Control circuit of electrode type liquid level meter, electrode type liquid level meter and control method of electrode type liquid level meter

A control circuit and liquid level gauge technology, which is applied in the field of liquid level gauges, can solve the problems of electrode type liquid level gauges without safety, unstable electrode signal acquisition, easy oxidation and scaling, etc., to ensure reliability and safety Good sealing performance and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

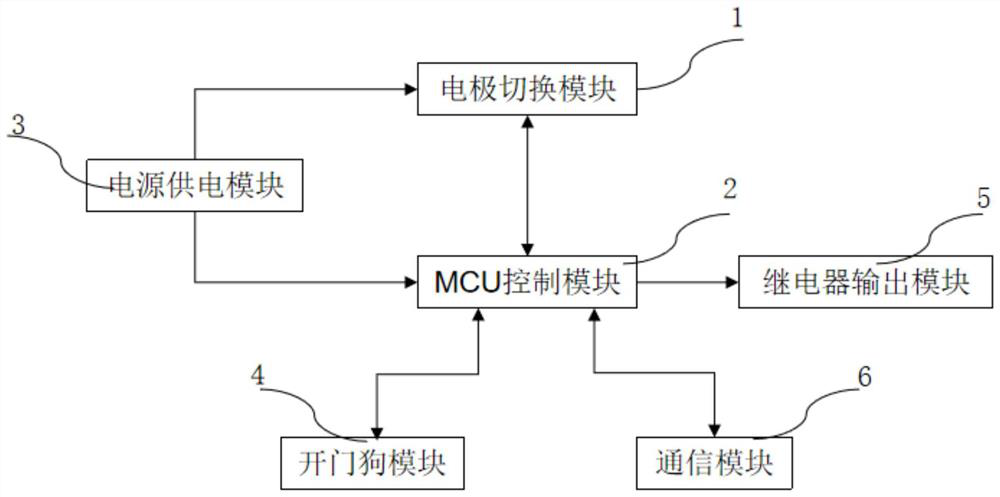

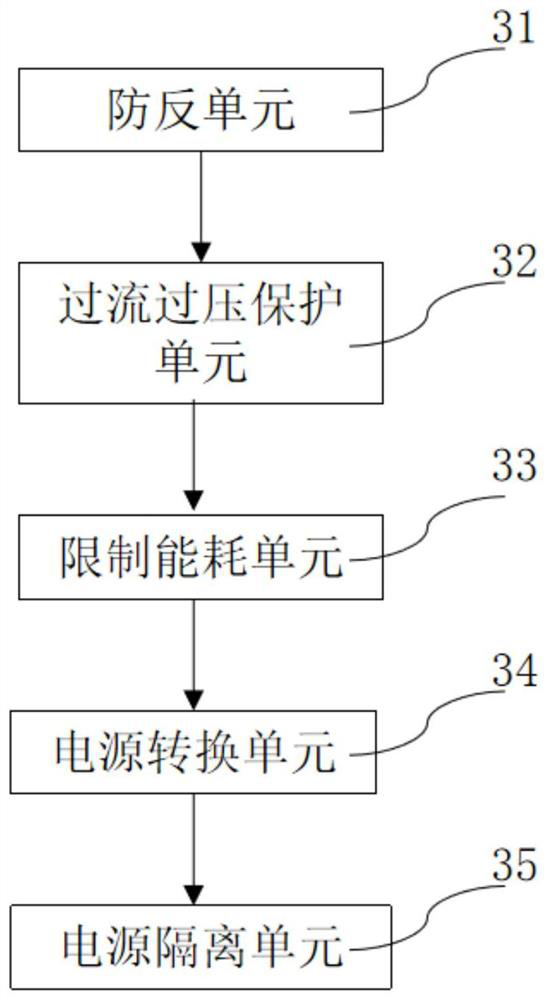

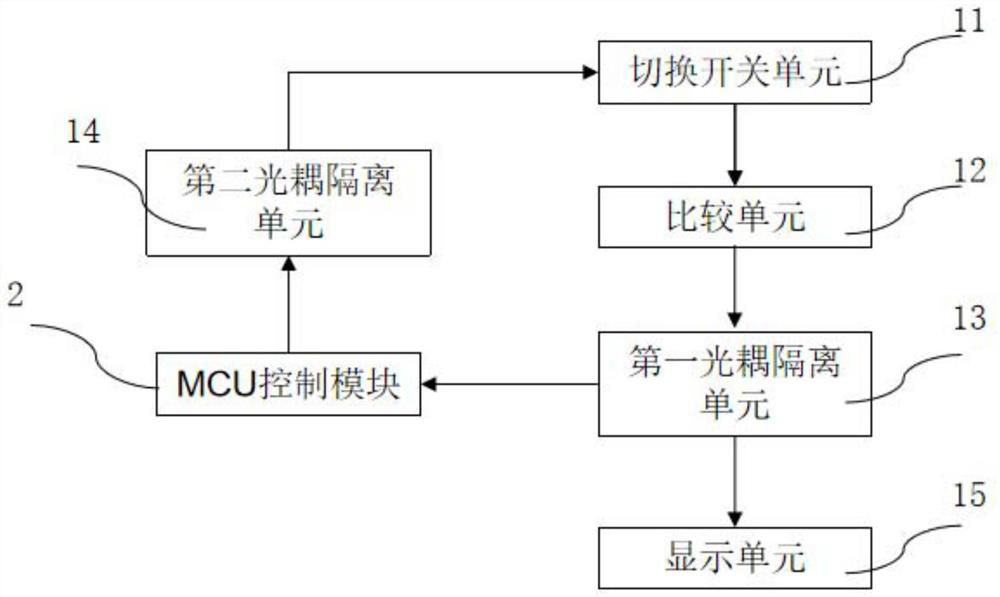

[0059] like figure 1 The control circuit includes: at least two electrodes; at least one electrode switching module 1, the electrode switching module 1 includes two input terminals, which are the first An input terminal and a second input terminal, the first input terminal is connected to the first electrode, and the second input terminal is connected to the second electrode, which is used to obtain the electrode signals of the first electrode and the second electrode. The electrode signal is converted by the electrode switching module 1 into The input signal of the control circuit; the MCU control module 2 is connected to the electrode switching module 1, the electrode switching module 1 transmits the input signal to the MCU control module 2, and the MCU control module 2 processes the transmission time of the input signal. When the time is within the first threshold time set by the MCU control module 2, the MCU control module 2 outputs a control signal to the electrode switch...

Embodiment 2

