Method for lifting end-beam-contained ballastless track structure under operation high-speed rail

A ballastless track and end beam technology, applied in the direction of track, track maintenance, roads, etc., can solve problems such as limiting the repairability of the line, difficult to repair the geometric state of the track, affecting the high-speed, safe and comfortable operation of the train, and achieving the goal of retaining reliability. Remainability, improvement of accuracy and stability, effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

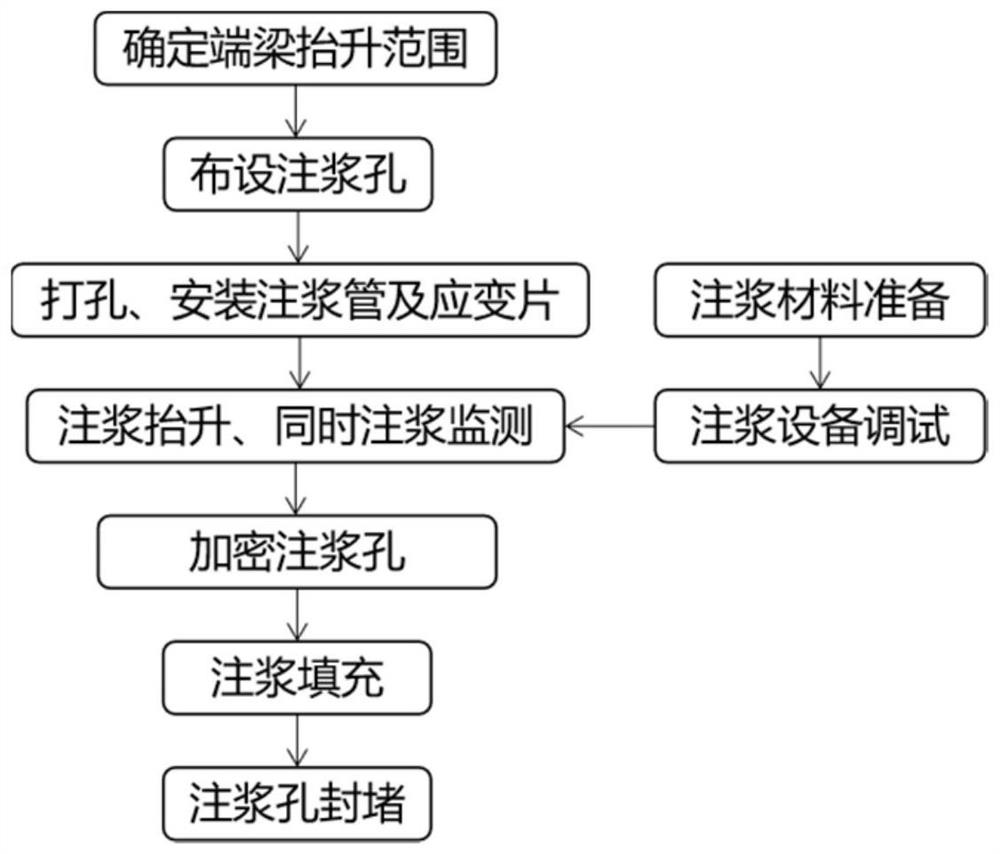

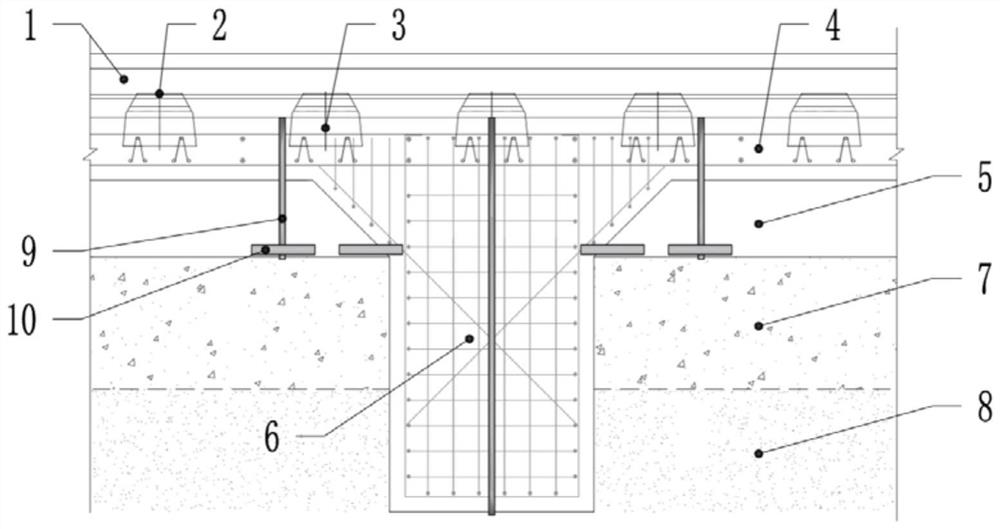

[0067] After a high-speed railway was opened to traffic, due to complex geological reasons, the lower end-beam 6 ballastless track and its front and rear ballastless tracks had a large uneven settlement. The maximum settlement was 60mm, which exceeded the adjustment range of the fastener 2 system and affected the Track smoothness. This patented technology is used to lift and repair the unevenly settled ballastless track to restore the track smoothness. Its process is as figure 1 The specific implementation is as follows:

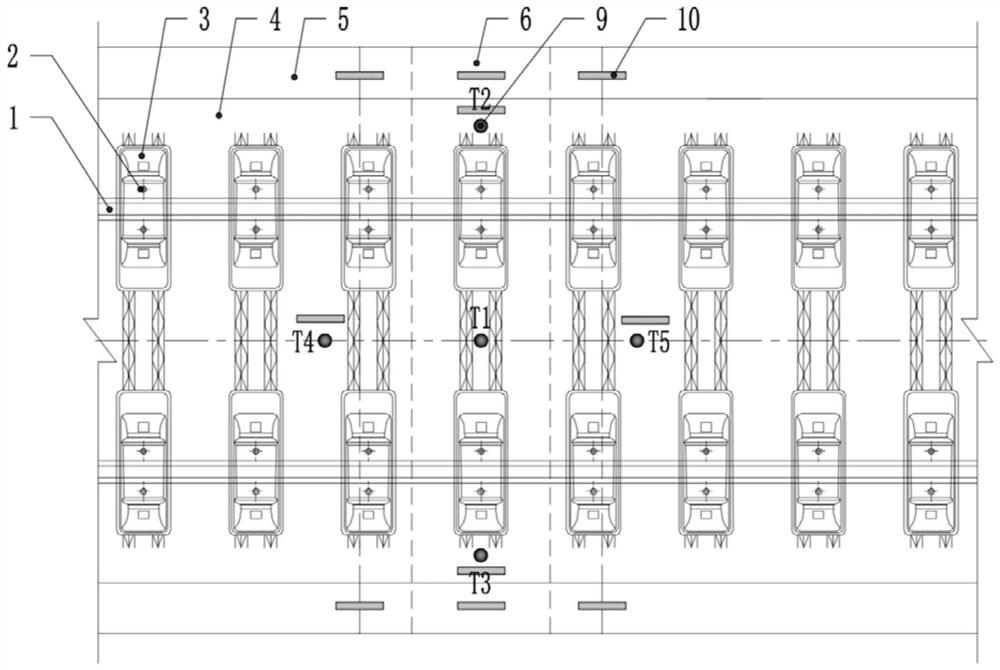

[0068] (1) Determine the lifting range and lifting amount of the ballastless track with the lower end beam 6, and arrange the strain gauges 10

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com