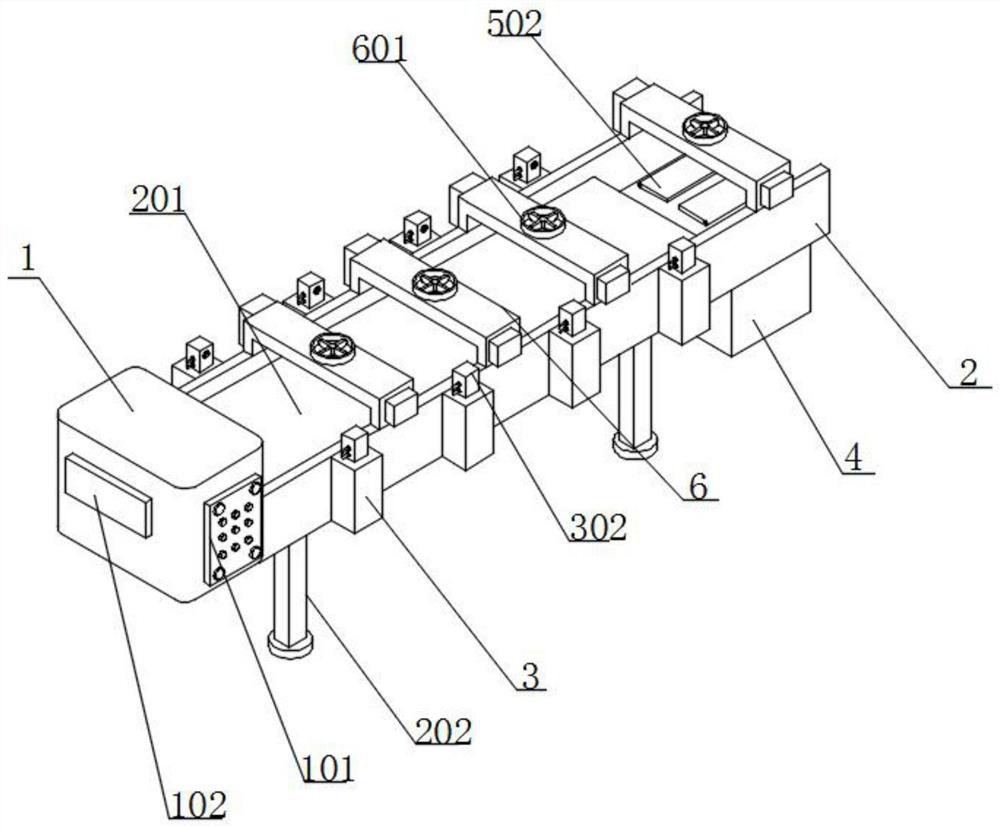

Ship material conveying rubber conveying belt with anti-falling protection function

An anti-dropping and conveyor belt technology, applied in the field of rubber conveyor belts, can solve the problems of lack of dust-proof structure, lack of anti-drop structure, lack of weight-measuring structure, etc., and achieve the effect of accurate weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

