Automatic detection device for preventing magnetic blocks of magnetic separator for feed processing from falling off

An automatic detection device and feed processing technology, applied in the direction of measuring device, using electric device, using electromagnetic means, etc., can solve the problems of damaged equipment and low equipment reliability, to prevent damage, improve equipment reliability, and improve production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

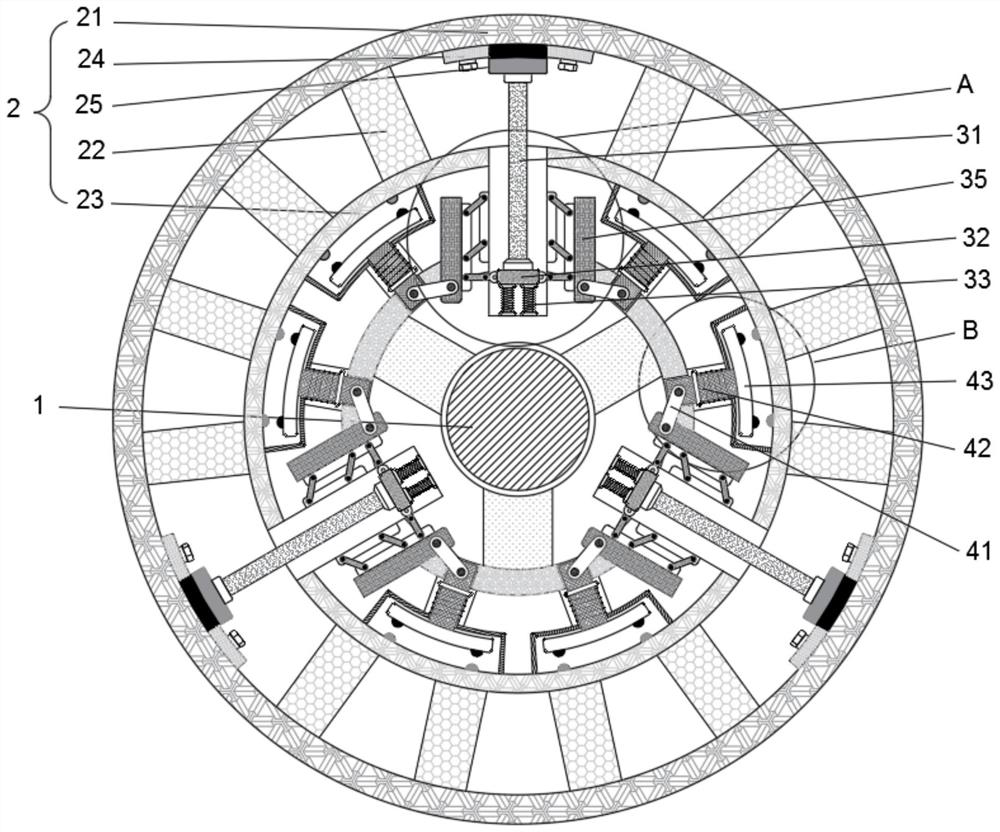

[0025] see figure 1 , an automatic detection device for preventing magnetic blocks from falling off of a magnetic separator for feed processing, comprising a rotating shaft 1, a fixing mechanism 2 is movably connected to the outer ring of the rotating shaft 1, a detection mechanism 3 is fixedly connected to the front of the fixing mechanism 2, and both sides of the detection mechanism 3 are An alarm mechanism 4 is movably connected, and a clutch mechanism 5 is movably connected to the back of the detection mechanism 3 .

[0026] When the equipment runs abnormally, the detection mechanism 3 is triggered when the magnetic block 25 falls off, and the detection mechanism 3 shrinks the magnetic block 25 to prevent the magnetic block 25 from scattering and damaging the equipment after falling, thereby improving the reliability of the equipment; the alarm mechanism 4 is triggered during the shrinking process of the detection mechanism 3, The alarm mechanism 4 energizes the alarm duri...

Embodiment 2

[0031] see figure 1 and image 3 , an automatic detection device for preventing magnetic blocks from falling off of a magnetic separator for feed processing, comprising a rotating shaft 1, a fixing mechanism 2 is movably connected to the outer ring of the rotating shaft 1, a detection mechanism 3 is fixedly connected to the front of the fixing mechanism 2, and both sides of the detection mechanism 3 are An alarm mechanism 4 is movably connected, and a clutch mechanism 5 is movably connected to the back of the detection mechanism 3 .

