A segmented prestressed large-span concrete beam

A concrete beam and prestressing technology, applied in the direction of load-bearing elongated structural components, buildings, building components, etc. Effective transfer of stress and other issues, to achieve the effect of improving performance, enhancing stiffness performance, and reducing construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

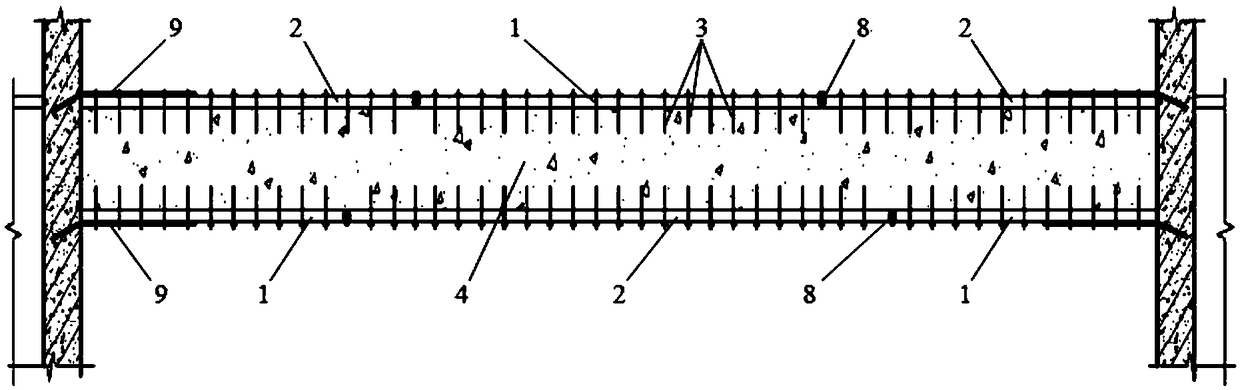

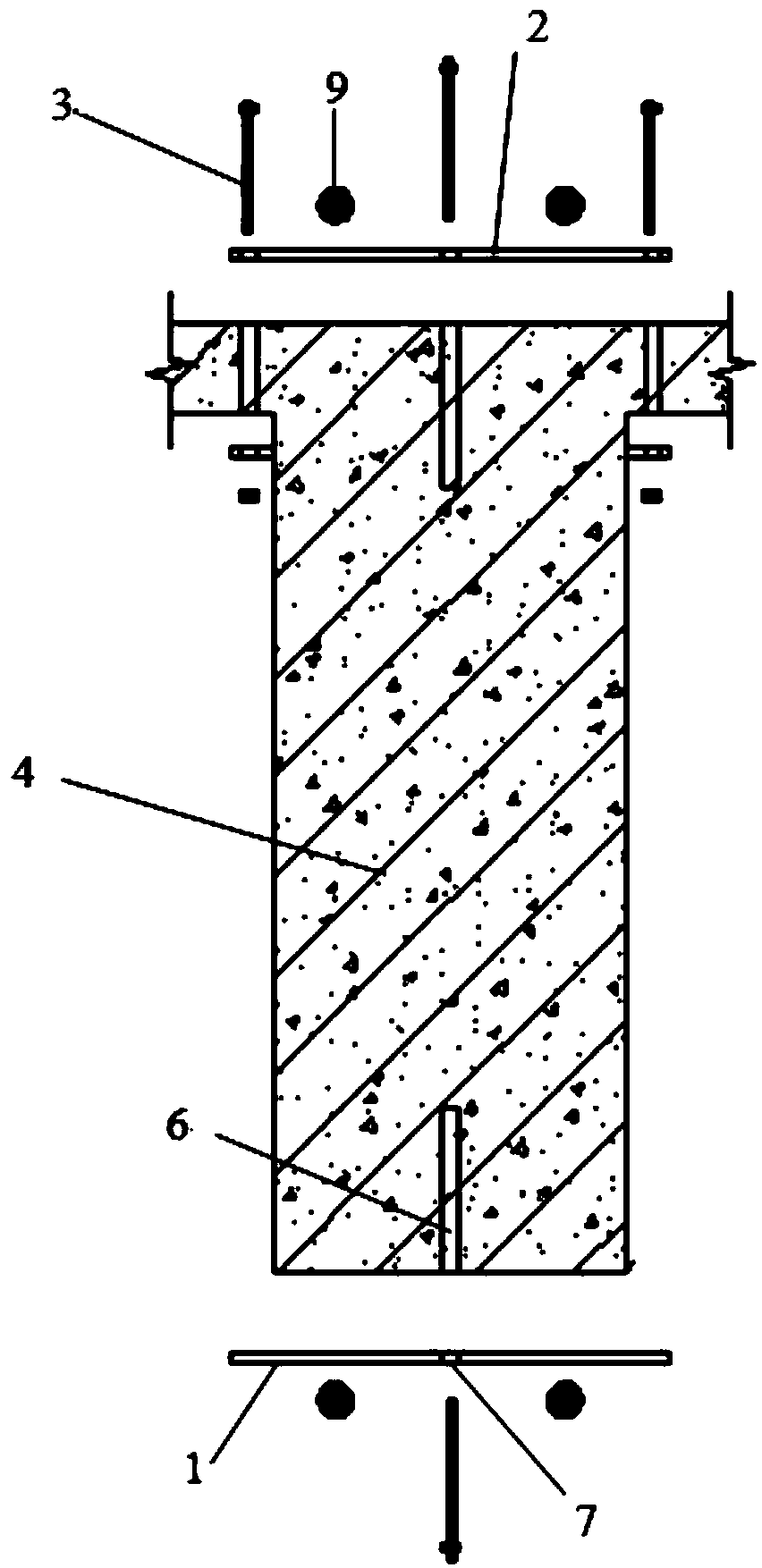

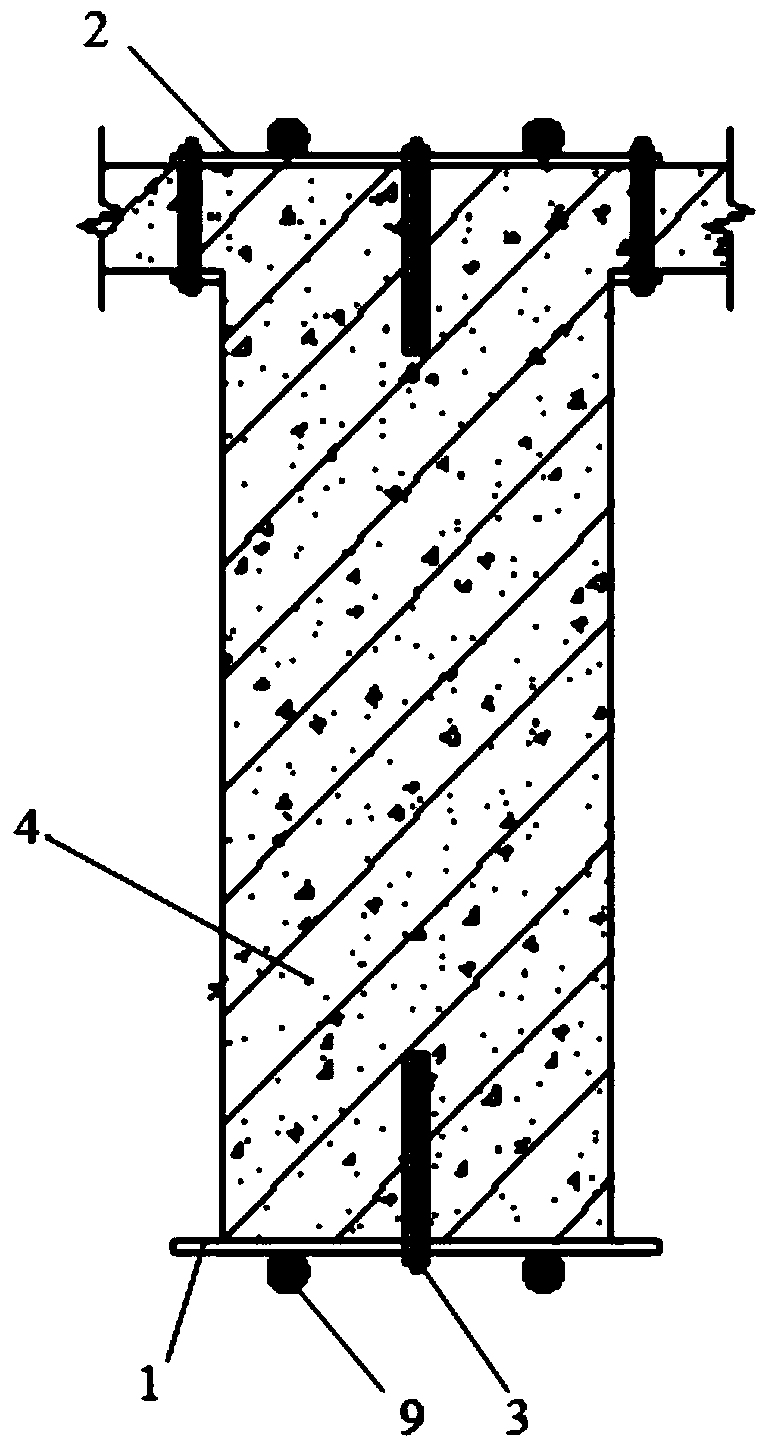

[0025] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as Figure 1-7 As shown, a long-span concrete beam with prestressed sections, including a large-span concrete beam 4 in the middle and concrete columns on both sides of the beam, the upper and lower surfaces of the concrete beam 4 are laid with fixed steel plates 1 and prestressed steel plates 2. The stress steel plate 2 is located in the negative bending moment area on the upper surface of the concrete beam 4, that is, the two ends of the upper surface of the beam, and the prestressed steel plate 2 is located in the positive bending moment area on the lower surface of the concrete beam 4, that is, the middle part of the lower surface of the beam, and the upper and lower sides of the concrete beam 4 The fixed steel plate 1 is laid on other parts of the surface, and the fixed steel plate 1 and the prestressed steel plate 2 are wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com