Movable disc anti-rotation ring assembly tool

An assembly tooling and anti-rotation technology, which is applied in the field of scroll compressors, can solve the problems of low work efficiency, cumbersome operation, and high rework rate, and achieve the effect of preventing improper installation and ensuring assembly accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

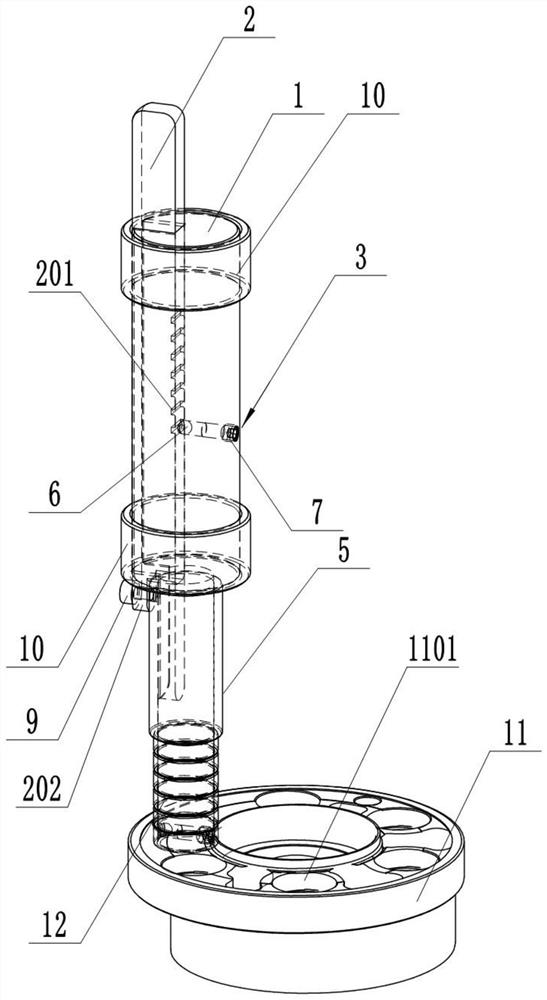

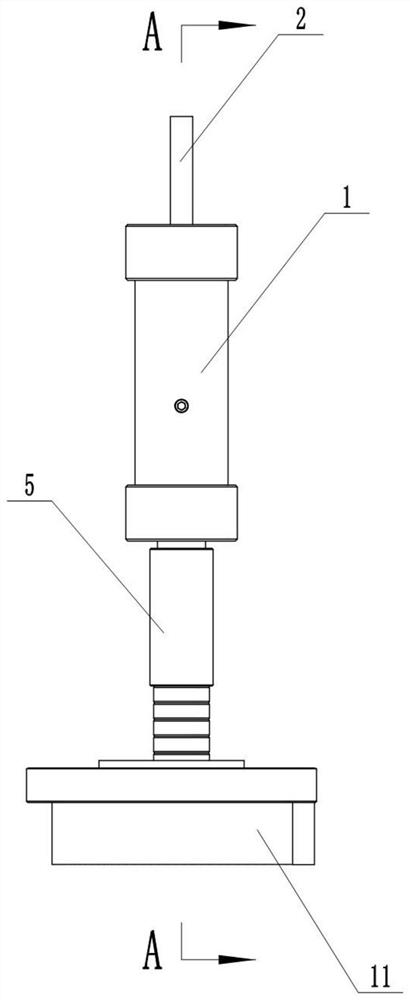

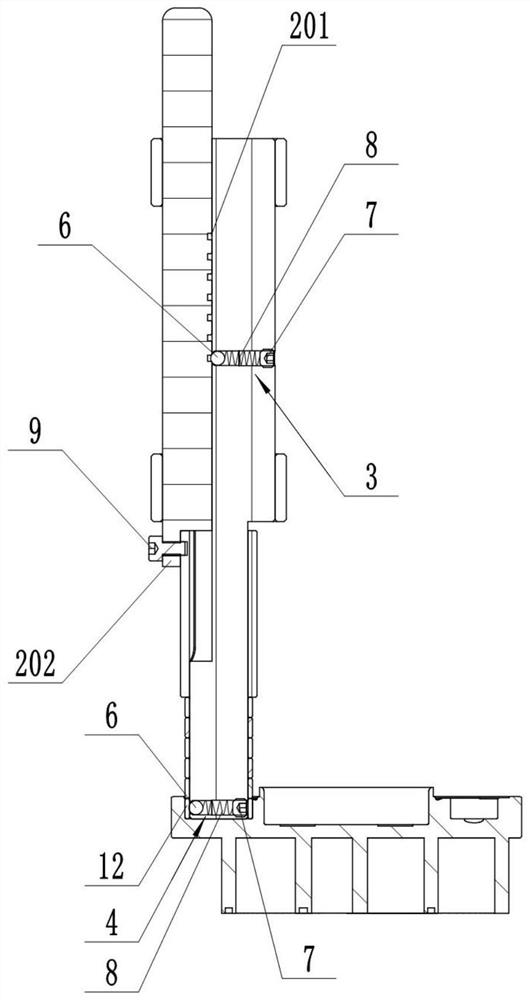

[0041] A moving plate anti-rotation ring assembly tool, comprising a grip rod 1, a mandrel 2 slidably arranged on the grip rod 1, the mandrel 2 is provided with seven axially evenly arranged clamping grooves 201, the grip rod 1 A radially-arranged retractable first stopper 3 is arranged thereon, a pressing naan 104 is radially penetrated on the grip rod 1, and the first stopper 3 is arranged in the pressing naan 104. One end of a stopper 3 is matched with the card slot 201, the lower end of the top rod 2 is provided with a feeding member 5, and the lower end of the grip rod 1 is provided with a radially arranged retractable second stopper 4, so The lower end of the grip rod 1 is radially provided with another pressing naan 104, the second stopper 4 is arranged in the other pressing naan 104, and the top rod 2 moves downward, then the first stopper 3 Entering into the next card slot 201, the shape of the lower end of the handle 1 matches the circular hole 1101 of the movable sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com