Insulating rubber sealing ring

A technology of rubber sealing ring and insulating rubber, applied in the direction of engine sealing, piston ring, fluid pressure actuating system components, etc., can solve the problems of loose sealing cover, heating of positioning pin and push rod, rotation of sealing ring, etc., to avoid The effect of force fracture, avoid force deformation, and avoid force rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

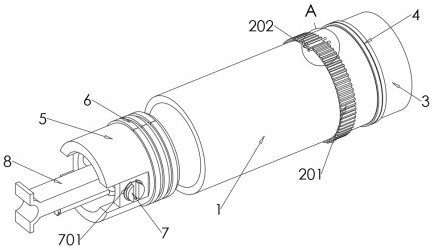

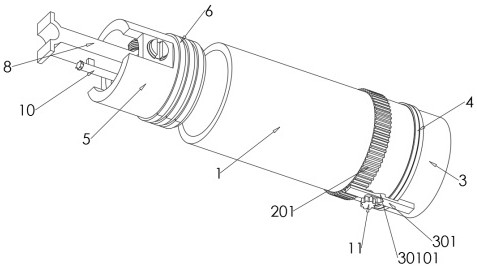

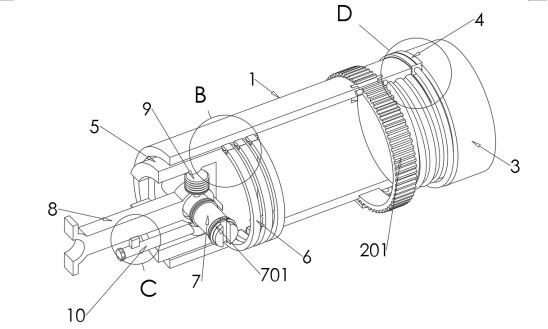

[0057] as attached figure 1 to the attached Figure 14 shown:

[0058] The present invention provides an insulating rubber sealing ring, comprising a sealing cylinder 1;

[0059] The sealing cylinder 1 is provided with an internal thread; the connecting ring 2 is installed on the outer side of the sealing cylinder 1, the connecting ring 2 includes a first locking tooth 201 and a first locking block 202, and an annular groove is opened on the outer side of the sealing cylinder 1 , the connecting ring 2 is snapped into the annular groove of the sealing cylinder 1, and the annular groove of the sealing cylinder 1 locates and hides the connecting ring 2. The first locking teeth 201 are distributed on the outside of the connecting ring 2 in an annular array. 201 is a right-angled trapezoid structure, the first locking tooth 201 locks the second locking tooth 30102, the first locking block 202 is at the end of the connecting ring 2, there are two first locking blocks 202, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com