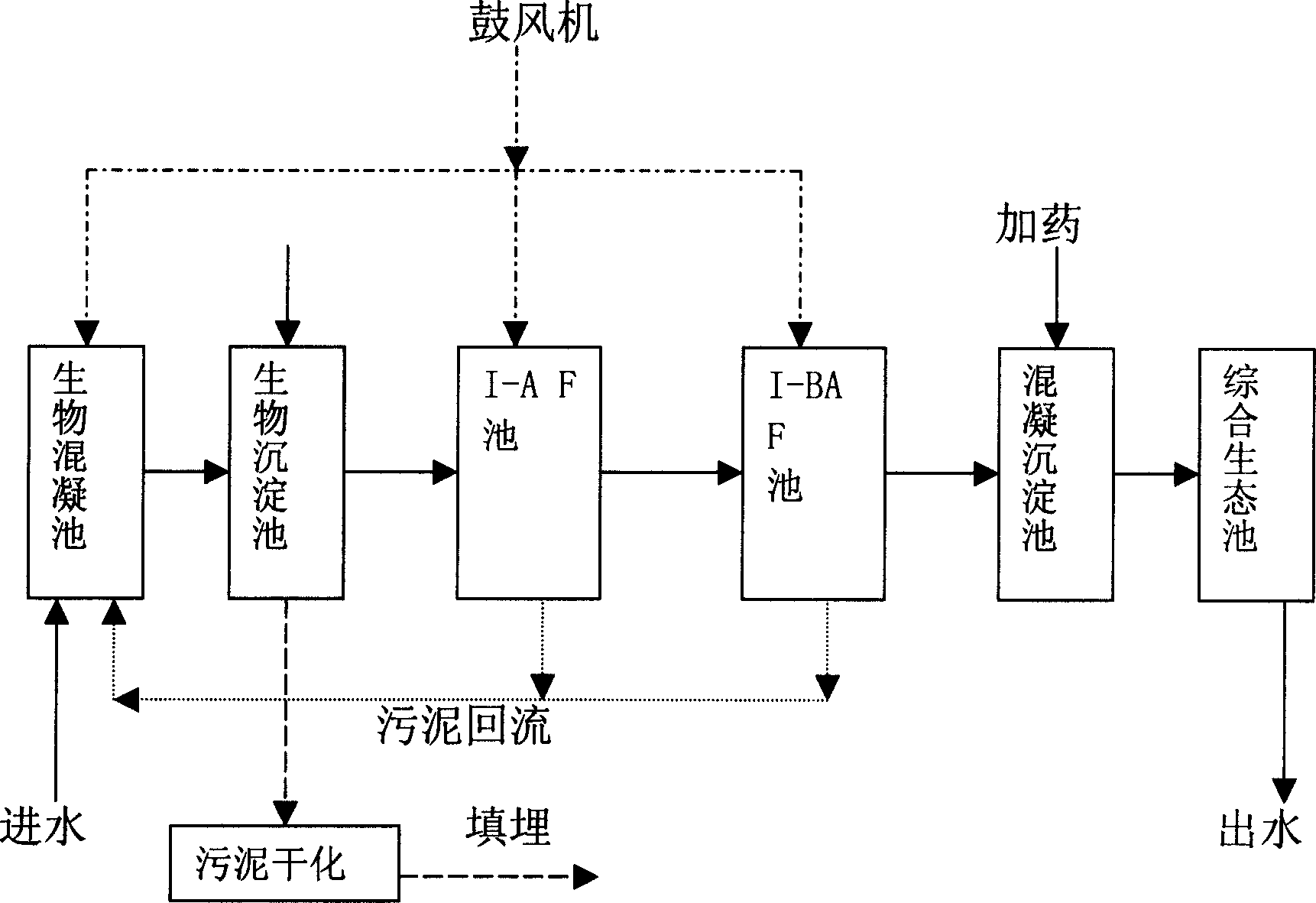

Disclosed are a method for processing rubbish percolating water and its system. The processing technique realizes the procession by combining the procession, biological processing technology and ecological procession. The system mainly comprises of adjusting pool, biological coagulation pool, high effective biological filtration pool, comprehensive ecological pool and so on. Compared with the present technology, it has rapid processing speed, high quality of water processed which can reach the first-class drainage standard, and can realize naugh drainage of waste water in rubbish processing factory.

Owner:PEKING UNIV

Method for protecting slope vegetation through plant fiber blankets

ActiveCN105123212AGuarantee the built effectEasy to buildExcavationsCultivating equipmentsFiberVegetation

The invention relates to a method for protecting slope vegetation through plant fiber blankets. The method for protecting slope vegetation through plant fiber blankets is applicable to fill roadbed slope protection during a construction period. According to the method, fill roadbed slopes are divided into two categories, according to one category, the fill roadbed slopes are formed slopes where roadbed filling is completed, and according to the other category, the fill roadbed slopes are non-formed slopes where roadbed filling is not completed. The operation that roadbeds are gradually filled and spreading is performed layer by layer is performed on the non-formed slopes, the plant fiber blankets are fixed, after filling of the all the roadbeds and covering of the plant fiber blankets are completed, plant seeds are sown on the surfaces of the plant fiber blankets, covering of thin soil is performed, and watering and curing are performed so that vegetation can be formed; the operations that grass seeds are sown on the total slopes, then the total slopes are covered with the plant fiber blankets, and curing is performed are adopted so that the vegetation can be built. By means of the method, the slopes can be greened as soon as possible, water and soil loss can be effectively controlled in the construction period, and the effectiveness of slope protection is enhanced in the construction period.

Owner:CHINA ACAD OF TRANSPORTATION SCI +1

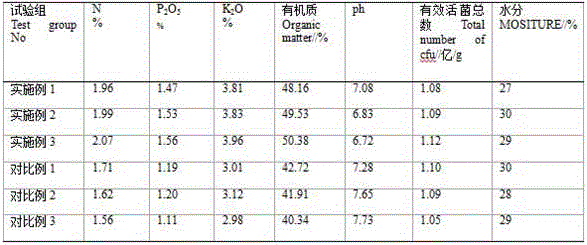

Preparing method of walnut green husk dreg organic fertilizer

ActiveCN106495879AAvoid pollutionProtect and improve the ecological environmentCalcareous fertilisersBioloigcal waste fertilisersLivestock manureAdditive ingredient

The invention relates to a preparing method of a walnut green husk dreg organic fertilizer. The preparing method comprises the steps of preparing the walnut green husk dreg organic fertilizer by adopting walnut green husk dregs, edible fungus dregs and plant ash as main ingredients, carrying out inoculation of a microorganism strain for fermentation and the like. The walnut green husk dreg organic fertilizer contains no poultry and livestock manure, avoids side effects of seeding blight, root blight, diseases and pests and the like caused by applying excrement and urine inorganic fertilizer of livestock and poultry, reasonably and effectively solves the problem of pollution of the walnut green husk and the edible fungus dregs to environment, and turns waste into wealth; the walnut green husk dreg organic fertilizer further has high potassium content, resistance to diseases and pests of fruit trees is strengthened after the use of the fertilizer, the yield of the fruit trees is increased, the fruit quality is sharply improved, and economic benefits are significantly increased.

Owner:SHANDONG ACAD OF GRAPE

Method for preparing micro-molecular hemepeptide from duck blood

InactiveCN102911990AIncrease added valueAchieve eco-efficiencyPeptide preparation methodsFermentationFractionationAnti coagulation

A method for preparing micro-molecular hemepeptide from duck blood includes that the duck blood which is a meat duck processing byproduct is used as a raw material, and an anti-coagulation and anti-oxidation technology, a high and low temperature changing alternation technology, a dynamic ultrahigh-pressure technology, a phased enzymatic hydrolysis technology, an enzymatic hydrolysis supernatant decoloration treatment and membrane fractionation technology, spray-drying technology and the like are integrated to develop the micro-molecular hemepeptide with physiological activity within a specific molecular weight range. The average peptide chain length of the micro-molecular hemepeptide prepared by the method ranges from 2.9 amino acid residues to 3.5 amino acid residues, the molecular weight distribution range of the micro-molecular hemepeptide is 1000-3000d, and the content of hemepeptide is higher than or equal to 35%. The method has the advantages that an additional value of the product is increased, duck blood resources are totally, effectively and comprehensively utilized, a preparation process is free of pollutant discharge, and an ecological benefit of zero environmental pollution can be achieved.

