Methanol-water steam reforming and hydrogen separation integrated low-pressure hydrogen production system and method thereof

A technology of steam reforming and hydrogen production system, which is applied in the field of low pressure hydrogen system, can solve the problems of inability to realize cyclic hydrogen production and complex hydrogen production process, and achieve the goals of obtaining ecological benefits, optimizing and simplifying the structure, and reducing carbon dioxide emissions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

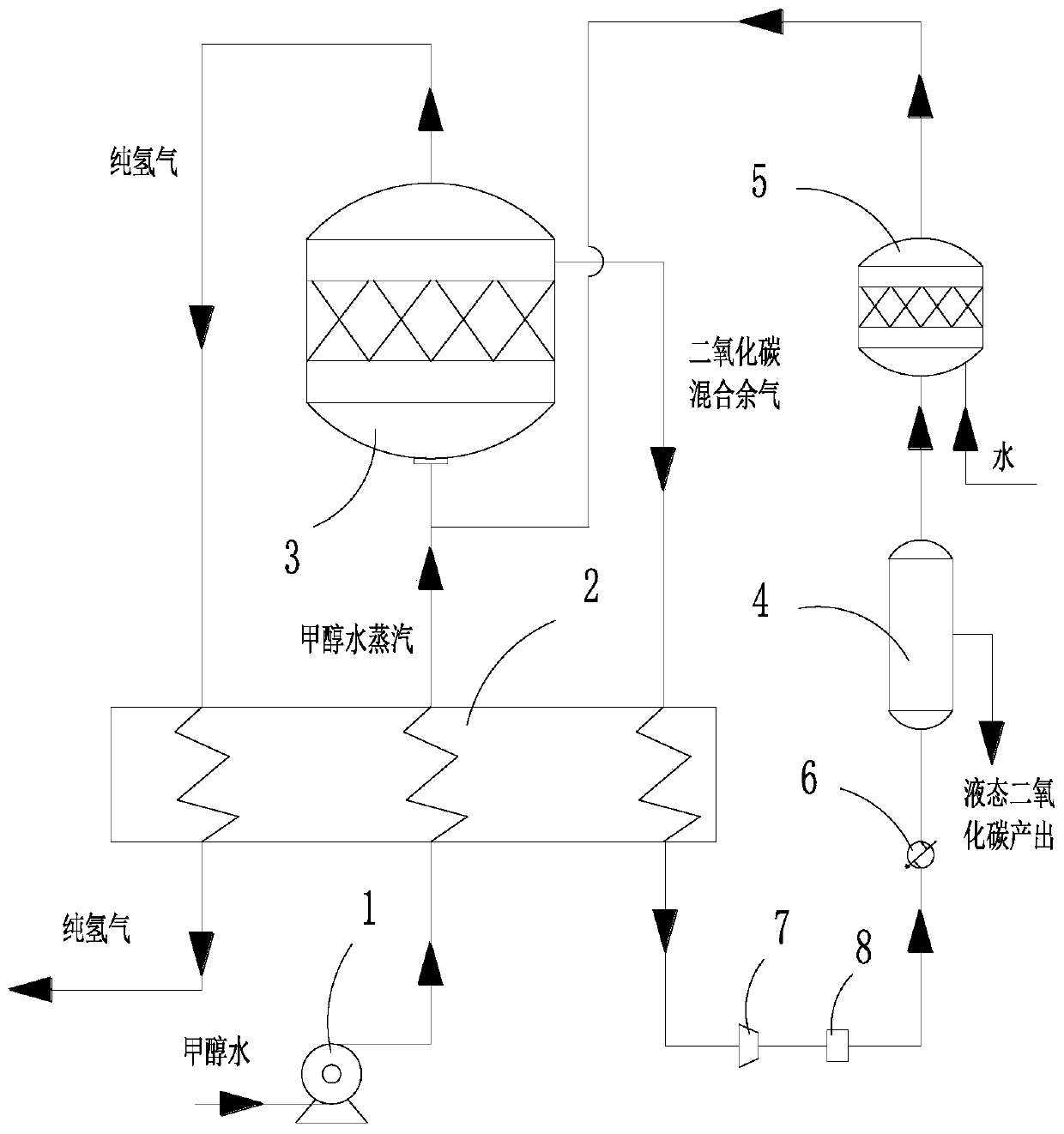

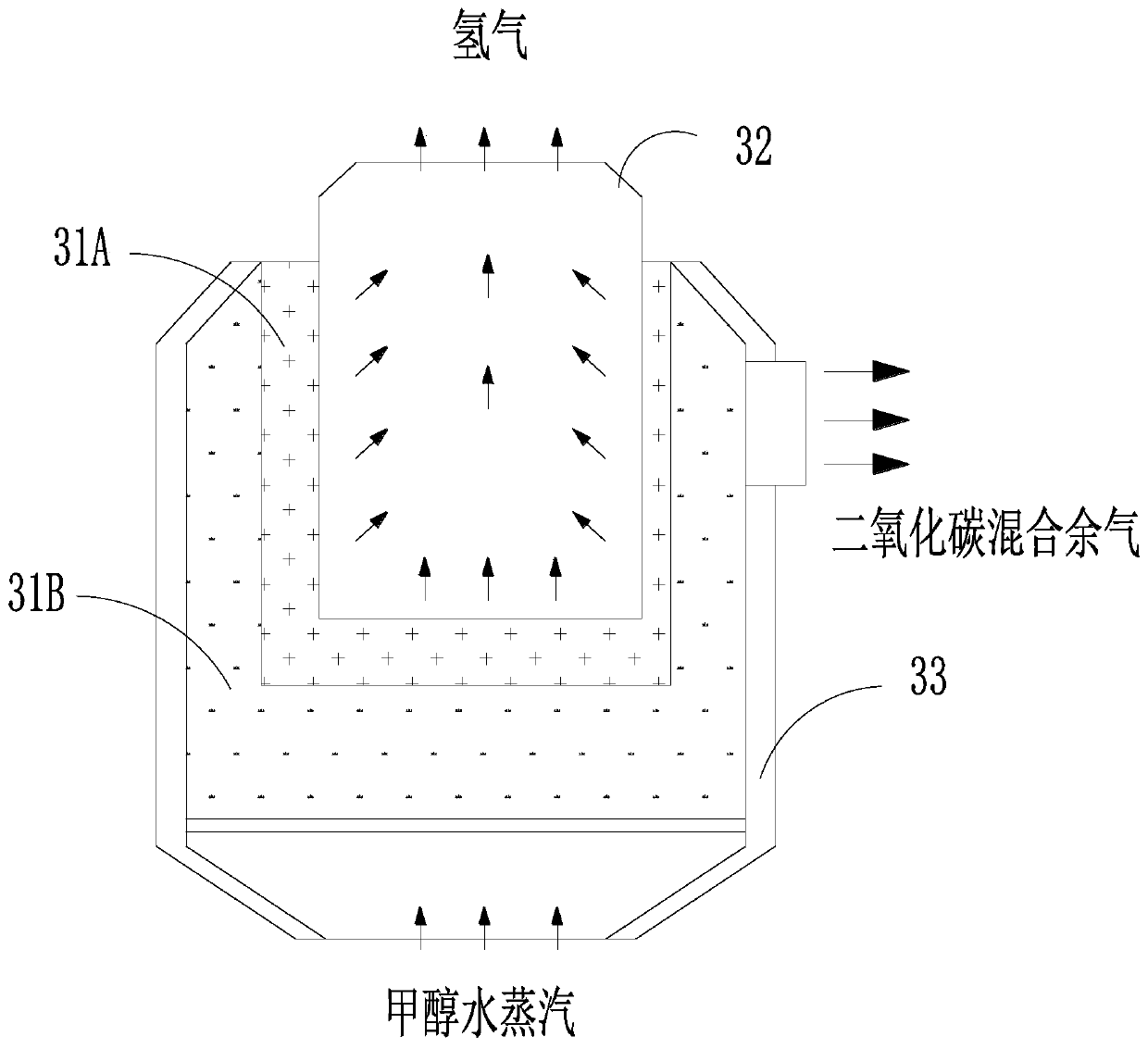

[0053] like figure 1 figure 2 As shown, a methanol steam reforming and hydrogen separation integrated low-pressure hydrogen system includes a reforming separation device 3, a three-phase heat exchange device 2, an air compressor 7, a steam trap 8, a refrigerator 6, and a carbon dioxide separation device 4 and water gas reforming device 5.

[0054] The reforming and separating device 3 is connected to the methanol water vapor inlet pipe, the hydrogen outlet pipe and the carbon dioxide mixed residual gas outlet pipe, and the carbon dioxide mixed residual gas outlet pipe is connected to the three-phase heat exchange device 2, the air compressor 7, and the steam trap 8 in sequence , refrigerating machine 6, carbon dioxide separation device 4 and water gas reforming device 5, the outlet of the water gas reforming device 5 is connected to the outlet pipe of the reformed mixed gas, and the outlet pipe of the reformed mixed gas is connected to the inlet of the reforming separation d...

Embodiment 2

[0073] A methanol-water low-pressure hydrogen system, using the above-mentioned low-pressure hydrogen system, comprising the following steps:

[0074] S1. The liquid pump 1 sends the methanol water into the methanol water vapor pipe, and the pump pressure is 2-5 MPa. The methanol water is heated and vaporized by the three-phase heat exchange device 2 to become methanol water vapor and enters the reaction chamber of the reforming separation device 3. Methanol steam is decomposed into a mixed gas of hydrogen, carbon dioxide and carbon monoxide;

[0075] The gas phase components of the mixed gas of hydrogen, carbon dioxide and carbon monoxide are 65-75% hydrogen, 20-26% carbon dioxide, and 0.3-3% carbon monoxide;

[0076] S2. The hydrogen suction pipe 32 separates the mixed gas of hydrogen, carbon dioxide and carbon monoxide, and the separated pure hydrogen is collected from the output of the hydrogen suction pipe 32; the remaining carbon dioxide mixed gas is output from the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com