Plate shearing machine with material collecting function

A shearing machine and functional technology, applied in the field of sheet metal cutting, can solve problems such as scratches and low efficiency, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

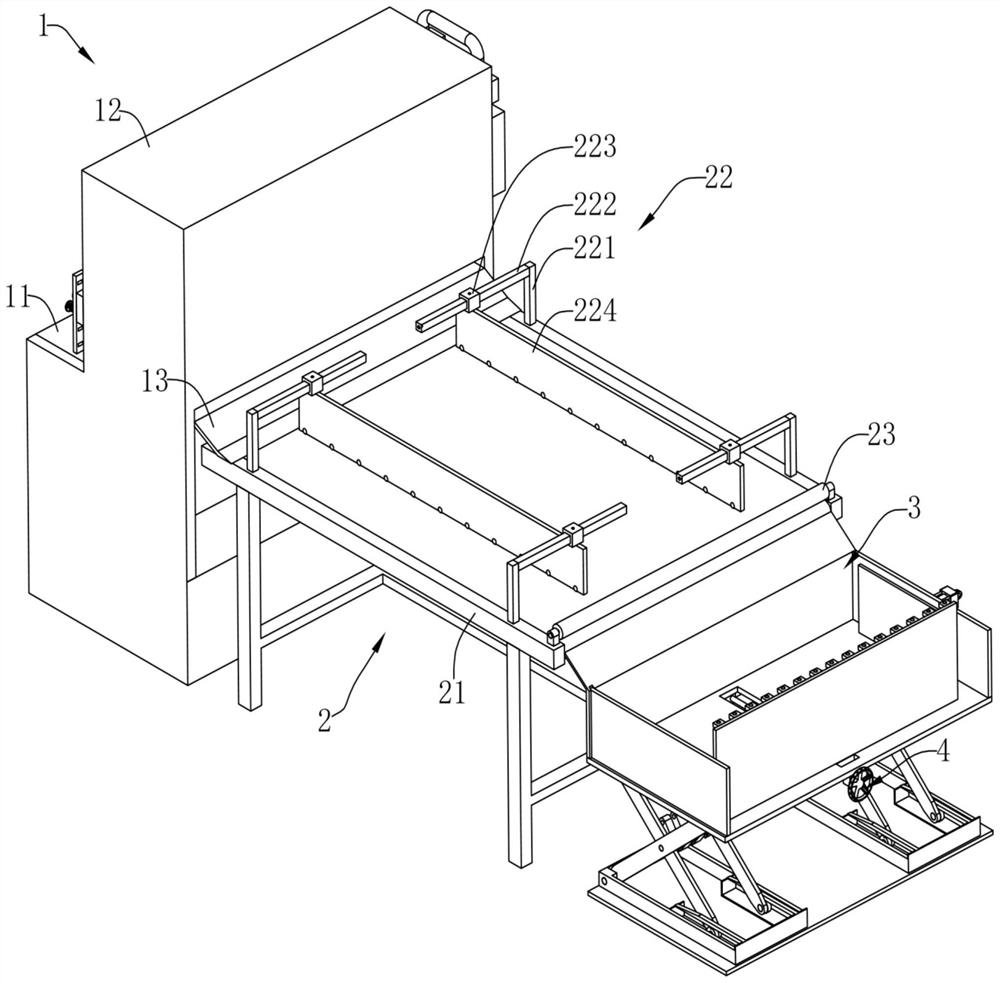

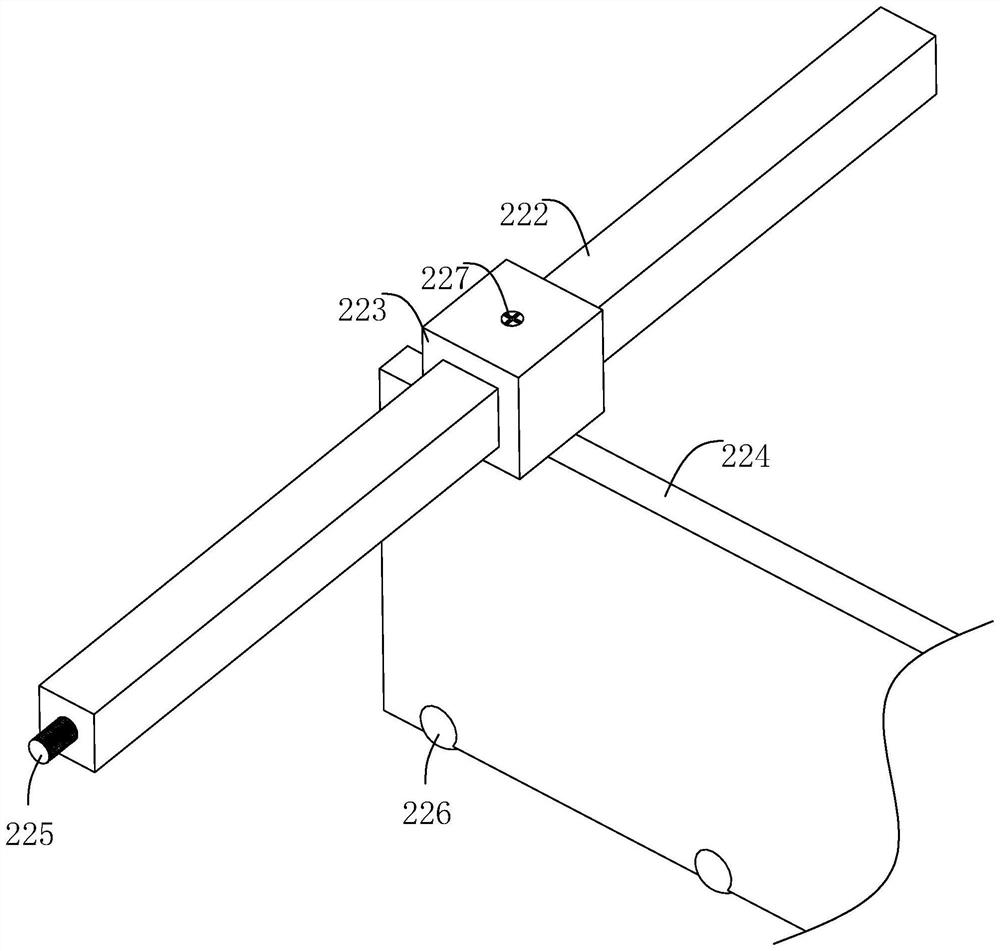

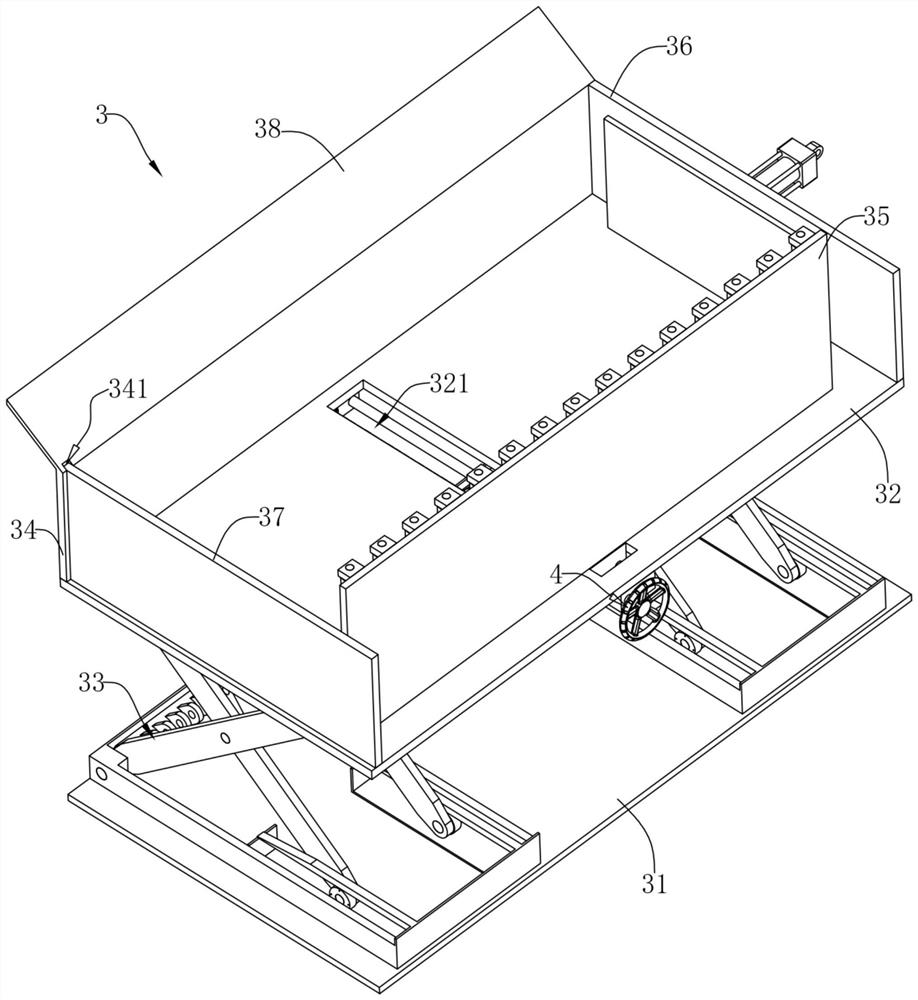

[0039] Attached to the following Figure 1-3 This application will be described in further detail.

[0040] The embodiment of the present application discloses a shearing machine with a material receiving function. refer to figure 1 , the shearing machine includes a shearing machine body 1 and a conveying device 2 and a receiving device 3 sequentially arranged at the discharge end of the shearing machine body 1; the main function of the shearing machine body 1 is to cut the sheet material; the transmission device 2 Its main function is to transport the cut sheets; the main function of the receiving device 3 is to receive the sheets conveyed by the conveying device 2 and stack them neatly; this application greatly improves the work efficiency by means of automatic collection. There is no need for manual participation in the collection process, so the security is more guaranteed.

[0041] The shearing machine body 1 includes a workbench 11 and a tool rest 12 integrally connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com