Medium bus interior noise testing method and medium bus interior noise analysis method

A technology of vehicle interior noise and testing methods, which is applied in vehicle testing, machine/structural component testing, measuring devices, etc., can solve the problem of inability to obtain accurate interior noise analysis results, and achieve accurate analysis results and accurate test results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The present embodiment provides a method for testing interior noise of a medium-sized passenger vehicle, comprising the following steps:

[0030] S1. Adjust the seat back, and then arrange the microphone in the car;

[0031] S2. Carry out the vehicle interior noise test on the medium-sized passenger car, and the test conditions include fixed-position conditions, constant-speed driving conditions, and acceleration and deceleration driving conditions;

[0032] S3. Collect the in-vehicle noise signal and the engine speed signal in the fixed working condition when the air-conditioning system is turned off and when the air-conditioning system is turned on, respectively, and collect the in-vehicle noise signal and Engine speed signal.

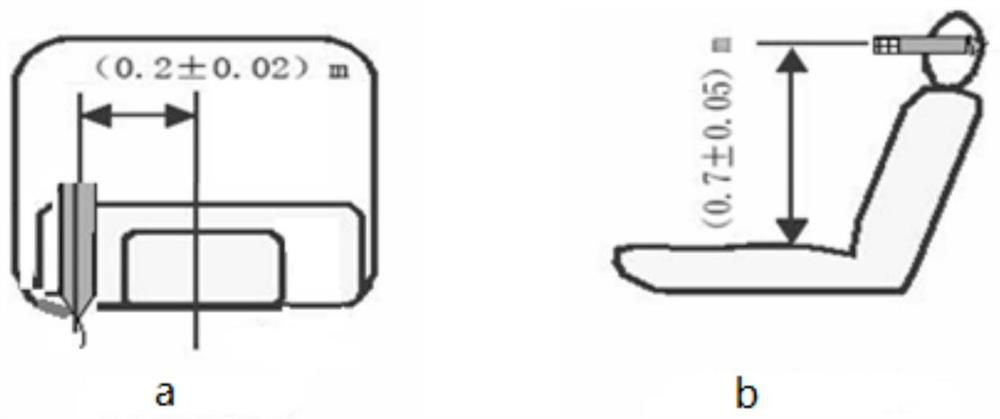

[0033] It should be noted that the arrangement position of the microphone should first comply with the regulations in GB / T 18697. The vertical height is 0.7m±0.05m based on the seat surface, and the horizontal distance is 102m±0.02m based on ...

Embodiment 2

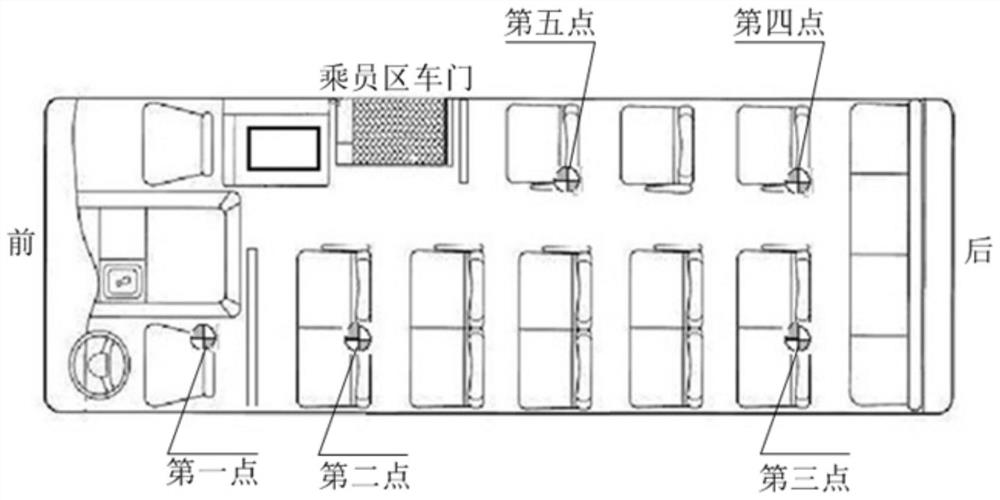

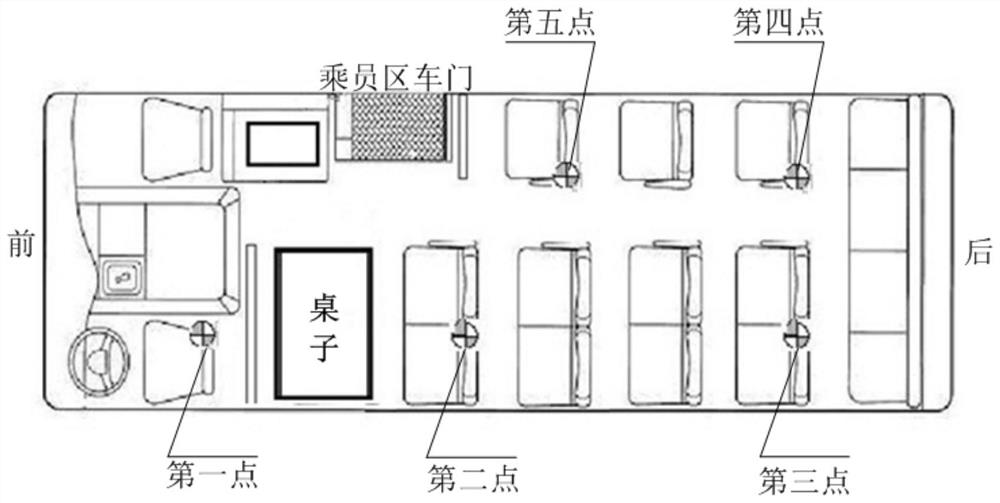

[0035] This embodiment is a further illustration of Embodiment 1, wherein the microphones in step S1 are arranged by a five-point arrangement method, and the specific arrangement positions of the five-point arrangement method are:

[0036] The first point is the inner ear position of the driver's seat, the second point is the inner ear position of the passenger seat near the window in the first row behind the driver, the third point is the inner ear position of the passenger seat near the window on the left side of the last row of seats, and the fourth point is The inner ear position of the right passenger seat in front of the last row of seats, and the fifth point is the inner ear position of the first row passenger seat behind the passenger compartment door.

[0037] For better understanding, this embodiment takes a 19-seat medium-sized passenger car and a 17-seat medium-sized passenger car as examples, and the five-point method for microphone arrangement of a 19-seat medium-...

Embodiment 3

[0039] This embodiment is a further illustration of Embodiment 1, wherein the measurement parameters and data acquisition settings of the microphone in step S1 are as follows: the noise signal analysis frequency is 20Hz-20kHz; the frequency resolution range is 0.5Hz-2Hz.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap