Biomass particle fuel and preparation method thereof

A biomass particle and fuel technology, applied in the direction of biofuel, waste fuel, fuel, etc., can solve the problem of low calorific value, achieve high combustion value, long combustion time, and expand the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

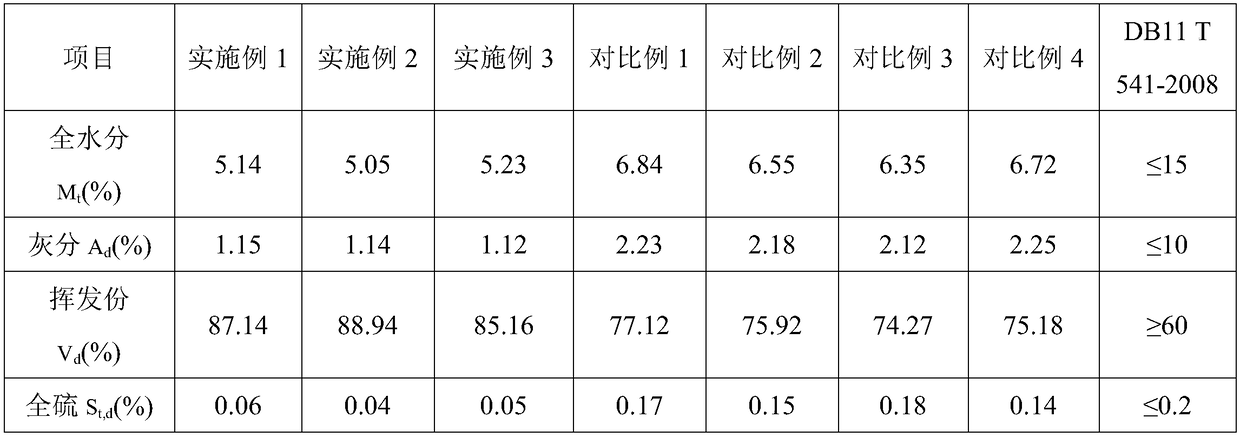

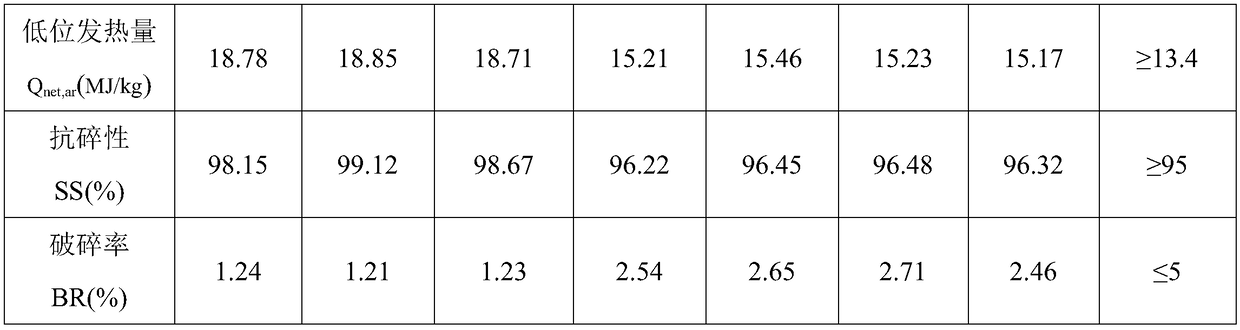

Examples

Embodiment 1

[0033] A biomass pellet fuel, comprising the following components by weight: 20 parts of bagasse, 10 parts of coconut shell powder, 5 parts of dried lotus leaves, 20 parts of sorghum stalks, 5 parts of peanut shells, 6 parts of bamboo chips, and 15 parts of corn cobs parts, 15 parts of elm wood chips, 1 part of combustion aid, lignin content in the elm wood chips is 30%, the combustion aid is a mixture of ammonium nitrate and potassium perchlorate, and the mass ratio of sodium nitrate to potassium perchlorate is 1:1.

[0034] A preparation method of biomass particle fuel, comprising the following steps:

[0035] Step 1: Dry bagasse, coconut shell powder, dried lotus leaves, sorghum stalks, peanut shells, bamboo chips, corncobs, and elm wood chips at 40°C, crush them and pass them through a 50-mesh sieve, and then pass the sieved The above-mentioned raw materials are mixed evenly to obtain a mixture;

[0036] Step 2: Send the mixed material to a pulverizer for pulverization to...

Embodiment 2

[0041] A biomass pellet fuel, comprising the following components by weight: 15 parts of bagasse, 13 parts of coconut shell powder, 8 parts of dried lotus leaves, 23 parts of wheat straw, 6 parts of peanut shells, 8 parts of bamboo chips, and 18 parts of corn cobs 18 parts, 18 parts of elm wood chips, 3 parts of combustion enhancer, lignin content in elm wood chips is 31%, combustion enhancer is the mixture of ammonium nitrate and potassium perchlorate, the mass ratio of sodium nitrate and potassium perchlorate is 1:2.

[0042] A preparation method of biomass particle fuel, comprising the following steps:

[0043] Step 1: Dry bagasse, coconut shell powder, dried lotus leaves, wheat straw, peanut shells, bamboo chips, corncobs, and elm wood chips at 50°C, crush them and pass through a 50-mesh sieve, and then pass the sieved The above-mentioned raw materials are mixed evenly to obtain a mixture;

[0044] Step 2: Send the mixed material to a pulverizer for pulverization to obtai...

Embodiment 3

[0049] A biomass pellet fuel, comprising the following components by weight: 30 parts of bagasse, 15 parts of coconut shell powder, 10 parts of dried lotus leaves, 25 parts of corn stalks, 8 parts of peanut shells, 10 parts of bamboo chips, and 20 parts of corn cobs 20 parts, 20 parts of elm wood chips, 5 parts of combustion aid, lignin content in elm wood chips is 32%, combustion aid is the mixture of ammonium nitrate and potassium perchlorate, the mass ratio of sodium nitrate and potassium perchlorate is 1:3.

[0050] A preparation method of biomass particle fuel, comprising the following steps:

[0051] Step 1: Dry bagasse, coconut shell powder, dried lotus leaves, corn stalks, peanut shells, bamboo chips, corncobs, and elm wood chips at 60°C, crush them and pass through a 50-mesh sieve, and then pass the sieved The above-mentioned raw materials are mixed evenly to obtain a mixture;

[0052] Step 2: Send the mixed material to a pulverizer for pulverization to obtain a fine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com