Ultralow-temperature heavy-load vehicle gear oil composition

A gear oil, heavy-duty technology, used in lubricating compositions, petroleum industry and other directions, can solve the problems of poor extreme pressure bearing capacity, low temperature Brookfield viscosity can not meet the requirements, high temperature foam and other problems, to achieve high bearing capacity, low Low temperature viscosity and low foam tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

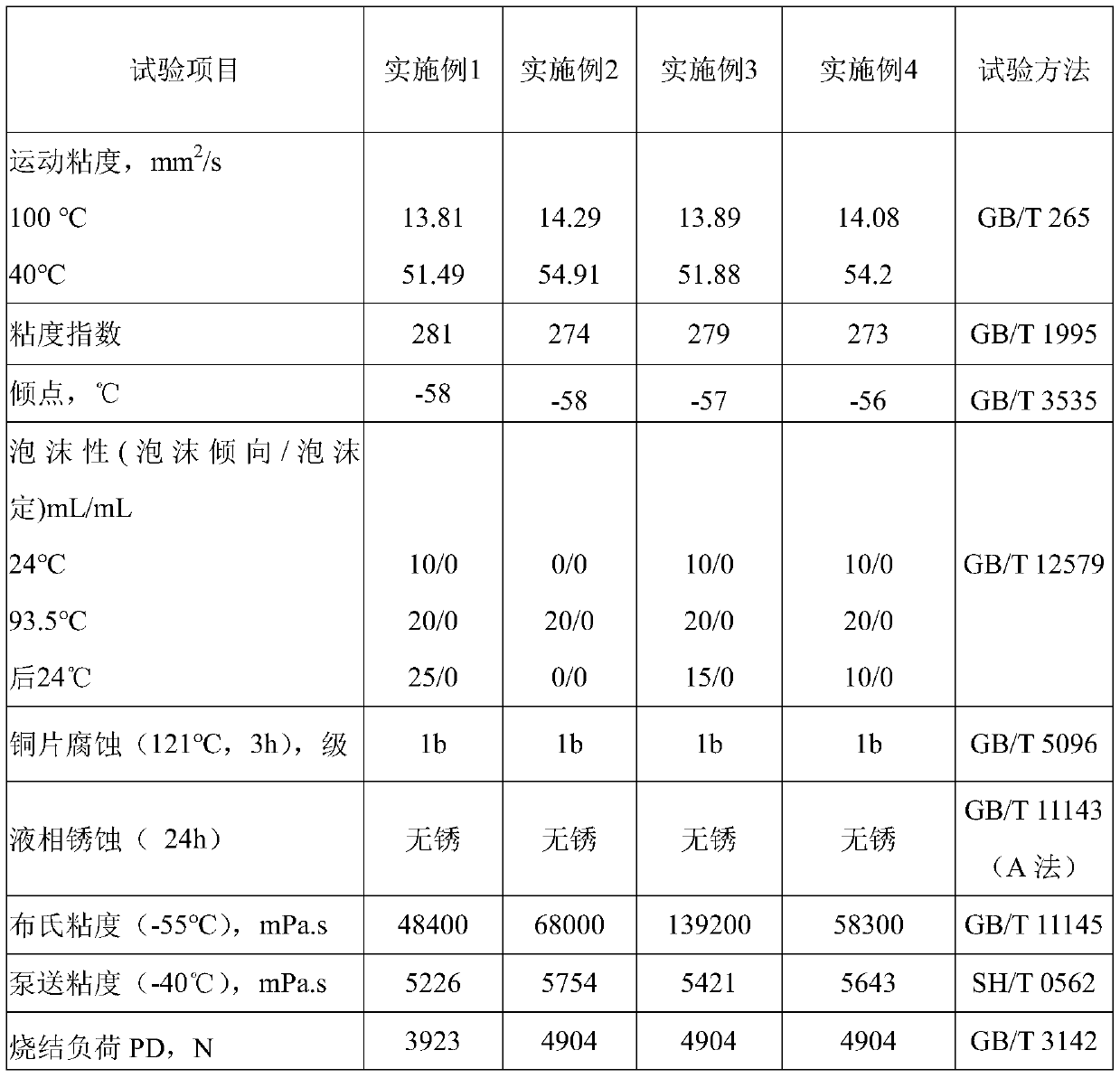

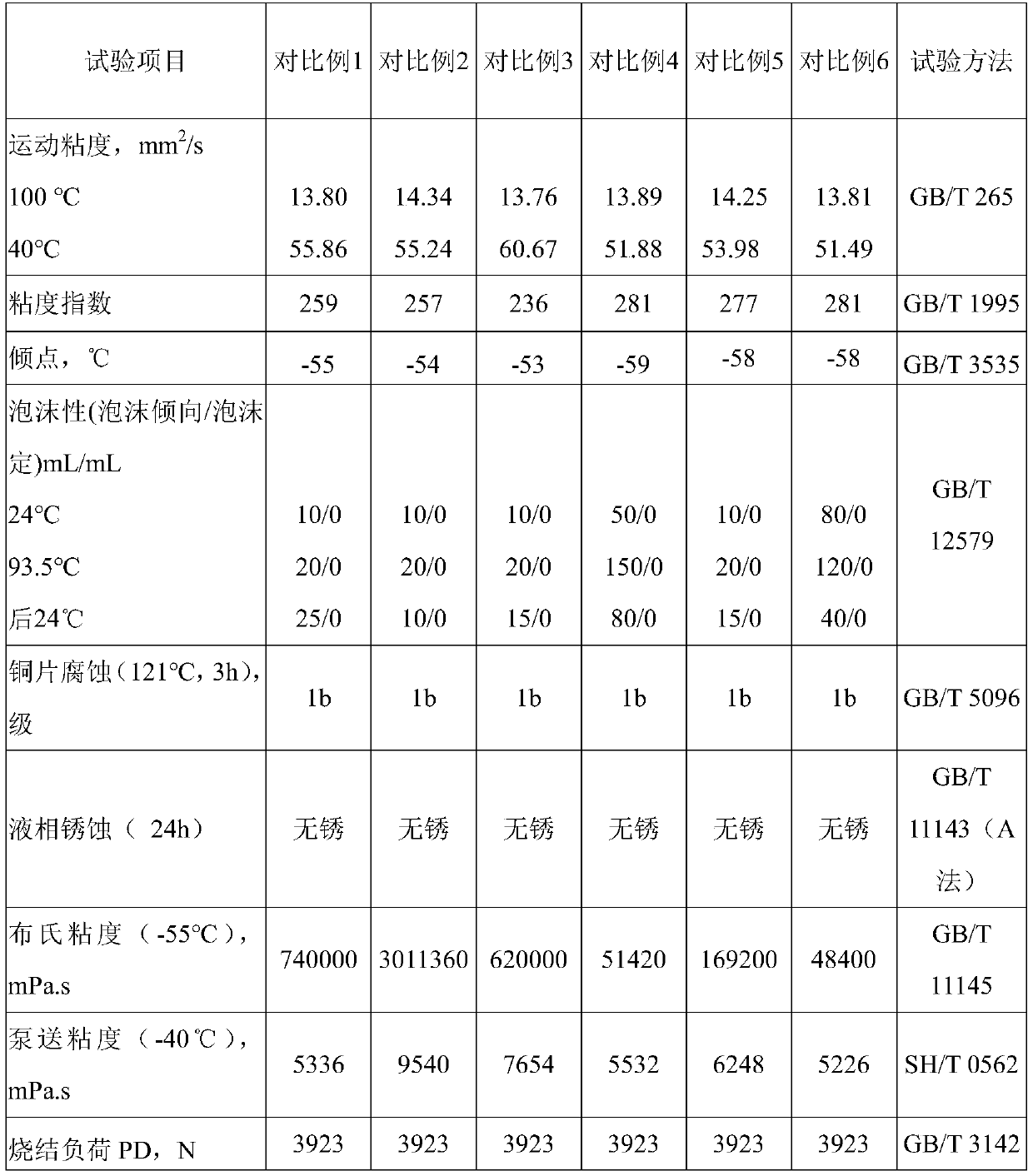

Examples

Embodiment 1

[0021] The ultra-low temperature heavy-duty vehicle gear oil composition GL-5 70W-90 in this embodiment is blended by the components shown in the following table 1 in weight percentage:

[0022] Table 1

[0023] components weight percentage Naphthenic oil NS-3 39.46% Synthetic ester KL19 32% Viscoplex 7-310 20.5% Gear oil compound HITEC 369 8% Antifoaming agent V14-520 0.04%

Embodiment 2

[0025] The ultra-low temperature heavy-duty vehicle gear oil composition GL-5 70W-90 in this embodiment is blended from the components shown in the following table 2 in weight percentage:

[0026] Table 2

[0027] components weight percentage Synthetic oil PAO2 20.94% Naphthenic oil NS-8 35% Synthetic ester KL16 15% Viscosity agent V7-305 22% Gear oil compounding agent Anglamol 6043 7% Antifoaming agent V14-520 0.06%

Embodiment 3

[0029] The ultra-low temperature heavy-duty vehicle gear oil composition GL-5 70W-90 in this embodiment is blended by the components shown in the following table 3 in percentage by weight:

[0030] table 3

[0031] components weight percentage Synthetic oil PAO2 11.95% Naphthenic oil NS-3 20% Synthetic ester KL16 40% Viscosity Index Agent V7-310 20% Gear oil compounding agent Anglamol 6043 8% Antifoam agent FOAM BAN 130B 0.05%

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com