Owner:NANCHANG UNIV

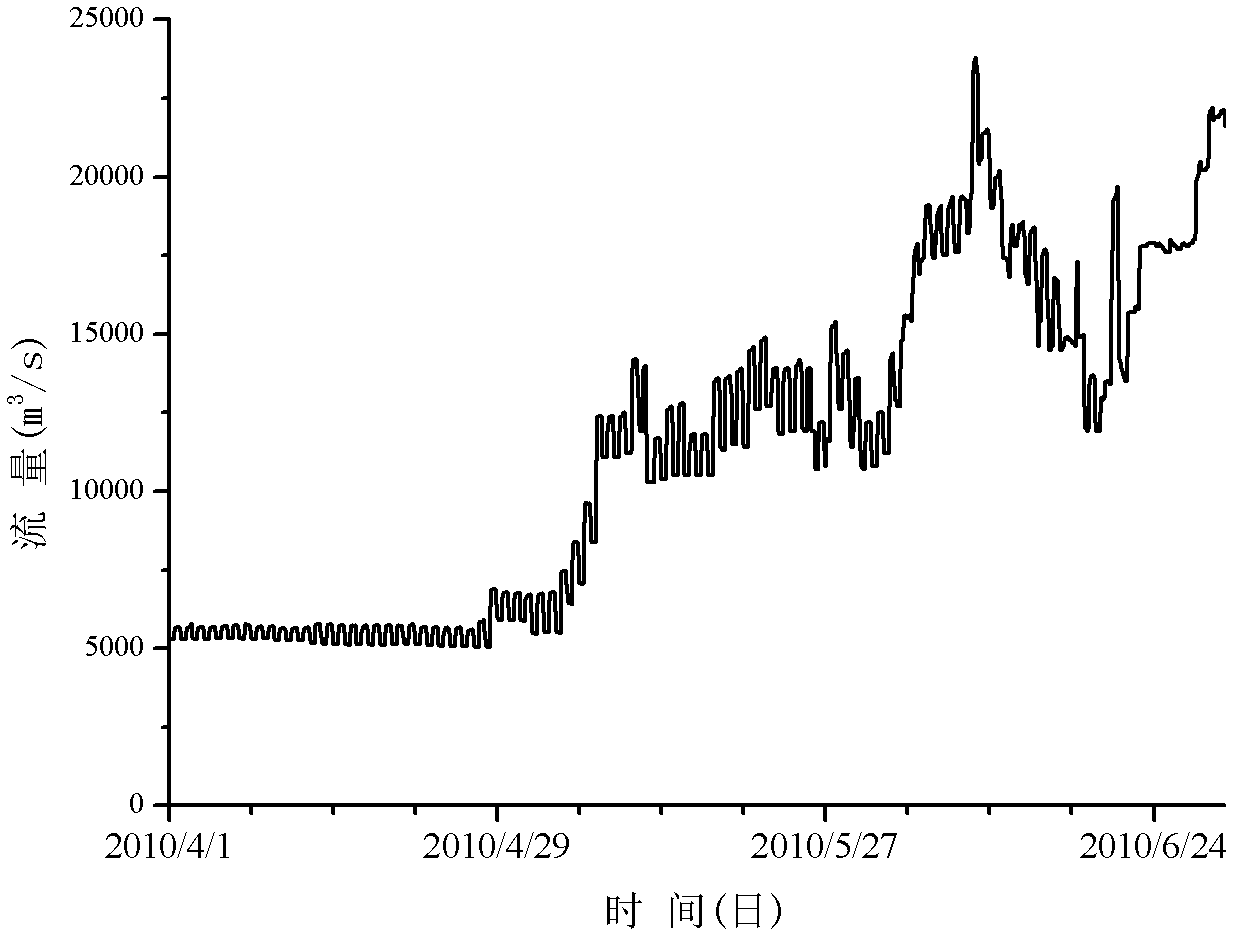

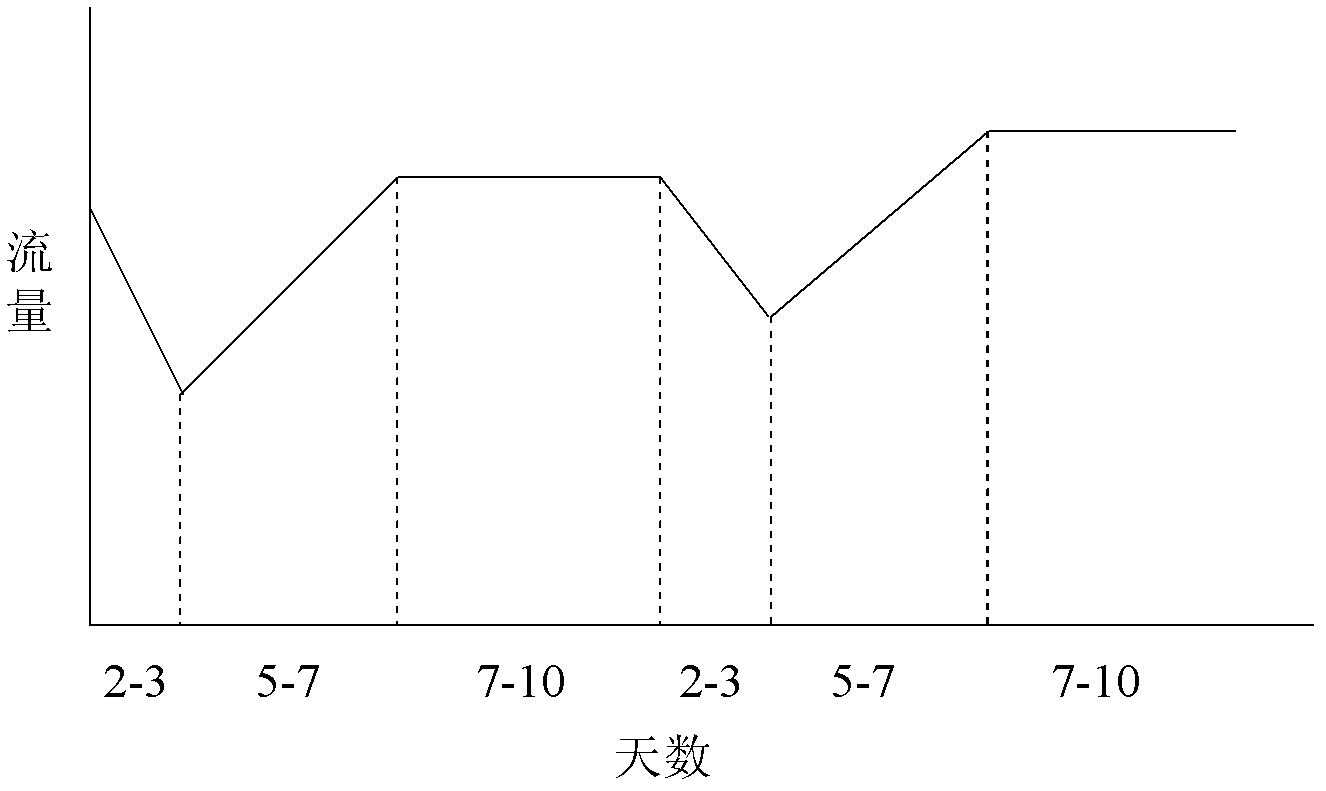

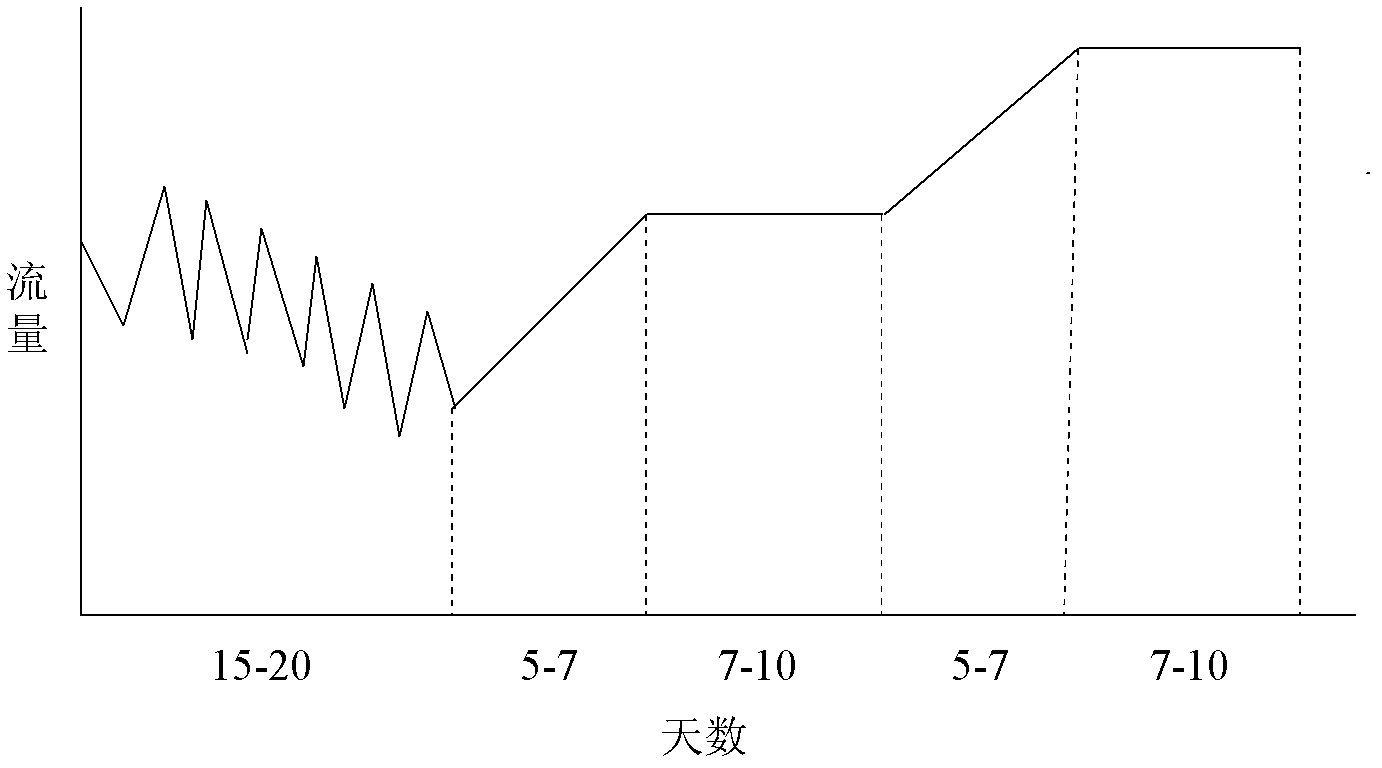

Ecological dispatching method of river channel type water reservoir suitable for home fish breeding

ActiveCN102605740AReduce the impactMeet traditional power generationPisciculture and aquariaStream regulationLeaking waterEcological environment

The invention relates to a water reservoir ecological dispatching method, in particular relates to an ecological dispatching method of a river channel type water reservoir suitable for home fish breeding. The ecological operation for a water reservoir which is suitable for home fish spawning is implemented at the home fish egg reproduction period based on a corresponding-period water reservoir regular dispatching process to make an 'artificial flood peak' process, so as to creat hydrologic conditions which are suitable for home fish breeding at the downstream. Through continuously reducing the leakage amount of a dam, a space for continuously leaking water is provided in the later stage and the daily amplification flow rate of the downstream is guaranteed, so that a good ecological environment is provided for the home fish breeding. The dispatching method disclosed by the invention meets the benefits of the conventional flood control, power generation, navigation and the like of a river channel type water reservoir, and also considers the ecological benefits of the downstream of the river channel type water reservoir, so that the benefit relation between water-power engineering and ecological protection of the reservoir is effectively coordinated; and the dispatching method has the advantages of strong operability and practical applicability.

Owner:CHINA THREE GORGES CORPORATION

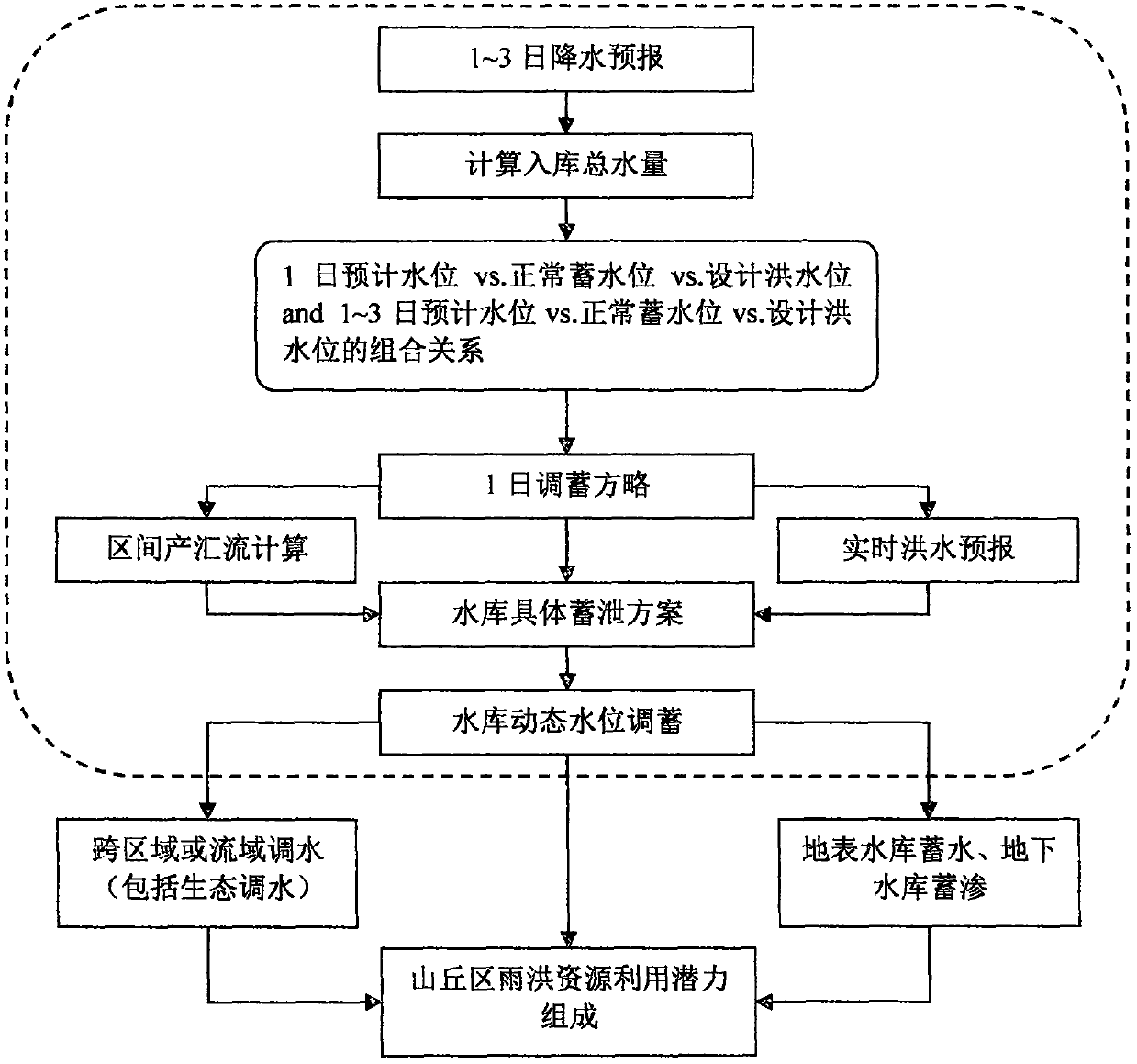

Method for estimating potential tapping quantity of rainfall flood resources

InactiveCN107916646AAlleviate tension between supply and demandLarge water supplyHydraulic engineering apparatusEngineering

The invention discloses a method for estimating the potential tapping quantity of rainfall flood resources. The method for estimating the potential tapping quantity of the rainfall flood resources comprises the steps that a hydraulic engineering system is combined, and corresponding engineering measures and non-engineering measures are taken to estimate the potential tapping quantity of flood resources of drainage basins of hilly regions and the potential tapping quantity of flood resources of drainage basins of plain regions. According to the method, surface flood runoffs are scientifically guided and stored to supplement underground water through underground water reservoirs so that the runoffs which flow into the sea and run off can be reduced; surface water and the underground water are effectively and jointly regulated and stored so that the potential of the increase of the exploitable quantity of the underground water in the plain regions can be great; as for the hilly regions and the plain regions, by means of the effective regulation and storage of the surface water and the underground water, the utilization amount of the rainfall flood resources can be averagely and newlyincreased by about 271 million m3 in total; and the increase of the total exploitation quantity of the underground water can bring great benefits to production, life and ecology.

Owner:SHANDONG SURVEY & DESIGN INST OF WATER CONSERVANCY

Lycium barbarum cottage planting method used in desertification region

ActiveCN105432316AImprove the ecological landscapeImprove eco-efficiencyPlant growth regulatorsBiocideMicrobial agentLycium barbarum fruit

The invention belongs to the field of plant cultivation and aims at providing a lycium barbarum cottage planting method capable of comprehensively improving the survival rate of lycium barbarum plants in a desertification region, improving the ecological benefits of wind prevention and sand fixation and improving ecological landscape of the desertification region. The lycium barbarum cottage planting method used in the desertification region comprises the steps that land plots with more plain terrain and suitable for sand-protecting barrier arrangement are selected, farmyard manure and a compound microbial agent are applied to the plots in autumn, and then deep soil ploughing is performed to form planting soil; the pH value of the planting soil is detected, and an appropriate amount of ferrous sulfate is added to regulate the pH value to be 6-8 when the pH value is greater than 8.5; straws are utilized to arrange latticed sand-protecting barriers capable of fixing quicksand and reducing wind speed in the planting soil in the last ten-day period of April of the second year after deep soil ploughing, and a relative stable environment is provided for lycium barbarum growth; rectangular land pieces for cuttage are made within the sand-protecting barriers in the first ten-day period of May, management and protection ways are reserved during making of the cottage land pieces so as to facilitate later-period management of the lycium barbarum plants.

Owner:LINGNAN LANDSCAPE

Germinating treatment method of acer yangjuechi seeds

ActiveCN103109618ABeautiful treeMeet the needs of greeningSeed immunisationHorticultureSeed dormancyLoment

The invention relates to a germinating treatment method of acer yangjuechi seeds. The germinating treatment method is characterized by comprising the following steps of: (1) seed collection: collecting winged fruits of acer yangjuechi in the first third and the second third of October, removing the fruit wings and obtaining complete seeds; (2) seed pretreatment; (3) seed sorting; (4) seed disinfecting treatment; (5) seed dormancy breaking; and (6) seed germination. The germinating treatment method comprises the following specific steps of: sowing the seeds with dormancy breaking into a germinating matrix, adopting garden soil, grass carbon and perlite with the volume ratio being 2:2:1, fully mixing, starting to germinate when the external temperature is 10-25 DEG C, expanding the seed leaves after 3 days, thus obtaining a normal and strong seedling with two true leaves after 5 weeks. The germinating treatment method has the advantages that the acer yangjuechi seedlings bred by the method has 34.5% germination rate, can be cultured by nursery garden, and the seedlings with neatness, consistency and excellent tree performance are generated so as to meet the greening requirement of urban and rural gardens, exert the ecological benefits, simultaneously be conductive to relieving the current critically-endangered living situation of the acer yangjuechi, expand the population quantity and realize conservation of endangered plants.

Owner:SHANGHAI ACADEMY OF LANDSCAPE ARCHITECTURE SCI & PLANNING

Submerged plant repairing, culturing and loading system for underwater ecological remediation

PendingCN107864774AIncrease profitImprove the water ecological environmentClimate change adaptationPisciculture and aquariaEcosystemFresh water organism

The invention discloses a submerged plant repairing, culturing and loading system for underwater ecological remediation. The system includes a buoyancy framework floating on the water surface, stretchable rod components and a supporting box body; the top end of each stretchable rod component is hung and buckled on the buoyancy framework, and the supporting box body is detachably connected with thebottoms of the stretchable rod components and sinks into the water; the top of the supporting box body is open, and an in-site bottom mud substrate layer is laid in the supporting box body and used for planting the submerged plants; by extracting substrates from the in-site bottom mud of to-be-restored fresh water areas such as creeks, rivers and lakes, evenly laying the substrates in the supporting box body and transplanting the submerged plants, a natural water plant bed ecosystem is directionally constructed with the artificial help, habitat and feed can be provided for aufwuch, benthonicanimals, fishes, shrimps and shells in the aquatic ecosystem, and meanwhile a propagation place can be provided for aquatic animals laying viscid eggs during a breeding season. Not only can a balancedecosystem be constructed and the utilization rate of high-quality water is increased, but also the aquatic ecological environment of low-quality water can be improved, and the ecological benefits ofthe aquatic system can be shown.

