Double-waist-wheel gas flowmeter

A technology of gas flowmeter and waist wheel, which is applied in the direction of liquid/fluid solid measurement, volume measurement, measuring device, etc. It can solve the problem that the bearing cannot be cleaned and lubricated well, the stability of the flowmeter is affected, and the measurement performance of the small flow is shortened. and other problems, to achieve the effect of compact structure, small space occupation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

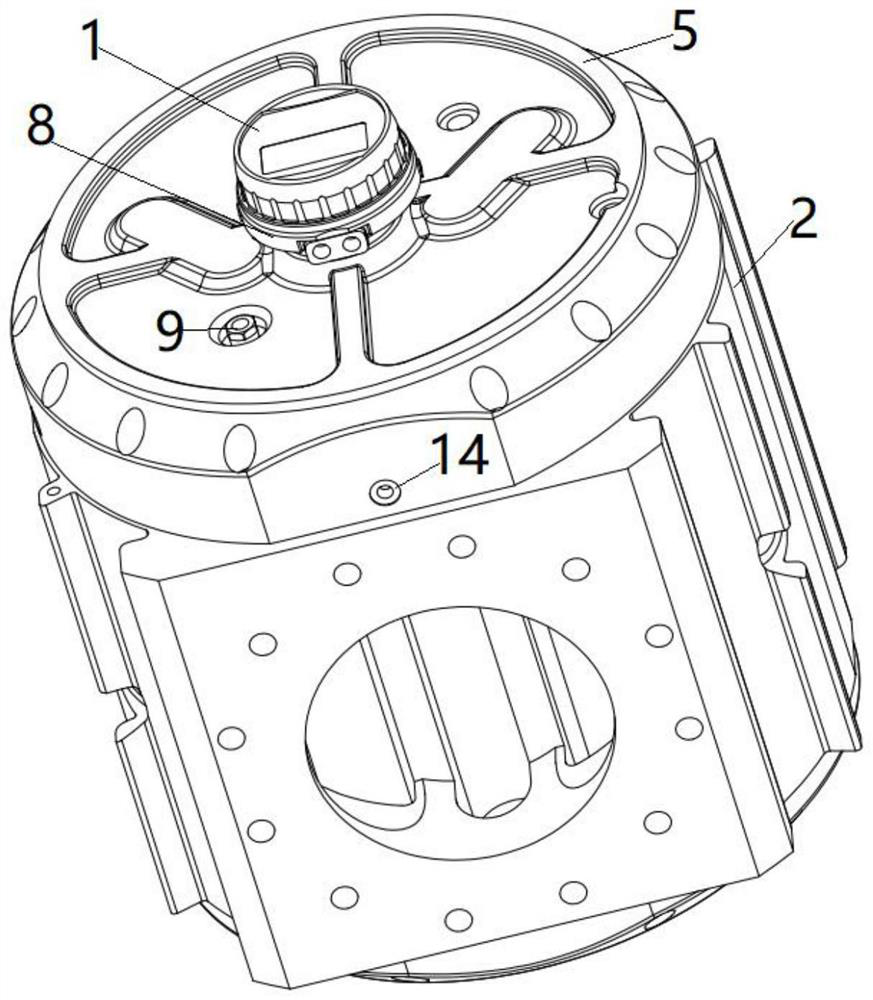

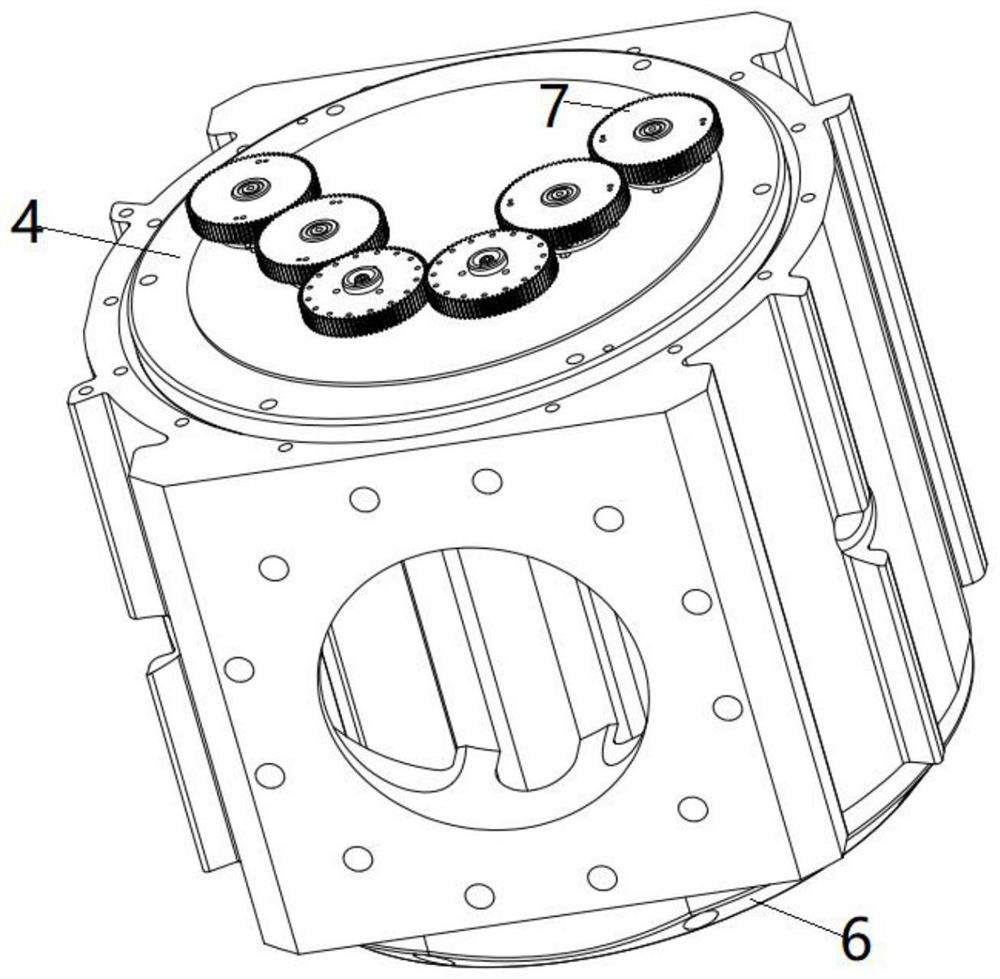

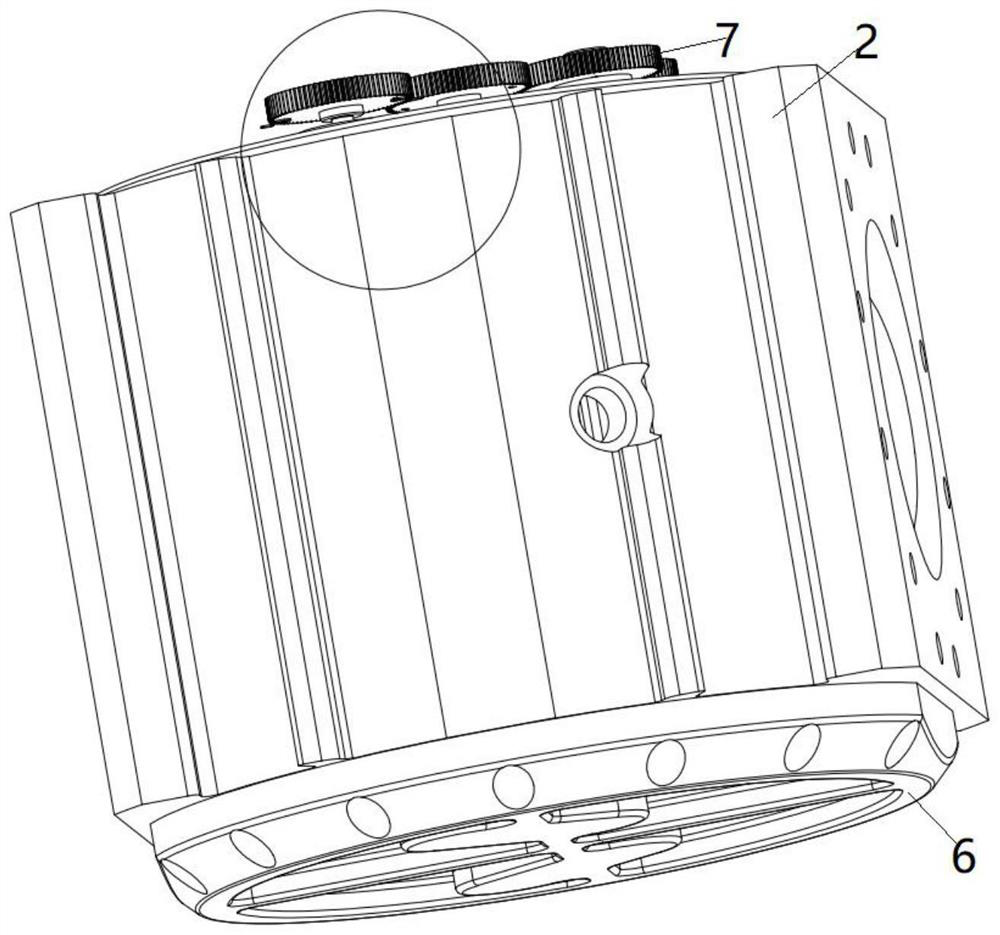

[0034] like Figure 1-8 As shown, the present invention discloses a double-waisted gas flow meter, including a counting module 1 and a metering module, the metering module includes a metering chamber shell 2, a synchronous rotor 3, a front end cover 5, a rear end cover 6, a front end plate 4, The rear end plate, the synchronous gear set 7 and the magnetic coupler 8, the synchronous rotor 3 is arranged in the measuring chamber shell 2, the synchronous rotor 3 is a figure-8 waist wheel, and the contour curve of the waist wheel is designed based on the involute meshing theory, and the synchronous rotor 3 There are two groups, two in each group. The two groups of synchronous rotors are arranged on both sides of the metering chamber shell 2, and the best matching clearance is maintained between the waist wheel, the metering chamber shell 2, the front end plate 4 and the rear end plate. , in order to ensure the non-contact sealing of the waist wheel during the rotation process, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com