Prefabricated assembly type stand plate connecting structure

A technology of prefabricated assembly and panel connection, which is applied to podiums, floors, building components, etc., can solve problems such as inaccurate alignment of grouting holes, insufficient grouting, and many wet operations, and achieve rapid and effective batch installation and improve on-site construction efficiency , the effect of making up for potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. Features such as component models, material names, connection structures, and control methods that are not explicitly described in this technical solution are regarded as common technical features disclosed in the prior art.

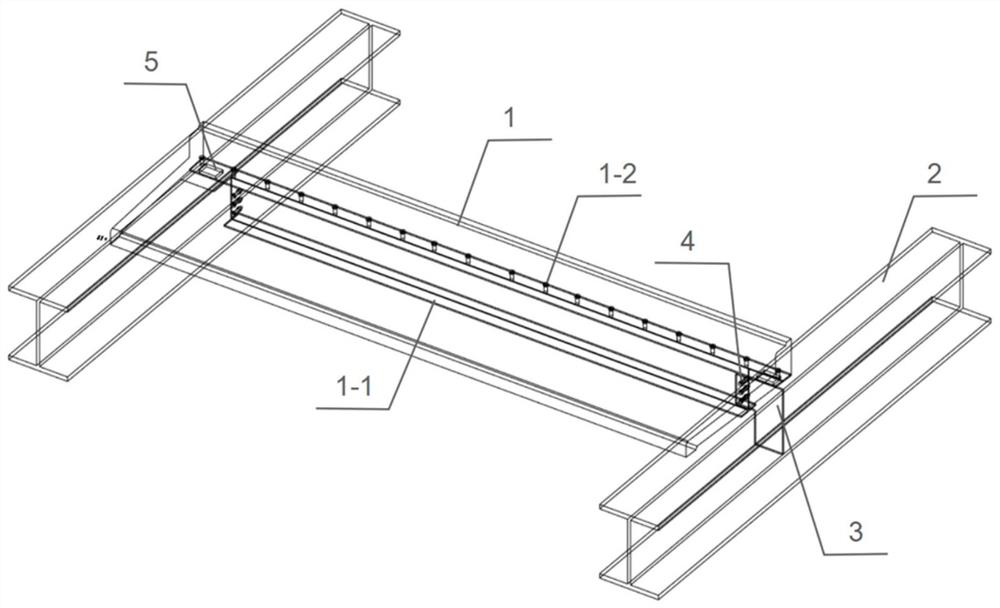

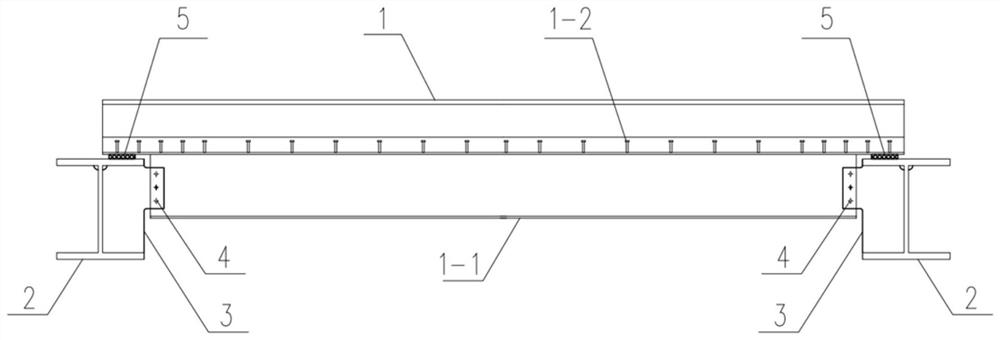

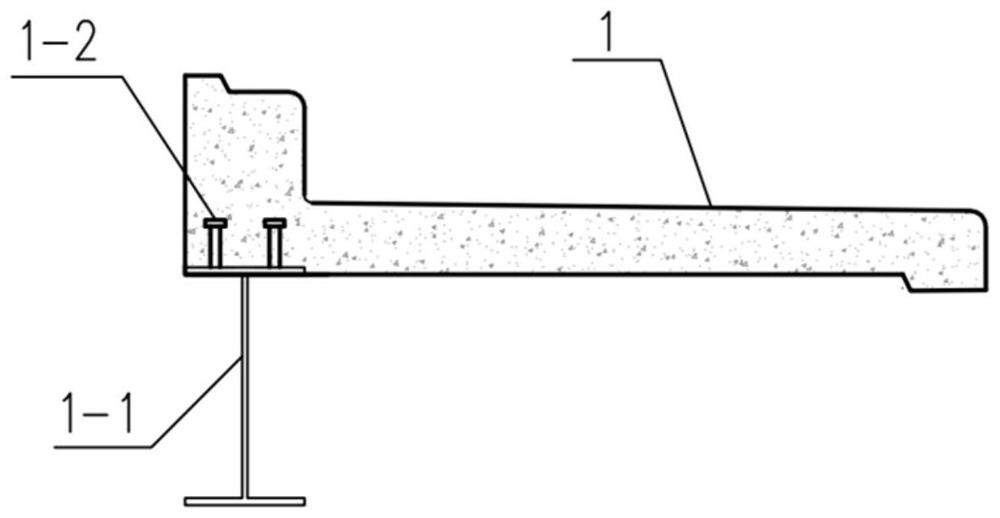

[0028] In this embodiment, the connection structure of the prefabricated stand panel includes a prefabricated stand panel 1 and a main structure radial main beam 2 respectively coupled to both ends of the prefabricated stand panel 1; the lower surface of the prefabricated stand panel 1 is fixedly connected with Composite steel beam 1-1. One side of the radial main beam 2 of the main structure is fixedly connected with a stiffening plate 3; the prefabricated stand plate 1 is erected on the upper surface of the radial main beam 2 of the main structure, and the stiffening plate 3 is fastened with the combined steel beam 1-1 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com