Owner:PEARL RIVER FISHERY RES INST CHINESE ACAD OF FISHERY SCI

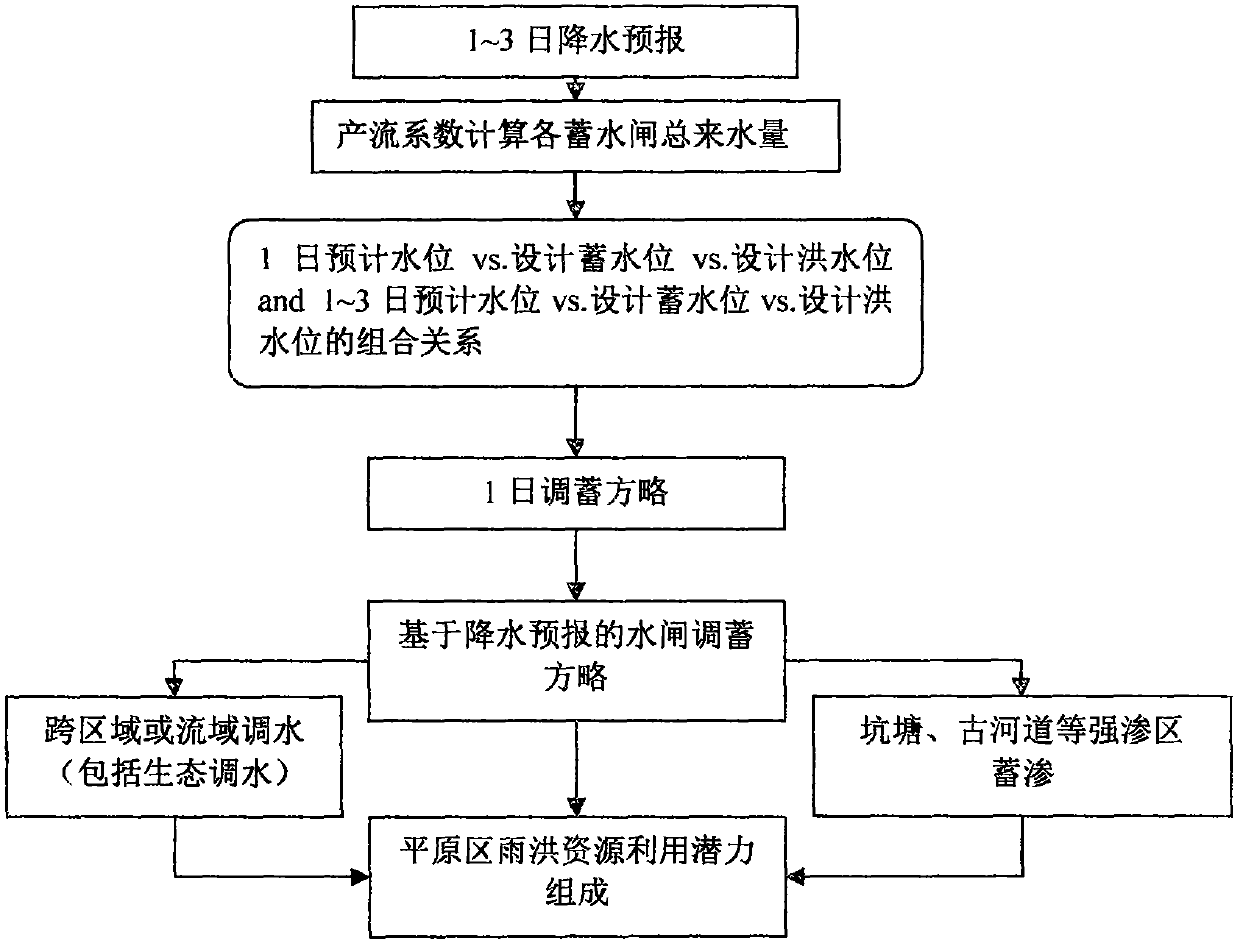

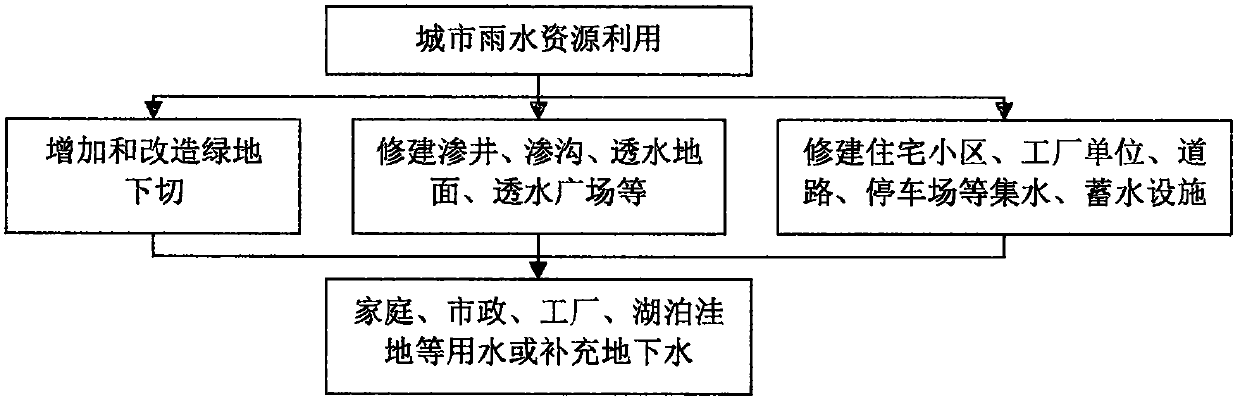

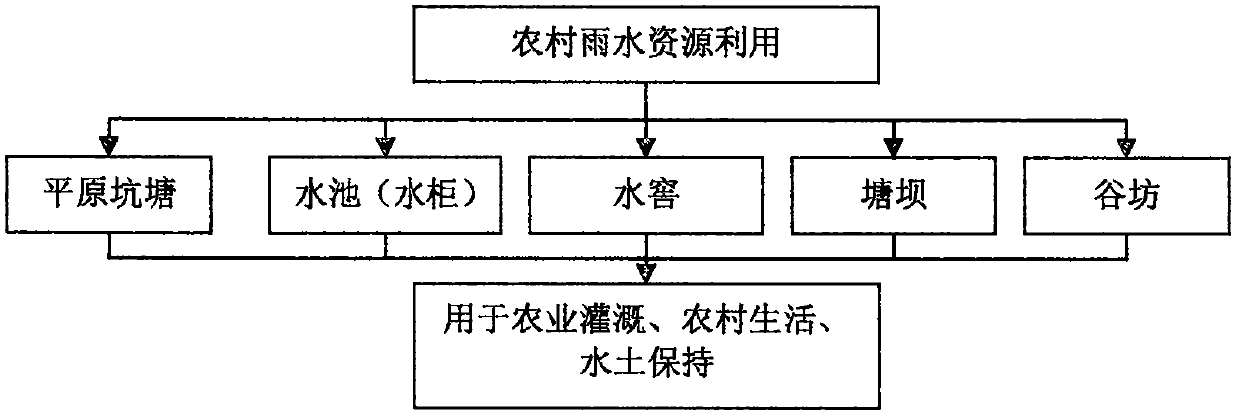

Rain-flood resource utilization method

InactiveCN107916708AAlleviate tension between supply and demandImprove water qualityFatty/oily/floating substances removal devicesSewerage structuresAgricultural irrigationEcological environment

The invention discloses a rain-flood resource utilization method. The structure includes an urban rainwater utilization mode and a rural rainwater utilization mode; in the urban rainwater utilizationmode, after runoff generated by undercutting of a greenbelt in a urban development and construction area, deepening of facilities in the permeable ground, precipitation of underground water collectingfacilities is collected and stored and seeps, the runoff can be used as undrinkable water for houses, greenbelts, car wash and the ecological environment; in the rural rainwater utilization mode, through pit-ponds in plains, pools, water cellars, small reservoirs and check dams, rainwater resources are collected, stored and used for the agricultural irrigation and the rural life or groundwater supplement, The method increase the utilization amount of surface water, flood is scientifically retained, flood water resources are dispatched, the flood water resources can be directly converted intoavailable surface water resources, the available amount of rain and flood resources can be increased to 1.91 billion per square meter, and the method is of great significance to support and guaranteethe sustainable development of the national economy and the society.

Owner:SHANDONG SURVEY & DESIGN INST OF WATER CONSERVANCY

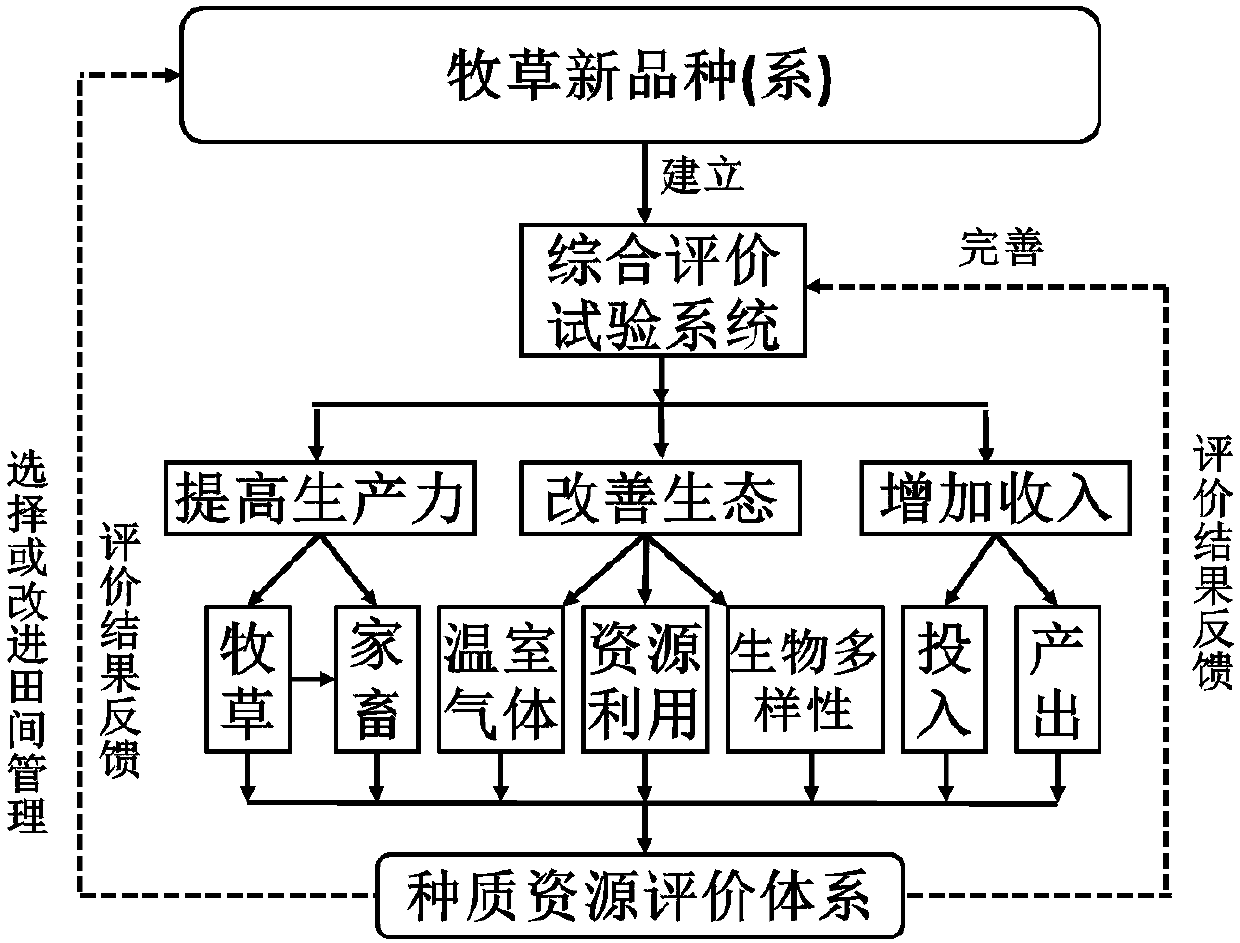

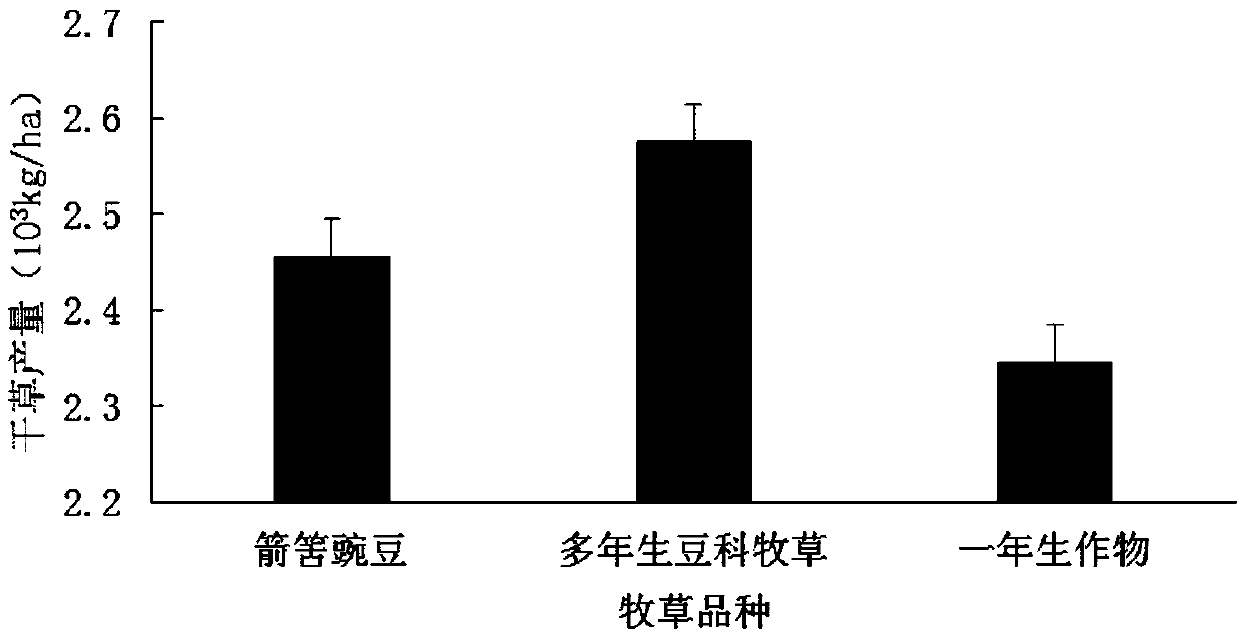

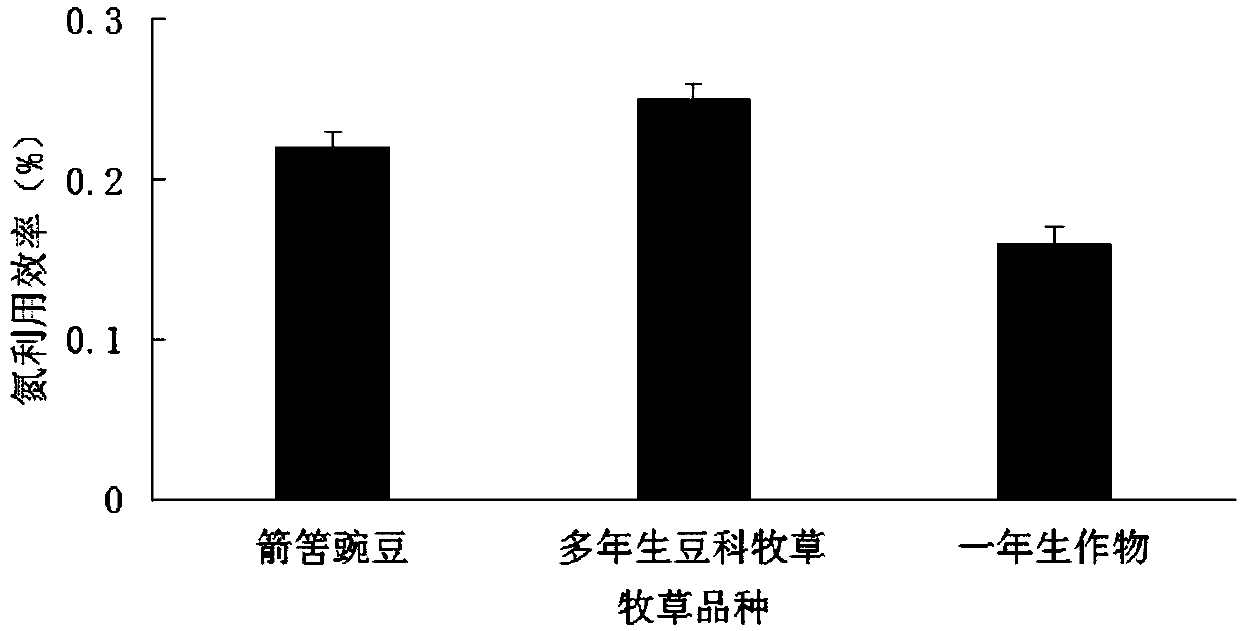

Grassland ecosystem based new germplasm resource and new variety evaluation method for pastures

