High-speed rail seat framework manufacturing process and device

A seat frame and manufacturing device technology, applied in the direction of manufacturing tools, workbenches, etc., to achieve the effects of cost saving, high degree of automation, and efficiency improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

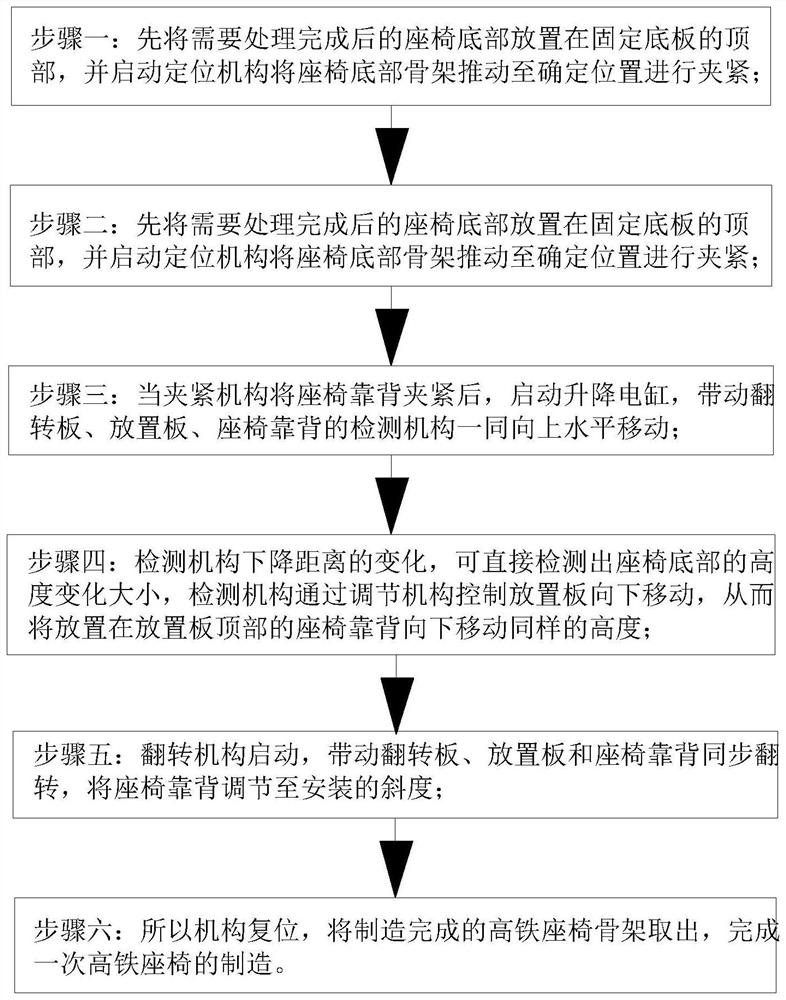

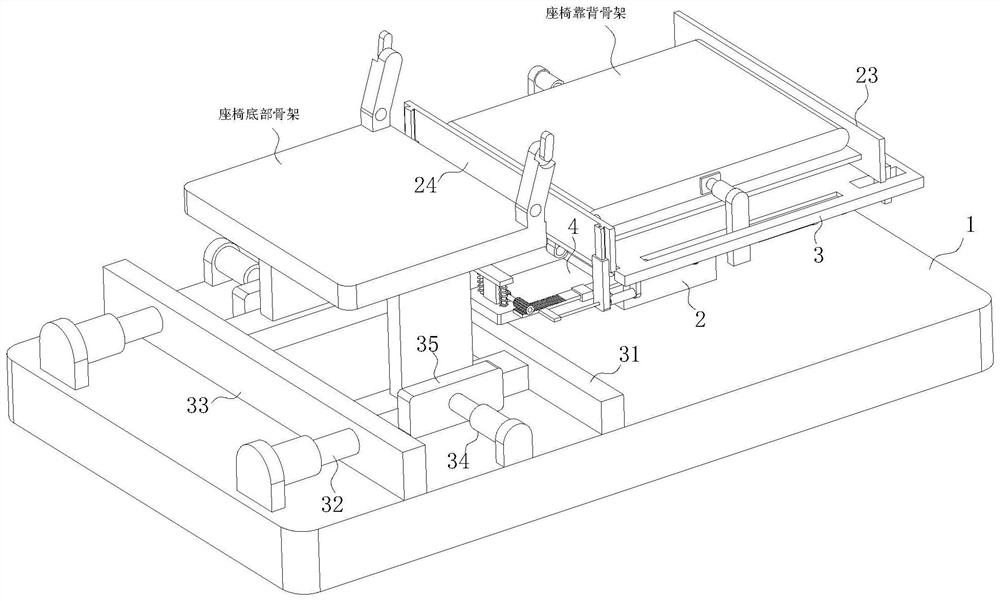

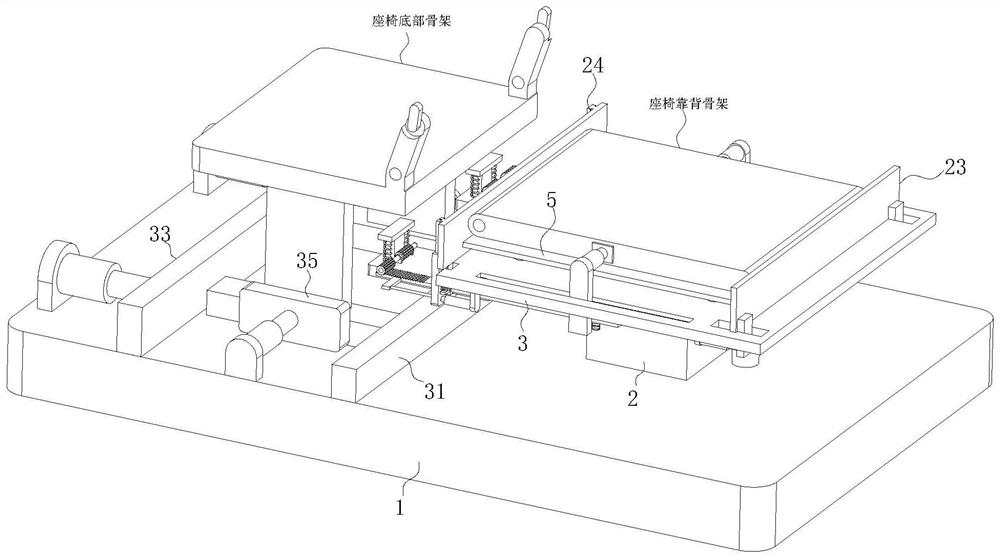

[0034] see Figure 1-9 , the present invention provides a technical solution: a high-speed rail seat frame manufacturing device, comprising a fixed bottom plate 1, the top left side of the fixed bottom plate 1 is connected with a positioning mechanism for positioning the bottom of the seat, and the right side of the top of the fixed bottom plate 1 is fixedly connected with a Lifting electric cylinder 2, the top of the lifting electric cylinder 2 is provided with a flipping plate 3, the extension end of the lifting electric cylinder 2 is connected with a flipping mechanism for flipping the flipping board 3 to the left, and the bottom left of the flipping board 3 is connected with two L-shaped The fixing frame 4, the left end of the L-shaped fixing frame 4 extends below the seat bottom, the two L-shaped fixing frames 4 are connected with a detection mechanism for detecting the height of the seat bottom, and the top of the flip plate 3 is provided with a placing plate 5, The bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com