[0087] like Figure 14 and 15 As shown, it is the second embodiment of the present invention, an electrode type liquid level gauge, including: a control box body 700 and a cover body 702 detachably assembled on the control box body 700, the control box body 700 is provided with a circuit board 701, a circuit The board 701 includes the control circuit of the electrode type liquid level gauge as described above; at least two electrodes are installed at the bottom of the control box 700, and the bottom of the control box 700 is provided with through holes, and the number of through holes is the same as the number of electrodes, and each An electrode holder 705 is coaxially disposed in each of the through holes. The top of the electrode holder 705 passes through the through hole to the inside of the control box body 700 . The bottom end of the electrode is connected to one end of the electrode, and the other end of the electrode is the collection end.

[0088] In the embodiment,...

Embodiment 3

[0094] A control method of an electrode type liquid level gauge, the control method adopts the control circuit of the electrode type liquid level gauge as described above, such as Figure 16 As shown, the control method includes:

[0095] Step S1: Set the electrode type liquid level gauge in the environment to be measured, and when the environment to be measured has liquid in contact with the first electrode and the second electrode, transmit the electrode signals of the first electrode and the second electrode to the electrode switching module 1 ;

[0096] Step S2: The electrode switching module 1 compares the electrode signal between the first electrode and the second electrode, and judges whether the height of the liquid contacted by the second electrode meets the preset threshold. If so, the electrode signal is converted into a control circuit by the electrode switching module 1 the input signal, the electrode switching module 1 transmits the input signal to the MCU contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com