InactiveCN107548915AAchieve eco-efficiencyAccurate and reliable evaluation systemClimate change adaptationPlant cultivationGermplasmPasture

The invention discloses a grassland ecosystem based new germplasm resource and new variety evaluation method for pastures. The grassland ecosystem based new germplasm resource and new variety evaluation method includes establishing a planting area; performing single sowing and combined sowing of pasture varieties and new varieties; collecting soil samples, measuring physico-chemical properties ofthe soil samples, tracking biological properties of the soil samples, and screening the pasture varieties or variety combinations; performing grazing tests on the screened-out varieties or variety combinations, tracking biological properties of the varieties or variety combinations, and measuring soil physico-chemical properties, digestibility of livestock and intestinal track and excrement management greenhouse gas emission; tracking economic input and output of the whole process, and calculating economic benefit of the whole production system. The grassland ecosystem based new germplasm resource and new variety evaluation method has the advantages that a single evaluation standard with the objective of simple yield or nutritional quality is upgraded into a multiple evaluation method withthe visual angle of the whole biological system, and ecological benefit is taken into consideration while maximum economic benefit is pursued; four aspects, land-pasture-livestock-economy, of the newgermplasm resources and the new varieties of the pastures are evaluated and identified, and scientific and reliable evaluation results are provided.

Owner:LANZHOU UNIVERSITY

Method for producing heme iron by using duck blood

InactiveCN102994584AIncrease added valueEcological benefit without environmental pollutionFermentationProtein proteinFerritin

The invention provides a method for producing heme iron by using duck blood. The heme iron with physiological activity within a specific molecular weight range is produced from duck blood which is a byproduct of meat duck processing by using integration of an anti-coagulation and anti-oxidization technology, a cold-hot varying temperature alternating technology, a dynamic superhigh pressure technology, a stage enzymolysis technology, an enzymolysis supernate decoloring technology, a membrane fractionation technology, a spraying drying technology and other technologies. The heme iron has the protein content being not less than 80 percent, the heme content being not less than 15 percent, and the iron content being 2.0-2.5 percent. According to the method provided by the invention, the additional value of the heme iron is increased, the duck blood resources are completely and comprehensively utilized, no pollutant emission is caused in the production process, and the ecological benefits without environment pollution can be achieved.

Owner:NANCHANG UNIV

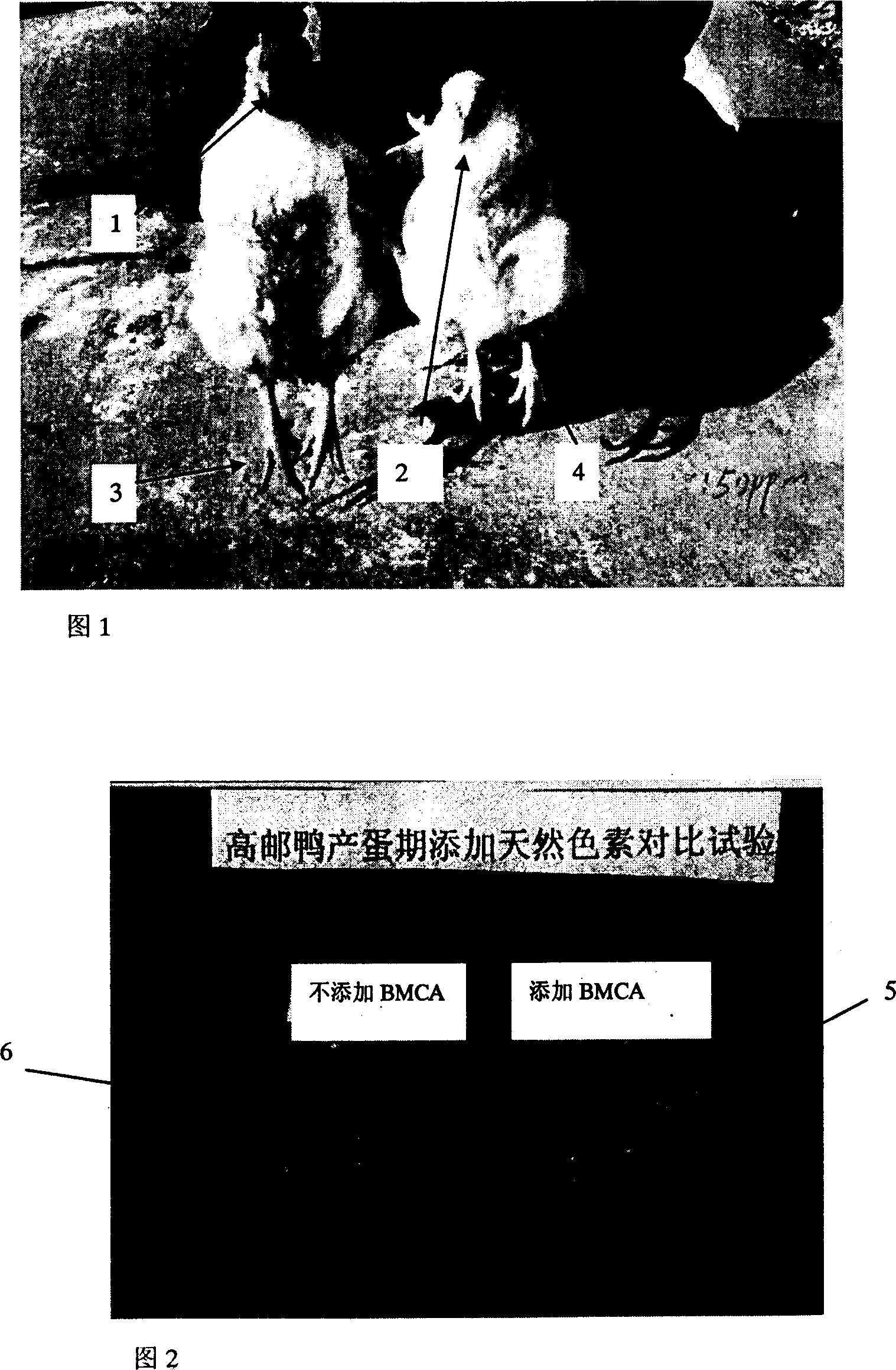

Production process and application of composite cord grass coloring agent for feed

InactiveCN101019606AHigh economic valueEasy to controlAnimal feeding stuffAccessory food factorsChemical synthesisFood safety

The present invention belongs to the field of ecological cultivation technology, and is production process and application of nutritious feed coloring agent. The present invention produces healthful and safe natural feed coloring agent with Spartina alterniflora as one exotic species, and the natural feed coloring agent is used to replace chemically synthesized coloring agent added into feed. The present invention is significant in ensuring food safety and promoting the health development of breeding industry.