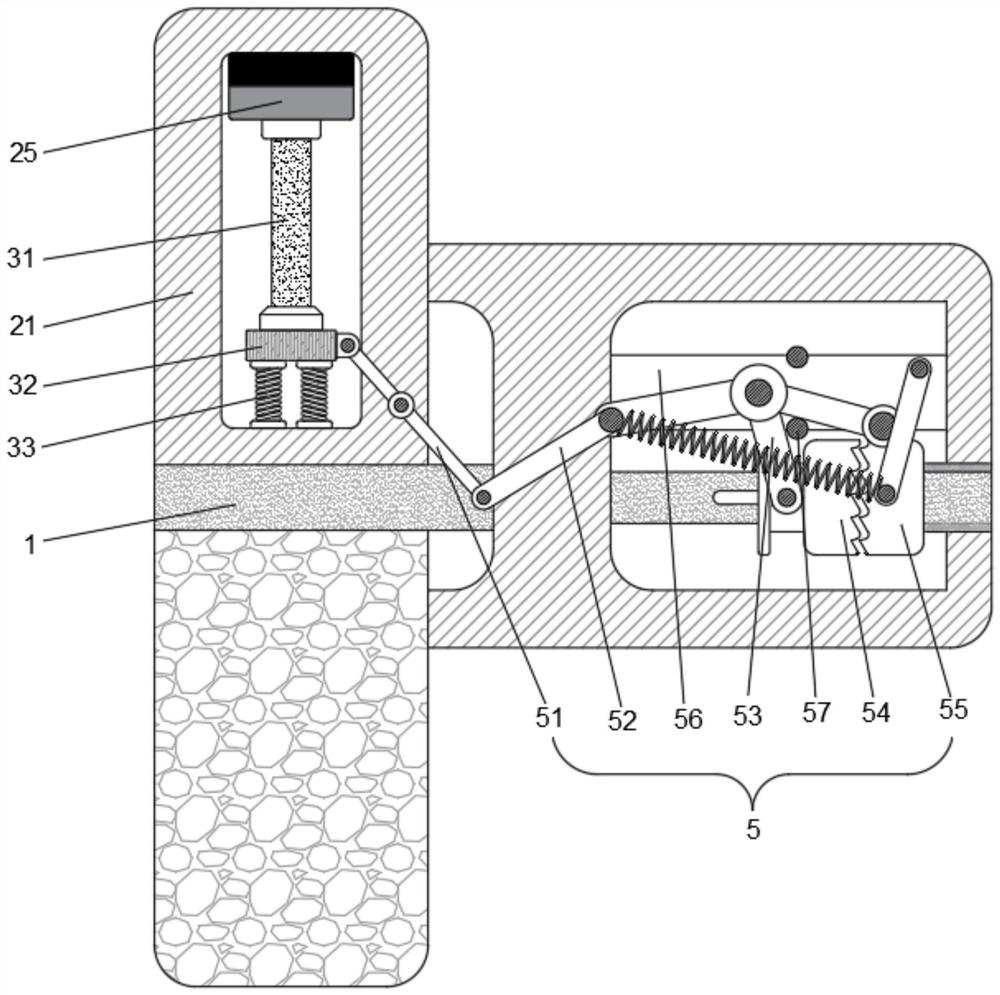

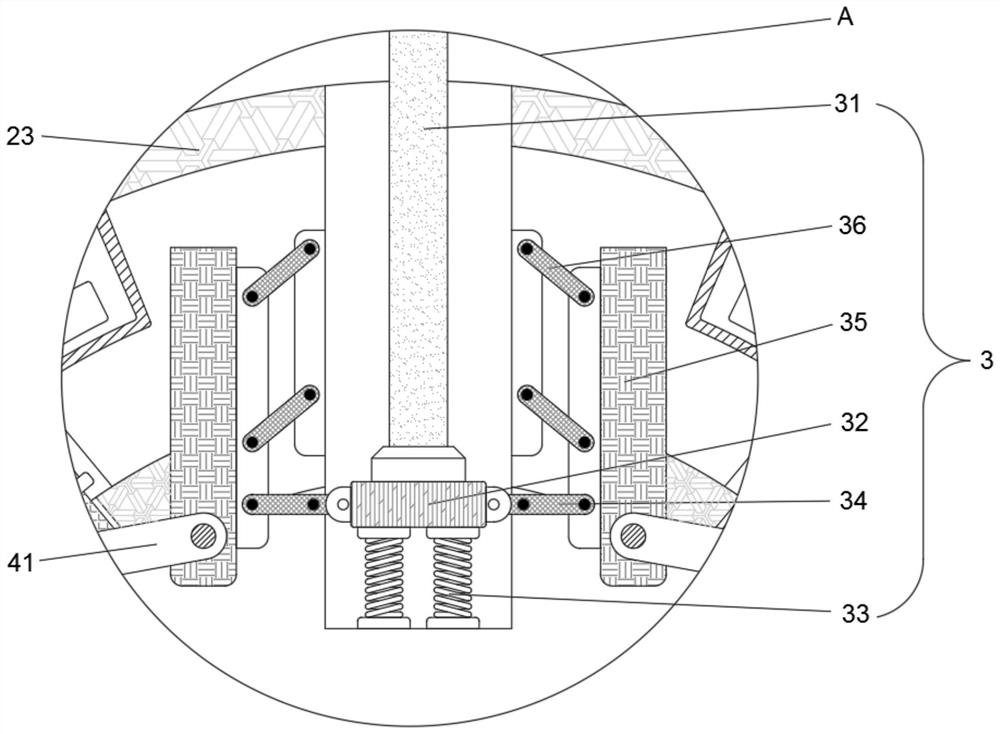

[0032] Further, the fixing mechanism 2 includes a casing 21, the inner side of the casing 21 is fixedly connected with a support rod 22, the inner end of the support rod 22 is fixedly connected with a fixing plate 23, and a hole that is adapted to the rotating shaft 1 is opened in the middle of the fixing plate 23. In order to install the rotating shaft 1 to facilitate the rotation of the fixed disk 23 , the inner surface of the housing 21 is fi...

Embodiment 3

[0036] see Figure 1-4, an automatic detection device for preventing the magnetic block from falling off of a magnetic separator for feed processing, including a rotating shaft 1, and a keyway matching the sliding sleeve 54 is provided on the side of the rotating shaft 1, which is used to install the sliding sleeve 54, and is convenient for the sliding sleeve 54 to move and Rotating, the outer ring of the rotating shaft 1 is movably connected with a fixing mechanism 2. The fixing mechanism 2 includes a casing 21. The inner side of the casing 21 is fixedly connected with a support rod 22, and the inner end of the support rod 22 is fixedly connected with a fixed plate 23. The hole matched with the rotating shaft 1 is used for installing the rotating shaft 1 to facilitate the rotation of the fixed disk 23 .

[0037] A detection mechanism 3 is fixedly connected to the front of the fixing mechanism 2. The detection mechanism 3 includes a straight rod 31. The inner end of the straig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com