Submersible pump capable of improving mechanical seal operation environment

A mechanical seal and operating environment technology, applied in mechanical equipment, pumps for special fluids, parts of pumping devices for elastic fluids, etc., can solve problems such as reducing the heat dissipation performance of mechanical seals, affecting sealing effects, and motor damage. To achieve the effect of ensuring long-term safe use, preventing wear and tear, and improving the operating environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention will be described in detail below with reference to the accompanying drawings.

[0022] The following description is merely exemplary in nature and is not intended to limit the disclosure, application, or uses. It should be understood that throughout the drawings, corresponding reference numerals indicate like or corresponding parts and features.

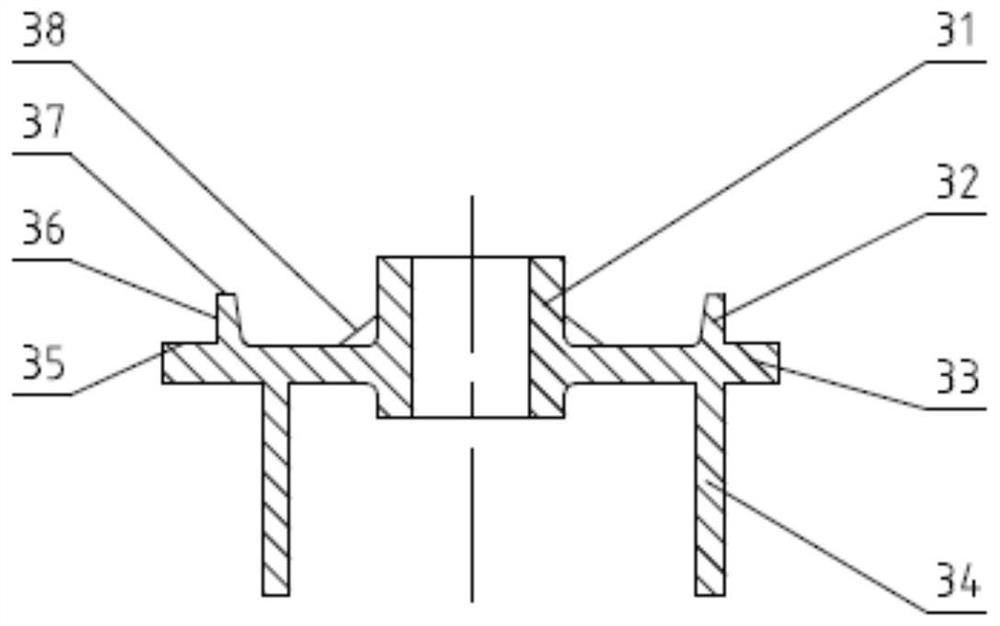

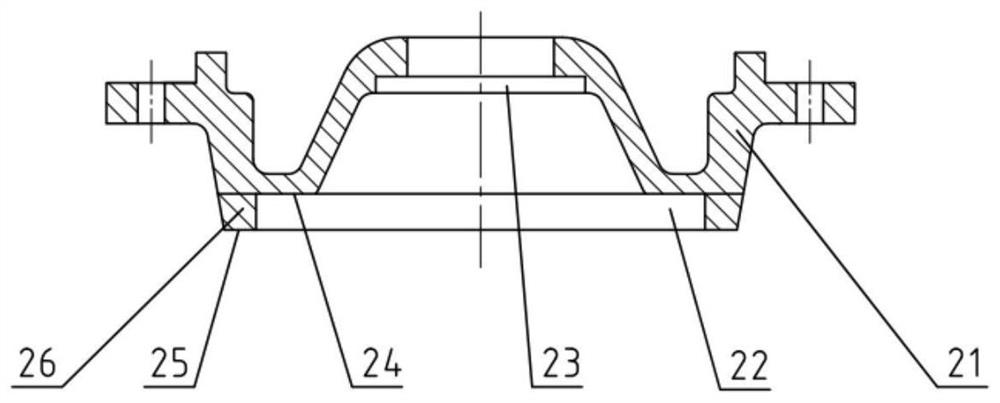

[0023] It should be noted that, for the convenience of description, the following term "lower end" is Figure 1 to Figure 2 The installation orientation of the middle impeller relative to the motor; the "upper end" is Figure 1 to Figure 2 The installation orientation of the middle motor relative to the impeller.

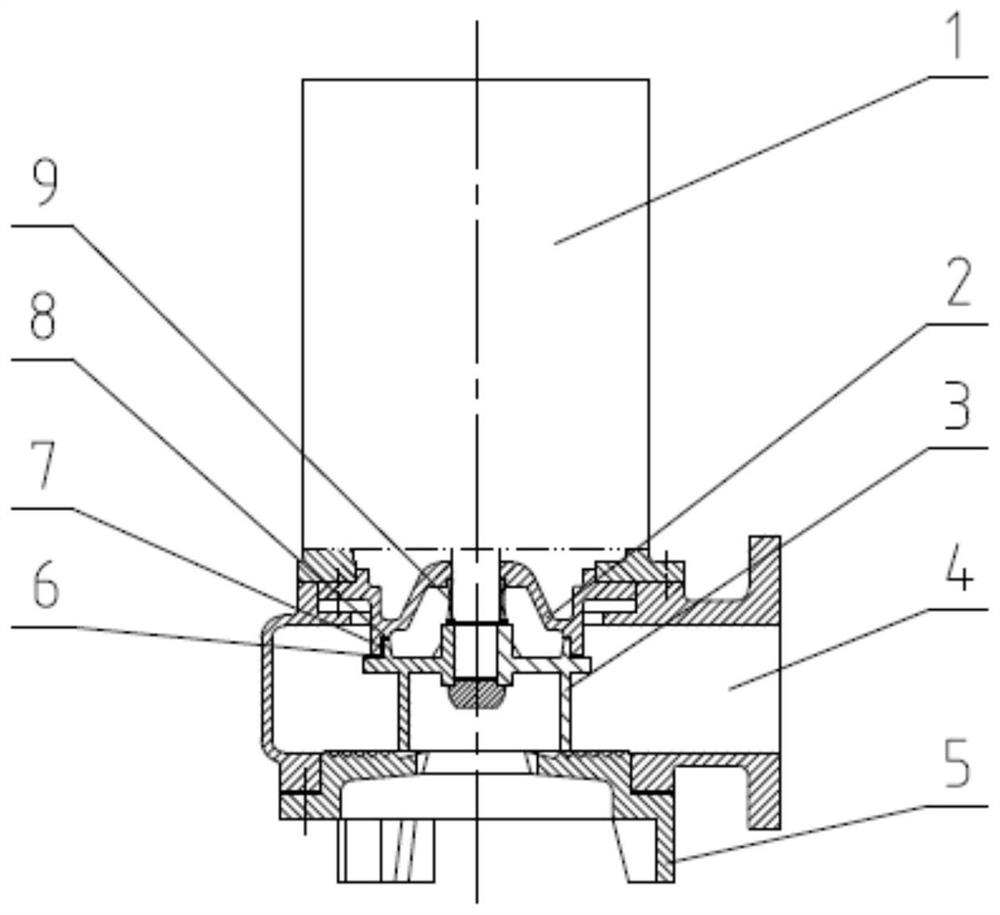

[0024] Embodiments of the present invention provide a submersible pump for improving the operating environment of a mechanical seal, such as figure 1 As shown, it includes a submersible electric pump 1 , a volute 4 , a bottom cover 5 , an impeller 3 , a mechanical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com