Method for operating a unit-based mobility production system

A production system and mobility technology, applied in general control systems, control/regulation systems, motor vehicles, etc., can solve problems such as limited production and difficult supply of vehicles, reduce bottlenecks, change quickly and accurately, and achieve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

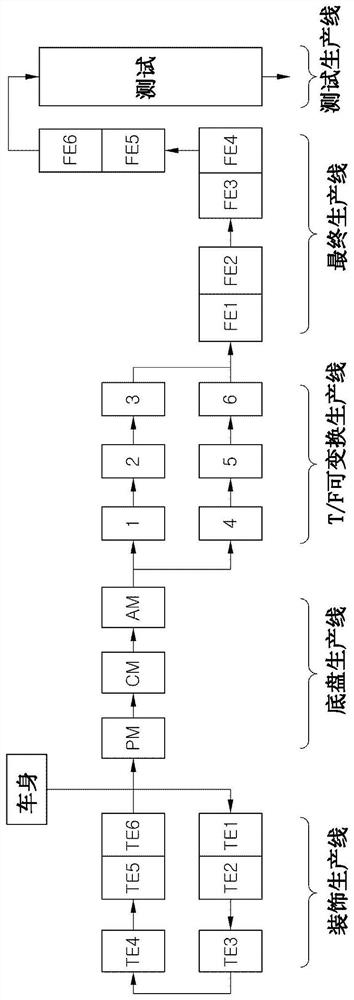

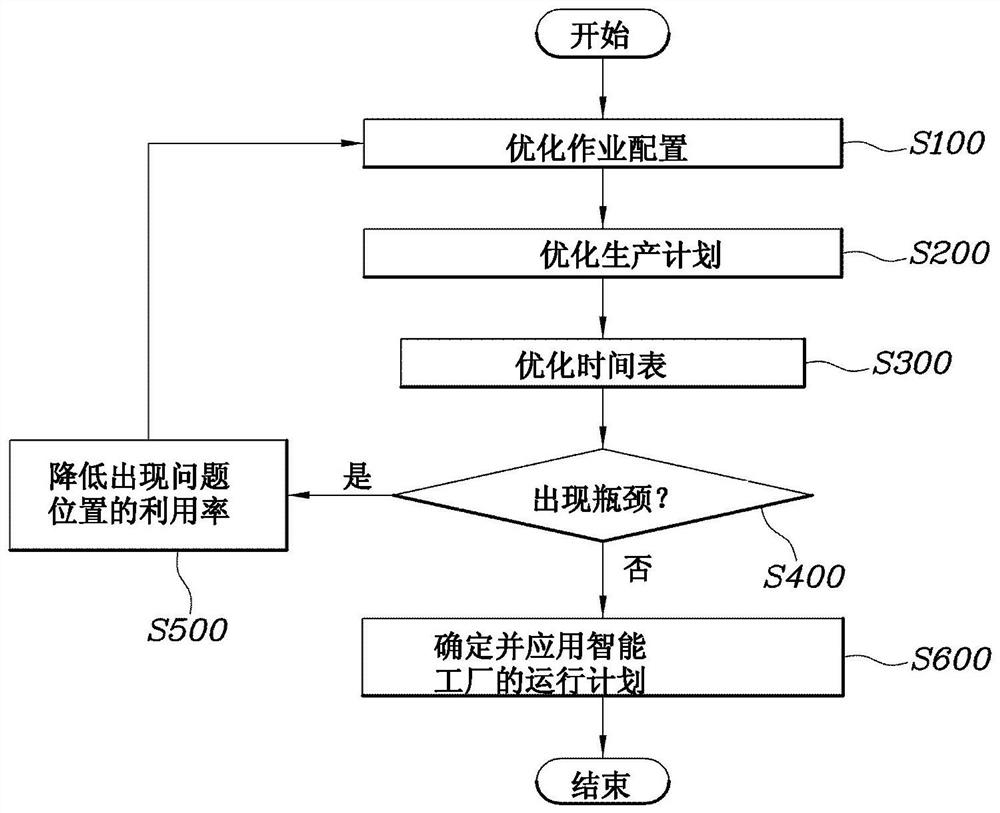

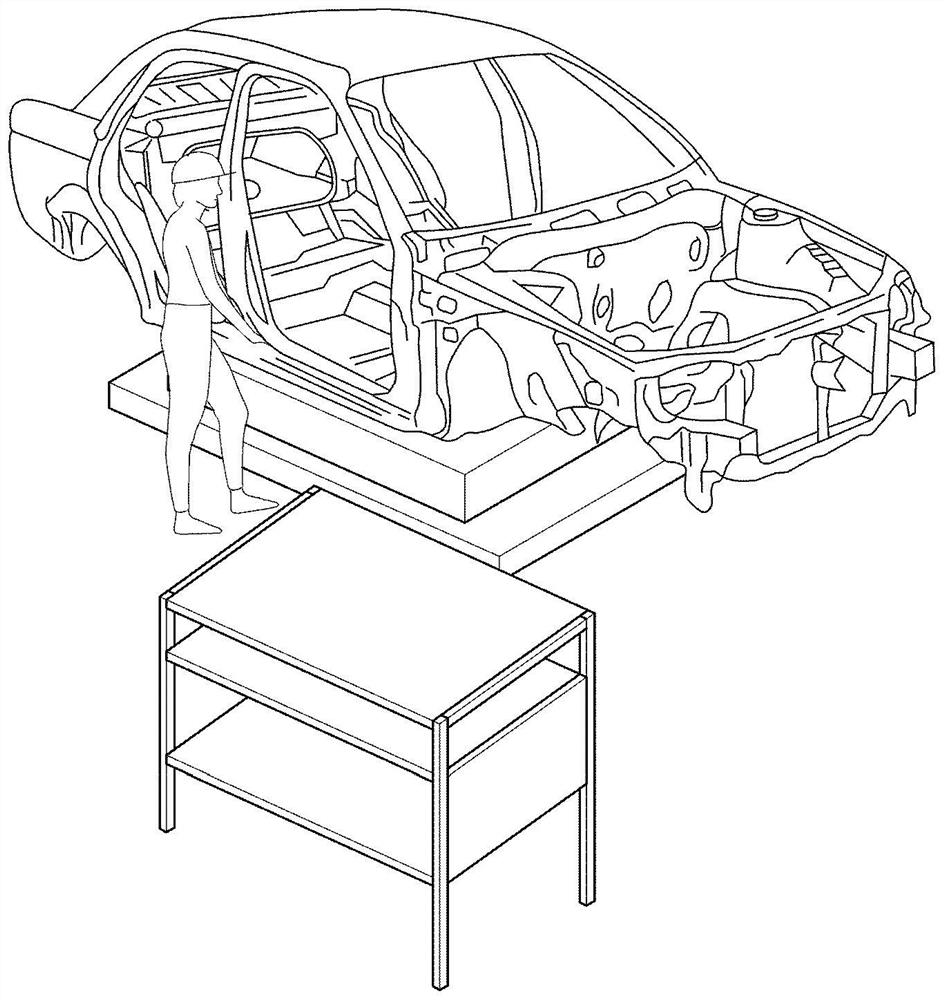

[0031] figure 1 is a diagram illustrating a production system to which a method for operating a cell-based mobility production system according to an embodiment of the present invention is applied, figure 2 is a flowchart of a method for operating a cell-based mobility production system according to an embodiment of the present invention, image 3 is a diagram illustrating a manual cell of a cell-based mobility production system according to an embodiment of the present invention, and Figure 4 is a diagram illustrating an automated cell of a cell-based mobility production system according to an embodiment of the present invention.

[0032] figure 1 is a diagram showing a production system to which the method for operating a cell-based mobility production system according to an embodiment of the present invention is applied, and shows the configuration of the cell-based smart factory production system instead of the conventional conveyor method.

[0033] Embodiments of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com