Abrasive particle flow machining clamp with clamping plates convenient to replace

A technology of abrasive particle flow and splint, applied in the direction of manufacturing tools, metal processing equipment, grinding workpiece support, etc., can solve the problems of cumbersome, easy to leave pinch marks, affect the appearance, etc., and achieve the effect of convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

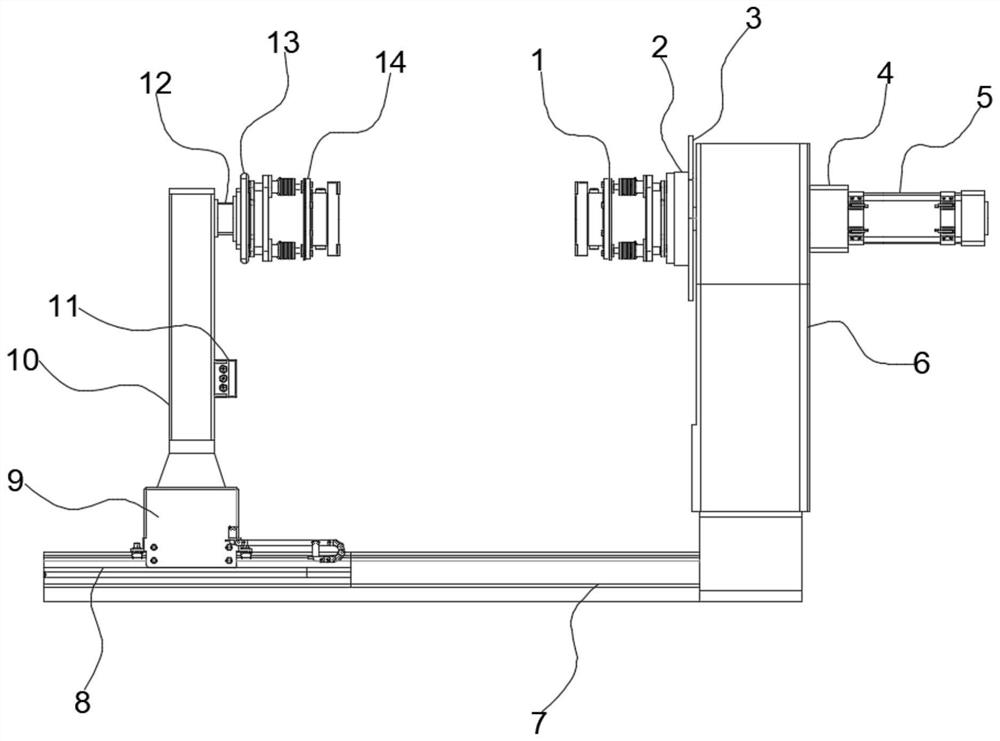

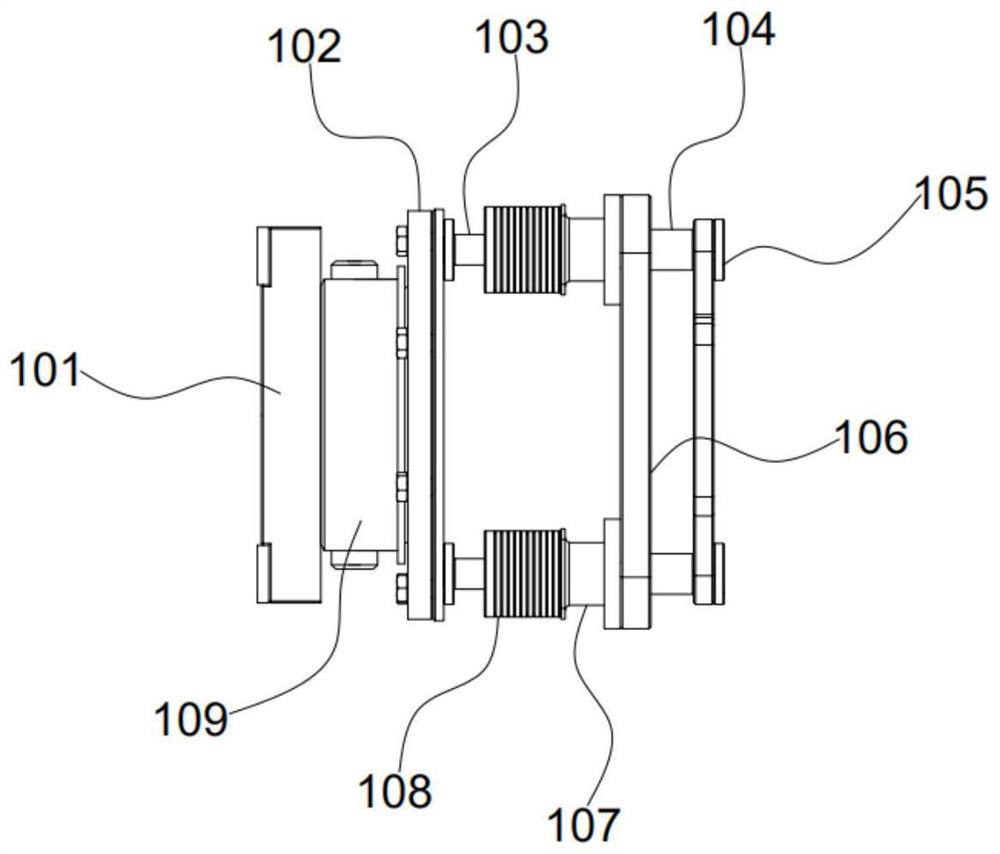

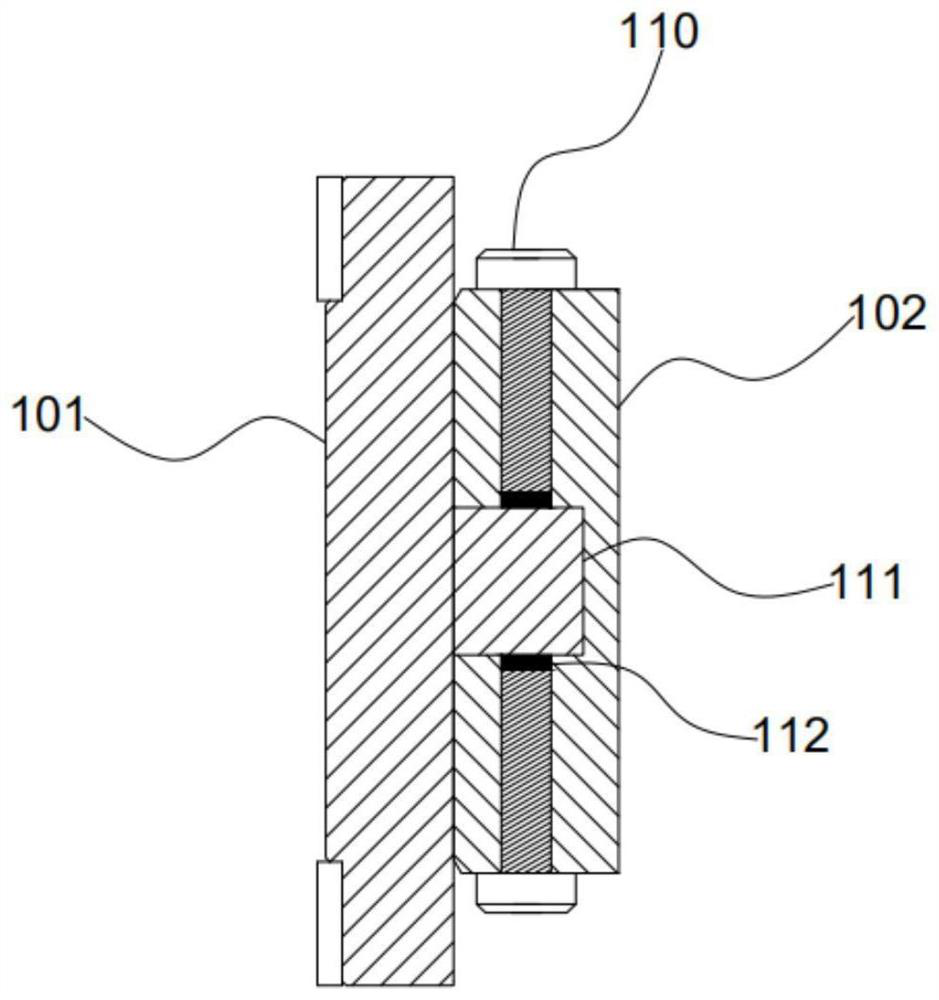

[0021] Example: see attached Figure 1-4 , the present invention provides a technical solution: an abrasive flow processing fixture that is easy to replace the splint, which includes:

[0022] The base 7, the top surface of the left part of the base 7 is provided with a slide rail 8, the slide rail 8 is slidably provided with a self-driving slide 9, and the top surface of the self-driving slide 9 is fixedly provided with a support base 10, and the support base 10 One end of the connecting rod 12 is fixedly arranged on the right side wall of the top, the other end of the connecting rod 12 is fixedly arranged with a force plate 14, and the right end surface of the force plate 14 is fixedly installed with a second elastic clamping component 14;

[0023] And the side stand 6, the bottom end of the side stand 6 is fixedly arranged on the right side wall of the base 7, the side wall of the top of the side stand 6 is provided with a mounting hole, and the mounting hole is fixedly pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com