Ultrasonic stirring friction welding device and welding method

A friction welding and ultrasonic stirring technology, applied in welding equipment, welding equipment, auxiliary devices, etc., can solve the problems of high temperature of welding bath, residue, easy softening and deformation of welding materials, etc., to prevent relative movement and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

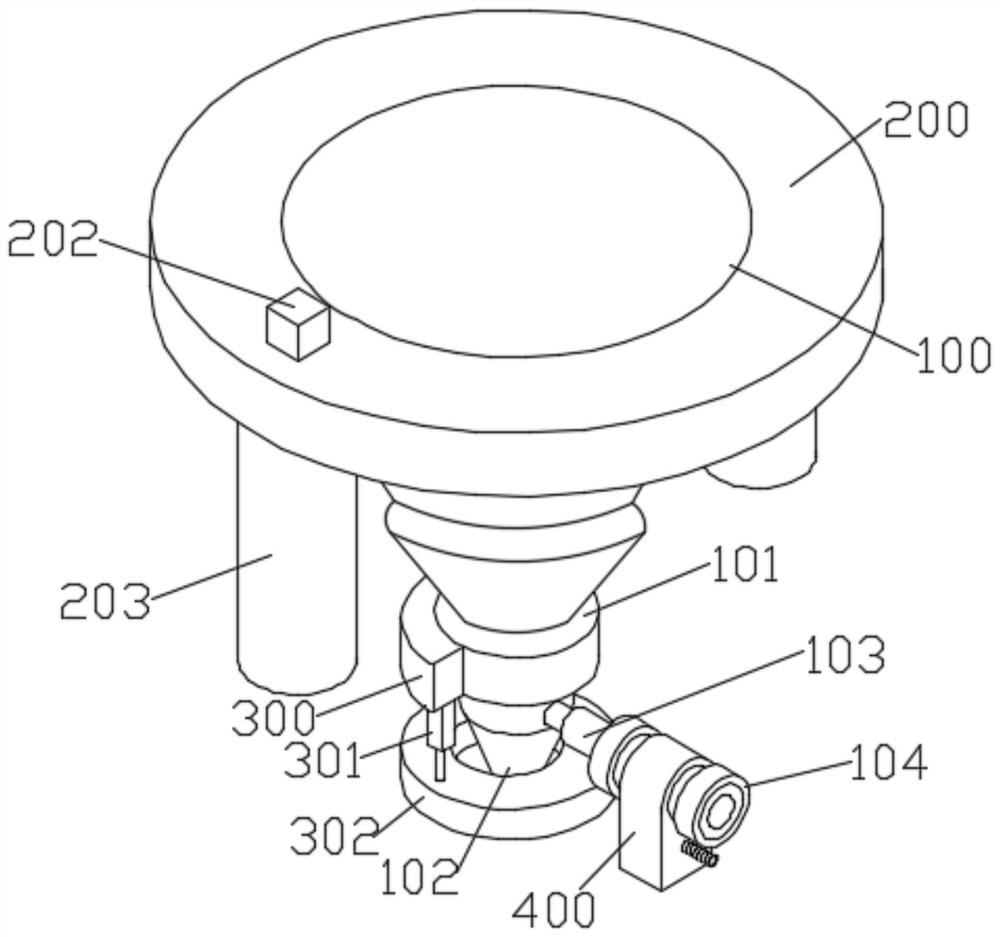

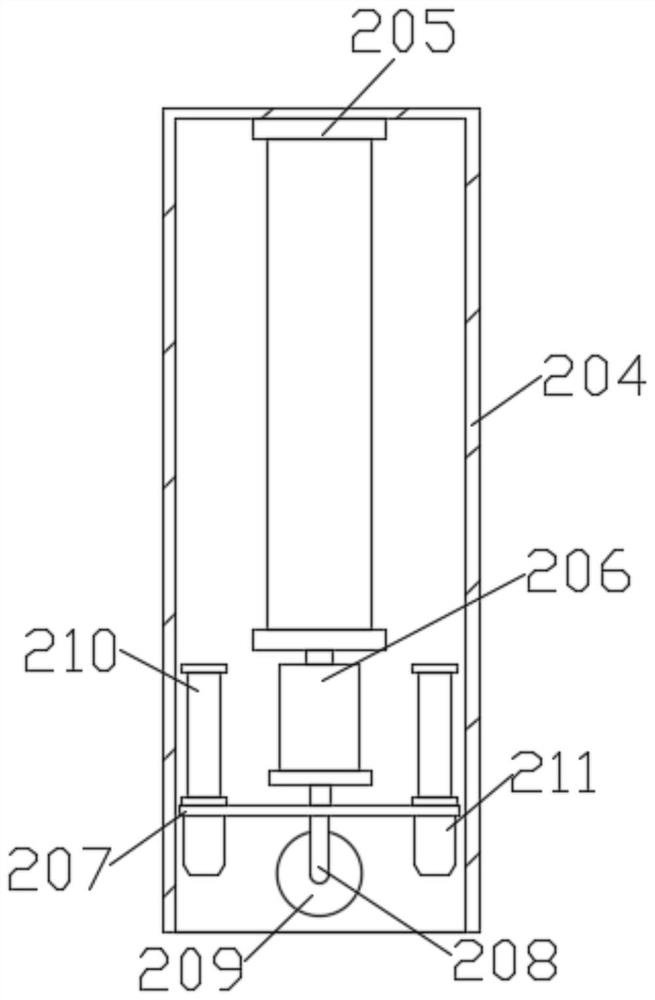

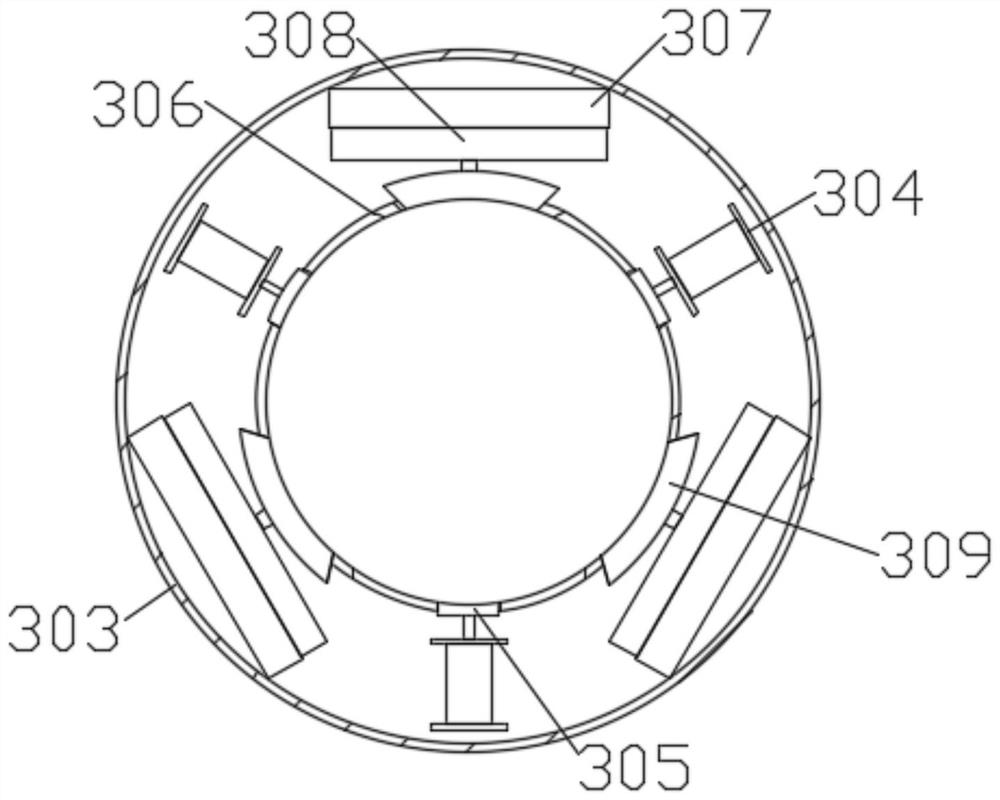

[0035] see figure 1 , Figure 7 As shown, the present invention is an ultrasonic friction stir welding device, which includes a mounting seat 100, a connecting piece 101, a static shaft shoulder 102, an ultrasonic probe 103, and a transducer 104. The connecting piece 101 is fixedly installed on the bottom of the mounting seat 100, and the static shaft The shoulder 102 is fixedly installed at the bottom of the connector 101, the bottom of the stationary shaft shoulder 102 is rotatably installed with a stirring needle, an ultrasonic probe 103 is installed on one side of the stationary shaft shoulder 102, and a transducer 104 is installed at one end of the ultrasonic probe 103 away from the stationary shaft shoulder 102, and the installation The outer ring of the seat 100 is rotatably connected to the annular casing 1 200. Two pressing and guiding mechanisms 203 are fixedly installed at the bottom of the annular casing 1 200. A fixing block 300 is installed on the connecting piec...

Embodiment 2

[0039] The present invention is an ultrasonic friction stir welding device, which includes a mounting seat 100, a connecting piece 101, a stationary shaft shoulder 102, an ultrasonic probe 103, and a transducer 104. The connecting piece 101 is fixedly installed on the bottom of the mounting seat 100, and the static shaft shoulder 102 is fixed Installed at the bottom of the connector 101, the bottom of the stationary shaft shoulder 102 is rotatably installed with a stirring needle, one side of the stationary shaft shoulder 102 is installed with an ultrasonic probe 103, and one end of the ultrasonic probe 103 away from the stationary shaft shoulder 102 is installed with a transducer 104, the transducer 104 A welding position cooling mechanism 400 is fixedly installed on the upper part.

[0040] see Figure 4-Figure 6 As shown, the welding position cooling mechanism 400 includes a fixed shell 401, the bottom of the fixed shell 401 is open, an inlet and outlet cylinder 402 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com