Owner:NANJING UNIV

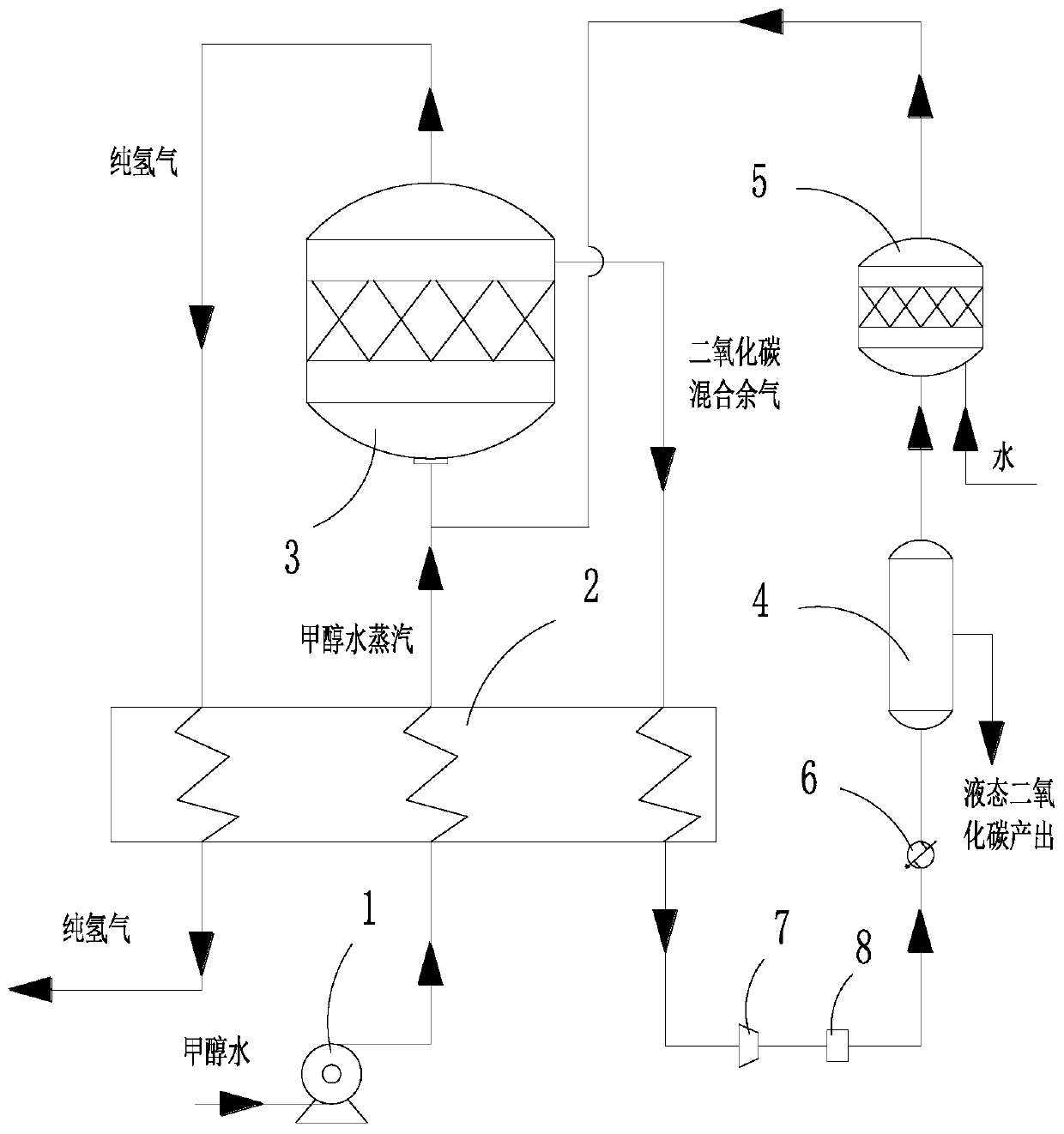

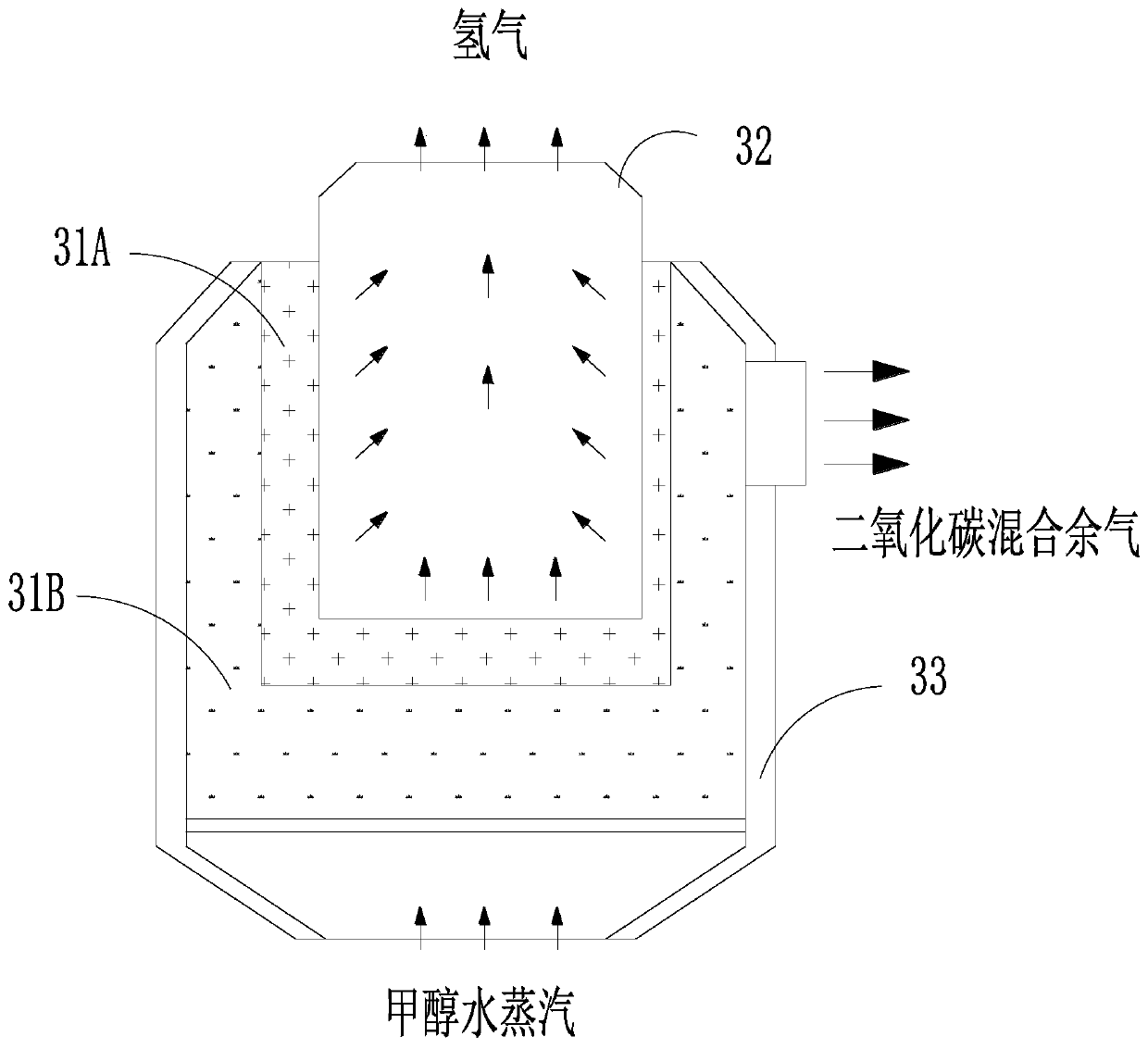

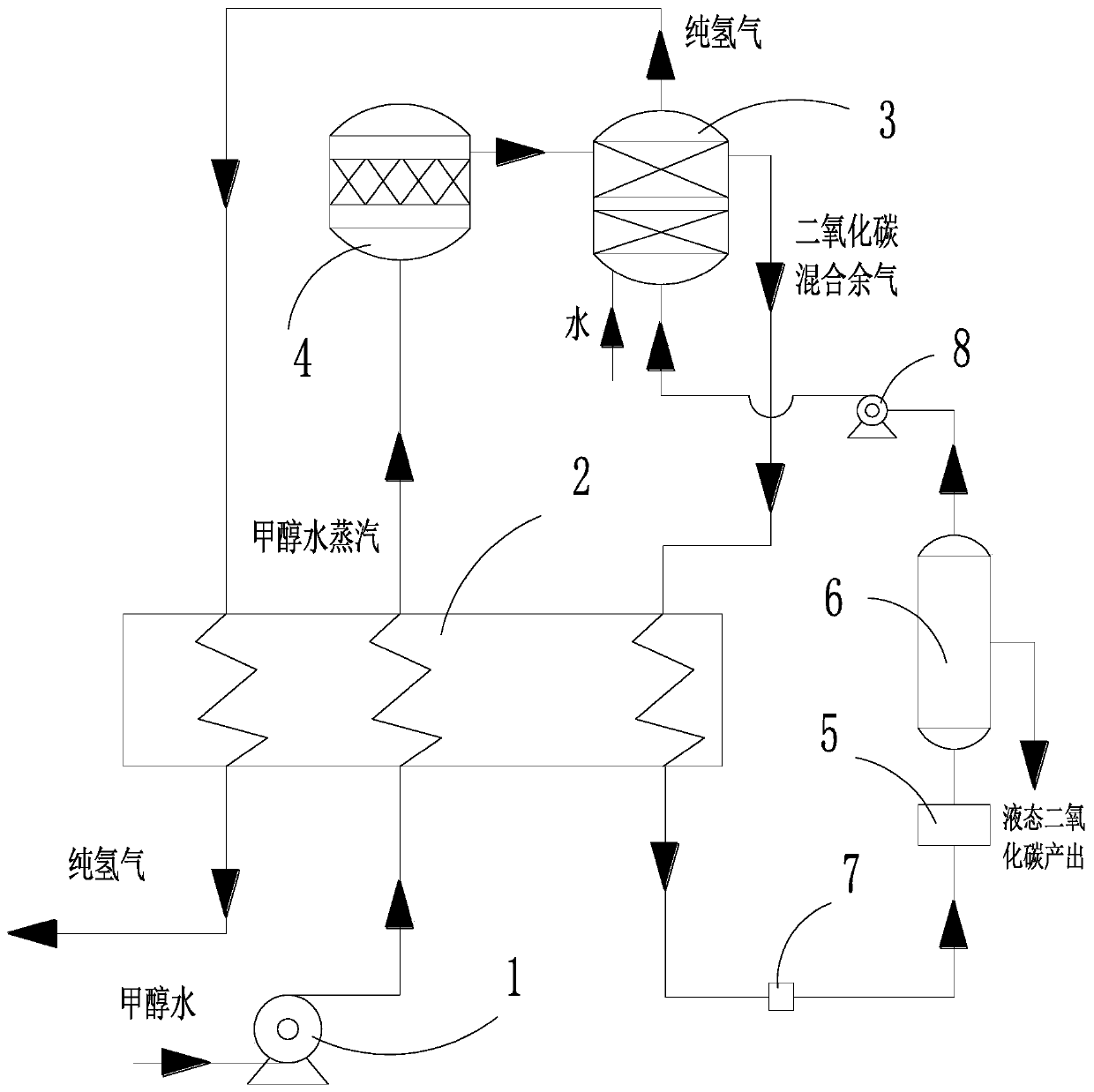

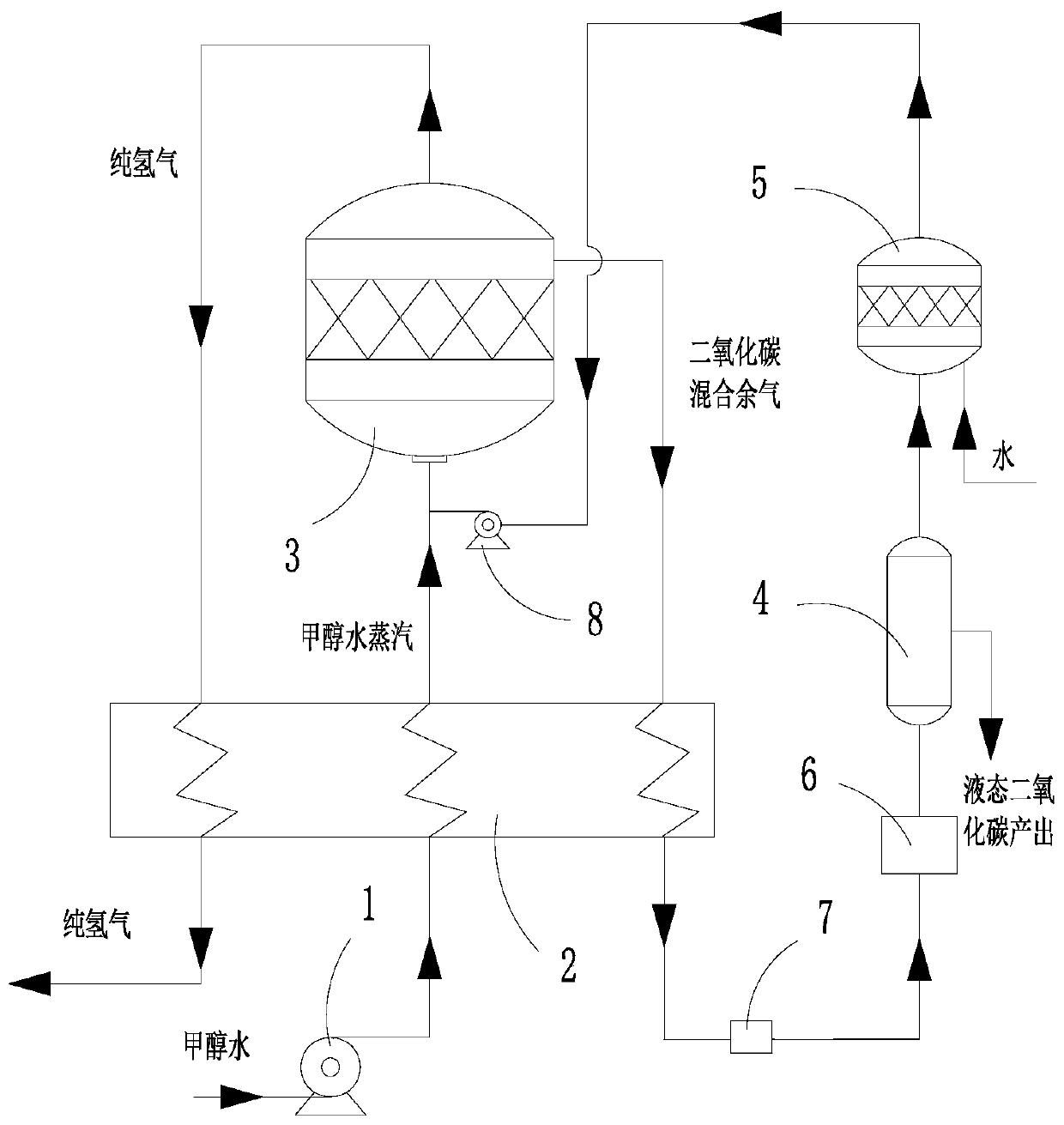

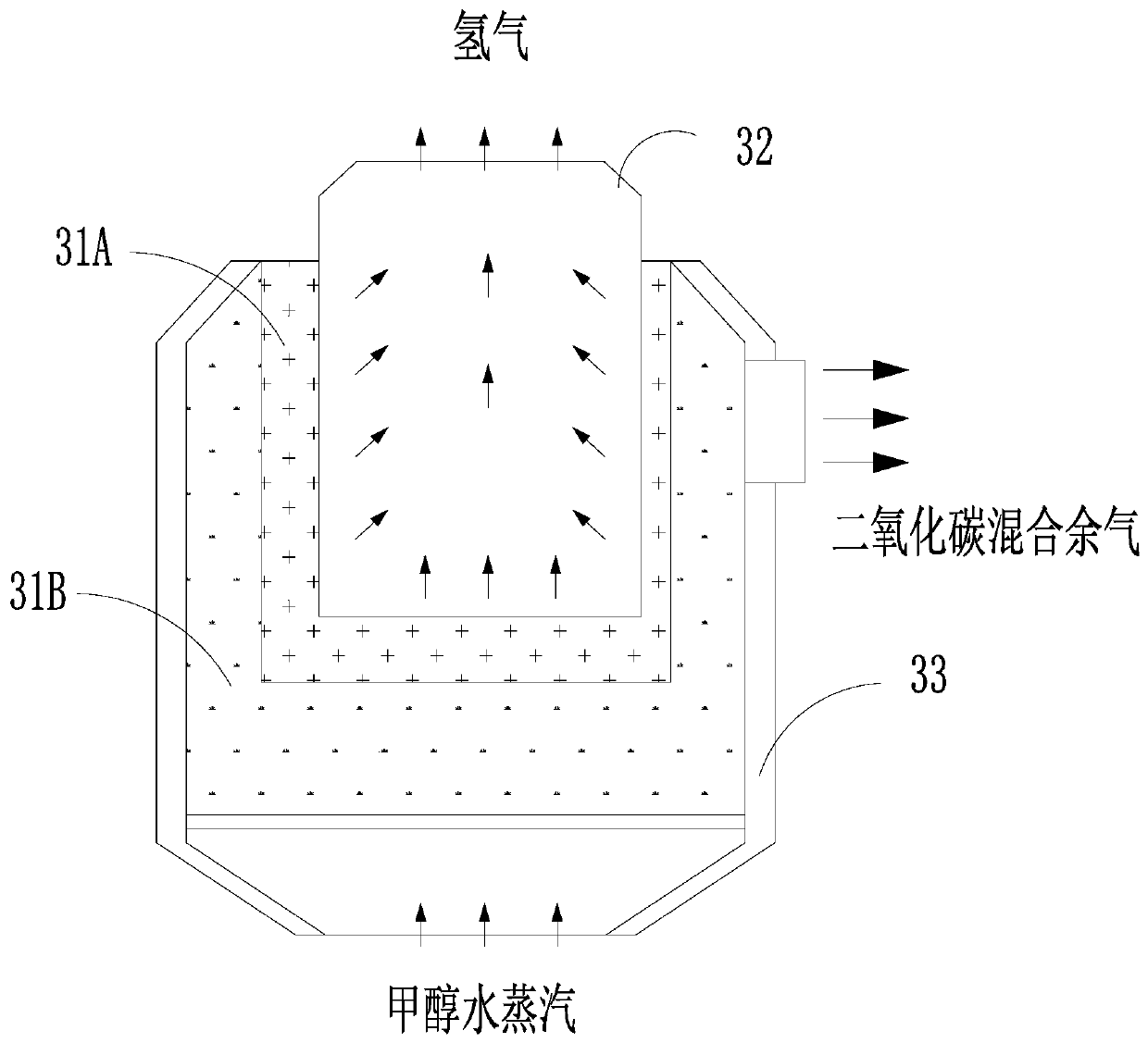

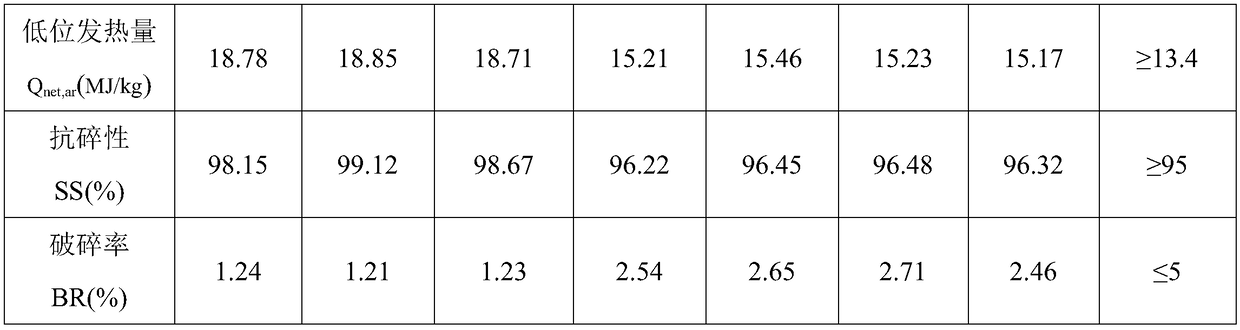

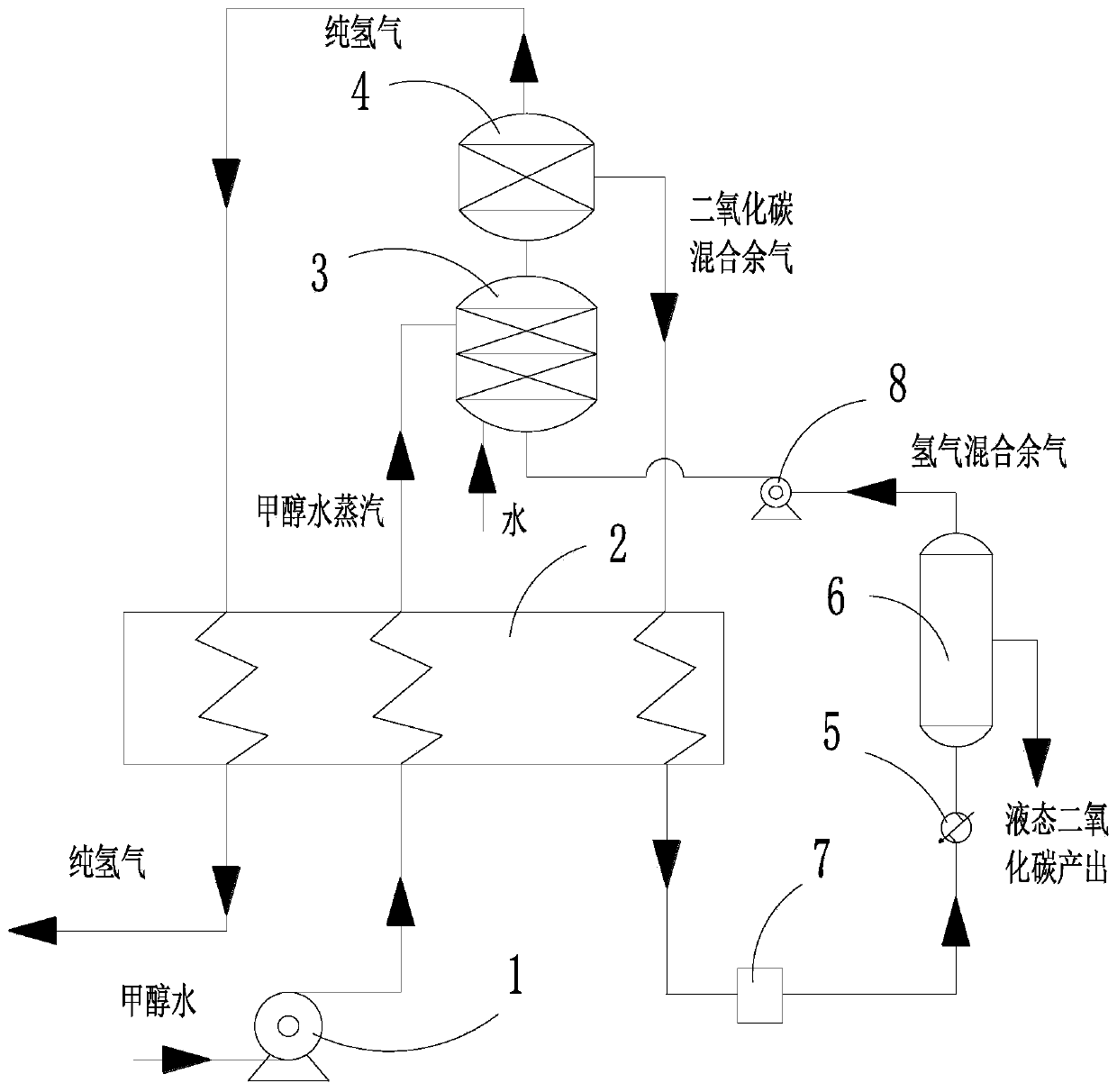

Methanol-water steam reforming and hydrogen separation integrated low-pressure hydrogen production system and method thereof

ActiveCN110817796AImprove hydrogen production efficiencyStructure optimization and streamliningSolidificationLiquefactionSteam reformingMethanol water

The invention relates to a methanol-water steam reforming and hydrogen separation integrated low-pressure hydrogen production system. The system comprises a reforming separation device, a three-phaseheat exchange device, an air compressor, a steam trap, a refrigerating machine, a carbon dioxide separation device and a water gas reforming device; and the pressure controlled by the air compressor is 5-30 MPa, and the temperature controlled by the refrigerating machine is -35-30.8 DEG C. A methanol-water low-pressure hydrogen production method comprises the following steps: methanol-water steamis decomposed to form a mixed gas of hydrogen, carbon dioxide and carbon monoxide, and the hydrogen mixed residual gas is fed into the water gas reforming device and is reformed to make a ratio of hydrogen to carbon dioxide to carbon monoxide in the reformed mixed gas close to a ratio of hydrogen to carbon dioxide to carbon monoxide in the mixed gas of hydrogen, carbon dioxide and carbon monoxide;and the mixed gas is fed into the reaction cavity again, and undergoes hydrogen separation operation. The gas in the system is circularly purified, the theoretical yield can reach 100%, and the hydrogen yield is greater than or equal to 95%.

Owner:中科液态阳光(苏州)氢能科技发展有限公司

Combined treatment method and system for landfill leachate

InactiveCN1277768CEasy to handleImprove efficiencyTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentFiltrationWater quality

Owner:PEKING UNIV

Crapet arlequin-erythroculter ilishaeformis-water spinach efficient culturing method based on net cages

InactiveCN105104274ASolve pollutionTake advantage ofClimate change adaptationPisciculture and aquariaPolycultureAquatic product

The invention discloses a crapet arlequin-erythroculter ilishaeformis-water spinach efficient culturing method based on net cages. Symbiotic planting and culturing organic combination is conducted on crapet arlequin, erythroculter ilishaeformis and water spinach, and the efficient ecological culturing mode that in deep-water polyculture net cages, the water spinach is planted on the water surface, the erythroculter ilishaeformis is cultured on an upper middle layer of a water body, and the crapet arlequin is cultured on a lower middle layer of the water body is formed. According to the crapet arlequin-erythroculter ilishaeformis-water spinach efficient culturing method based on the net cages, the production potentiality of net cage culture is fully tapped, the water body space is fully utilized, the output rate of unit area is effectively increased, and the tail water pollution problem caused in the current aquaculture process can be well solved.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

