Method for treating incinerated fly ash with harmful heavy metals

A treatment method, heavy metal technology, applied in the direction of lighting and heating equipment, etc., to achieve very effective and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

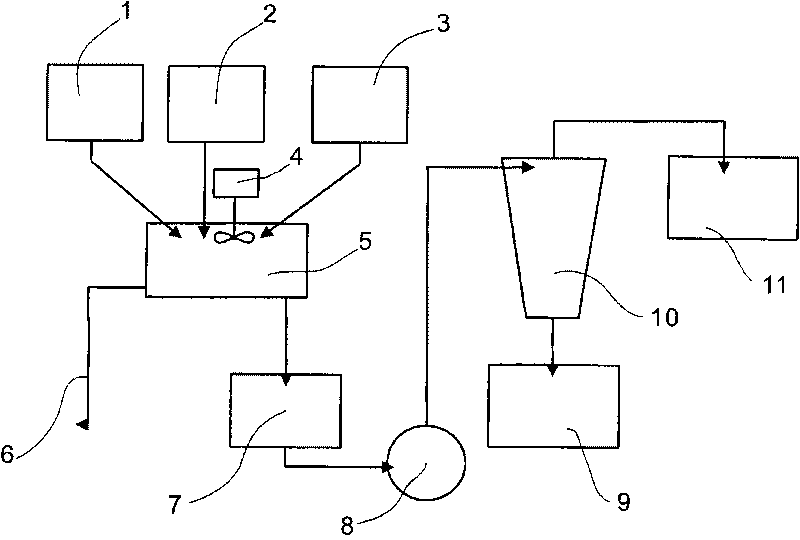

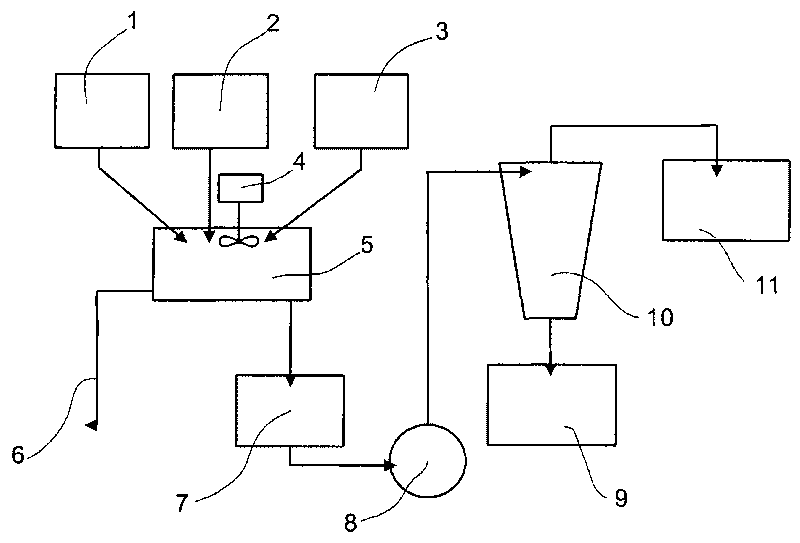

Method used

Image

Examples

Embodiment 1

[0038] Take reaction ash 10wt% and add water 100wt% at the same time, stir for 10 minutes and wash with water. Only a small amount of salt remains and the weight loss of quartz sand added therein is relatively large. The salt compounds of KCl and NaCl are also dissolved in water, and only compounds such as Ca and Si remain.

[0039] table 3

[0040]

Embodiment 2

[0042] Mix the reaction ash, quartz sand heavy medium and water in Example 1 with solid-liquid ore slurry without addition and with addition, and send them into the wet vortex separator by pressure pump respectively, with three different feed pressures of 20, 80 and 140Kpa Sorting by pressure makes the particles with large particles and high density move downward and outward along the tube wall, and flow out from the underflow port (UF for short). The inner vortex is carried by the inner vortex to the overflow port (Overflow referred to as OF) for discharge. The physical and chemical properties and elemental composition after sorting are shown in Table 4, Table 5, Table 6 and Table 7.

[0043] The model of the wet vortex separator used in this embodiment is Mozley C705 type, and the enrichment and separation of heavy metals in the incineration fly ash is carried out with the wet vortex separator with a diameter of 2 o'clock.

[0044] Table 4

[0045]

[0046] □The content...

Embodiment 3

[0060] Repeat Example 2, but only use reaction ash to add solid-liquid slurry with dense medium quartz sand, and carry out wet vortex separation with incineration fly ash / quartz sand: 2 / 1 and 3 / 1, the influence on the enrichment efficiency is obtained Such as Table 8 and Table 9.

[0061] Table 8

[0062]

[0063] Table 9

[0064]

[0065]

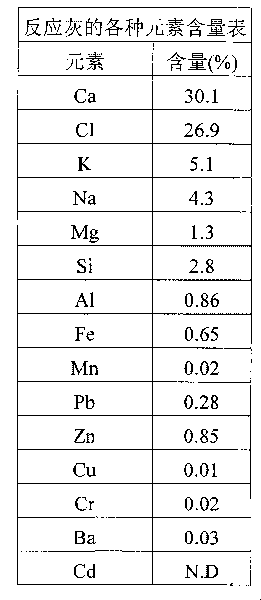

[0066] It can be seen from the above examples that the composition of the incineration fly ash of the present invention is mainly Ca, Si, K, Na, Cl, the contents of unburned carbon and activated carbon are respectively 0.219 and 11.73%, and the TCLP dissolution concentrations of Pb and Zn are relatively high And the dissolution concentration of Pb exceeded the standard of 5mg / l, which was 34.08mg / l.

[0067] Feed pressure has an effect on the efficiency of heavy metal enrichment in wet vortex cone separation. As the feed pressure increases, the efficiency of heavy metal enrichment also increases. The enrichment effect is the be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com