Preparing method of walnut green husk dreg organic fertilizer

A technology of walnut green peel and organic fertilizer, which is applied in the direction of organic fertilizer, inorganic fertilizer, potassium fertilizer, etc., can solve the problems of less research and technology on the overall treatment of walnut green peel, large oxygen consumption, and less practice of resource utilization, so as to achieve protection and improvement Agricultural ecological environment, enhanced ability to resist diseases and insect pests, and the effect of obtaining ecological benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

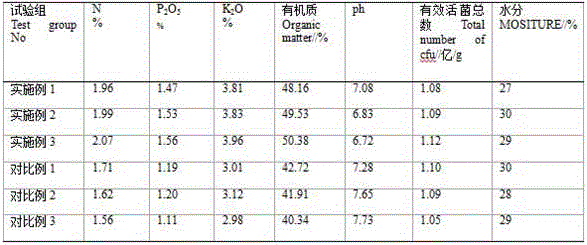

Examples

Embodiment 1

[0025] A preparation method of walnut green peel slag organic fertilizer, the steps comprising:

[0026] 1) Weigh walnut green peel residue, edible fungus residue and plant ash after squeezing fresh walnut green peel according to the weight ratio of 40:50:10; adjust the water content of walnut green peel residue to 55%, add Aureobasidium pullulans, triethanolamine, and stir well Aerobic fermentation for 16 hours (add 10g of Aureobasidium pullulans and 5g of triethanolamine to 1kg of walnut green skin dregs); add calcium hydroxide and zeolite to the edible fungus dregs, heat up to 85°C and stir for 30min, then cool down to 30°C and add walnuts Green skin juice, stir evenly and let it stand for 18 hours (add 10g calcium hydroxide, 5g zeolite and 300g walnut green skin juice to every 1kg of edible fungus residue); mix the above raw materials evenly to get compost raw materials;

[0027] 2) Add the mixed bacterial agent (the number of effective viable bacteria ≥ 1 billion / g) to th...

Embodiment 2

[0031] A preparation method of walnut green peel slag organic fertilizer, the steps comprising:

[0032]1) Weigh walnut green peel residue, edible fungus residue and plant ash according to the weight ratio of 50:40:10; adjust the water content of walnut green peel residue to 50%, add Aureobasidium pullulans and triethanolamine, stir evenly, and then aerobically ferment for 10 hours (per Add 10g of Aureobasidium pullulans and 5g of triethanolamine to 1kg of walnut green skin dregs); add calcium hydroxide and zeolite to edible fungus dregs, heat up to 85°C and stir for 30 minutes, then cool down to 30°C, add walnut green peel juice, stir well Stand still for 15 hours (add 10g calcium hydroxide, 5g zeolite and 300g walnut green peel juice to 1kg edible fungus residue); mix the above raw materials evenly to obtain compost raw materials;

[0033] 2) Same as embodiment 1;

[0034] 3) The fermentation product is mixed with 5%wt bamboo vinegar liquid, dried, extruded and granulated t...

Embodiment 3

[0037] A preparation method of walnut green peel slag organic fertilizer, the steps comprising:

[0038] 1) Weigh walnut green peel residue, edible fungus residue and plant ash according to the weight ratio of 60:30:10; adjust the water content of walnut green peel residue to 60%, add Aureobasidium pullulans and triethanolamine, stir well, and then ferment with oxygen for 20 hours (per Add 10g of Aureobasidium pullulans and 5g of triethanolamine to 1kg of walnut green skin dregs); add calcium hydroxide and zeolite to edible fungus dregs, heat up to 85°C and stir for 30 minutes, then cool down to 30°C, add walnut green peel juice, stir well Stand still for 20 hours (add 10g of calcium hydroxide, 5g of zeolite and 300g of walnut green peel juice to 1kg of edible fungus residue); mix the above raw materials evenly to obtain compost raw materials;

[0039] 2), 3) are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com