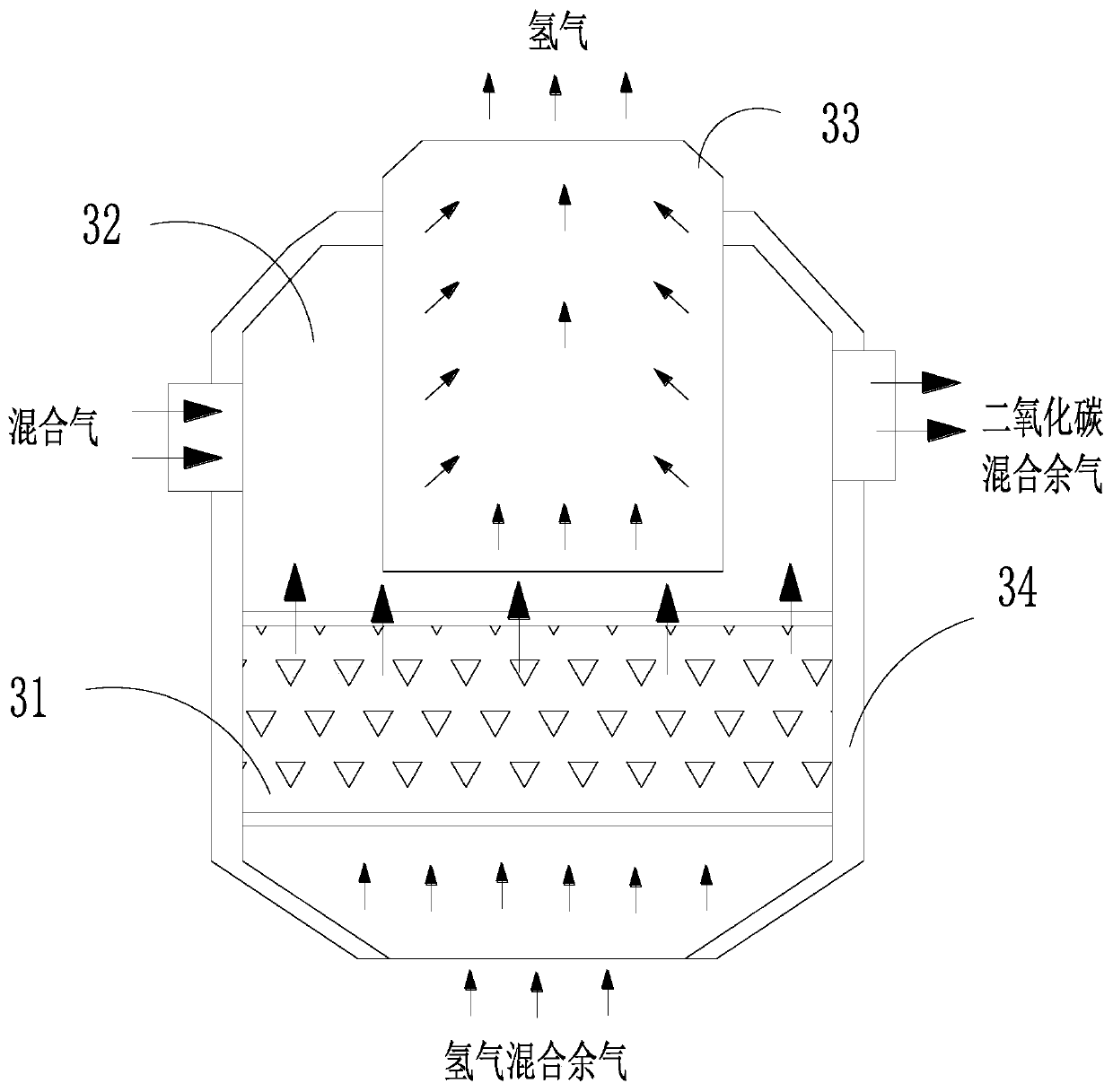

Hydrogen separation and water gas reforming integrated high-pressure hydrogen production system and method

PendingCN110921623AImprove hydrogen production efficiencyStructure optimization and streamliningHydrogen separationCarbon compoundsMethanol waterWater vapor

The invention relates to a hydrogen separation and water gas reforming integrated high-pressure hydrogen production system. The system comprises a reformer, a three-phase heat exchange device, a steamtrap, a water-cooled heat exchanger, a carbon dioxide liquefaction device and a hydrogen separation and water gas reforming integrated device; and the pump pressure of a liquid pump is 18-50 Mpa, andthe operating temperature of the water-cooled heat exchanger is 18-30.8 DEG C. A high-pressure hydrogen production method comprises the following steps: methanol-water steam undergoes a reforming reaction in the reformer to generate a mixed gas of hydrogen, carbon dioxide and carbon monoxide, the obtained hydrogen mixed residual gas is fed into the water gas reforming cavity of the water gas reforming integrated device, and water is distributed to prepare a reformed mixed gas; and the reformed mixed gas enters a hydrogen separation cavity and is mixed with the mixed gas of hydrogen, carbon dioxide and carbon monoxide, and the finally obtained mixed gas is subjected to hydrogen separation operation in the hydrogen separation cavity. The gas in the system is circularly purified, the theoretical yield can reach 100%, and the hydrogen yield is greater than or equal to 95%.

Owner:中科液态阳光(苏州)氢能科技发展有限公司

High-pressure hydrogen production system integrating methanol water vapor reforming and hydrogen separation, and method thereof

ActiveCN110835095AImprove hydrogen production efficiencyStructure optimization and streamliningHydrogen/synthetic gas productionHydrogen separation by diffusionMethanol waterWater vapor

The invention relates to a high-pressure hydrogen production system integrating methanol water vapor reforming and hydrogen separation. The system comprises a reforming separation device, a three-phase heat exchange device, a steam trap, a water-cooled heat exchanger, a carbon dioxide separation device, and a water gas reforming device. The pump pressure of a liquid pump is 18-50 MPa. A high-pressure method for producing hydrogen from methanol water includes steps that: the liquid pump feeds methanol water to a feeding pipe of a methanol water vapor pipe, with the pump pressure being 18 to 50MPa; carbon dioxide mixed residual gas is conveyed to the carbon dioxide separation device for carbon dioxide liquefaction and separation; hydrogen mixed residual gas is conveyed to the water gas reforming device for reforming; reformed mixed gas, along with the mixed gas of hydrogen, carbon dioxide and carbon monoxide, is conveyed into the reaction chamber again for hydrogen separation. Cyclic purification for gas in the system is achieved, the theoretical yield can reach 100% and the hydrogen yield of not less than 95% is achieved.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI

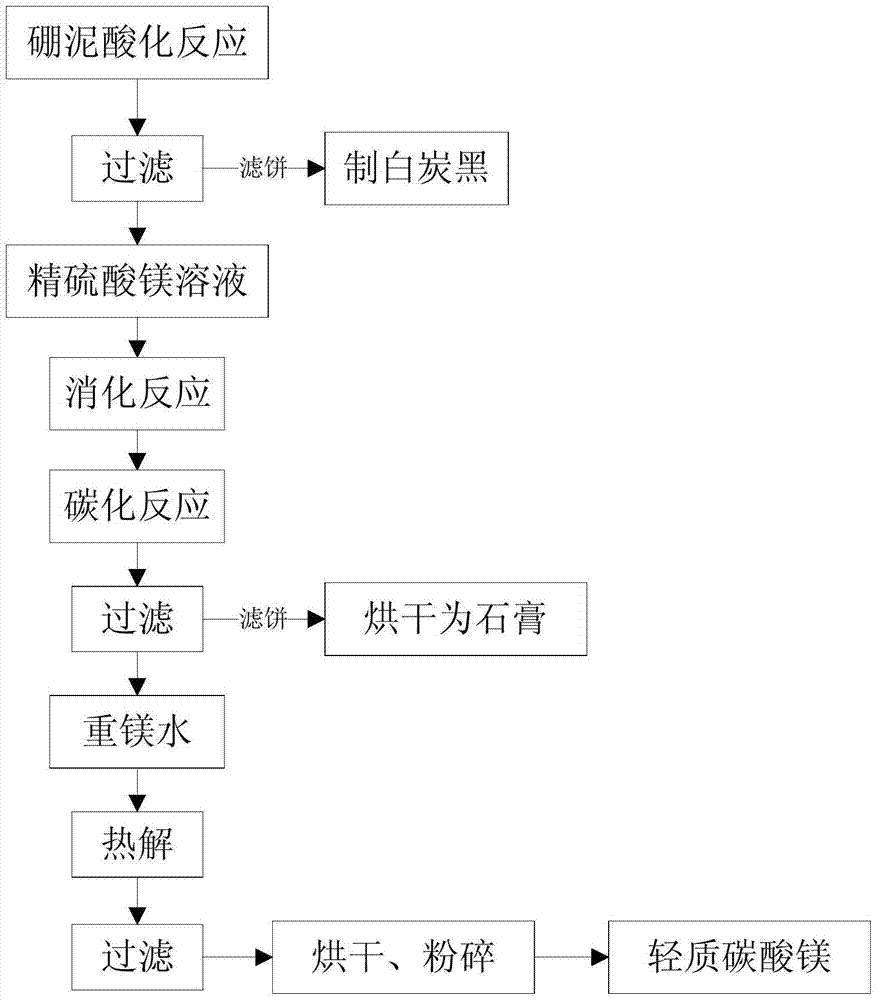

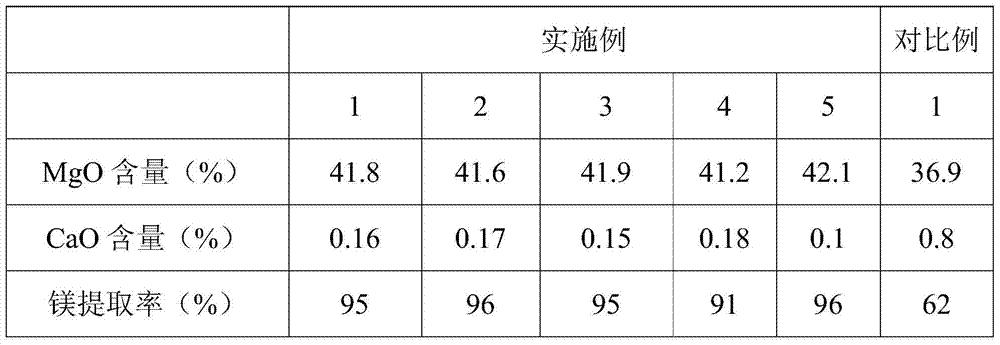

A kind of light magnesium carbonate prepared by borate method and its production method and application

