A kind of light magnesium carbonate prepared by borate method and its production method and application

A light magnesium carbonate and boron mud technology, applied in magnesium carbonate and other directions, can solve the problems of inability to achieve comprehensive recovery and utilization, low waste residue reduction, low magnesium recovery rate, etc., achieve great use value and promotion value, and low equipment requirements. , to achieve the effect of ecological benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

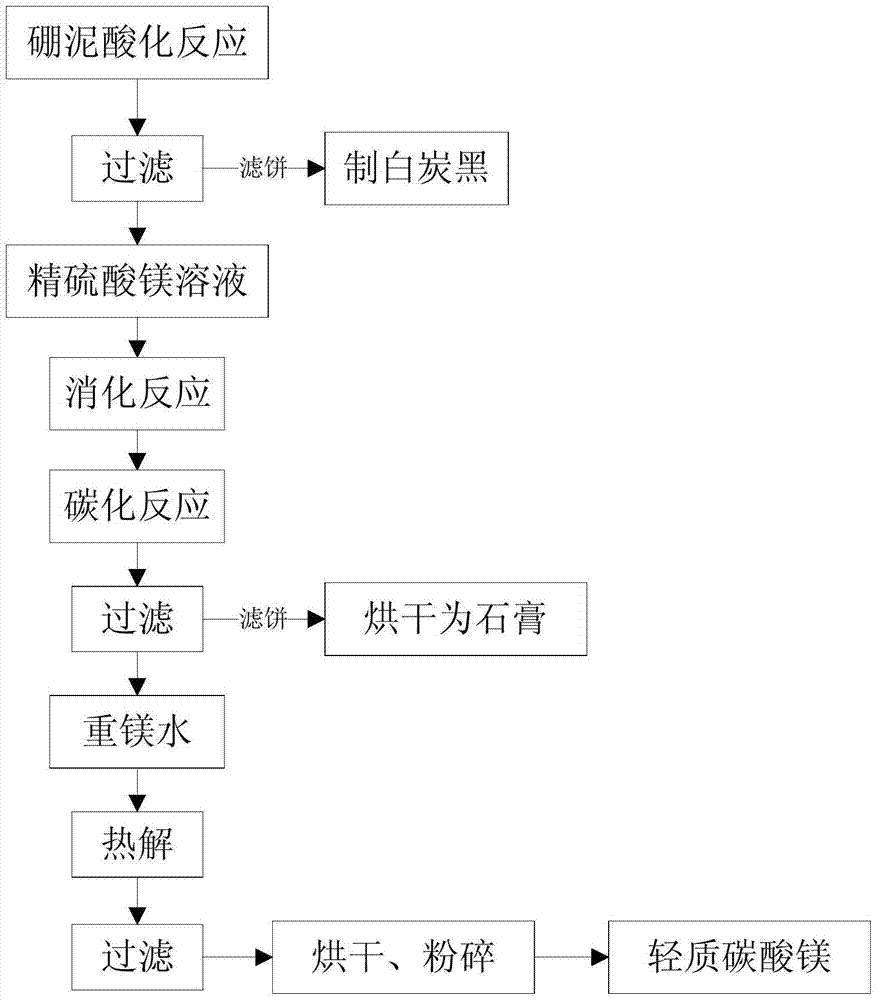

Method used

Image

Examples

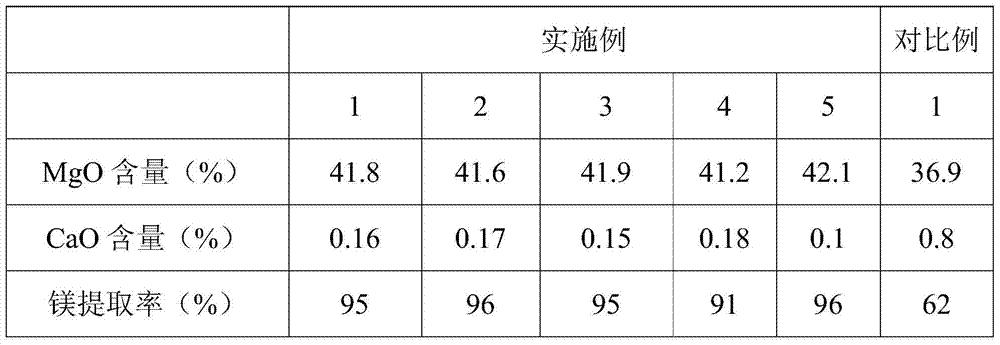

Embodiment 1

[0056] (1) Weigh 10kg of boron mud, 15kg of sulfuric acid and 30kg of water according to the mass ratio of 1:1.5:3, mix and stir evenly, the reaction time is 1h, and the reaction temperature is 90°C.

[0057] (2) The above-mentioned acidification solution is filtered, and the filter cake is used to prepare white carbon black, and the resulting filtrate is 40L, and the 2 o 2 Add H at a volume ratio of 0.012:1 to the filtrate 2 o 2 to 0.48L, add calcium oxide to adjust the pH to 9, and filter to obtain refined magnesium solution.

[0058] (3) Add 12kg of quicklime to the refined magnesium solution according to the ratio of the mass of quicklime kg to the volume L of the magnesium solution of 0.3, the reaction temperature is 80°C, and the reaction time is 1h.

[0059] (4) Carbon dioxide gas is passed into the obtained digested slurry to carry out carbonization reaction, the carbon dioxide gas pressure is 0.4MPa, the concentration is 35%, and the carbonization time is 2h.

[0...

Embodiment 2

[0063] (1) Weigh 10kg of boron mud, 18kg of sulfuric acid and 50kg of water according to the mass ratio of 1:1.8:5, mix and stir evenly, the reaction time is 1h, and the reaction temperature is 95°C.

[0064] (2) The above-mentioned acidification solution is filtered, and the filter cake is used to prepare white carbon black, and the obtained filtrate is 41L, and the 2 o 2 Add H at a volume ratio of 0.015:1 to the filtrate 2 o 2 to 0.62L, add calcium oxide to adjust the pH to 9, and filter to obtain refined magnesium solution.

[0065] (3) Add 24.6kg of quicklime to the refined magnesium solution according to the ratio of the mass of quicklime kg to the volume L of the magnesium solution of 0.6, the reaction temperature is 90°C, and the reaction time is 2h.

[0066] (4) Carbon dioxide gas is passed into the obtained digested slurry to carry out carbonization reaction, the carbon dioxide gas pressure is 0.4MPa, the concentration is 40%, and the carbonization time is 2h.

[...

Embodiment 3

[0070] (1) Weigh 10kg of boron mud, 16kg of sulfuric acid and 40kg of water according to the mass ratio of 1:1.6:4, mix and stir evenly, the reaction time is 1h, and the reaction temperature is 95°C.

[0071] (2) The above-mentioned acidification solution is filtered, and the filter cake is used to prepare white carbon black, and the obtained filtrate is 41L, and the 2 o 2 Add H at a volume ratio of 0.013:1 to the filtrate 2 o 2 to 0.55L, add calcium oxide to adjust the pH to 9, and filter to obtain refined magnesium solution.

[0072] (3) Add 20kg of quicklime to the refined magnesium solution according to the ratio of the mass of quicklime kg to the volume L of the magnesium solution of 0.5, the reaction temperature is 90°C, and the reaction time is 1.5h.

[0073] (4) Carbon dioxide gas is passed into the obtained digested slurry to carry out carbonization reaction, the carbon dioxide gas pressure is 0.4MPa, the concentration is 38%, and the carbonization time is 2h.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com