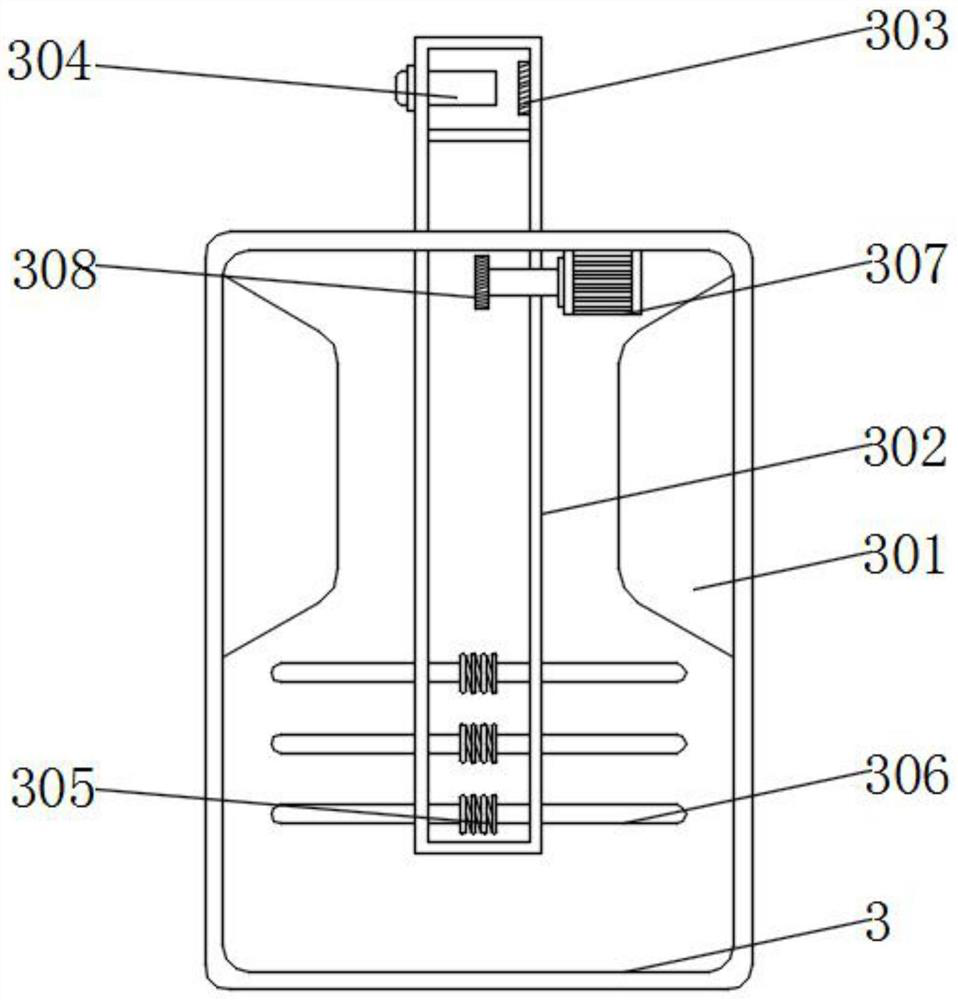

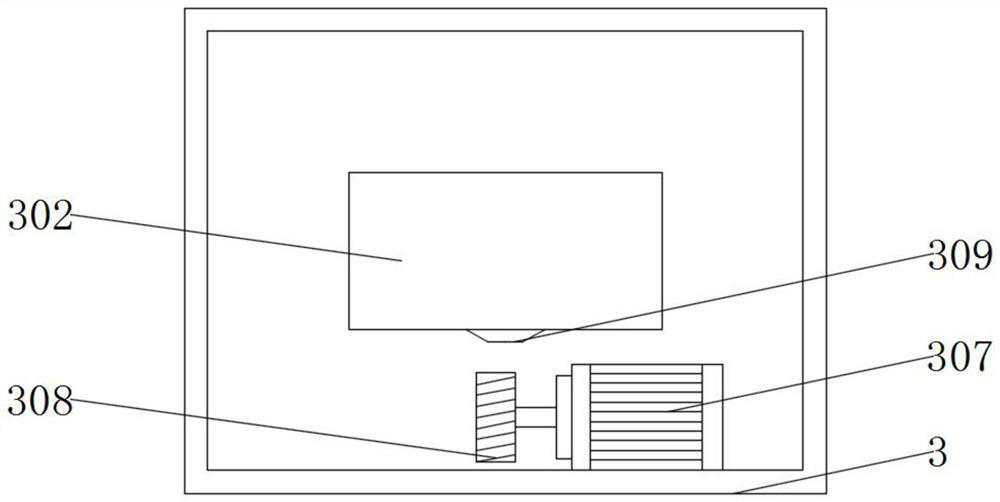

[0043] Example 2: see figure 2 and image 3 , an embodiment provided by the present invention: a rubber conveyor belt with anti-fall protection for ship material transportation, the inner wall of the protective box 3 is installed with a rounded block 301, and the top of the protective box 3 is installed with a lifting column 302, A signal transmitter 303 is installed on the inner wall of the lifting column 302, an infrared detector 304 is installed through the outer wall of the lifting column 302, and a plurality of No. 1 springs 305 are installed on the inner wall of the lifting column 302. A rod 306, and one end of the blocking rod 306 extends out of the outer wall of the lifting column 302, a gear slot 309 is provided on the front of the lifting column 302, a No. 1 motor 307 is installed on the inner top wall of the protective box 3, and a No. Gear 308, and the No. 1 gear 308 meshes with the gear groove 309. When conveying materials, the infrared detector 304 emits an inf...

Embodiment 3

[0044] Example 3: see Figure 7 and Figure 8 , an embodiment provided by the present invention: a rubber conveyor belt with anti-fall protection for ship material transportation, the inner wall of the weighing box 4 is installed with a weighing plate 401 through a rotating shaft, and the inner wall of the weighing plate 401 is installed with a The weight sensor 403, the No. 2 spring 402 is installed on the top of the weighing plate 401, and one end of the No. 2 spring 402 is connected to the inner wall of the weighing box 4, and the inner wall of the weighing box 4 is installed with a fixing frame 404, and the fixing frame 404 is located at Above the weight plate 401, a spring 405 is installed on the outer wall of the fixing frame 404, a winding roller 406 is installed at one end of the spring 405, and the second gear 407 is installed on the outer wall of the winding roller 406. A cable 408 is installed around the outer wall, and one end of the cable 408 is connected to the ...

Embodiment 4

[0045] Example 4: see Image 6 , an embodiment provided by the present invention: a rubber conveyor belt with anti-fall protection for ship material transportation, an exhaust fan 601 is installed on the top of the dust removal board 6, and two groups of exhaust fans are installed at the bottom of the exhaust fan 601 One end of the exhaust pipe 602 extends into the interior of the dust removal board 6, the inner wall of the dust removal board 6 is installed with a siphon pipe 603, the outer wall of the siphon pipe 603 is installed with a plurality of first suction heads 604, and the outer wall of the siphon pipe 603 is installed with Two suction heads 605 , a waterproof case 701 is installed on the inner wall of the collection box 7 , a water pump 702 is installed on the inner bottom wall of the waterproof case 701 , and a water inlet pipe is installed at the input end of the water pump 702 , and one end of the water inlet pipe extends into the collection tank 7 . Inside, a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com