ActiveCN104671262BRealize the purpose of complete comprehensive recyclingReduce manufacturing costMagnesium carbonatesFiltrationSludge

The invention provides a method for preparing light magnesium carbonate by a boric sludge acidification method. The method comprises the following steps: (1) boric sludge acidification, namely mixing boric sludge, sulfuric acid and water for acidification reaction to obtain an acidified slurry; (2) slurry filtration and impurity removal, namely filtering the obtained acidified slurry, leaching the precipitated phase with alkali and then acidifying the precipitated phase to obtain amorphous white carbon black, adjusting the pH of the filtrate and adding hydrogen peroxide to remove impurities; and (3) digestion, carbonization and pyrolytic reaction, namely sequentially performing digestion reaction and carbonization reaction on the magnesium solution subjected to impurity removal, then filtering, performing pyrolysis on the filtrate to obtain a semi-finished light magnesium carbonate product, drying and crushing to obtain the light magnesium carbonate product, and drying the precipitate to obtain gypsum. According to the method, magnesium is leached with the sulfuric acid, the magnesium sulfate filtrate is used for preparing high-purity light magnesium carbonate, and the precipitated phase is used for preparing the amorphous white carbon black, so that the extraction rate of magnesium is equal to or greater than 95%, the purpose of complete comprehensive recycling is fulfilled, zero discharge is realized in the whole process and the production cost is reduced.

Owner:苏州诺济玛金属制品有限公司

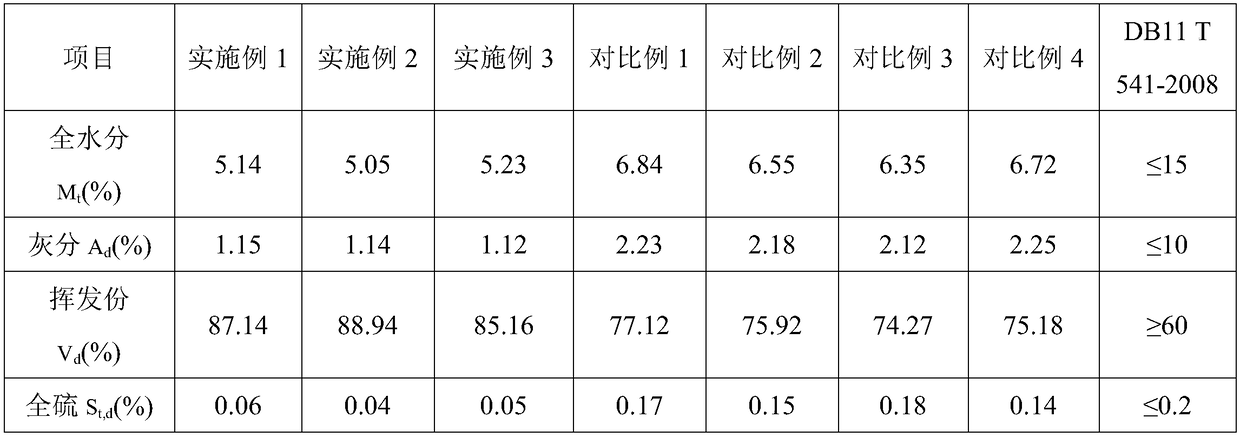

Biomass particle fuel and preparation method thereof

InactiveCN109207229AHigh combustion valueImprove toughnessBiofuelsSolid fuelsEcological environmentEngineering

The invention belongs to the field of comprehensive utilization of biomass fuel and specifically relates to biomass particle fuel and a preparation method thereof. The biomass particle fuel is prepared from the following ingredients in parts by weight: 20 to 30 parts of bagasse, 10 to 15 parts of coconut shell powder, 5 to 10 parts of dried lotus leaves, 20 to 25 parts of crop stalks, 5 to 8 partsof peanut shell, 6 to 10 parts of bamboo sawdust, 15 to 20 parts of corncob, 15 to 20 parts of elm wood flour and 1 to 5 parts of combustion improver. The biomass particle fuel disclosed by the invention has the advantages of high combustion value, low sulfur value and high shaping rate; namely, a lower heating value is larger than 18 MJ / kg and is far higher than the average heat values of corn stalks and sorghum stalks, and the combustion efficiency of the fuel is effectively improved; nearly no sulfur dioxide or fly ash is generated, and ecological environment construction is facilitated; the biomass particle fuel is not prone to being broken. The prepared biomass particle fuel disclosed by the invention has better comprehensive performance, an application range of the biomass particlefuel disclosed by the invention is expanded, and good economic benefits can be achieved.

Owner:联合优发生物质能源徐州有限公司

Leymus chinensis culture method and application thereof in seed production

InactiveCN106941922AImprove low stock carrying capacityImprove the current situation of insufficient supply of high-quality beef and muttonPlant cultivationCultivating equipmentsSeedlingLeymus

The invention discloses a leymus chinensis culture method and application thereof in seed production. The leymus chinensis culture method comprises the following steps: (1) sowing leymus chinensis seeds in spring; (2) immediately conducting water irrigating once after sowing, conducting water irrigating for multiple times from emergence of leymus chinensis seedlings to the end of the trefoil stage to replenish water, and determining whether irrigation needs to be conducted according to actual situations from the end of the trefoil stage to the time before overwintering; and (3) performing the following operations every year from the second year of sowing: applying a fertilizer once every 10-20 days after leymus chinensis turns green, immediately conducting water irrigating once after fertilizer application, and determining whether irrigation needs to be conducted according to actual situations from the time that the leymus chinensis turns green to the time before overwintering. A Zhongke leymus chinensis field management method provided by the invention is simple and feasible and can greatly improve the yield of leymus chinensis seeds when popularized in a large area in an artificial leymus chinensis land, so that the pressure of demands on high-quality leymus chinensis seeds in China is relieved, and ecological benefits are realized to a great extent while economical benefits are realized.

Owner:刘辉

California perch, paddlefish and water spinach stereoscopic culturing method based on net cages

ActiveCN105165681ASolve pollutionTake advantage ofClimate change adaptationAgricultural fishingPaddlefishAquatic product

The invention discloses a California perch, paddlefish and water spinach stereoscopic culturing method based on net cages. California perches, paddlefish and water spinach are subjected to organic combination of symbiotic breeding and planting, and the stereoscopic ecological culturing mode that the water spinach is planted on the water surfaces of the deep water net cages, the paddlefish is cultured in the upper middle layer of a water body, and the California perches are cultured in the lower middle layer of the water body. By means of the method, the culturing production potential of the net cages is fully dug, the space of the water body is fully utilized, the output rate of unit area is effectively increased, and the problem of tail water pollution brought by the current aquaculture process can be well solved.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Lepomis macrochirus-bighead carp-water spinach stereoscopic cultivation method based on net cage

InactiveCN105123588ATap production potentialUse of water spaceClimate change adaptationPisciculture and aquariaLepomis macrochirusCage culture

The invention discloses a lepomis macrochirus-bighead carp-water spinach stereoscopic cultivation method based on a net cage. Lepomis macrochirus, bighead carp and water spinach are cultivated together and combined organically to form a stereoscopic ecological cultivation mode of planting the water spinach on the water surface of the deep water type mixed cultivation net cage, cultivating the bighead carp in the middle and upper layer of a water body, and cultivating the lepomis macrochirus in the middle and lower layer of the water body. According to the method, cultivation production potentials of the net cage are fully exploited, space of the water body is fully utilized, the yield in a unit area is effectively increased, and the problem of tail water pollution caused in the current aquaculture process can be well solved.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Biomass granular fuel

InactiveCN110684579AQuality improvementIncreased durabilityBiofuelsSolid fuelsEconomic benefitsManihot esculenta

The invention discloses a biomass granular fuel. The biomass granular fuel comprises the following components in parts by weight: 30-35 parts of corn straw, 15 to 20 parts of poplar sawdust, 20 to 30parts of cassava stems, 3-5 parts of coffee grounds, 0.3 to 0.5 part of a leveling agent, 0.5 to 1 part of a sulfur fixing agent, 4-6 parts of a flame accelerator and 1-3 parts of an additive. The rawmaterials of the biomass granular fuel are wide in source and belong to waste; so the waste is turned into the valuable, pollution to the environment is treated, an ecological environment is protected from the source, certain ecological benefits are obtained, cost is low, income can be increased, and good economic benefits are obtained.

Owner:联合优发生物质能源徐州有限公司

Ultrahigh-pressure hydrogen production system integrating methanol water vapor and hydrogen mixed gas, and method thereof

ActiveCN110835094ALow costGuaranteed uptimeSolidificationLiquefactionMethanol waterUltra high pressure

The invention relates to an ultrahigh-pressure hydrogen production system integrating methanol water vapor and hydrogen mixed gas. The system includes a three-phase heat exchange device, a reformer, ahydrogen separation device, a steam trap, a water-cooled heat exchanger, a refrigerator, and a carbon dioxide liquefaction device, wherein the pump pressure of a liquid pump is 40 to 100 MPa, the operating temperature of the water-cooled heat exchanger is not more than 30.8 DEG C, and pure hydrogen is pumped into a hydrogen storage tank under the pump pressure of the liquid pump. An ultrahigh-pressure hydrogen production method includes subjecting methanol water vapor to a reforming reaction to generate a mixed gas of hydrogen, carbon dioxide and carbon monoxide; then performing hydrogen separation; preparing, in a carbon dioxide separator, liquid carbon dioxide and residual hydrogen mixed gas having a hydrogen-carbon dioxide-carbon monoxide ratio close to that in the mixed gas of hydrogen, carbon dioxide and carbon monoxide; feeding the mixed gas together into a hydrogen separation chamber for hydrogen separation. The hydrogen production efficiency of the hydrogen production system is improved, so that the hydrogen production system can be made into small hydrogen production equipment.

Owner:中科液态阳光(苏州)氢能科技发展有限公司

Stereoscopic culture method of California perch-spoonnose sturgeon-water spinach based on cages

ActiveCN105165681BSolve pollutionTake advantage ofClimate change adaptationAgricultural fishingPaddlefishAquatic product

The invention discloses a California perch, paddlefish and water spinach stereoscopic culturing method based on net cages. California perches, paddlefish and water spinach are subjected to organic combination of symbiotic breeding and planting, and the stereoscopic ecological culturing mode that the water spinach is planted on the water surfaces of the deep water net cages, the paddlefish is cultured in the upper middle layer of a water body, and the California perches are cultured in the lower middle layer of the water body. By means of the method, the culturing production potential of the net cages is fully dug, the space of the water body is fully utilized, the output rate of unit area is effectively increased, and the problem of tail water pollution brought by the current aquaculture process can be well solved.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

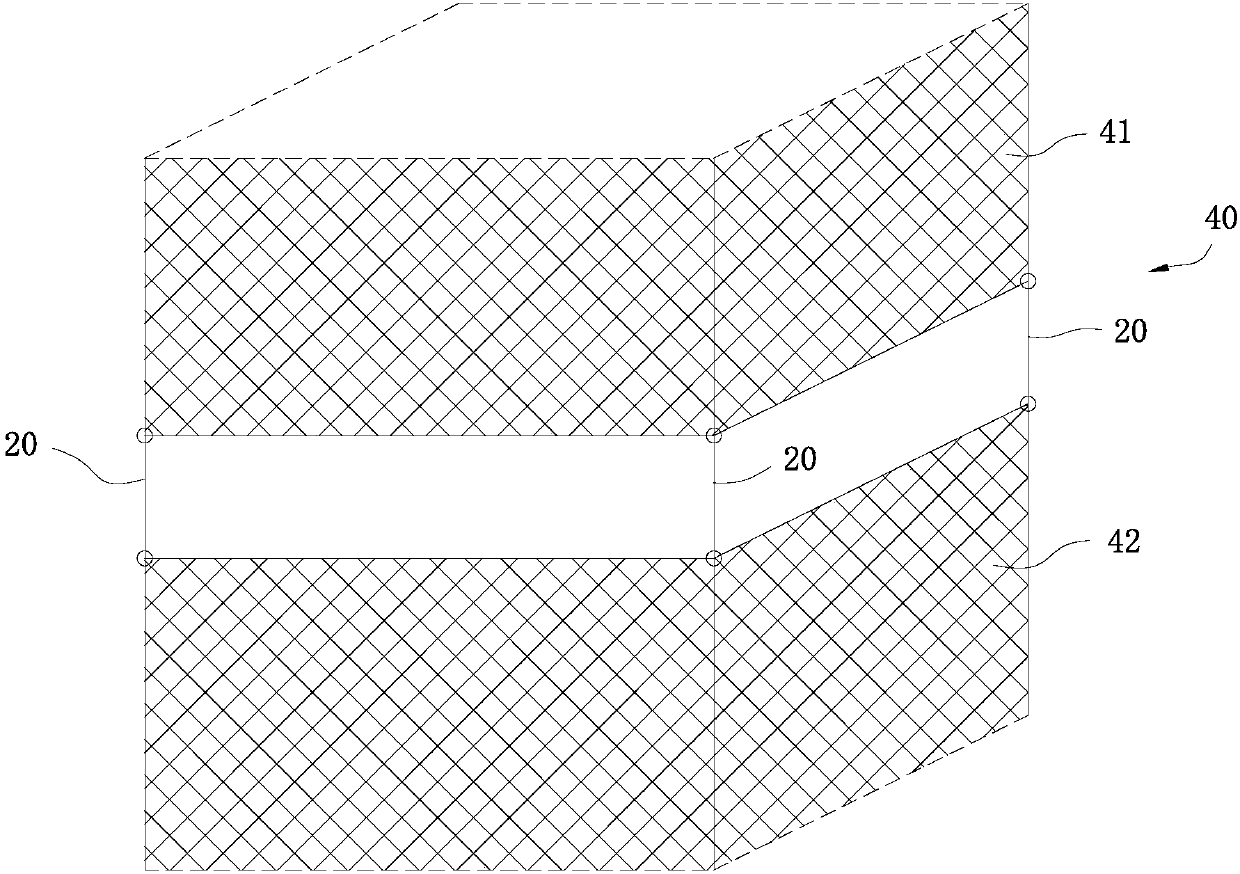

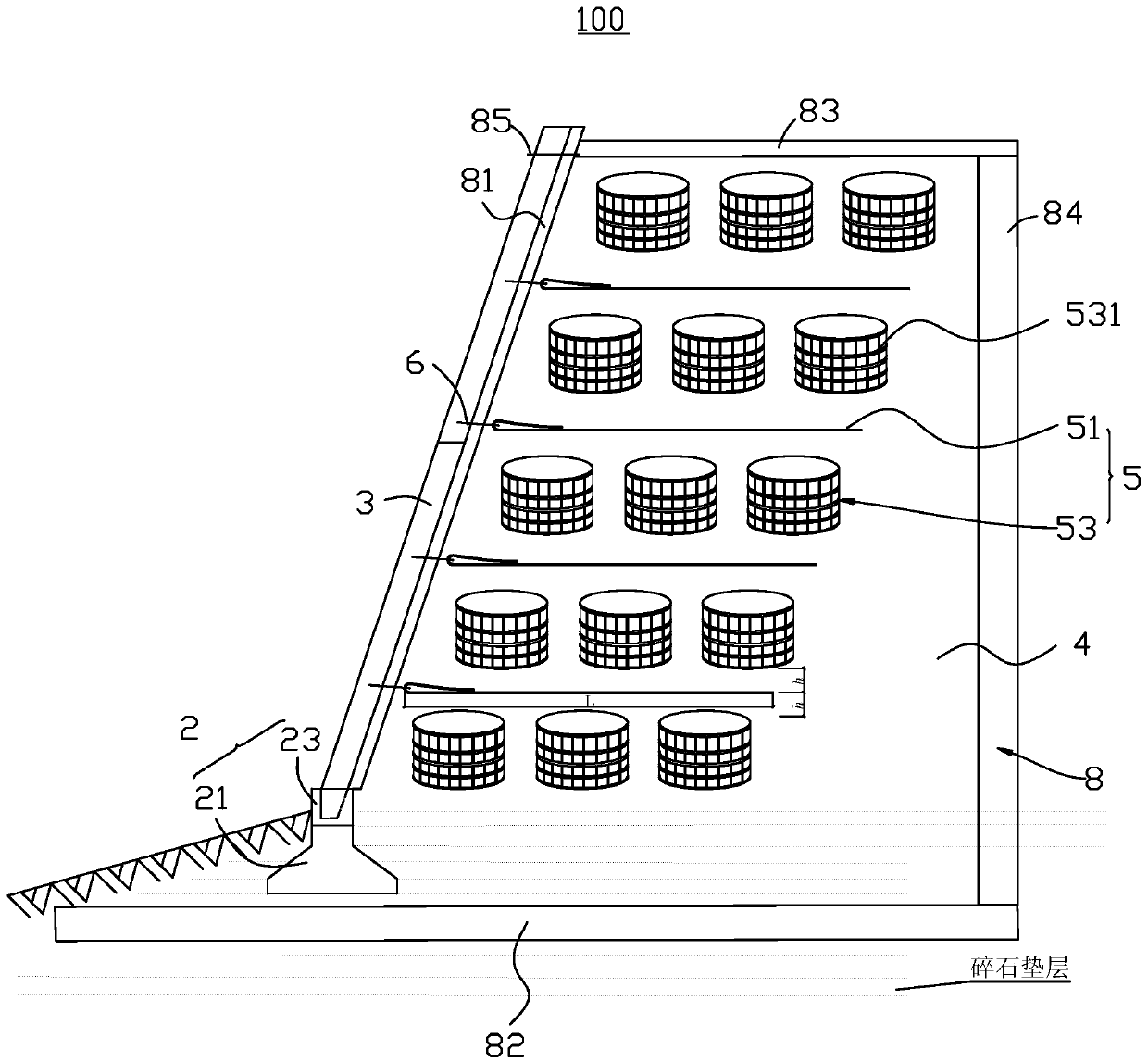

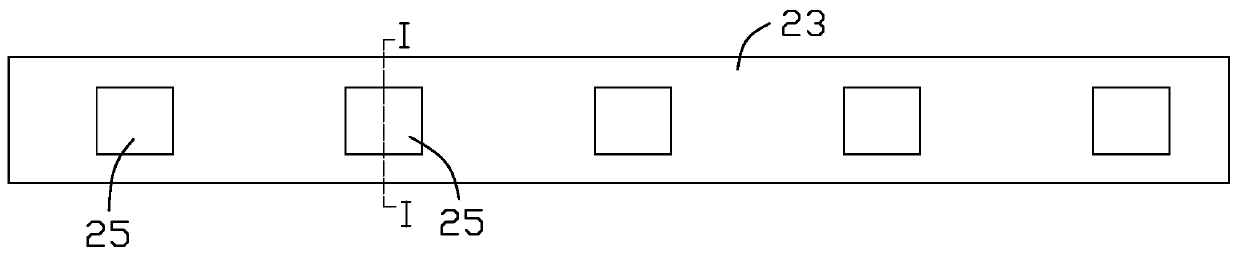

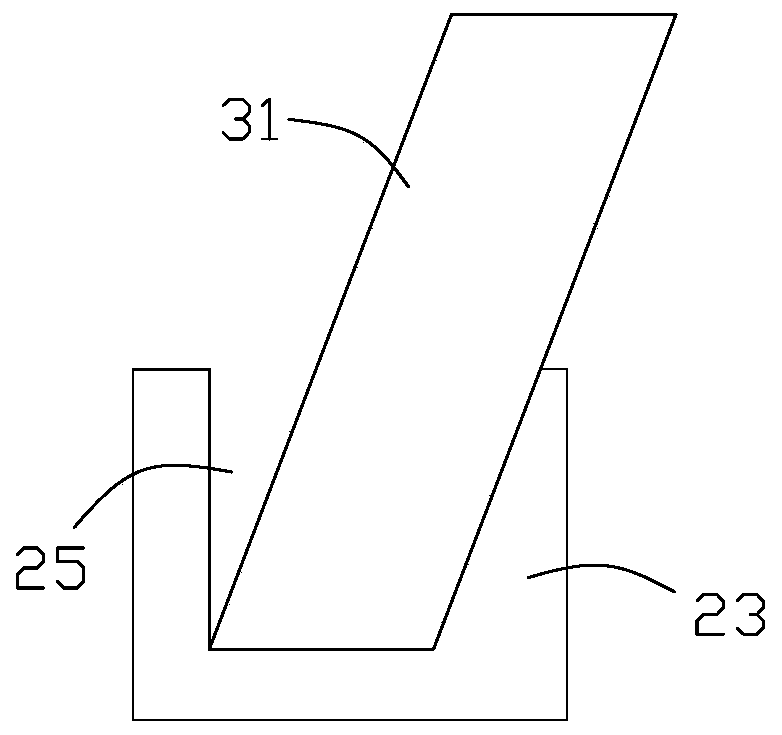

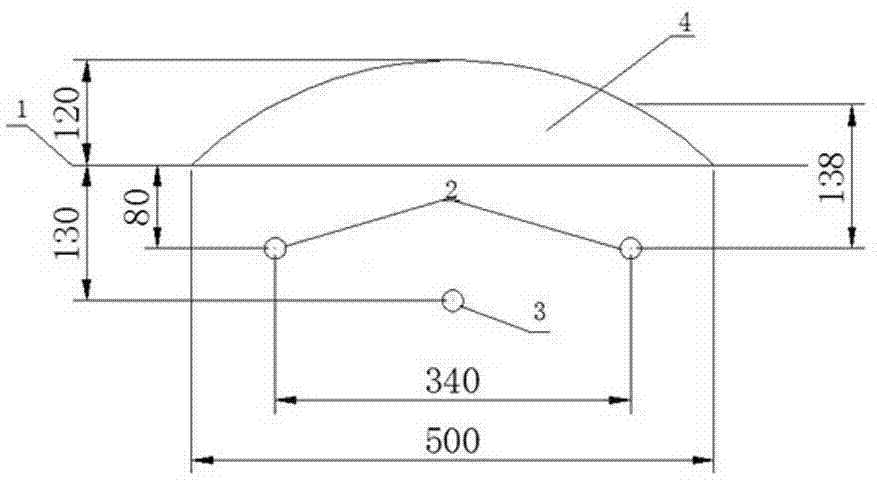

Fabricated solid reinforced earth retaining wall and construction method thereof

PendingCN111005403ALarge lateral earth pressureImprove carrying capacityArtificial islandsProtective foundationGeogridRetaining wall

The invention provides a fabricated solid reinforced earth retaining wall. The fabricated solid reinforced earth retaining wall comprises a retaining wall foundation, a retaining wall panel, fillers and rib strips, wherein the retaining wall panel is arranged on the retaining wall foundation, one side of the retaining wall panel is filled with the fillers, the rib strips comprise a plurality of tiled geogrids and a plurality of annular geogrid reinforcement layers, the tiled geogrids and the annular geogrid reinforcement layers are respectively arranged in the fillers layer by layer, the plurality of tiled geogrids and the plurality of annular geogrid reinforcement layers are alternately distributed in a vertical direction, two adjacent rib strips are arranged at an interval, one side, which is close to a wallboard, of each tiled geogrid is wrapped reversely so as to form a reversely wrapped area and connect with the retaining wall panel, and the annular geogrid reinforcement layers are composed of a plurality of geogrid rings which are arranged at intervals. According to the solid reinforced earth retaining wall, the bearing performance and the deformation resistant capability ofthe retaining wall can be obviously increased. The invention further provides a construction method of the fabricated solid reinforced earth retaining wall.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

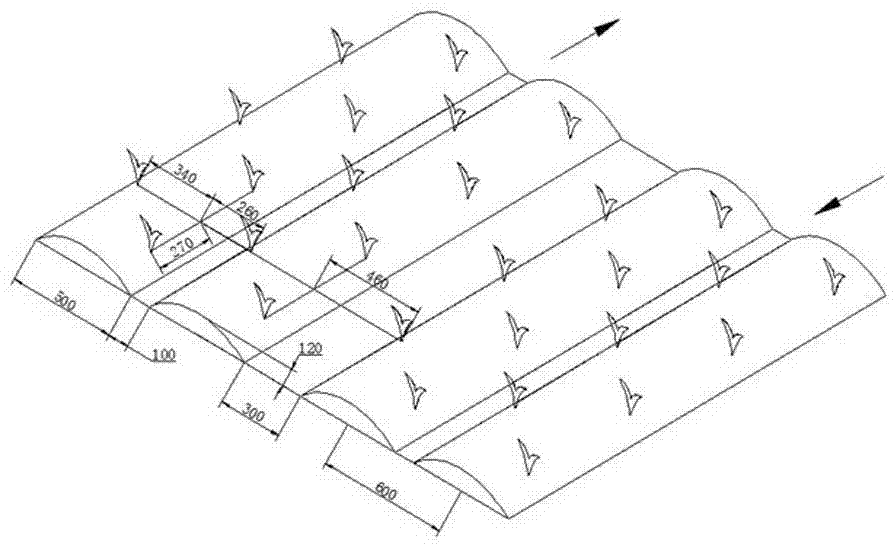

Micro-ridge film-mulched side-sown agronomic method for dry farming potatoes

InactiveCN103460967BReduce exposed areaReduce ineffective evaporation lossHorticultureEvaporationSolanum tuberosum

The invention relates to a micro-ridge film-mulched side-sown agronomic method for dry farming potatoes. The method comprises the following steps: (a) ditching and fertilizing; (b) seeding; (c) ridging; (d) spraying herbicides; (e) laying films; (f) repeating the steps (a) to (e). According to the method, one-film double-ridge is adopted, so that the inter-line land exposed area during single-line film mulching is reduced, and the invalid evaporation loss of soil moisture is lowered effectively.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

Method of eliminating residual pollutant on surface of vegetable

InactiveCN1276705CQuality improvementNo pollution in the processPlant protective coveringsChemical reactionGlass vessel

The method for eliminating residual pollution on the surface of vegetable and fruit is characterized by utilizing the photo-chemical property and according to the different light absorption property of vegetable to make glassware of anti-radiation and having air permeable hole; 2. after flower, fruit and pollination covering the vegetable and fruit with the disinfected glassware and closing its mouth; and 3. in the defined growth period, implementing monitoring and management program. When between of vegetable and fruit and glassware has no gap, picking off the vegetable and fruit, so that it can raise quality and yield of vegetable and fruit.

Owner:李红 +1

A method for protecting slope vegetation by using plant fiber blanket

ActiveCN105123212BGuarantee the built effectEasy to buildExcavationsCultivating equipmentsVegetationFiber

The invention relates to a method for protecting slope vegetation through plant fiber blankets. The method for protecting slope vegetation through plant fiber blankets is applicable to fill roadbed slope protection during a construction period. According to the method, fill roadbed slopes are divided into two categories, according to one category, the fill roadbed slopes are formed slopes where roadbed filling is completed, and according to the other category, the fill roadbed slopes are non-formed slopes where roadbed filling is not completed. The operation that roadbeds are gradually filled and spreading is performed layer by layer is performed on the non-formed slopes, the plant fiber blankets are fixed, after filling of the all the roadbeds and covering of the plant fiber blankets are completed, plant seeds are sown on the surfaces of the plant fiber blankets, covering of thin soil is performed, and watering and curing are performed so that vegetation can be formed; the operations that grass seeds are sown on the total slopes, then the total slopes are covered with the plant fiber blankets, and curing is performed are adopted so that the vegetation can be built. By means of the method, the slopes can be greened as soon as possible, water and soil loss can be effectively controlled in the construction period, and the effectiveness of slope protection is enhanced in the construction period.

Owner:CHINA ACAD OF TRANSPORTATION SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com